A kind of highly wear-resistant PVC foam sole material and its manufacturing method

A shoe sole material, high wear-resistant technology, applied in the field of shoe sole materials, can solve the problems of affecting the service life of shoes, loss of wear resistance, etc., and achieve the effect of less agglomeration, improved compatibility, reunion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

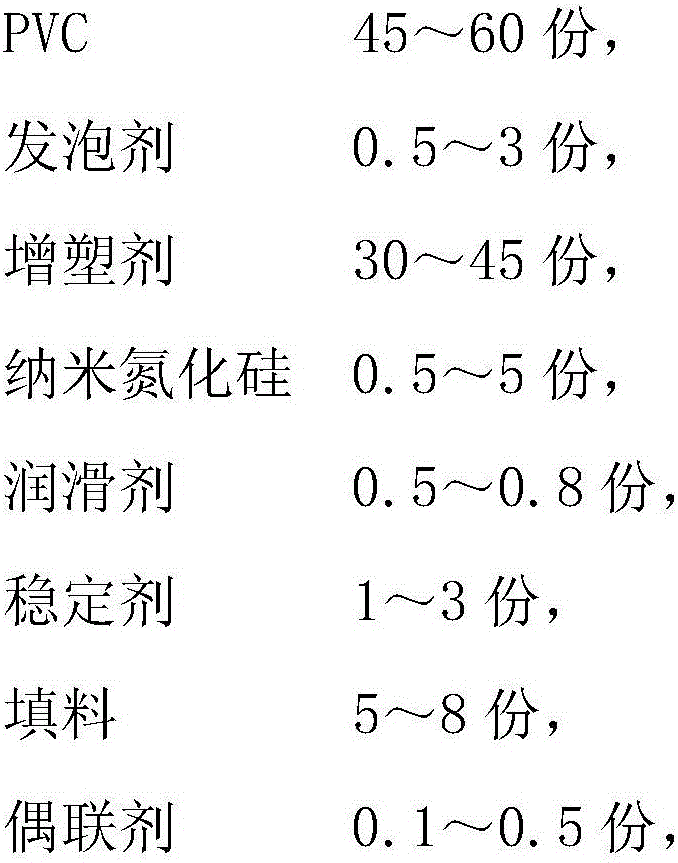

[0026] A kind of highly wear-resistant PVC foam sole material, its parts by weight consist of:

[0027]

[0028] Its manufacturing method comprises the following steps:

[0029] (1) Dissolve the coupling agent in water, adjust the pH value to 5, add nano-silicon nitride and acetone to the aqueous solution of the coupling agent, stir for 3 minutes at a speed of 2000r / min, and volatilize the solvent in a fume hood Removed, dried in vacuum at 50°C for 10 hours to obtain modified nano-silicon nitride;

[0030] (2) Add other components and the modified nano-silicon nitride obtained in step (1) into a kneader for heating and kneading, and discharge after kneading for 1.5 hours;

[0031] (3) Add the kneaded mixture into a twin-roller plastic mixer to masticate the pull sheet, and the mastication temperature is 120° C. to obtain the sheet material;

[0032] (4) The sheet material is sent into a hot press machine for heating and plasticizing, foaming, cooling and shaping after foa...

Embodiment 2

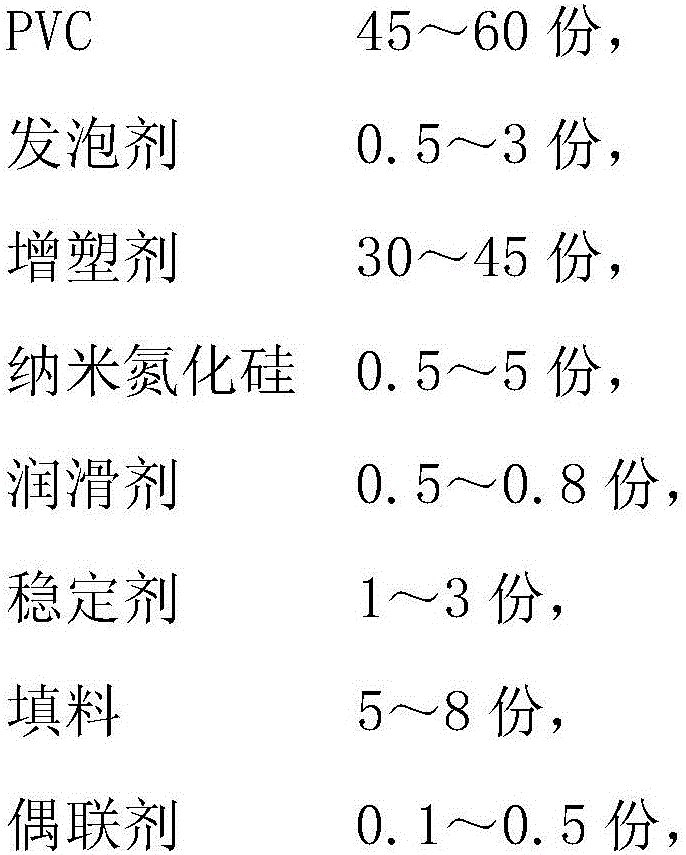

[0036] A kind of highly wear-resistant PVC foam sole material, its parts by weight consist of:

[0037]

[0038] Its manufacturing method comprises the following steps:

[0039] (1) Dissolve the coupling agent in water, adjust the pH value to 5, add nano-silicon nitride and acetone to the aqueous solution of the coupling agent, stir for 3 minutes at a speed of 2000r / min, and volatilize the solvent in a fume hood Removed, dried in vacuum at 50°C for 10 hours to obtain modified nano-silicon nitride;

[0040] (2) Add other components and the modified nano-silicon nitride obtained in step (1) into a kneader for heating and kneading, and discharge after kneading for 1.5 hours;

[0041] (3) Add the kneaded mixture into a twin-roller plastic mixer to masticate the pull sheet, and the mastication temperature is 120° C. to obtain the sheet material;

[0042] (4) The sheet material is sent into a hot press machine for heating and plasticizing, foaming, cooling and shaping after foa...

Embodiment 3

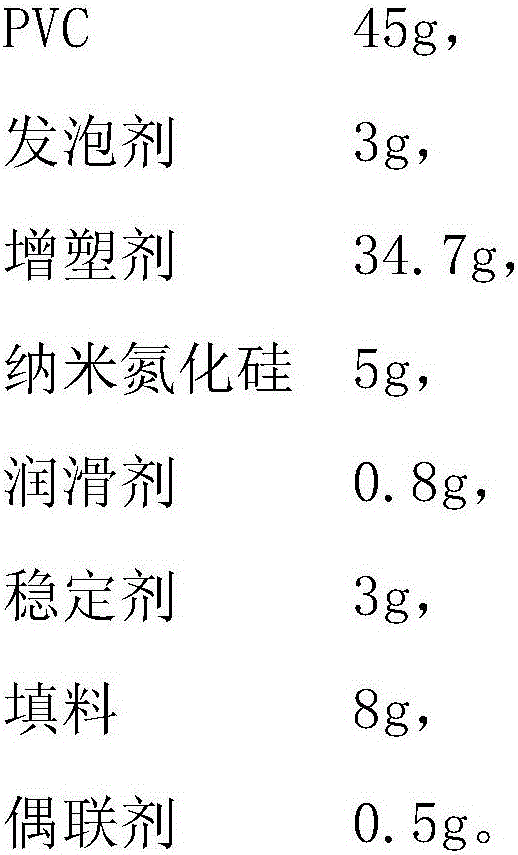

[0046] A kind of highly wear-resistant PVC foam sole material, its parts by weight consist of:

[0047]

[0048] Its manufacturing method comprises the following steps:

[0049] (1) Dissolve the coupling agent in water, adjust the pH value to 5, add nano-silicon nitride and acetone to the aqueous solution of the coupling agent, stir for 3 minutes at a speed of 2000r / min, and volatilize the solvent in a fume hood Removed, dried in vacuum at 50°C for 10 hours to obtain modified nano-silicon nitride;

[0050] (2) Add other components and the modified nano-silicon nitride obtained in step (1) into a kneader for heating and kneading, and discharge after kneading for 1.5 hours;

[0051] (3) Add the kneaded mixture into a twin-roller plastic mixer to masticate the pull sheet, and the mastication temperature is 120° C. to obtain the sheet material;

[0052] (4) The sheet material is sent into a hot press machine for heating and plasticizing, foaming, cooling and shaping after foa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com