High-power, low-speed and positive-pressure type explosion-proof induction motor

An induction motor, high-power technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of poor cooling effect, large leakage, etc., achieve the effect of small friction loss, good self-lubrication, and solve cooling difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

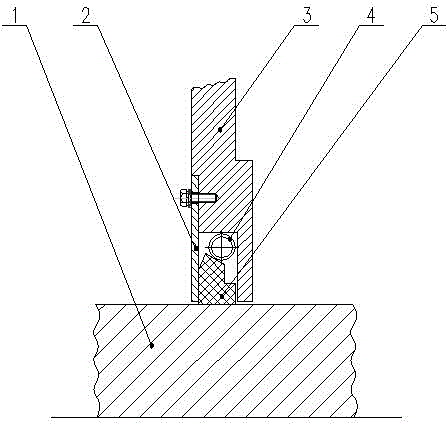

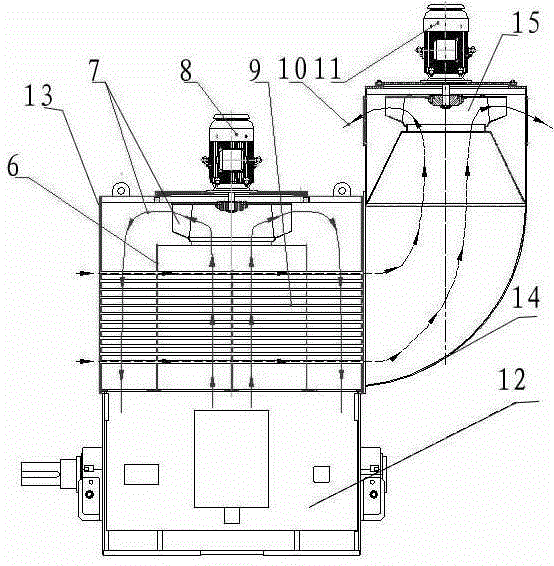

[0013] Such as figure 1 and 2 As shown, the present invention includes a high-power low-speed positive-pressure explosion-proof induction motor, including a positive-pressure explosion-proof induction motor body, a sealing device and an air-to-air cooler device.

[0014] The sealing device is arranged at the shaft penetration part of the motor. In the shaft penetration part of the motor, there is a clearance fit between the cover plate 2 and the end cover 3 and the rotating shaft 1, leaving a gap of at least 1 mm to avoid the cover plate 2 and the end cover. Noise and vibration are caused by friction between the cover 3 and the shaft 1; and a sealing device composed of a spring ring 4 and a carbon ring 5 is provided between the cover plate 2 and the end cover 3, and the spring ring 4 is far away from the shaft 1. The carbon ring 5 seals the gap between the cover plate 2, the end cover 3, the spring ring 4 and the rotating shaft 1. Since the setting of the spring ring 4 plays...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com