Improved structure planetary gear

A technology for planetary gears and improved structures, applied in the direction of gear lubrication/cooling, belts/chains/gears, elements with teeth, etc., can solve the problem of shortening the service life of planetary gears and planetary shafts, reducing the working stability of differentials, Does not conform to the development trend and other issues, to achieve the effect of improving work stability, reasonable design, simple installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

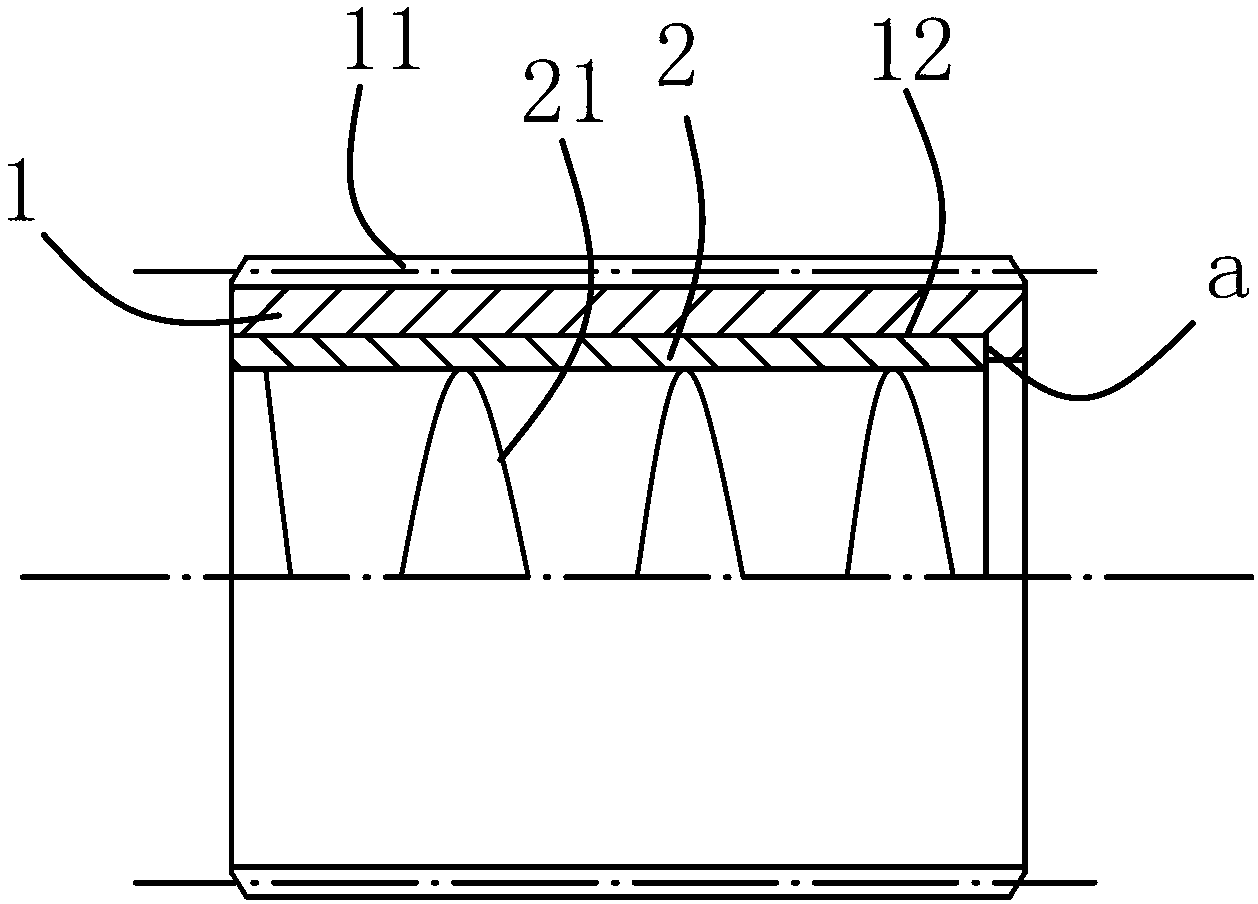

[0017] Such as figure 1 As shown, the planetary gear of this improved structure includes a body 1 with several teeth 11, chamfered surfaces are provided at both ends of each tooth 11, and a central hole 12 is provided at the axial center of the body 1. The optimization scheme, here The teeth 11 are helical teeth. On the body 1, there is an annular shoulder a located at one end of the central hole 12. In the central hole 12, there is a powder metallurgy bushing 2 with one end against the annular shoulder a. , an oil storage structure is provided on the powder metallurgy bushing 2 . Obviously, the design of this embodiment is more reasonable, the installation and disassembly are relatively simple, and it has the function of oil storage, good self-lubricating effect, improves the working stability of the differential, and conforms to the current trend of social and technological development.

[0018] Specifically, the oil storage structure of this embodiment includes a spiral oi...

Embodiment 2

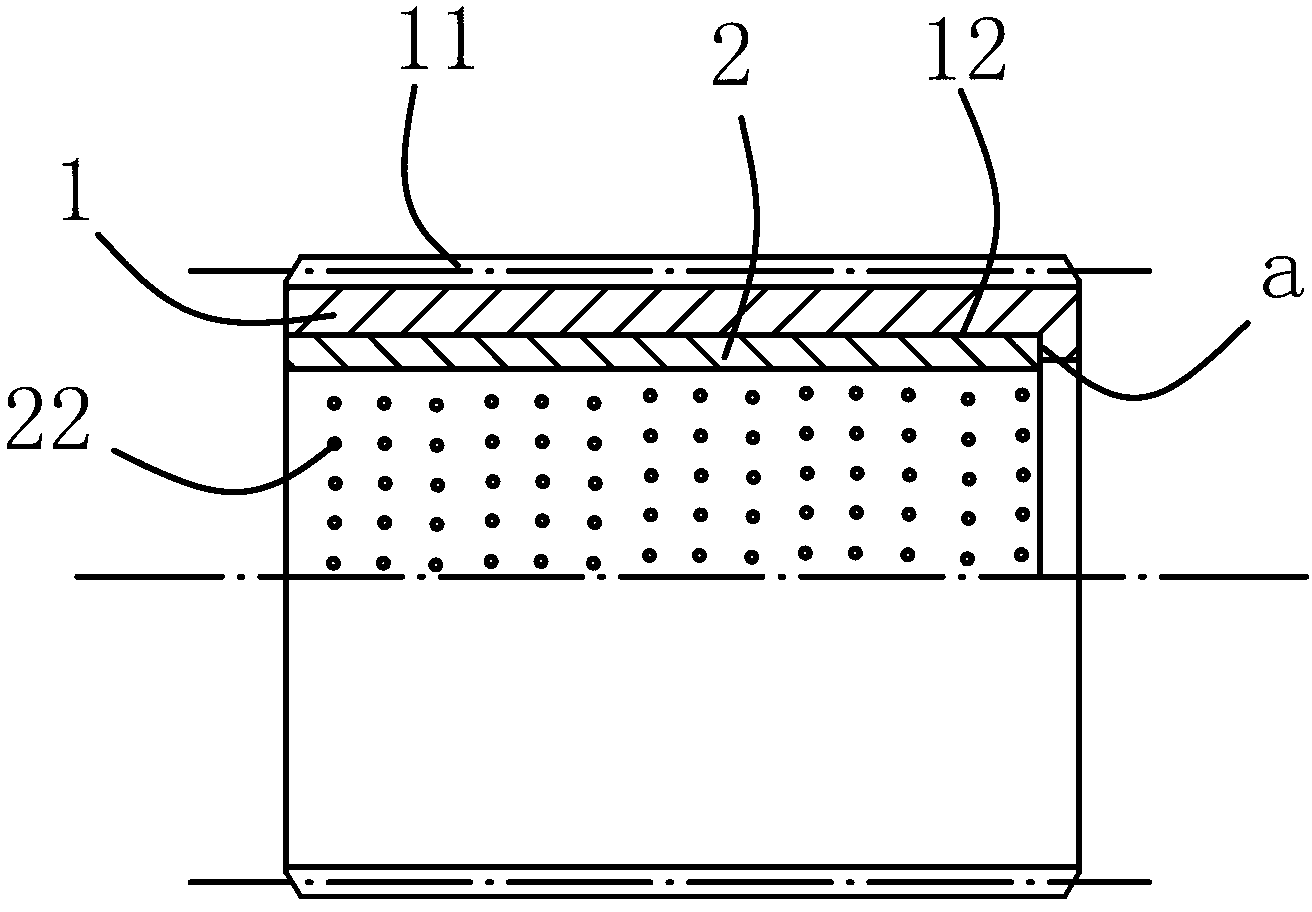

[0020] Such as figure 2 As shown, the structure and principle of this embodiment are basically the same as those of Embodiment 1, except that the oil storage structure includes a number of small oil storage holes 22 arranged on the inner wall of the powder metallurgy bushing 2; the diameter of the small oil storage holes 22 is is 2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com