Adhesive material for laminated composite bonding transition layer of hydrogenated nitrile rubber and unsaturated non-polar rubber

A technology of hydrogenated nitrile rubber and non-polar rubber, which is applied in the field of composite rubber products and can solve problems such as poor oil resistance, poor solvent resistance, and poor aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

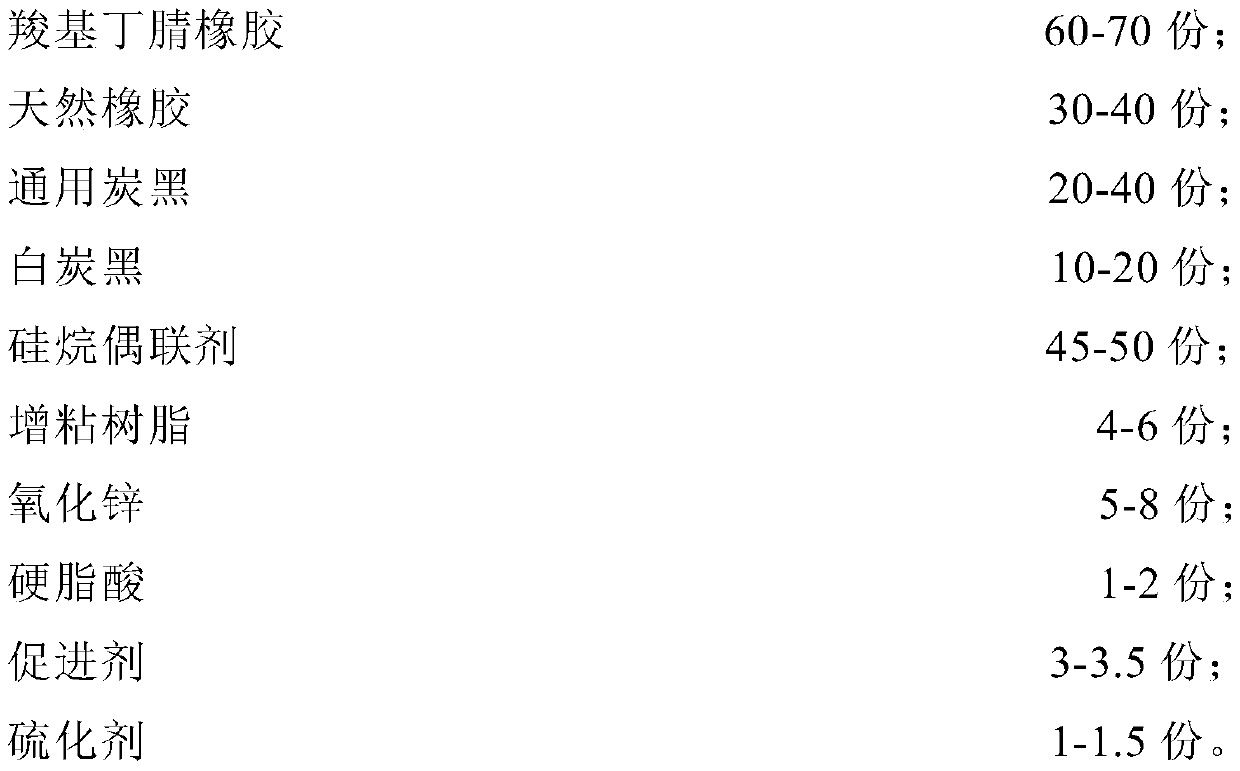

[0080] transition layer compound

[0081] 1. The rubber compound for the transition layer is prepared from the following mass fractions of raw materials:

[0082]

[0083]

[0084] 2. The rubber material of the transition layer is bonded with hydrogenated nitrile rubber, natural rubber, natural rubber / styrene-butadiene rubber, natural rubber / butadiene rubber, respectively Films of the same thickness are made by calendering on the machine, and standard samples are made by using a flat vulcanizing agent), wherein,

[0085] The formulation of hydrogenated nitrile rubber and natural rubber is:

[0086]

[0087] The formula of natural rubber / styrene butadiene rubber compound is:

[0088]

[0089]

[0090] The formula of natural rubber / butadiene rubber blend is:

[0091]

[0092]

[0093] 3. Carry out the rubber peeling test, the test method and results are as follows:

[0094]

Embodiment 2

[0096] transition layer compound

[0097] 1. The rubber compound for the transition layer is prepared from the following mass fractions of raw materials:

[0098]

[0099]

[0100] 2. The rubber material of the transition layer is bonded with hydrogenated nitrile rubber, natural rubber, natural rubber / styrene-butadiene rubber, natural rubber / butadiene rubber, respectively Films of the same thickness are made by calendering on the machine, and standard samples are made by using a flat vulcanizing agent), wherein,

[0101] The formulation of hydrogenated nitrile rubber and natural rubber is:

[0102]

[0103] The formula of natural rubber / styrene butadiene rubber compound is:

[0104]

[0105]

[0106] The formula of natural rubber / butadiene rubber blend is:

[0107]

[0108]

[0109] 3. Carry out the rubber peeling test, the test method and results are as follows:

[0110]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com