Manufacturing process of a plastic synchronous pulley

A technology of synchronous pulley and manufacturing process, which is applied to components with teeth, belts/chains/gears, portable lifting devices, etc. It can solve problems such as difficulty in ensuring assembly consistency, reducing the service life of molds, and difficult control of shrinkage ratio , to achieve the effect of ensuring the size and shape tolerance of each part, improving assembly consistency, and reducing process deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

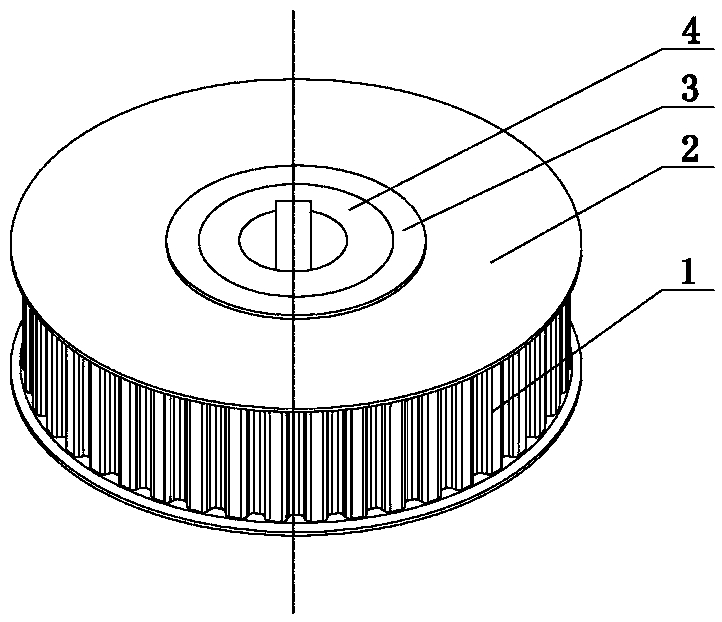

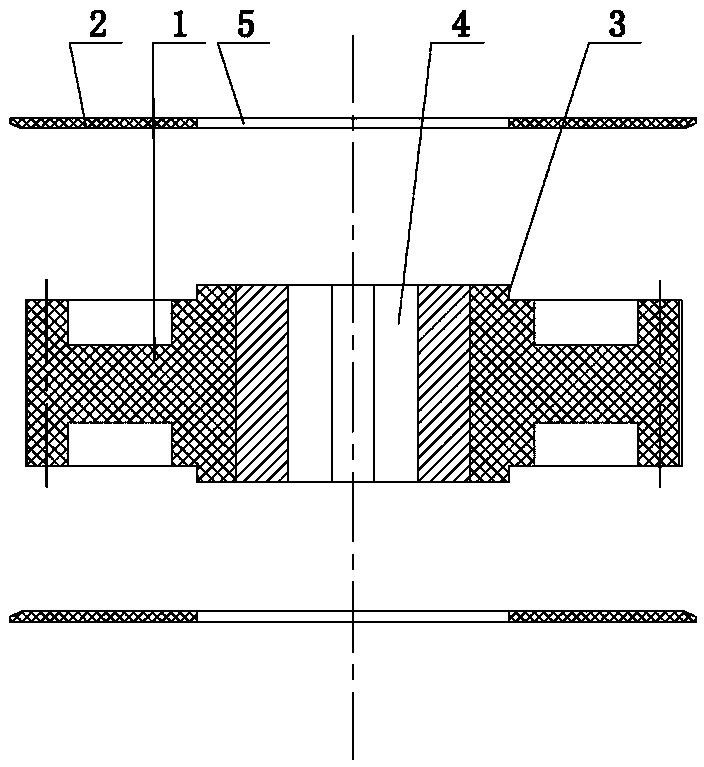

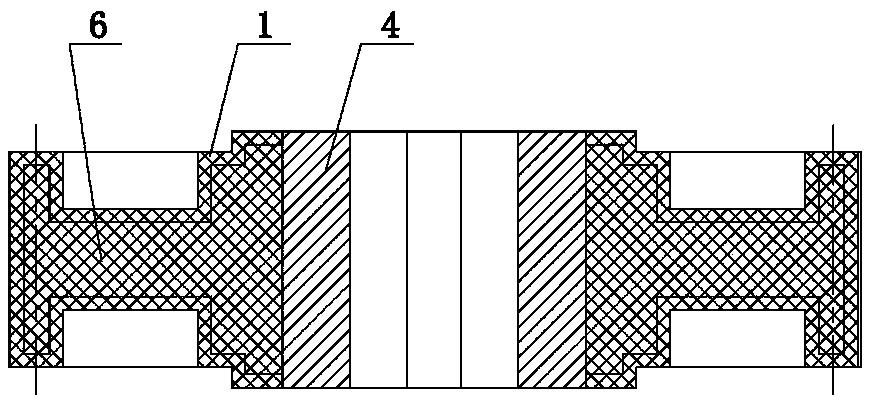

[0028] The plastic synchronous pulley of the present invention is characterized in that it includes a metal centering sleeve 4, a plastic synchronous pulley main body 1 is arranged outside the metal centering sleeve 4, and blocking pieces 2 are arranged on both sides of the plastic synchronous pulley main body 1.

[0029] Spokes 3 are provided on both sides of the main body 1 of the plastic synchronous pulley, and through holes 5 matching with the spokes 3 are provided on the blocking piece 2 .

[0030] The invention also provides a plastic synchronous pulley manufacturing process capable of ensuring high tooth profile precision and small deformation of the plastic synchronous pulley and ensuring consistent assembly of the synchronous pulley.

[0031] The manufacturing process of the plastic synchronous pulley of the present invention, step 1: set a metal centering sleeve 4 in the prefabricated pulley molding mold, inject nylon material into the prefabricated pulley molding mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com