Polyolefin and preparation method thereof

A polyolefin and olefin technology, applied in the field of polyolefin and its preparation, can solve the problems that restrict the development and application of high isotactic polyolefin alloys, reduce Vicat softening point, and reduce product performance, so as to improve polymerization activity and product specifications. Degree, improve catalytic activity, improve the effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

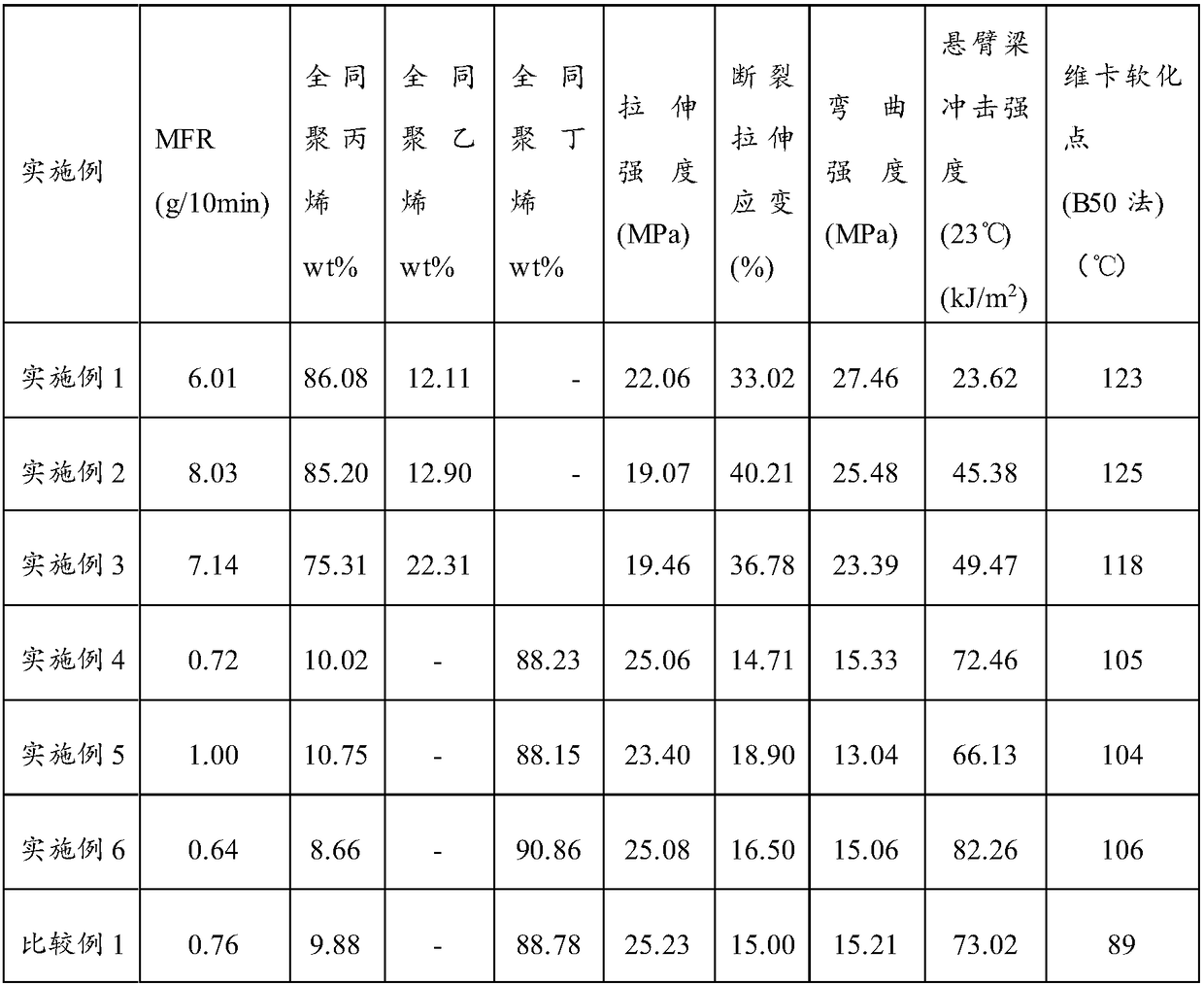

Examples

Embodiment 1

[0035] Through the refining system, 1.6kg of liquid-phase propylene and 0.4kg of ethylene were respectively refined;

[0036] After the 10L polymerization kettle was replaced with nitrogen and vacuumized, triethylaluminum, external electron donor diphenyldimethoxysilane and MgCl were put into the reaction kettle in sequence. 2 Loaded TiCl 4 Catalyst (titanium loading is 2.6wt%, internal electron donor is ester) 0.20g, put into propylene 1.0kg, hydrogen 1.0L, wherein Al / Ti=60 (molar ratio), Si / Ti=15 (molar ratio) . Through the DCS control system, the polymerization was controlled at a constant temperature of 60°C for 30 minutes, followed by evacuation and cooling.

[0037] When the temperature of the reaction kettle is lowered to 20°C, put 1.0kg of ethylene-propylene mixed solution, triethylaluminum, and external electron donor diphenyldimethoxysilane into the reaction kettle, and put in 1.0L of hydrogen gas, among which, the ethylene-propylene mixed solution Among them, eth...

Embodiment 2

[0039] Through the refining system, 1.6kg of liquid-phase propylene and 0.4kg of ethylene were respectively refined;

[0040] After the 10L polymerization kettle was replaced with nitrogen and vacuumized, triethylaluminum, external electron donor diphenyldimethoxysilane and MgCl were put into the reaction kettle in sequence. 2 Loaded TiCl 4 Catalyst (2.6wt% titanium loading, esters as internal electron donor) 0.22g, propylene 1.0kg, hydrogen 2L, wherein Al / Ti=60 (molar ratio), Si / Ti=15 (molar ratio). Through the DCS control system, the polymerization was controlled at a constant temperature of 60°C for 30 minutes, followed by evacuation and cooling.

[0041] After the temperature of the reactor is lowered to 20°C, put 1.0kg of ethylene-propylene mixed solution, triethylaluminum, and the external electron donor into the reactor, which is compounded by diphenyldimethoxysilane and dicyclohexyldimethoxysilane , drop into 1L of hydrogen, wherein, in the ethylene-propylene mixture...

Embodiment 3

[0043] Through the refining system, 4.0kg of liquid-phase propylene and 1.5kg of ethylene were respectively refined;

[0044] After the 10L polymerization kettle was replaced with nitrogen and vacuumized, triethylaluminum, external electron donor diphenyldimethoxysilane and MgCl were sequentially put into the 10L reaction kettle 2 Loaded TiCl 4 Catalyst (titanium loading is 2.6wt%, internal electron donor is ester) 0.36g, input propylene 2.5kg, hydrogen 4.0L, wherein Al / Ti=60 (molar ratio), Si / Ti=20 (molar ratio) . Through the DCS control system, control the polymerization at a constant temperature of 70°C for 60 minutes, and then evacuate and lower the temperature.

[0045] When the temperature of the 10L reactor is lowered to 20°C, transfer the catalytically active polypropylene particles in the 10L reactor to the 20L reactor with the help of liquid phase propylene, and put in 3.0kg of ethylene-propylene mixture, triethylaluminum, and an external electron donor For the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com