Graphene/carbon fiber enhanced nylon composite wear-resistant material and preparation method and application thereof

A technology of wear-resistant materials and graphene, which is applied in the field of graphene/carbon fiber reinforced nylon composite wear-resistant materials and its preparation, can solve the problems of inability to realize graphene dispersion, failure to meet the basic requirements of bearings, high friction coefficient and wear, and achieve Reduce equipment operating noise and maintenance costs, excellent self-lubrication, good self-lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Reference example 1 for preparation of high viscosity nylon resin

[0037] The PA66 is heated and reacted for 10h and cooled for 6h under the conditions of 170℃ and vacuum degree of -0.08MPa to obtain relative characteristics.

[0038] PA66-1 with a viscosity of 3.50.

[0039] Reference example 2 for preparation of high viscosity nylon resin

[0040] The PA66 is heated and reacted for 12h and cooled for 8h under the conditions of 190℃ and vacuum degree of -0.08MPa to obtain relative characteristics.

[0041] PA66-2 with a viscosity of 4.0.

[0042] Reference example 3 for preparation of high viscosity nylon resin

[0043] The relative viscosity of PA1010 is obtained by heating and reacting for 12h and cooling for 8h under the condition of 190℃ and vacuum degree of -0.08MPa.

[0044] For PA1010 of 4.2.

Embodiment 1~10

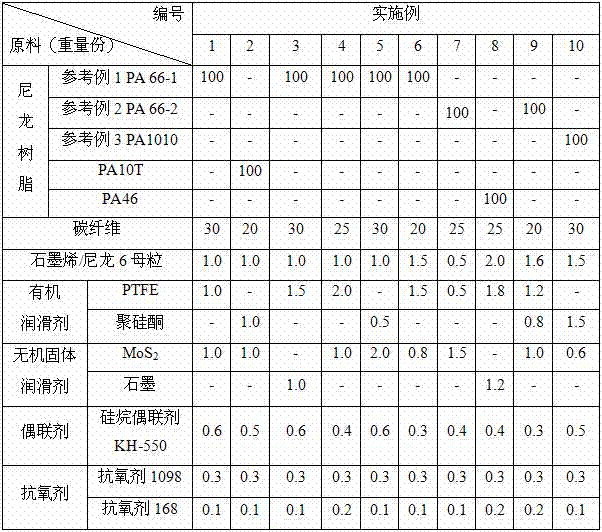

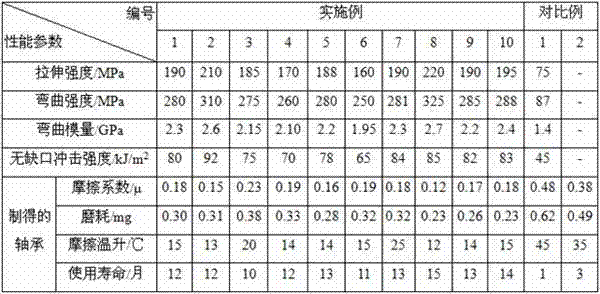

[0046] The raw material composition of the graphene / carbon fiber reinforced nylon composite wear-resistant material in Examples 1-10 is shown in Table 1:

[0047] Table 1 The raw material composition of the graphene / carbon fiber reinforced nylon composite wear-resistant material in Examples 1-10

[0048]

[0049] Note: "-" in the table means not added.

[0050] Preparation method of graphene / carbon fiber reinforced nylon composite wear-resistant material Examples 1-10

[0051] (1) According to the weight parts of the raw materials in Examples 1-10 in Table 1, the inorganic solid lubricant and the coupling agent were mixed and coupled for 5 minutes at 60°C and a stirring speed of 400 r / min. , Get coupled inorganic solid lubricant;

[0052] (2) Measure graphene / nylon 6 masterbatch, organic lubricant, coupled inorganic solid lubricant and antioxidant obtained in step (1) according to the weight parts of each raw material in Examples 1-10 in Table 1, respectively Add to the mixer and mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com