Skate rack and manufacturing method

A manufacturing method and technology of skates, applied in the direction of skates, skating parts, sports accessories, etc., can solve the problems of poor sliding effect, unstable quality, short service life, etc., and achieve low deformation and scrap rate, light weight, self-lubricating good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

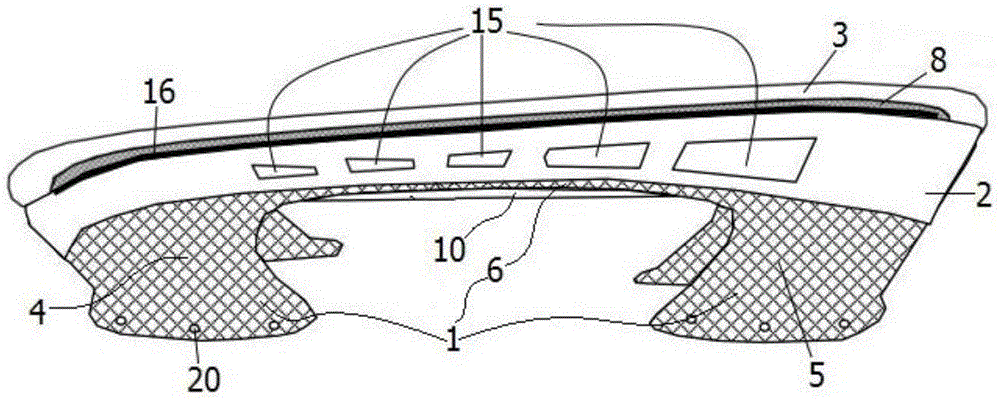

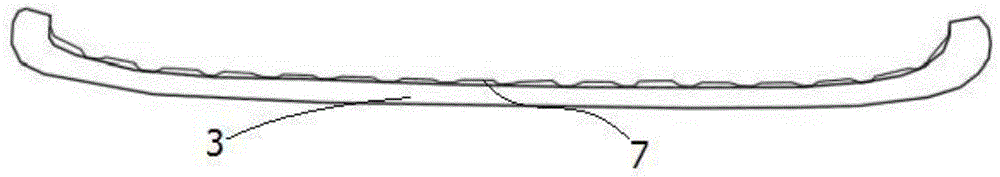

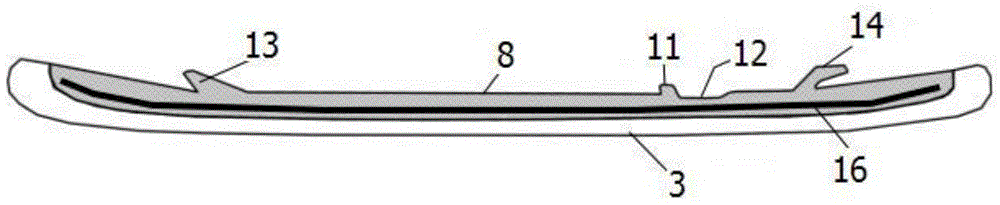

[0063] Such as figure 1 The illustrated embodiment is a skate rack, comprising a sole support base 1, a strip-shaped vertical plate 2 that is arranged on the sole support base and runs through the front and rear ends of the lower surface of the sole support base, and an ice blade 3 connected with the strip-shaped vertical plate; The support seat includes a front sole support seat 4, a rear sole support seat 5 and a connecting strip 6 connecting the front sole support seat, the rear sole support seat and arching downwards; the front sole support seat and the rear sole support seat are all open at the upper end And the cross-sectional area gradually increases from bottom to top in a cylindrical shape, the rear part of the front sole support seat is provided with an opening, the front part of the rear sole support seat is provided with an opening, and the height of the upper end surface of the front sole support seat increases gradually from front to back. The upper end surface o...

Embodiment 2

[0090] Embodiment 2 includes all structures and steps in Embodiment 1, and uses the following steps to replace step 215 in Embodiment 1:

[0091] Paste and connect the preformed body of the front sole support seat, the preform body of the rear sole support seat and the preform body of the connecting strip, and separate the openings of the preform body of the front sole support seat and the preform body of the rear sole support seat with ultra-thin glass fiber cloth. Wrap to obtain the sole support seat preform; surround the shoe sole support seat preform with a glass fiber material with a width of 1.4cm.

[0092] Use the following steps to replace step 211 in Embodiment 1:

[0093] Paste the glass fiber material layer by layer on the front shoe sole support preform which has the same shape as the front shoe sole support to obtain the front shoe sole support preform; put the front shoe sole support preform into a sealed bag to evacuate, Make the layers of the yarn material mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com