Preparation method of high thermal stretching high molecular weight polyethylene sheet

A high-molecular-weight and ultra-high-molecular-weight technology, which is applied in the field of preparation of high-molecular-weight polyethylene sheets with high heat-stretching, can solve problems such as rising product costs, easy distortion of products, difficult welding and hot melting, etc., to improve circulation capacity , excellent mechanical properties, the effect of eliminating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preparation method of the high-power heat-stretched high-molecular-weight polyethylene sheet of the present invention comprises the following steps:

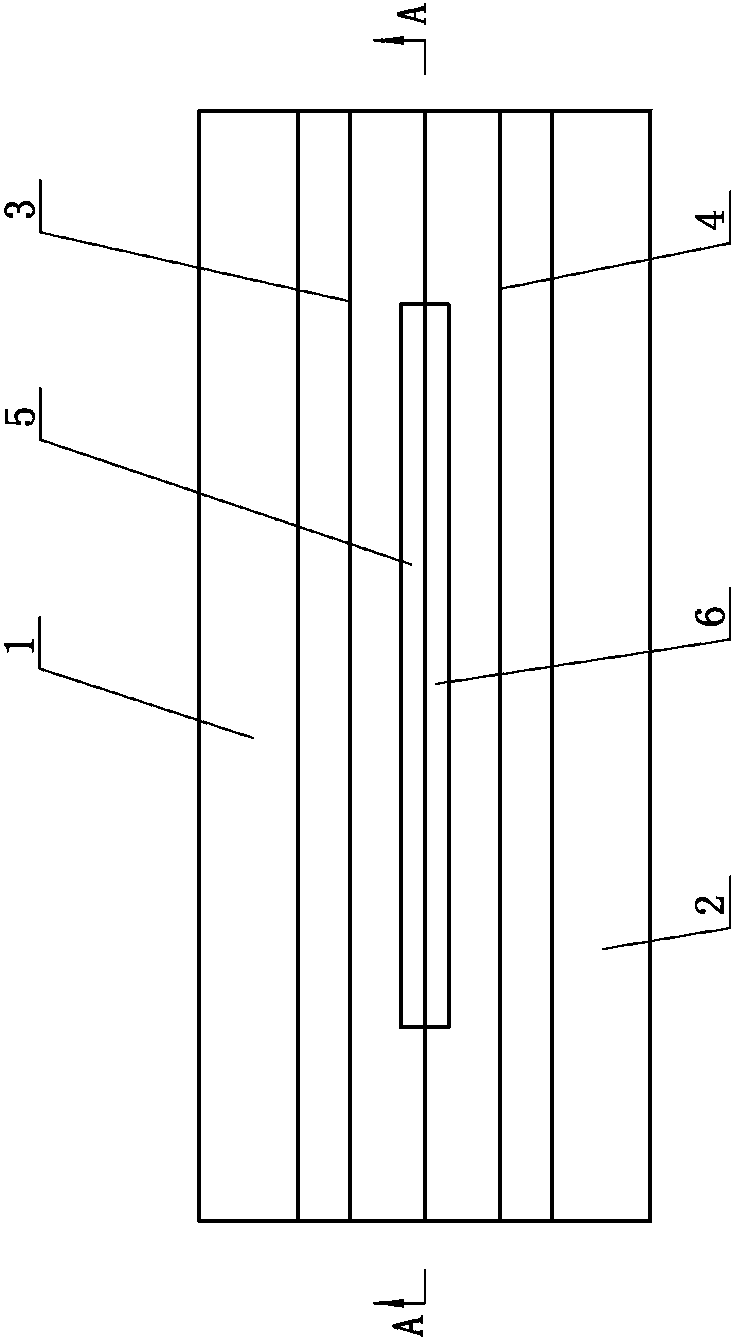

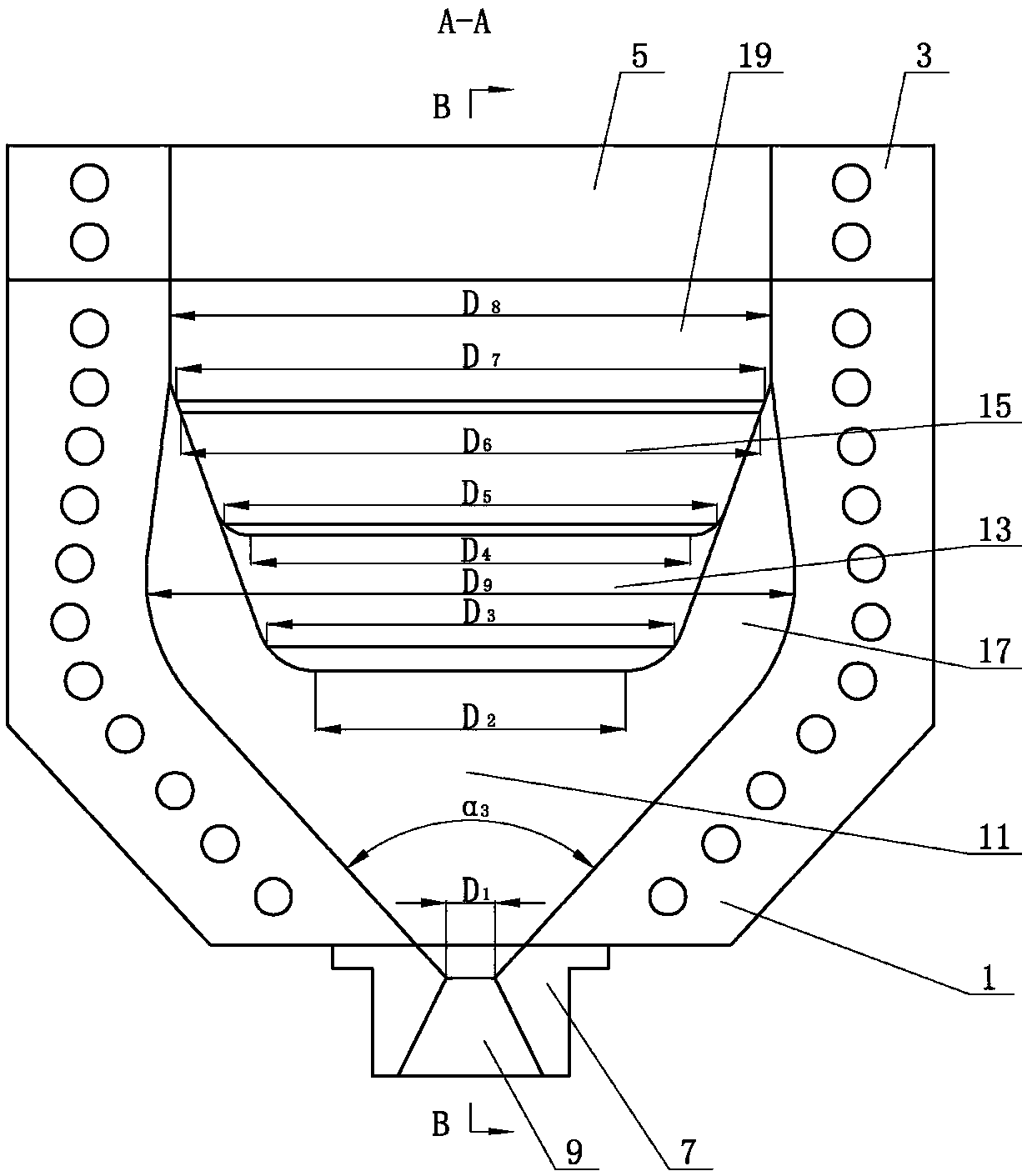

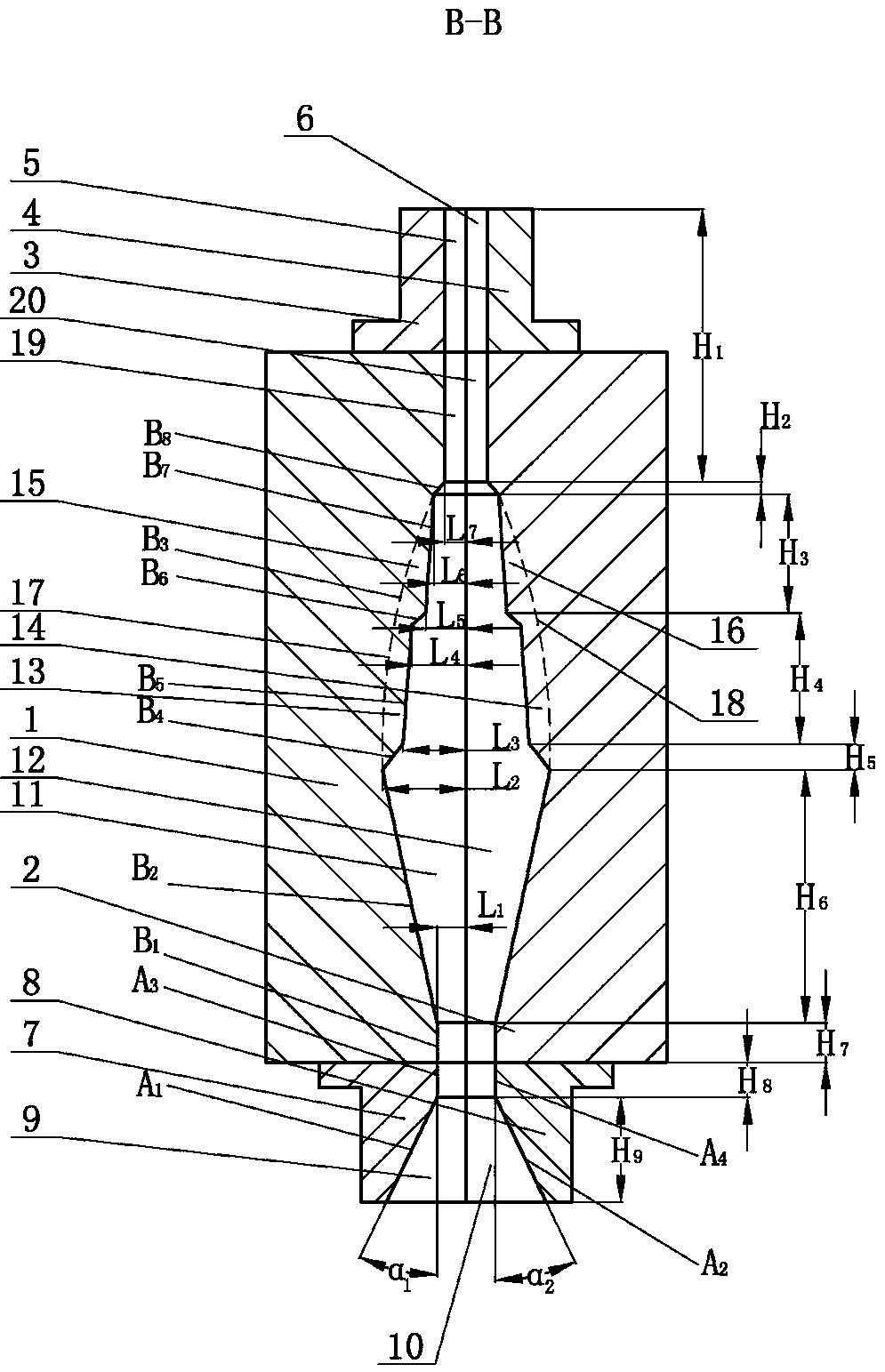

[0015]① Take 95 parts by weight of ultra-high molecular weight polyethylene resin, 4.5 parts of polyethylene wax, and 0.5 part of carbon black, mix the above raw materials and put them into a single-screw extruder, extrude the slab, and the single-screw extruder The outlet of the thin plate extrusion die is installed, and the thin plate extrusion die is provided with a first feed plate 7 and a second feed plate 8, and the first feed plate 7 and the second feed plate 8 are respectively connected to the outlet of the single-screw extruder , the first feed plate 7 is connected to one end of the first template 1, the other end of the first template 1 is connected to the first extruding plate 3, the second feed plate 8 is connected to one end of the second template 2, and the second template 2 is in addition One end is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com