A visible light and infrared compatible camouflage material and preparation method thereof

A visible light and infrared technology, used in protective equipment, camouflage devices, clothing, etc., can solve the problems of low physical and mechanical properties and adhesion, inconvenient carrying and application, high infrared emissivity, and achieve good visible light camouflage effect, excellent camouflage Performance, the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

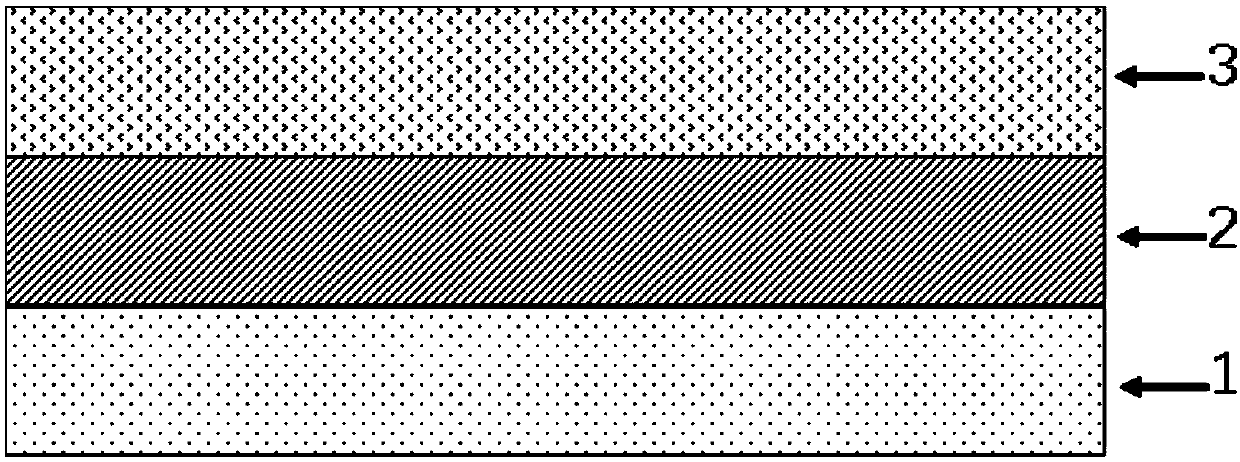

[0034] A visible light and infrared compatible camouflage material of the present invention is a layered structure, such as figure 2 As shown, from bottom to top, it is composed of substrate 1 (Si sheet), infrared low emissivity layer 2 and oxide thin film layer 3, wherein infrared low emissivity layer 2 is an Al thin film with a thickness of 160nm, and oxide thin film layer 3 Cr with a thickness of 300nm 2 o 3 film.

[0035] The preparation method of the visible light and infrared compatible camouflage material of this embodiment includes the following steps:

[0036] (1) Prepare a layer of Al film with a thickness of 160nm as the infrared low emissivity layer by radio frequency magnetron sputtering method on the Si substrate, wherein the radio frequency magnetron sputtering process conditions are: the Al target is used as the sputtering target, The background vacuum is 7×10 -8 Torr, the sputtering temperature is room temperature, the sputtering pressure is 5mTorr, and t...

Embodiment 2

[0041] A visible light and infrared compatible camouflage material of the present invention is a layered structure, such as figure 2 As shown, from bottom to top, it is composed of substrate 1 (Si sheet), infrared low emissivity layer 2 and oxide thin film layer 3, wherein infrared low emissivity layer 2 is an Ag thin film with a thickness of 160nm, and oxide thin film layer 3 Cr with a thickness of 400nm 2 o 3 film.

[0042] The preparation method of the visible light and infrared compatible camouflage material of this embodiment includes the following steps:

[0043] (1) Prepare a layer of Al film with a thickness of 160nm as the infrared low emissivity layer by radio frequency magnetron sputtering method on the Si substrate, wherein the radio frequency magnetron sputtering process conditions are: the Al target is used as the sputtering target, The background vacuum is 5×10 -8 Torr, the sputtering temperature is room temperature, the sputtering pressure is 3mTorr, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com