Combined continuous filling type solid lubricating bearing

A technology of solid lubricated bearings and solid lubricants, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of small bearing size, insufficient application of large size, limited types of solid lubricants, etc., and achieve good self-lubrication , easy to replace, easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

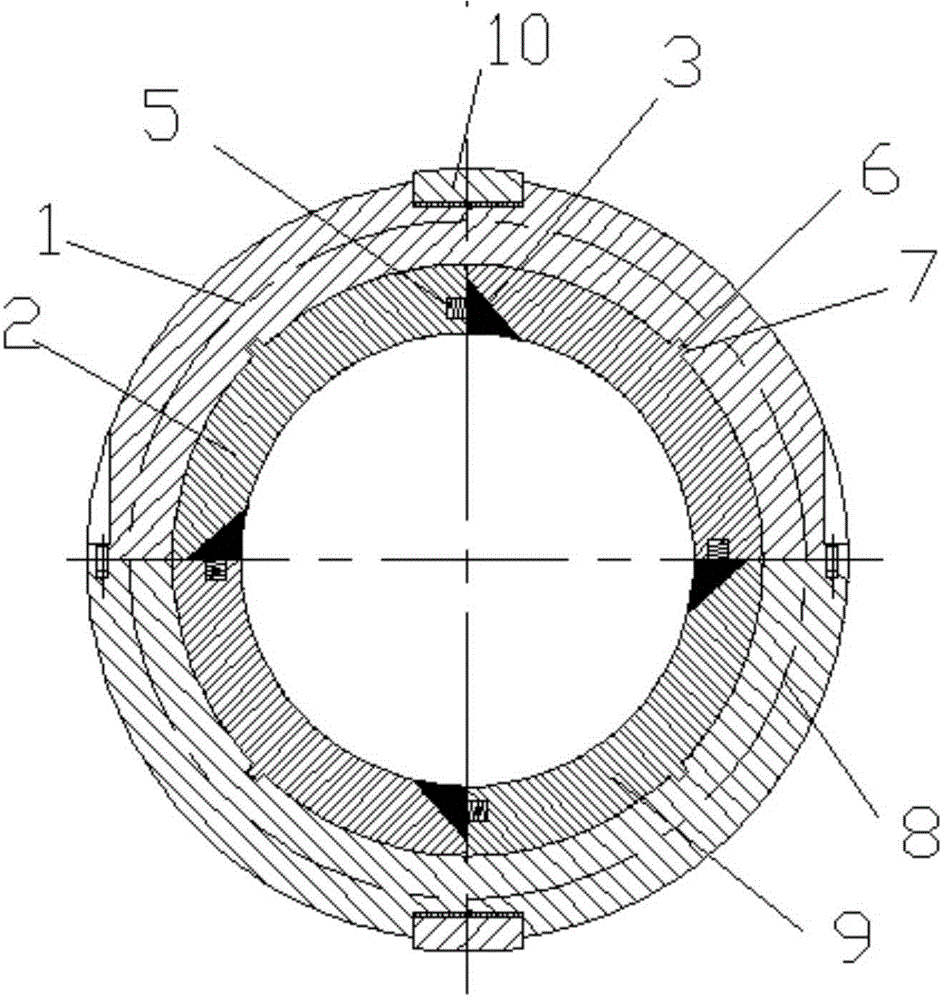

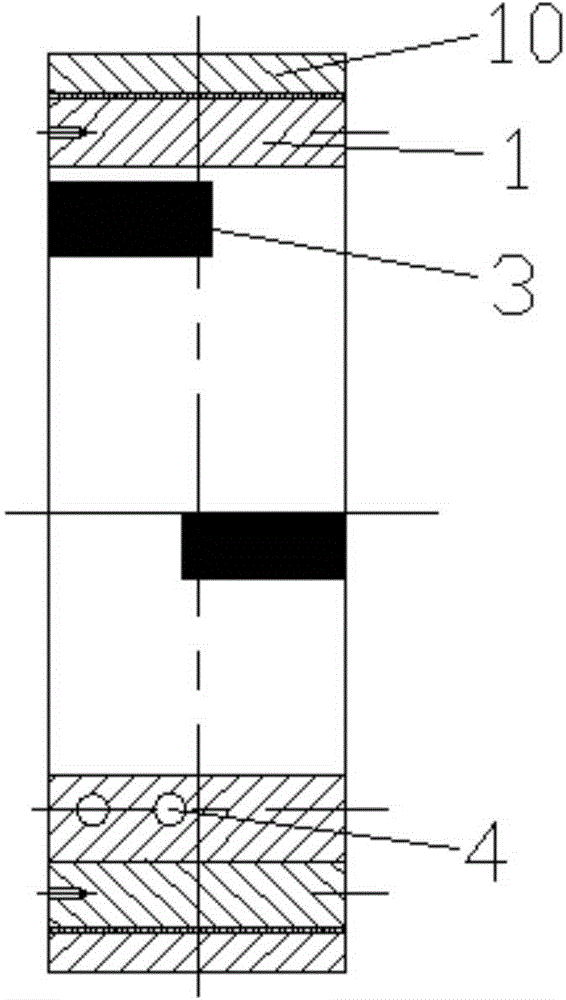

[0013] Such as figure 1 , 2 As shown, a combined continuous filling solid lubricating bearing includes a matrix and a solid lubricant 3. The matrix is composed of a carbon steel outer layer 1 and a copper alloy inner layer 2. The carbon steel outer layer 1 is composed of two semicircular parts 8 through bolts. Connected structure, each semicircular part 8 top outside has a notch, the notch is equipped with an adjustment pad 10, the inner layer of the copper alloy 2 is composed of at least 4 arc-shaped copper alloy inner layer blocks 9 of the same size, and two adjacent Triangular strip-shaped solid lubricants 3 are embedded between the copper alloy inner layer blocks 9, and the triangular strip-shaped solid lubricants 3 are staggeredly distributed on both sides of the copper alloy inner layer blocks 9, and there is a certain amount of overlap in the circumferential direction. One end of each copper alloy inner layer block is provided with at least two blind holes 4 in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com