Production method of cast iron retainer with self-lubricating performance

A cage and cast iron technology, applied in the field of mold hardware accessories, can solve the problems of complex preparation process and high implementation cost, and achieve the effects of simple process implementation, reasonable process arrangement, and improved wear resistance and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

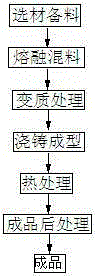

Image

Examples

Embodiment 1

[0018] The specific manufacturing steps of the self-lubricating cast iron cage mentioned in the present invention are as follows:

[0019] a) Material selection and preparation, the main components and percentage ratio of the cast iron cage are: C3.6%, Si2.1%, Mn0.7%, Mg4.5%, RESiFe1.7%, 75SiFe1%, MoS24 %, trace alloy 0.3%, impurity below 0.05%, and the rest is Fe; among them, Mg and RESiFe components are used as nodularizers for cage materials; 75SiFe components are used as inoculants for cage materials; MoS2 components are used as self-lubricating cage materials additives; trace alloys include Cu, Cr, Mo, Ni, Zn, Bi, Sb, Pb, etc.; impurities include P and S, the content of P is controlled below 0.03%, and the content of S is controlled at 0.01%-0.02%;

[0020] b) Melting and mixing, first, add a certain amount of scrap steel and pig iron to the medium-frequency induction furnace, the temperature of the induction furnace is controlled at 1350°C-1380°C, completely melt and rem...

Embodiment 2

[0026] The specific manufacturing steps of the self-lubricating cast iron cage mentioned in the present invention are as follows:

[0027] a) Material selection and preparation, the main components and percentage ratio of the cast iron cage are: C3.7%, Si2.2%, Mn0.75%, Mg5%, RESiFe1.5%%, 75SiFe1.2%, MoS24.5%, trace alloy 0.25%, impurities less than 0.05%, and the rest is Fe; among them, Mg and RESiFe components are used as nodularizers for cage materials; 75SiFe components are used as inoculants for cage materials; MoS2 components are used as cage materials self-lubricating agent; trace alloys include Cu, Cr, Mo, Ni, Zn, Bi, Sb, Pb, etc.; impurities include P and S, the content of P is controlled below 0.03%, and the content of S is controlled at 0.01%-0.02% ;

[0028] b) Melting and mixing, first, add a certain amount of scrap steel and pig iron to the medium-frequency induction furnace, and the temperature of the induction furnace is controlled at 1380°C-1400°C to completel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com