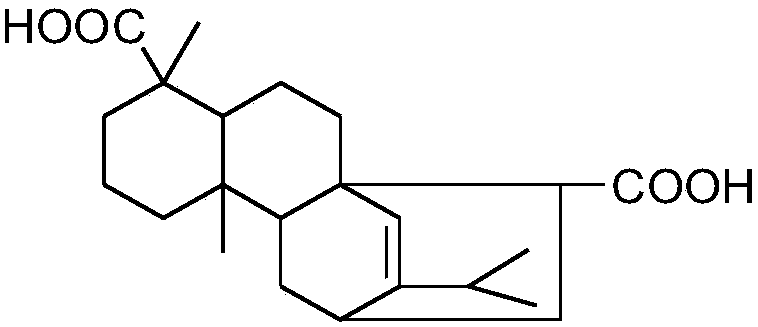

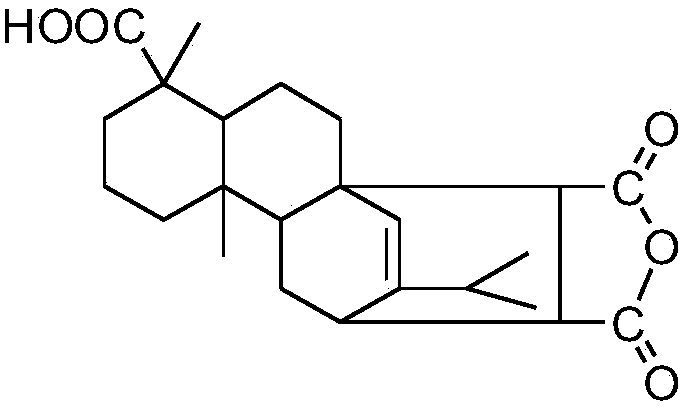

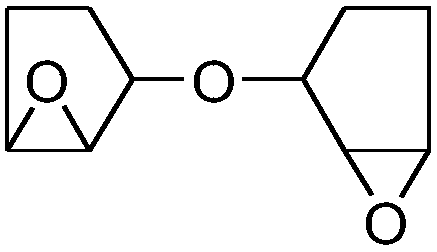

A kind of rosin epoxy resin composition and preparation method thereof

A technology for rosin epoxy resin and epoxy resin, which is applied in the field of resin compositions, can solve the problems of complex methods, high toxicity of raw materials, and various types, and achieves the effects of simple preparation steps, easy preparation steps, and widening application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) First mix 3 kilograms of bisphenol A epoxy resin and 4.5 kilograms of 400# epoxy resin, and heat appropriately to make it uniform;

[0030] (2) Take 10 kilograms of modified rosin II and mix with 7.5 kilograms of epoxy resin in step (1), heat to 130° C., and stir slowly until the mixture melts and becomes a uniform viscous liquid;

[0031] (3) Keep the temperature of the uniform viscous liquid at 130°C, add 0.08 kg of dodecyltrimethylammonium bromide therein, and stir evenly;

[0032] (4) Import the mixed solution of step (3) into the pouring machine mold, and carry out pressurized pre-curing time under the conditions of temperature 130°C and pressure 3Mpa for 1 hour;

[0033] (5) Return to normal pressure, cure for 3 hours at a temperature of 150° C., and cool down to obtain a rosin epoxy resin composition.

Embodiment 2

[0035] (1) First mix 4.5 kilograms of bisphenol A epoxy resin and 3 kilograms of 400# epoxy resin, and heat appropriately to make it uniform;

[0036] (2) Take 10 kilograms of modified rosin II and mix with 7.5 kilograms of epoxy resin in step (1), heat to 130° C., and stir slowly until the mixture melts and becomes a uniform viscous liquid;

[0037] (3) Keep the temperature of the uniform viscous liquid at 130°C, add 0.08 kg of dodecyltrimethylammonium bromide therein, and stir evenly;

[0038] (4) Import the mixed solution of step (3) into the pouring machine mold, and carry out pressurized pre-curing time under the conditions of temperature 130°C and pressure 3Mpa for 1 hour;

[0039] (5) Return to normal pressure, cure for 3 hours at a temperature of 150° C., and cool down to obtain a rosin epoxy resin composition.

Embodiment 3

[0041] (1) First mix 3 kilograms of bisphenol A epoxy resin and 4.5 kilograms of 400# epoxy resin, and heat appropriately to make it uniform;

[0042] (2) Mix 10 kg of modified rosin II, 1 kg of citric acid with 7.5 kg of epoxy resin in step (1), heat to 130° C., and stir slowly until the mixture melts and becomes a uniform viscous liquid;

[0043] (3) Keep the temperature of the uniform viscous liquid at 130°C, add 0.08 kg of dodecyltrimethylammonium bromide therein, and stir evenly;

[0044] (4) Import the mixed solution of step (3) into the pouring machine mold, and carry out pressurized pre-curing time under the conditions of temperature 130°C and pressure 3Mpa for 1 hour;

[0045] (5) Return to normal pressure, cure for 3 hours at a temperature of 150° C., and cool down to obtain a rosin epoxy resin composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com