Method for casting high manganese steel composite gear, and high manganese steel composite casted gear

A composite gear and high manganese steel technology, applied in the field of mining machinery transmission, can solve the problems of unsolvable machining problems, unrealized high manganese steel gear manufacturing aspirations, and poor machining performance of high manganese steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

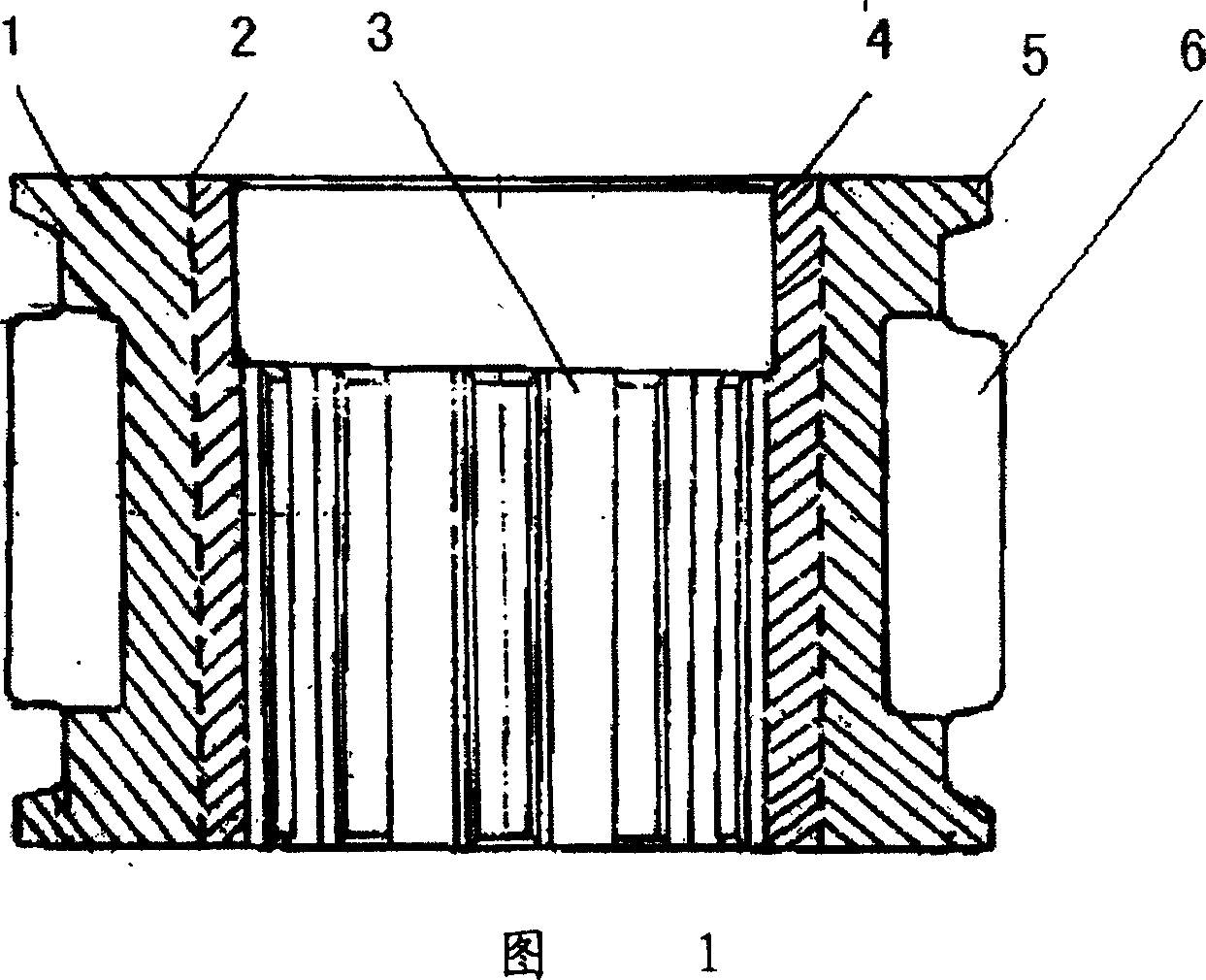

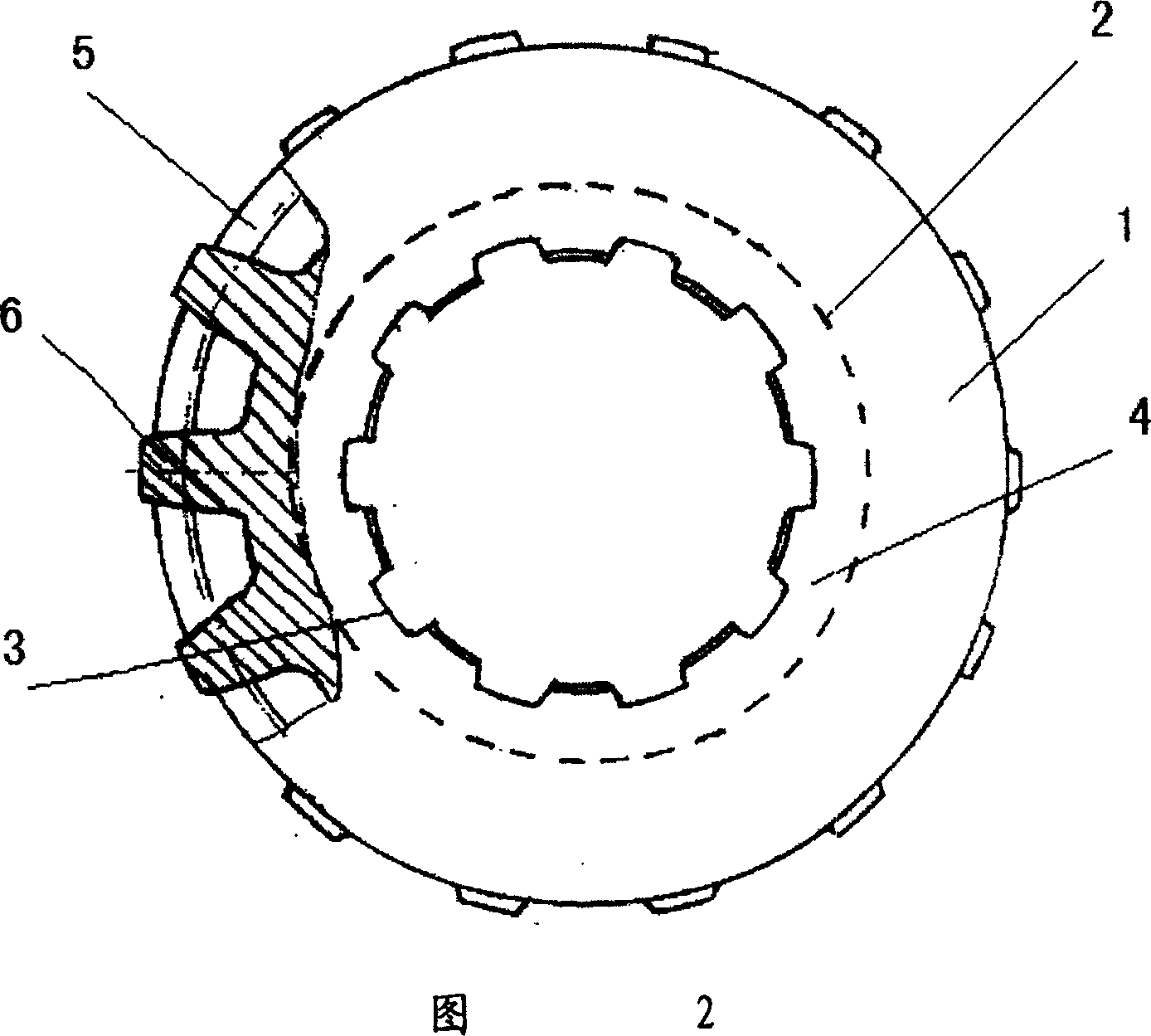

[0023] This embodiment is a high manganese steel compound casting gear used for mining machinery transmission, as shown in Figure 1 and Figure 2, the gear is composed of a high manganese steel gear outer ring 1 including a tooth profile 6 and a carbon structural steel inner ring 4 is formed by integral casting, and the joint surface 2 of the outer high manganese steel outer ring 1 and the carbon structural steel inner ring 4 is located in the middle of the minimum thickness of the ring gear, which is a metal phase combination formed by casting. The structural steel inner ring 4 is formed with an inner hole with a spline 3 . Since the carbon structural steel has good machinability, the spline structure of the inner hole is formed by machining according to the required precision after casting. Both sides of this gear are shaped on ribs 5 integrally cast with the tooth profile of the high manganese steel gear outer ring 1, which can automatically limit the axial position of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com