High-temperature corrosion-resistant anti-slagging composite material and preparation method thereof

A composite material and corrosion-resistant technology, applied in the direction of joint combustion mitigation, etc., can solve the problems of complex materials and corrosiveness, and achieve the effects of good self-wetting, low apparent porosity, and improved thermal stability and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

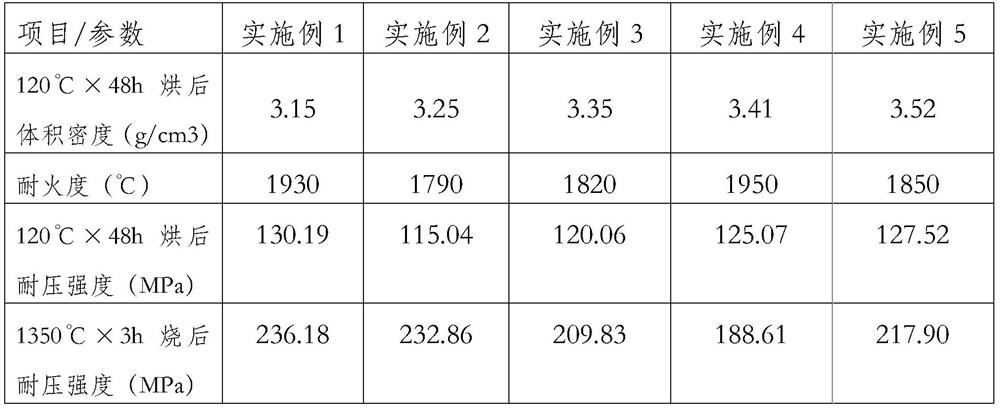

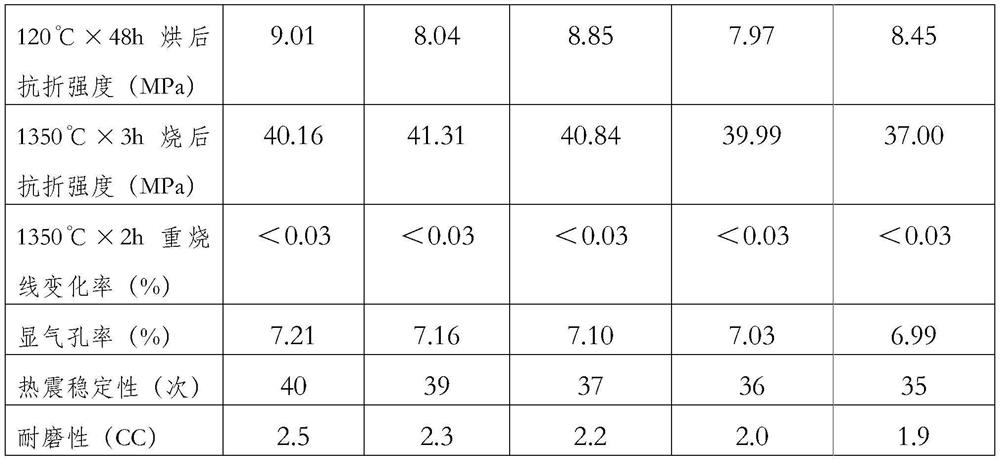

Examples

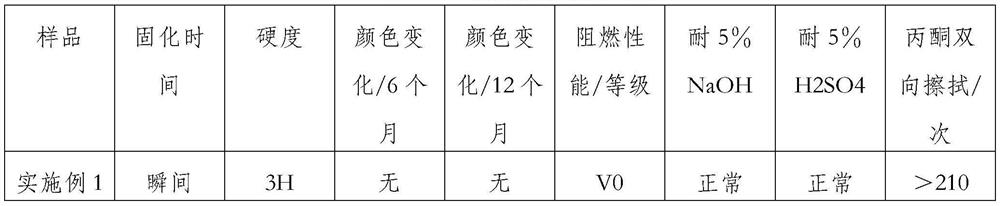

Embodiment 1

[0030] A high-temperature corrosion-resistant and anti-slagging composite material, comprising in parts by weight: 20 parts of fused zirconium corundum fine powder specification mixture, 2 parts of boron carbide powder with a particle size of 0.01 mm, 10 parts of barium metaborate, and 15 parts of nano silicon dioxide parts, 2 parts of quartz powder, 0.5 part of nano-yttrium oxide with particle size of 30nm, 1 part of nano-cerium oxide with particle size of 30nm, 0.2 part of dispersant, 1 part of Aerosil3001, 10 parts of fatty alcohol polyoxyethylene ether, polyvinyl butyral 1.5 parts, 2 parts sodium nitrite, 10 parts ethanol, 0.5 parts oleic acid, FeCl 2 5 servings.

[0031] Among them, the fused zirconium corundum fine powder specification mixture specifically includes 40% fused zirconium corundum fine powder with a particle size of 0.075mm, 35% fused zirconium corundum fine powder with a particle size of 0.5mm, and 25% of the fused zirconium corundum fine powder with a part...

Embodiment 2

[0043] A high-temperature anti-corrosion and anti-slagging composite material, comprising, in parts by weight, 30 parts of fused tabular corundum fine powder specification mixture, 5 parts of aluminum nitride powder with a particle size of 0.025mm, 15 parts of barium metaborate, nanometer dioxide 20 parts of silicon, 6 parts of quartz powder, 1 part of nano-yttrium oxide with particle size of 30nm, 2 parts of nano-cerium oxide with particle size of 30nm, 0.5 part of dispersant, 3005 parts of Aerosil, 10 parts of fatty alcohol polyoxyethylene ether, polyvinyl alcohol condensation 2.5 parts of butyraldehyde, 5 parts of sodium nitrite, 10 parts of ethanol, 0.5 parts of oleic acid, FeCl 2 5 servings.

[0044] Among them, the specification mixture of fused tabular corundum fine powder specifically includes 40% fused tabular corundum fine powder with a particle size of 0.1 mm, 35% fused tabular corundum fine powder with a particle size of 1.2 mm, and an electrofused tabular corundum...

Embodiment 3

[0056] A high-temperature corrosion-resistant and slagging-resistant composite material, comprising, in parts by weight, 25 parts of fused zirconium corundum fine powder specification mixture, 4 parts of silicon nitride powder with a particle size of 0.021 mm, 12 parts of barium metaborate, and nano-silica 18 parts, 4 parts of quartz powder, 0.8 part of nano-yttrium oxide with particle size of 30nm, 1.5 parts of nano-cerium oxide with particle size of 30nm, 0.3 part of dispersant, 3004 parts of Aerosil, 10 parts of fatty alcohol polyoxyethylene ether, polyvinyl butyral 2 parts aldehyde, 3 parts sodium nitrite, 10 parts ethanol, 0.5 part oleic acid, FeCl 2 5 servings.

[0057] Among them, the fused zirconium corundum fine powder specification mixture specifically includes 40% fused zirconium corundum fine powder with a particle size of 0.075mm, 35% fused zirconium corundum fine powder with a particle size of 1.0mm, and 25% of the fused zirconium corundum fine powder with a part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com