Solid lubricated thrust sliding bearing capable of being continuously filled

A technology for thrust sliding bearings and solid lubrication, which is applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of insufficient fillability of solid lubricants for bearings, restrictions on the types of solid lubricants, and restrictions on load-carrying capacity, etc., to achieve Improvement of sustainable fillability, increase in types of use, and long bearing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

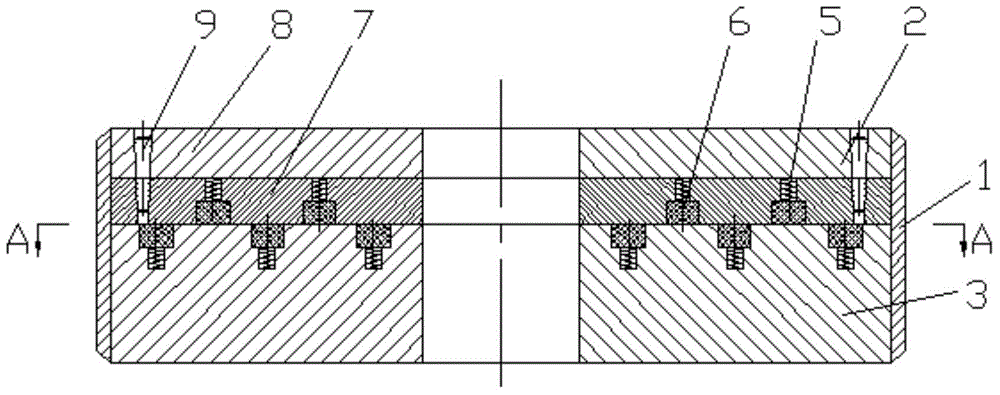

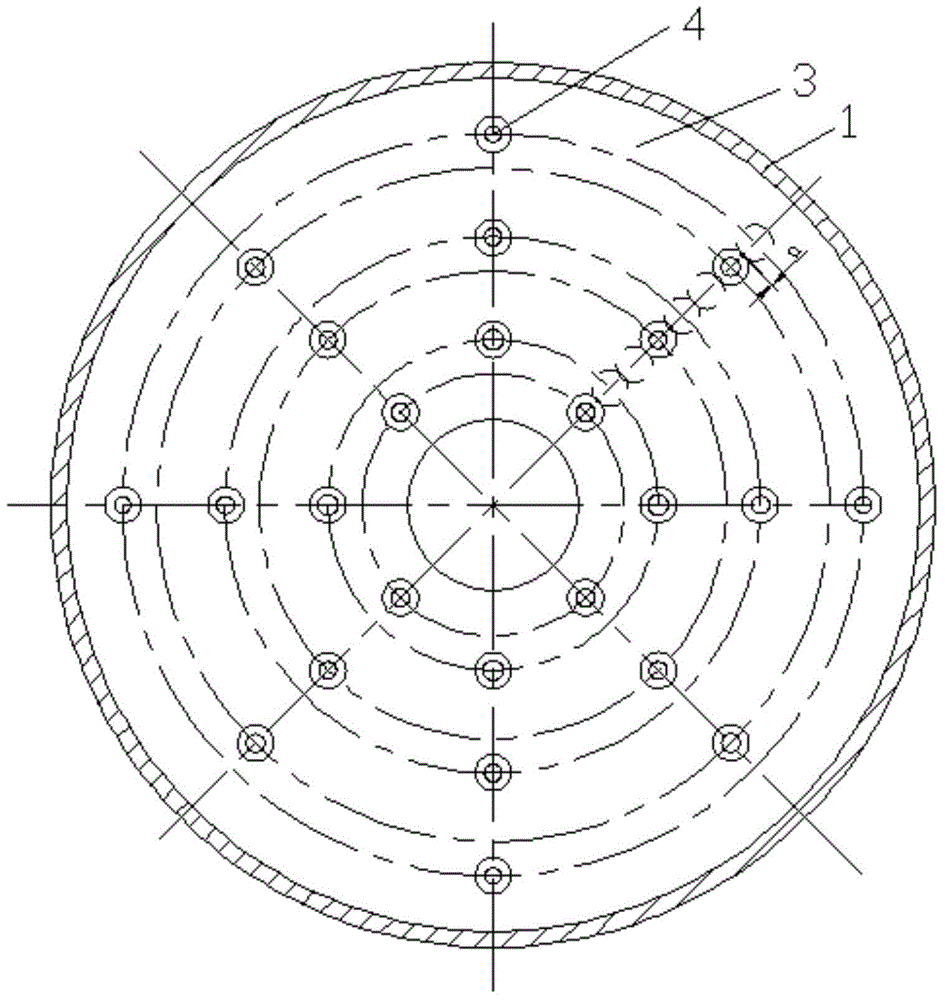

[0016] Refer to the attached drawings, a continuously filled solid lubrication thrust sliding bearing, including a sealing ring 1, a copper alloy upper ring 2, a steel lower ring 3, a lower ring 3 and a lower ring are installed on the lower part of the inner wall of the sealing ring 1 3 The upper ring 2 is installed on it. The upper ring 2 is composed of a base layer 8 distributed on the upper layer and a wear-resistant layer 7 on the lower layer. The base layer 8 and the wear-resistant layer 7 are connected by pins 9 and the wear-resistant layer of the upper ring Step holes 4 are arranged in the upper plane of the inner and lower ring 3 respectively. The small diameter section of the step hole 4 is equipped with a spring 5, and the large diameter section is equipped with a solid lubricating block 6. 6 are in contact with each other, and the stepped holes 4 on the contact planes of the upper and lower rings 2, 3 overlap in the relative sliding direction of the upper ring and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com