Nut with gap eliminating function

A function and gap technology, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve problems such as noise, looseness, and lower transmission accuracy, and achieve the effect of eliminating transmission noise, reducing material loss, and improving transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

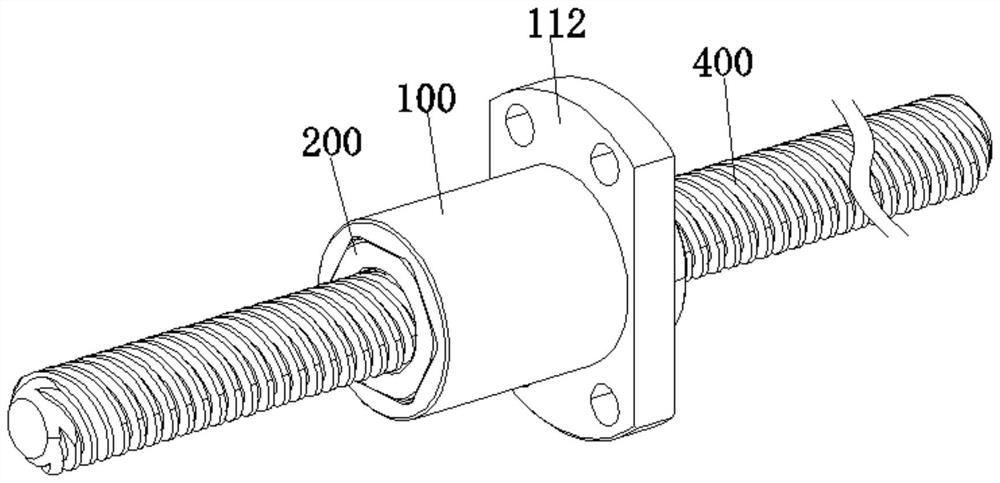

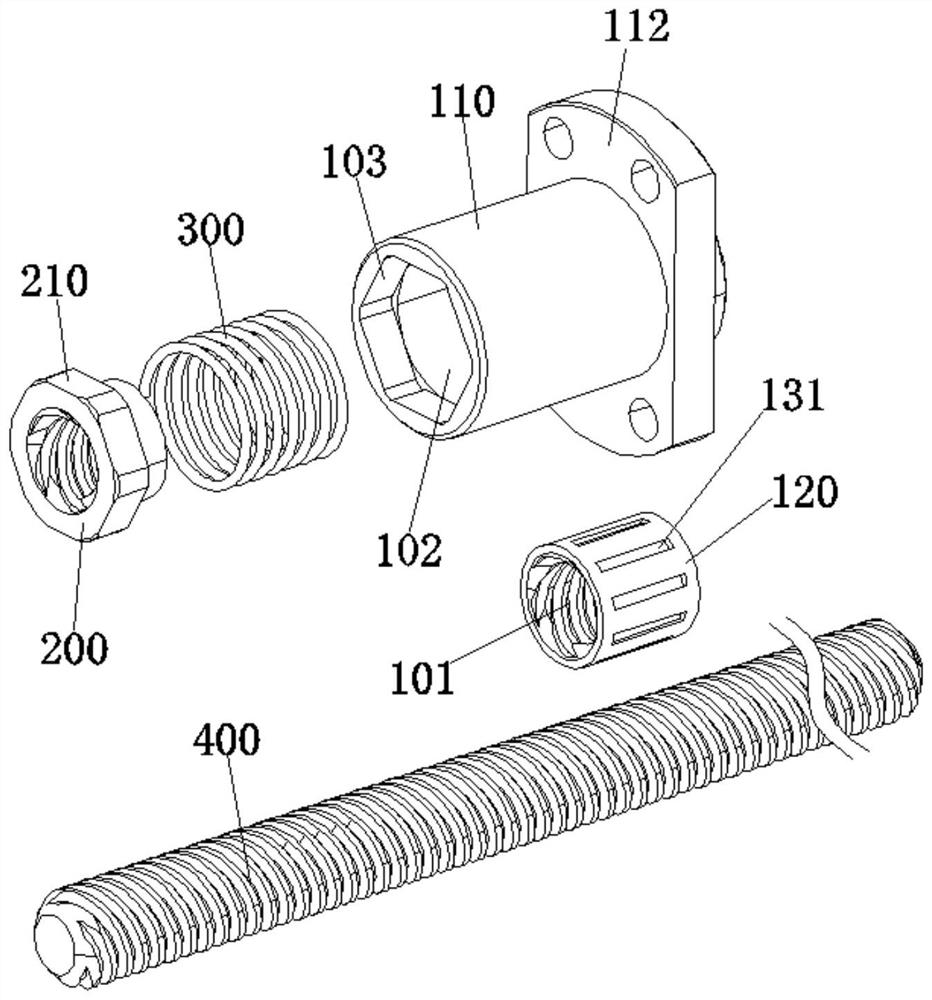

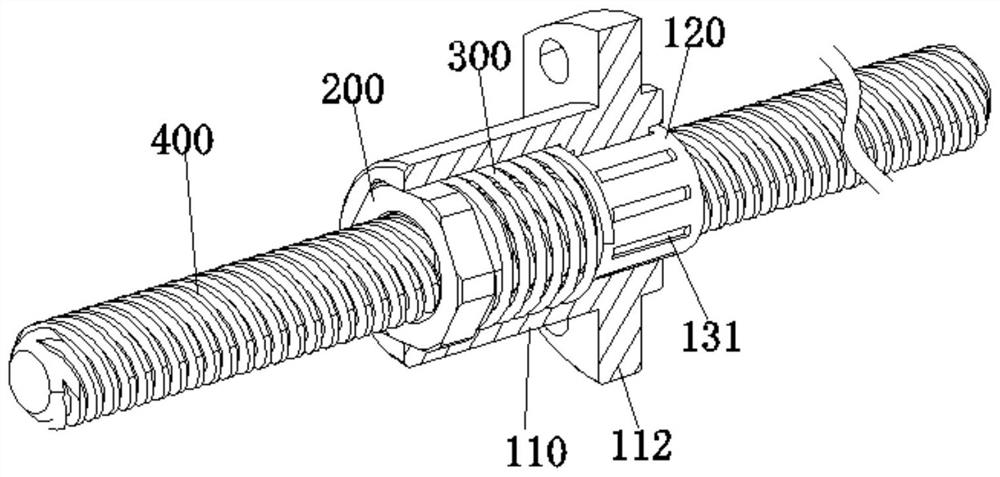

[0023] This embodiment relates to a nut with the function of eliminating gaps. The nut is mainly used in a screw drive structure. During the rotation of the screw 400 , the nut can reciprocate along the axis of the screw 400 . It includes: a first nut body 100 , a second nut body 200 and an elastic member 300 .

[0024] Specifically, one end of the first nut body 100 is provided with a threaded hole 101 for assembling with the screw rod 400 , and the other end is provided with an assembly hole 102 . The thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com