Wear-resistance oil slinger for high-speed wire rod mill

A high-speed wire rod and oil flinger technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of burning shaft, water leakage of roll box, affecting oil circuit system, etc., so as to improve the service life , Improve the effect of anti-friction and self-lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

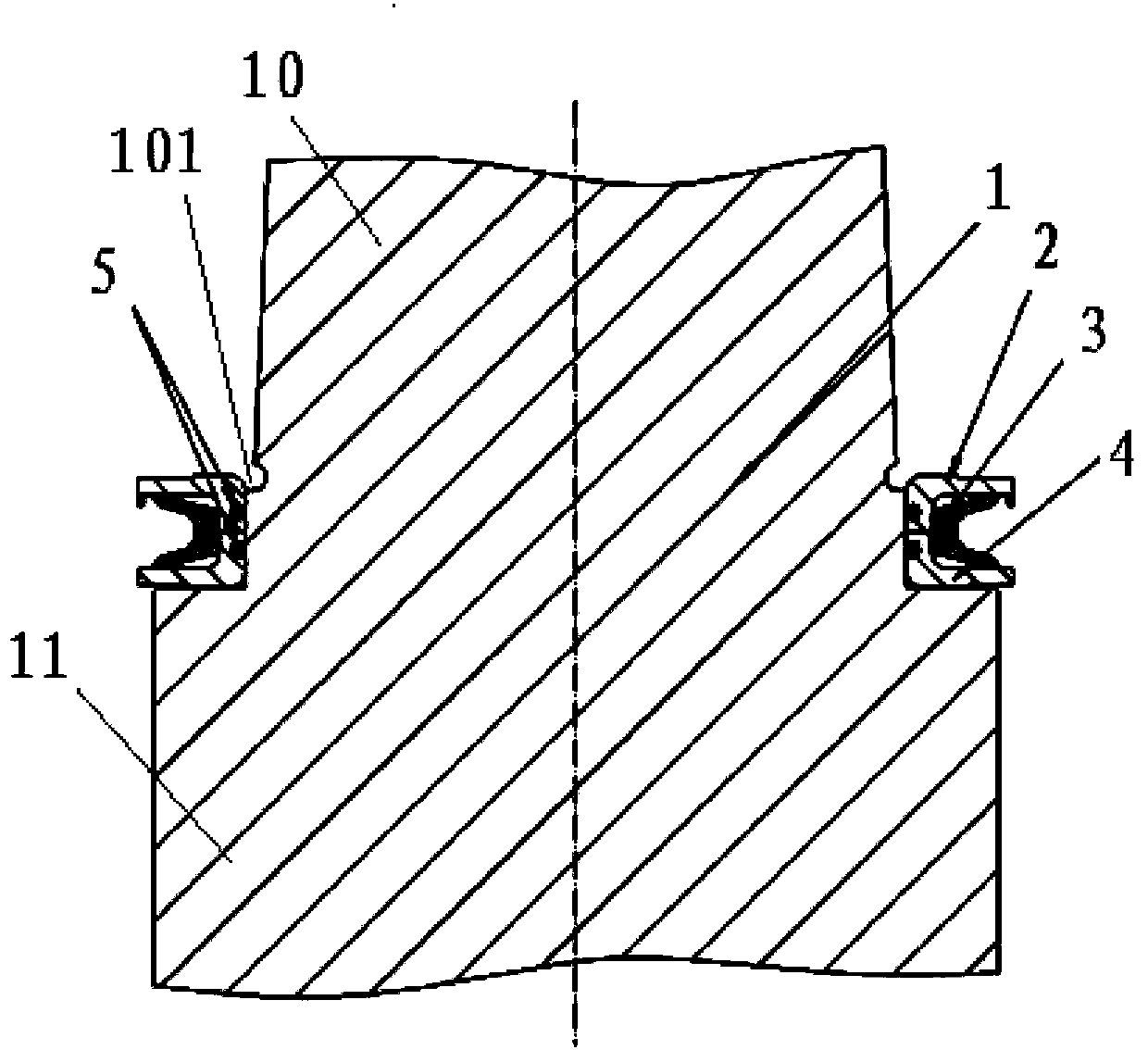

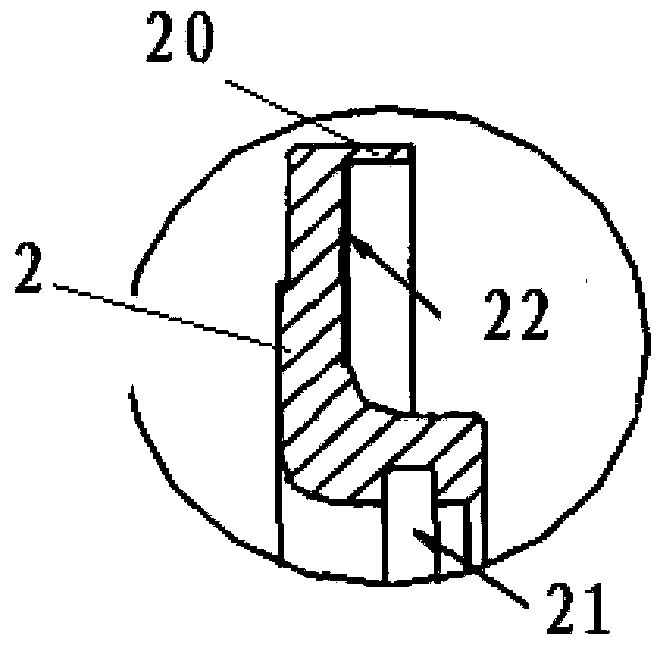

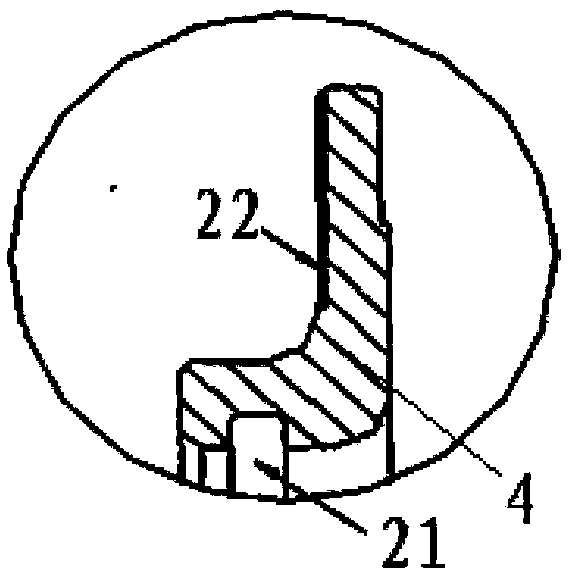

[0012] Combine below Figure 1 to Figure 3 The seal structure of the roll shaft and the roll box of the high-speed wire rod mill is described in detail. It includes a roll shaft 1 with a stepped structure. The roll shaft 1 includes a connected large-diameter portion 11 and a small-diameter portion 10. The small-diameter portion is a tapered shaft. Inner oil slinger 4 and outer oil slinger 2, the cross-sectional profiles of the inner oil slinger and the outer oil slinger are both L-shaped, and the bottom surfaces of the inner oil slinger and the outer oil slinger are provided with sealing grooves 21, An O-shaped sealing ring 5 is arranged in the sealing groove, and the cross-sectional profile of the inner oil throwing ring and the outer oil throwing ring is U-shaped, and the inner wall of the inner oil throwing ring and the outer oil throwing ring is provided with a wear-resistant coating. The U-shaped interior of the inner and outer oil flingers is provided with double-lip se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com