A kind of preparation method of cast iron cage with self-lubricating performance

A cage and cast iron technology, applied in the field of mold hardware accessories, can solve the problems of high implementation cost and complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

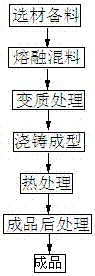

[0018] The specific manufacturing steps of the self-lubricating cast iron cage mentioned in the present invention are as follows:

[0019] a) Material selection and preparation, the main components and percentage ratio of the cast iron cage are: C 3.6%, Si 2.1%, Mn0.7%, Mg 4.5%, RESiFe 1.7%, 75SiFe 1%, MoS2 4%, Trace alloy 0.3%, impurity less than 0.05%, the rest is Fe; among them, Mg and RESiFe components are used as nodulizers for cage materials; 75SiFe components are used as inoculants for cage materials; MoS2 components are used as self-lubricating agents for cage materials; Trace alloys include Cu, Cr, Mo, Ni, Zn, Bi, Sb, Pb, etc.; impurities include P and S, the content of P is controlled below 0.03%, and the content of S is controlled at 0.01%-0.02%;

[0020] b) Melting and mixing, first, add a certain amount of scrap steel and pig iron to the medium-frequency induction furnace, the temperature of the induction furnace is controlled at 1350°C-1380°C, completely melt and...

Embodiment 2

[0026] The specific manufacturing steps of the self-lubricating cast iron cage mentioned in the present invention are as follows:

[0027] a) Material selection and preparation, the main components and percentage ratio of the cast iron cage are: C 3.7%, Si 2.2%, Mn0.75%, Mg 5%, RESiFe 1.5%, 75SiFe 1.2%, MoS2 4.5% , trace alloy 0.25%, impurities below 0.05%, and the rest is Fe; among them, Mg and RESiFe components are used as nodularizers for cage materials; 75SiFe components are used as inoculants for cage materials; MoS2 components are used as self-lubricating agents for cage materials ; Trace alloys include Cu, Cr, Mo, Ni, Zn, Bi, Sb, Pb, etc.; impurities include P and S, the content of P is controlled below 0.03%, and the content of S is controlled at 0.01%-0.02%;

[0028] b) Melting and mixing, first, add a certain amount of scrap steel and pig iron to the medium-frequency induction furnace, and the temperature of the induction furnace is controlled at 1380°C-1400°C to com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com