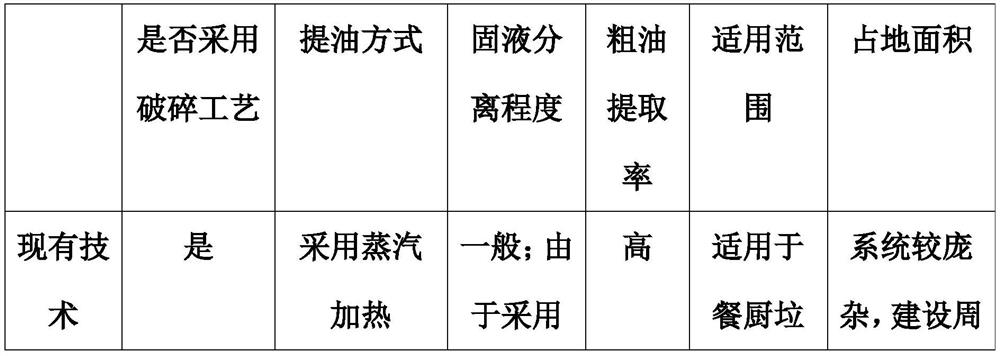

Patents

Literature

37results about How to "Reduce heating steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-performance polycarboxylate superplasticizer via heat resource-free process

The invention discloses a method for preparing high-performance polycarboxylate superplasticizer via a heat resource-free process, and the method comprises the following steps of 1) adding unsaturated polyoxyethylene ether and water in certain proportion into a reaction still and stirring for dissolution, 2) adding oxidizing agent water solution at 5-30 DEG C at one time and stirring, and 3) respectively dropping mixed solution of accelerant and chain transfer agent in proper proportion and comonomer in 2-4h, after the dropping, curing for 1.5h, and finally adding alkaline modifier for neutralization so as to obtain the polycarboxylate superplasticizer. The method is simple in process and the prepared polycarboxylate superplasticizer has high dispersing performance in low amount of admixture. By using the heat resource-free process, the step of heating is decreased, so that the production is more simple and convenient, the cost is lower, the environmental-friendly property is provided and the energy consumption is decreased.

Owner:KZJ NEW MATERIALS GROUP CO LTD

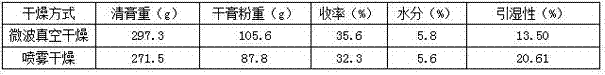

A process for producing oral blueberry powder by vacuum freeze-drying

InactiveCN102273598AImprove protectionSimple process routeFood shapingFood preparationBiotechnologyHigh humidity

The invention provides a process for producing oral blueberry powder by vacuum freeze-drying method. The blueberry fruit is cleaned and drained for later use; the drained blueberry fruit is pre-frozen at -20 to -25°C, and the vacuum degree is 10 to 30 mTorr. Keeping constant temperature for 2-20 hours; crushing at -20 to -25° C. to obtain crude blueberry freeze-dried powder. The process route is simplified, and the present invention does not need a long-term high-temperature sublimation process to obtain blueberry freeze-dried powder, which reduces production costs; reduces the heating steps, and further improves the protection of active substances in blueberries; the processing process can avoid high temperature and high humidity, light, and oxidation The influence of factors such as protecting the whole active substance of blueberry; Through comparative measurement the content of anthocyanin contained in the blueberry freeze-dried powder produced by the preparation method of oral blueberry freeze-dried powder provided by the present invention is about 3.0mg / g, conventional method The anthocyanin content contained in the prepared blueberry freeze-dried powder is about 2.4 mg / g, and the anthocyanin content is increased by 15-20%.

Owner:袁利佳

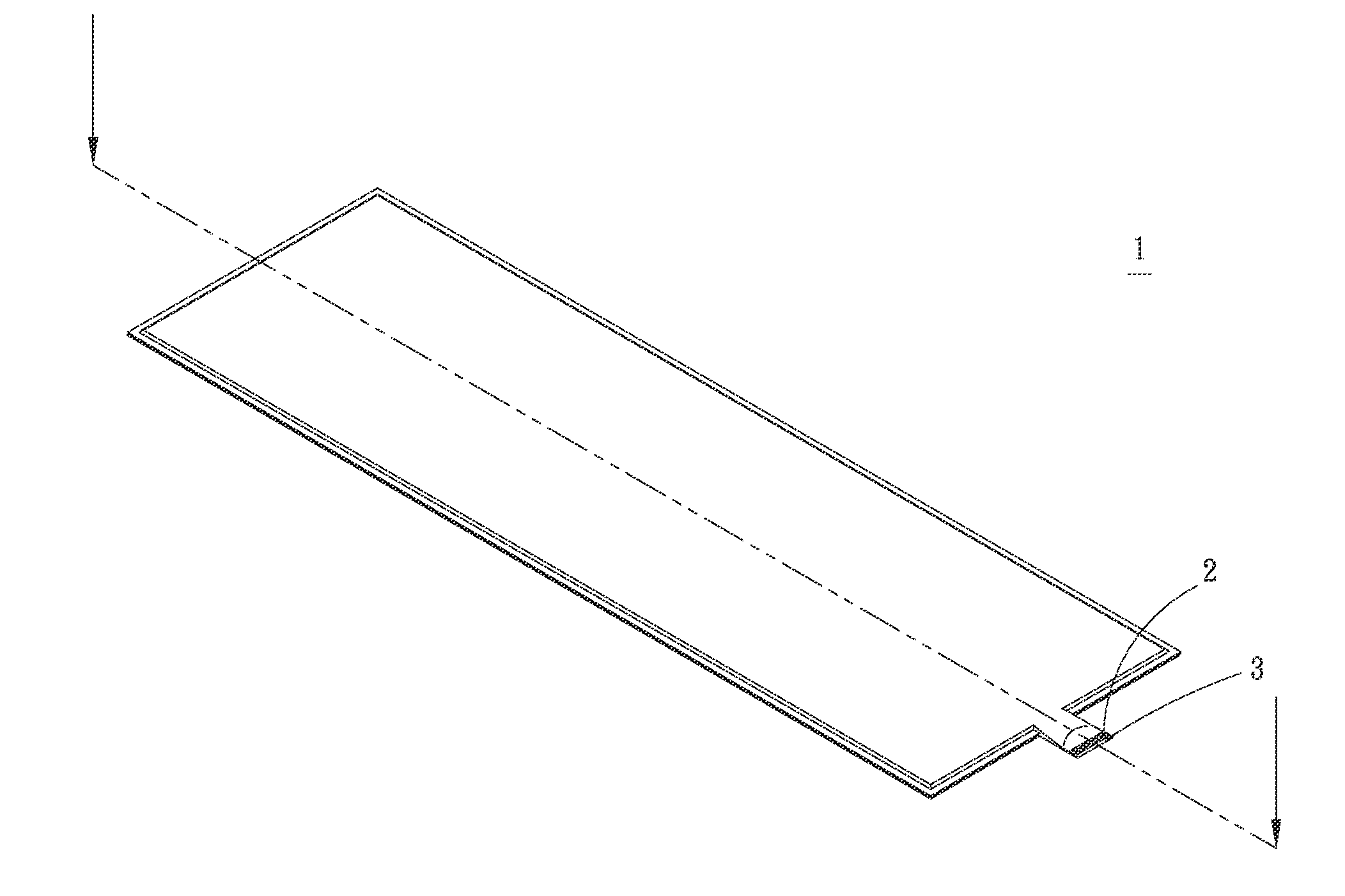

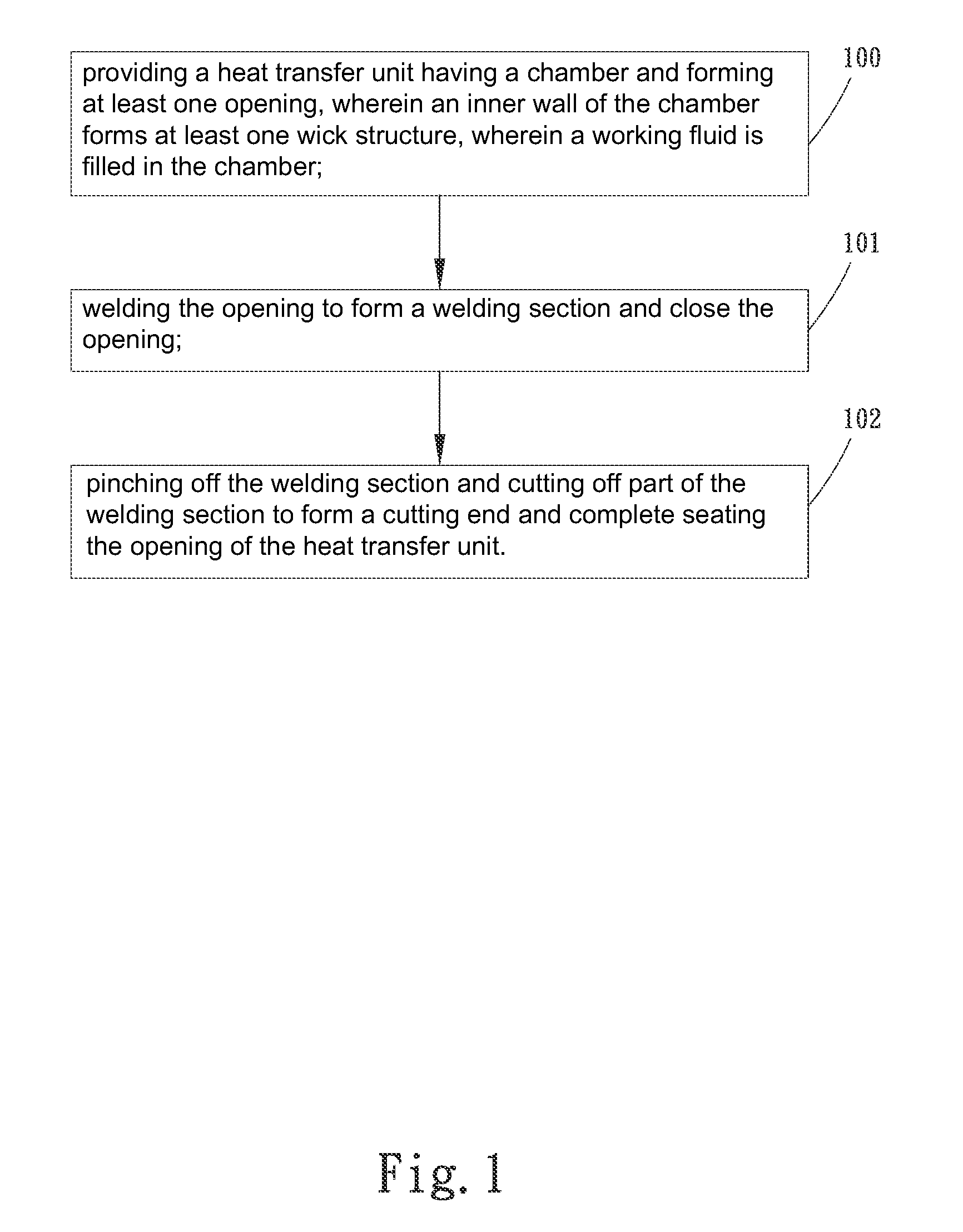

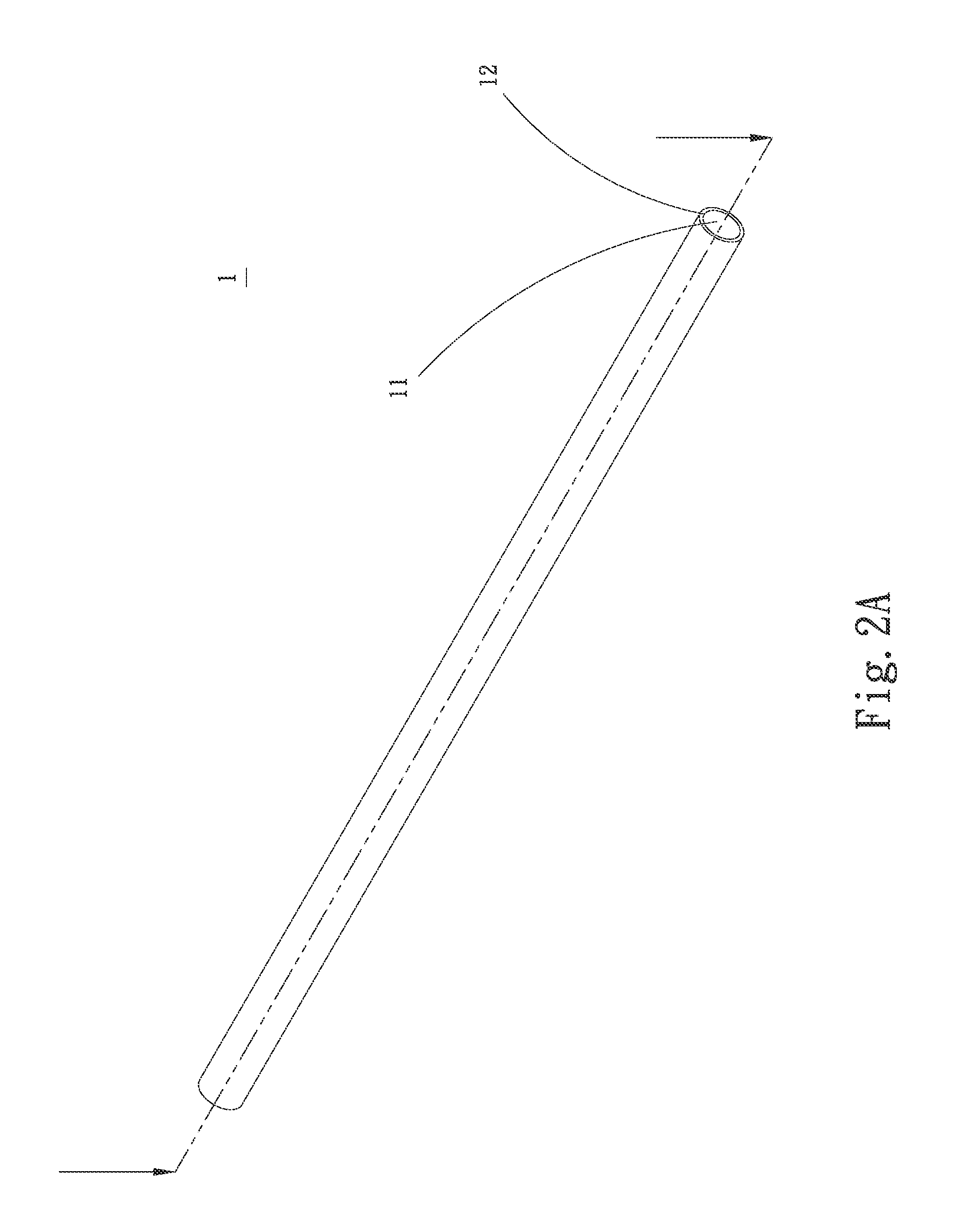

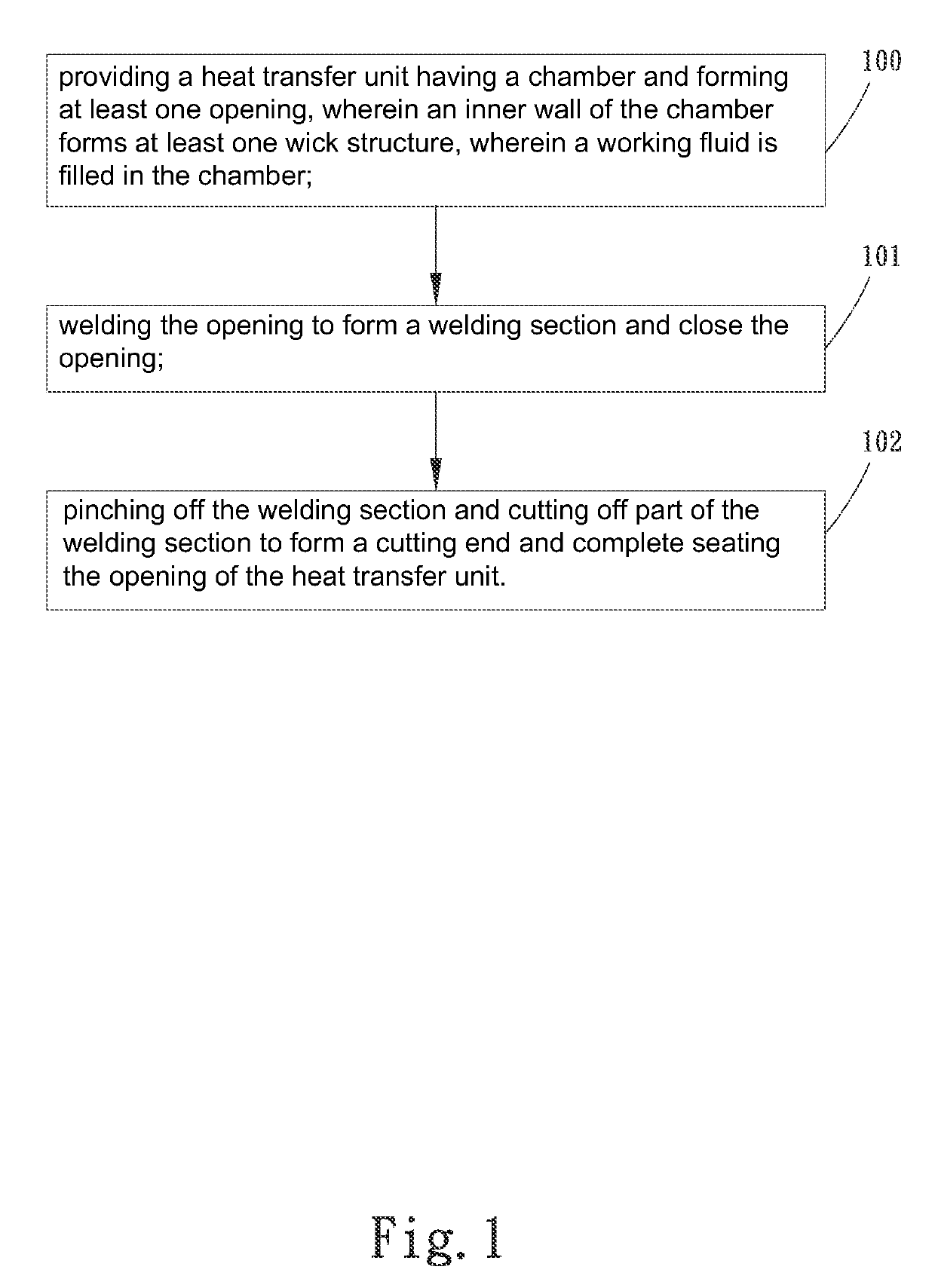

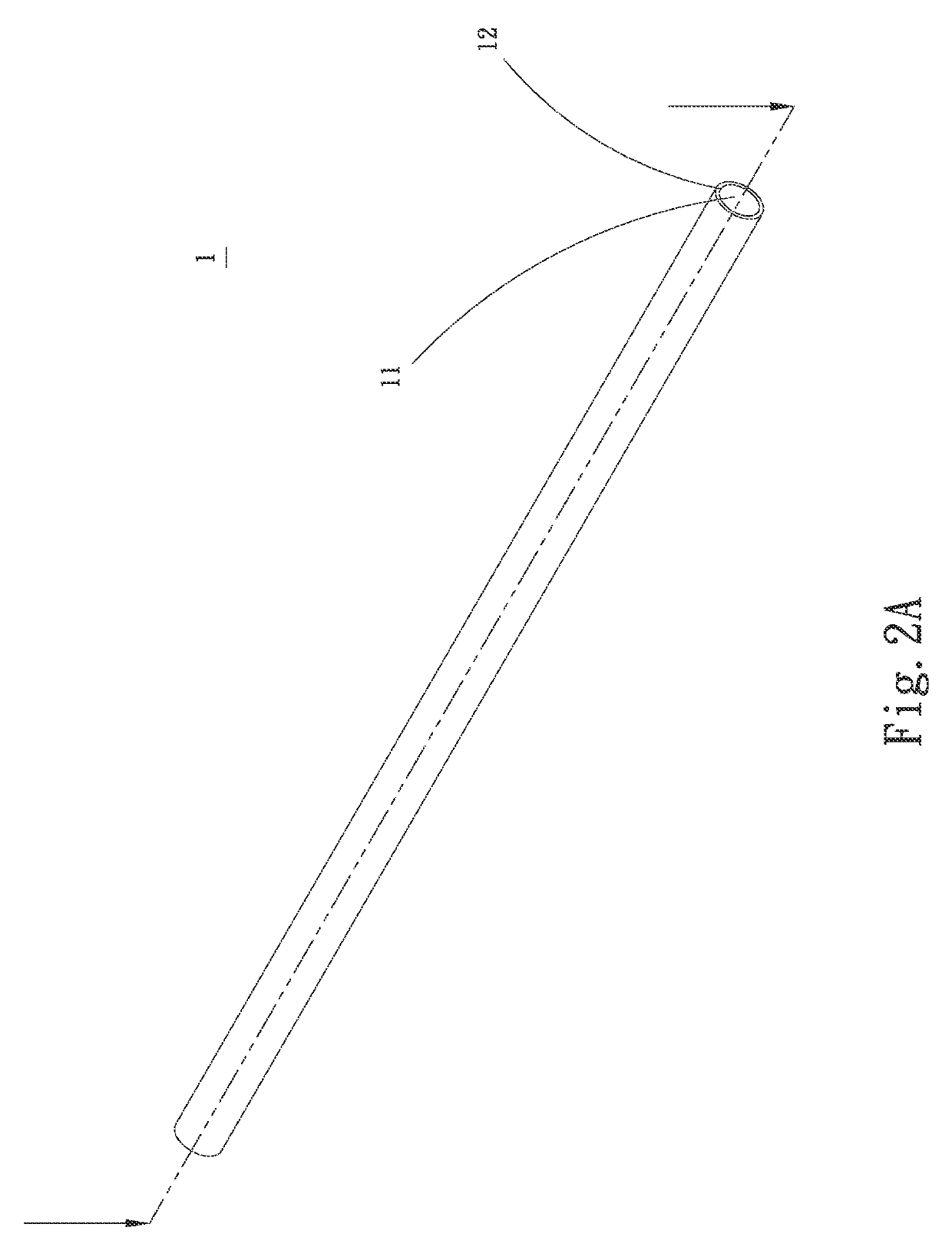

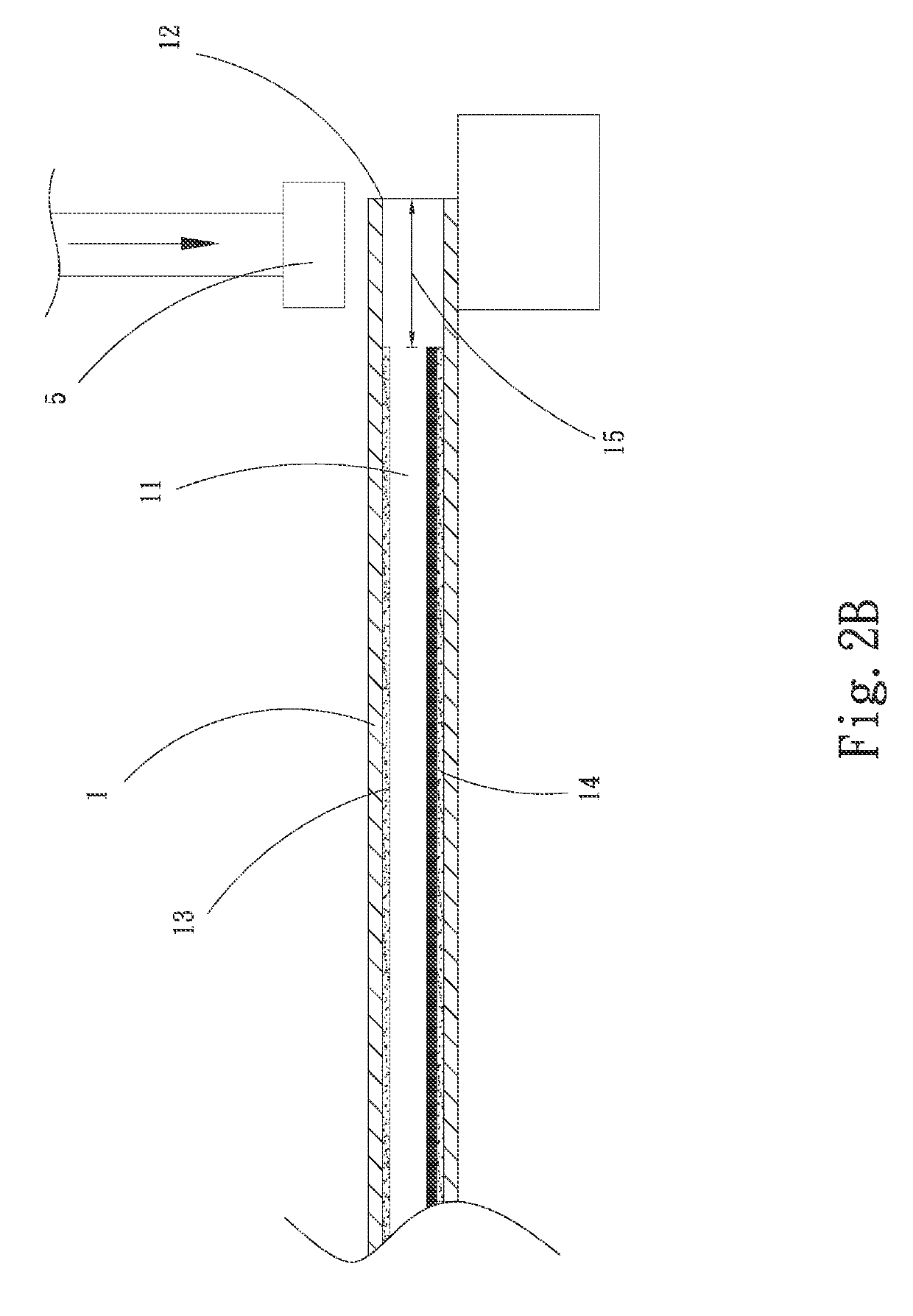

Method for sealing a heat transfer unit

ActiveUS20160193702A1Heat conduction efficiency be improveArrangement space be reduceSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingHeat pipeWelding

The present invention relates to a method for sealing a heat transfer unit, which includes the steps of providing a heat transfer unit having at least one opening, welding the opening to form a welding section and close the opening, and pinching off the welding section and cutting part of the welding section to form a cutting end and complete sealing the opening of the heat transfer unit. By means of the method of the present invention, an extremely short dead zone can be obtained and high heat conduction efficiency is enhanced, further having the effects of reducing the arrangement space and shrinking steps of the heat pipe.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

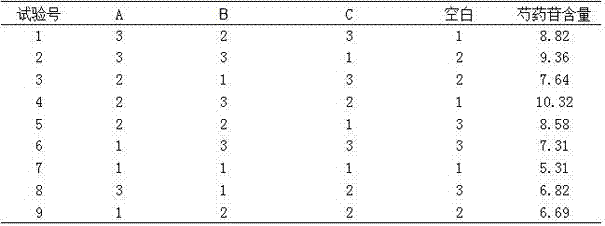

Preparation method of cassia twig and poria cocos pills

The invention discloses a preparation method of cassia twig and poria cocos pills and belongs to the technical field of traditional Chinese medicines. By adopting the technical scheme, the preparation method comprises the following steps: crushing poria cocos into fine powder respectively; then carrying out alcohol extraction and water extraction on peach kernels and red paeony roots in sequence; or crushing cassia twigs and coxtex moutan into fine powder or extracting and concentrating to prepare concentrated water-paste pills or water-honeyed pills by adopting different blending technologies; carrying out a subsequent pill preparation technology to prepare the cassia twig and poria cocos pills. According to the preparation method of the cassia twig and poria cocos pills, a complete technical scheme is formed by powdering, concentration, blending and pelleting, so that the extract yield is improved, effective components are sufficiently extracted, the bioavailability is improved and the dissolution time limit is effectively controlled; the preparation method has the advantages of short production period, stable preparation quality, high effective component content, rapidness in disintegration, high bioavailability, small oral administration dosage, convenience for oral administration and the like, and can be applied to preparation of cassia twig and poria cocos water-paste pill and water-honeyed pill dosage forms.

Owner:SHANXI SHUANGREN PHARMA

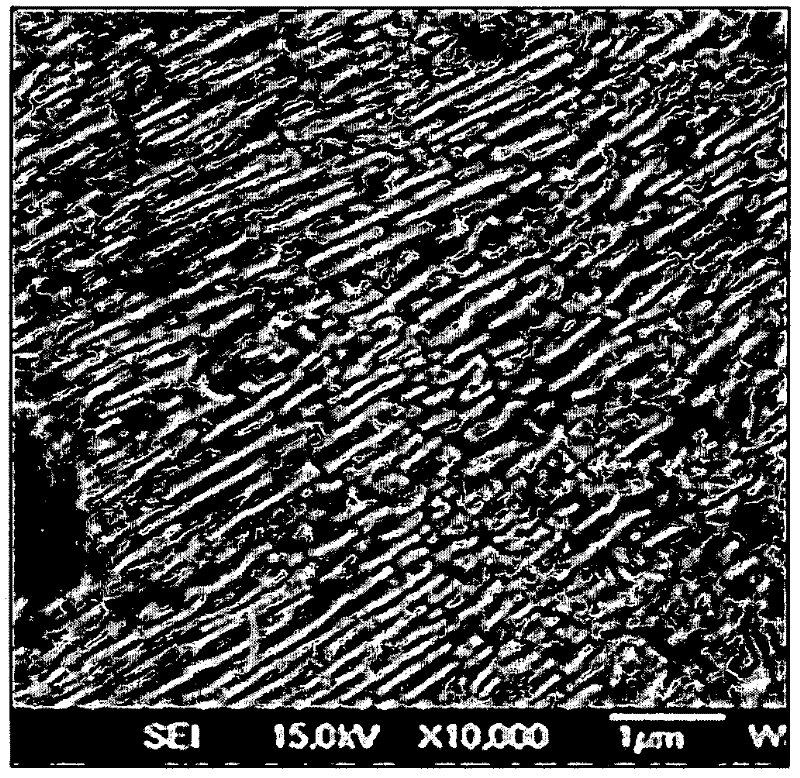

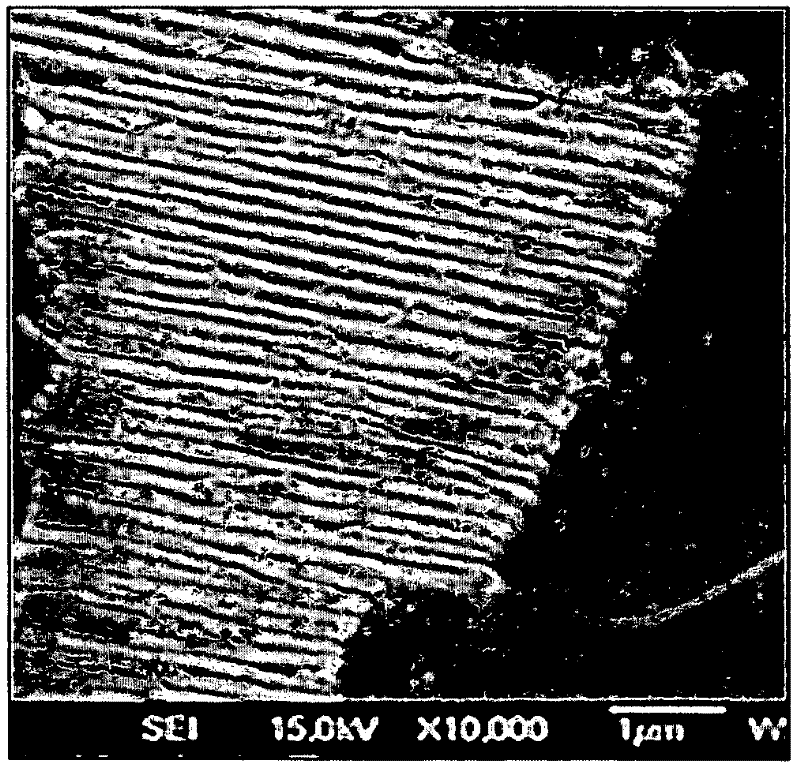

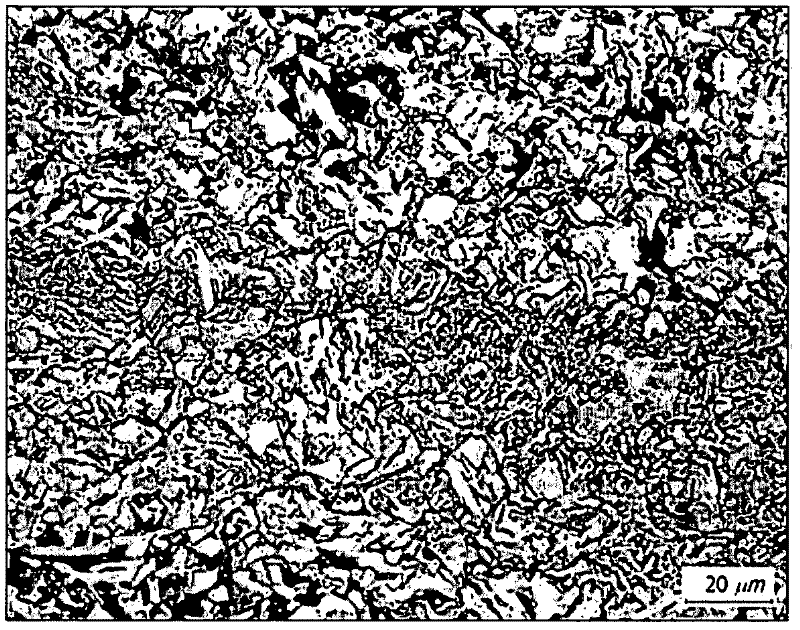

Non-heat treated rolled steel and drawn wire rod with excellent toughness, and method for manufacturing the same

There is provided a rolled steel with excellent toughness, a drawn wire rod prepared by drawing the rolled steel, and a method for manufacturing the same, in which even if a heating step is omitted, the toughness of the steel can be improved by securing a de-generated pearlite structure in an internal structure of the rolled steel by controlling a content of Mn among components and cooling conditions, and then preventing C diffusion. The rolled steel according to the present invention includes C: 0.15 to 0.30 %, Si: 0.1 to 0.2 %, Mn: 1.8 to 3.0 %, P: 0.035 % or less, S: 0.040 % or less, the remainder Fe, and other inevitable impurites, as a percentage of weight, in which the microstucture of the rolled steel is composed of ferrite and pearlite including cementite with 150 nm or less of thickness.

Owner:POSCO CO LTD

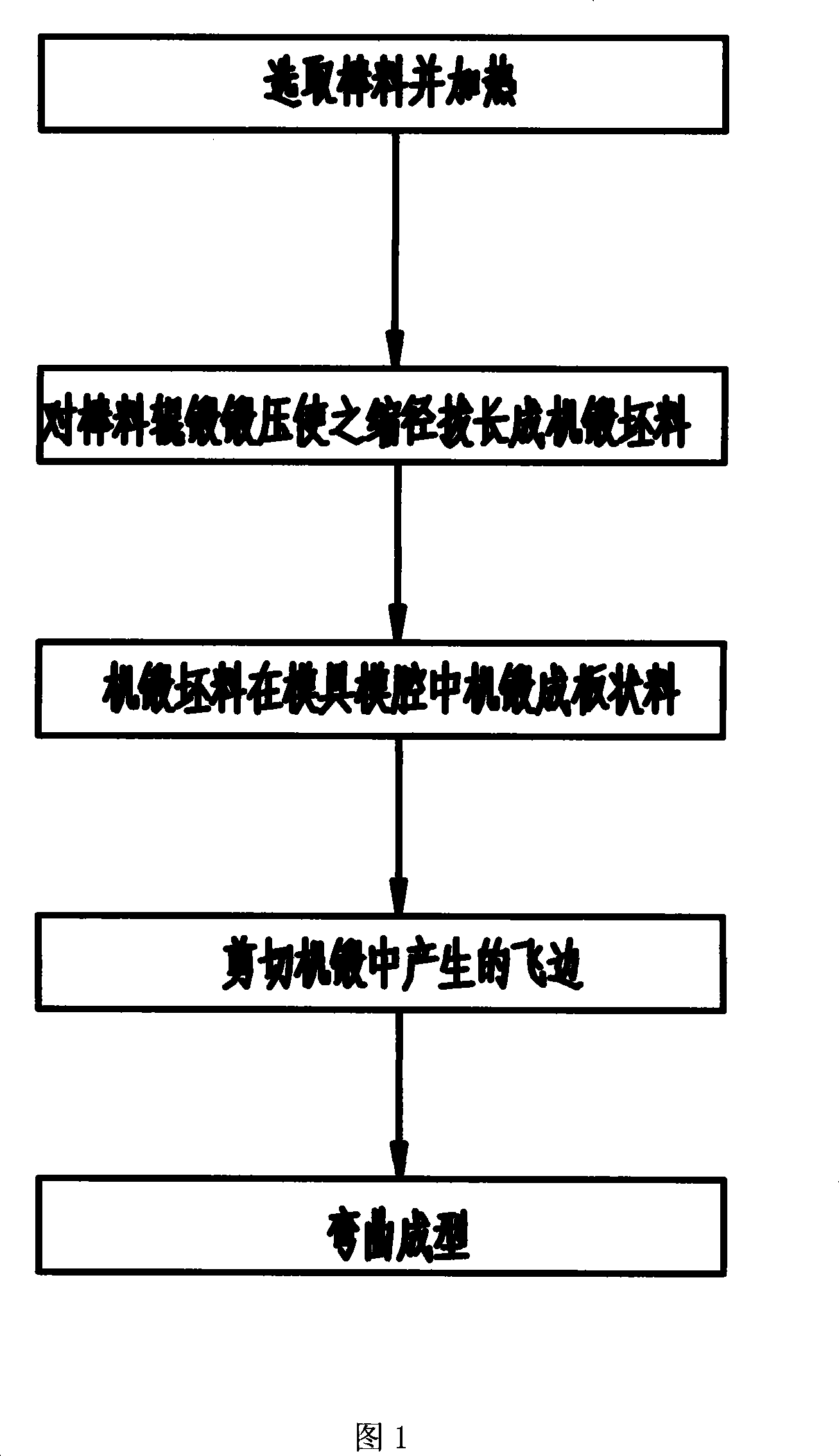

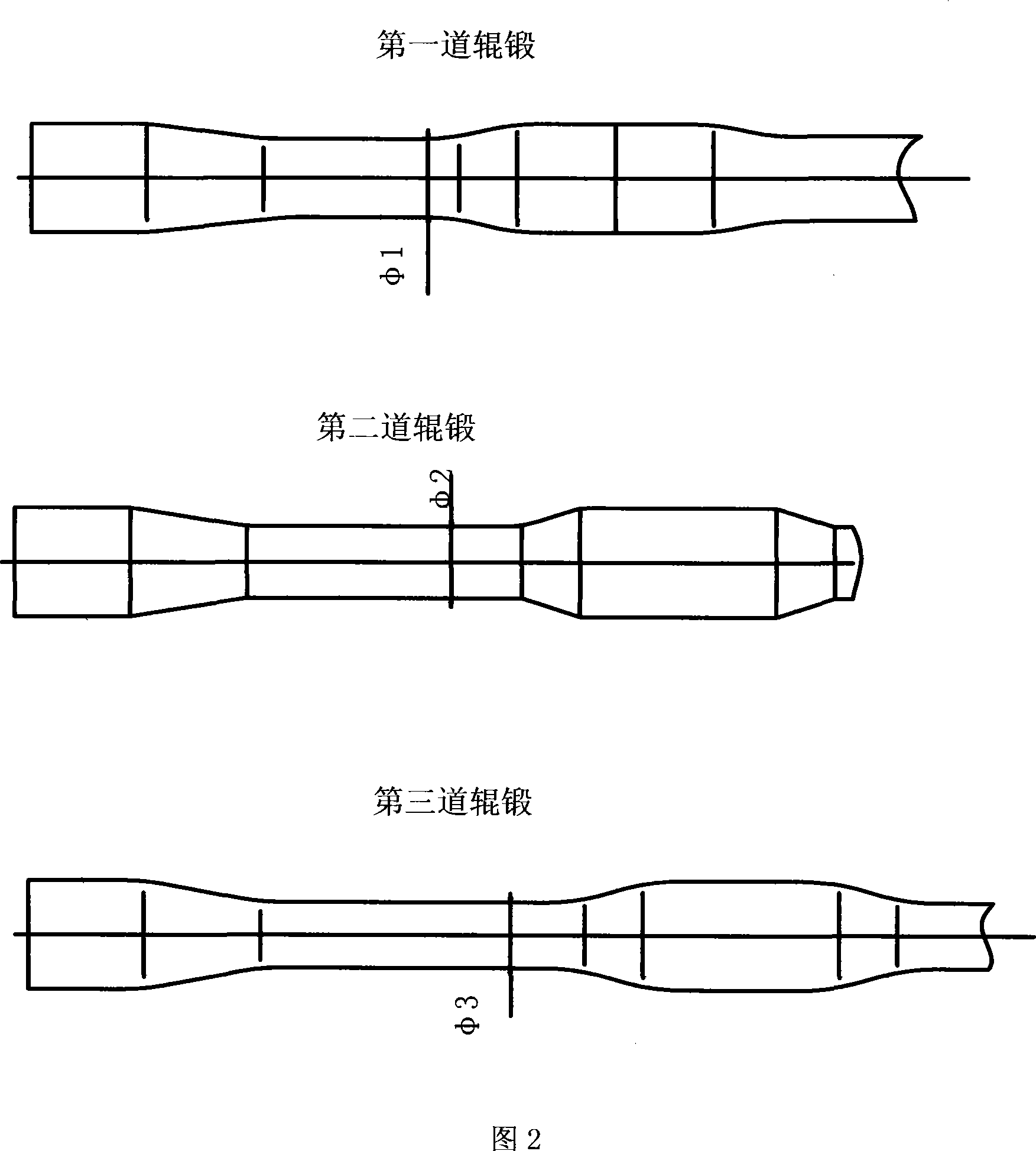

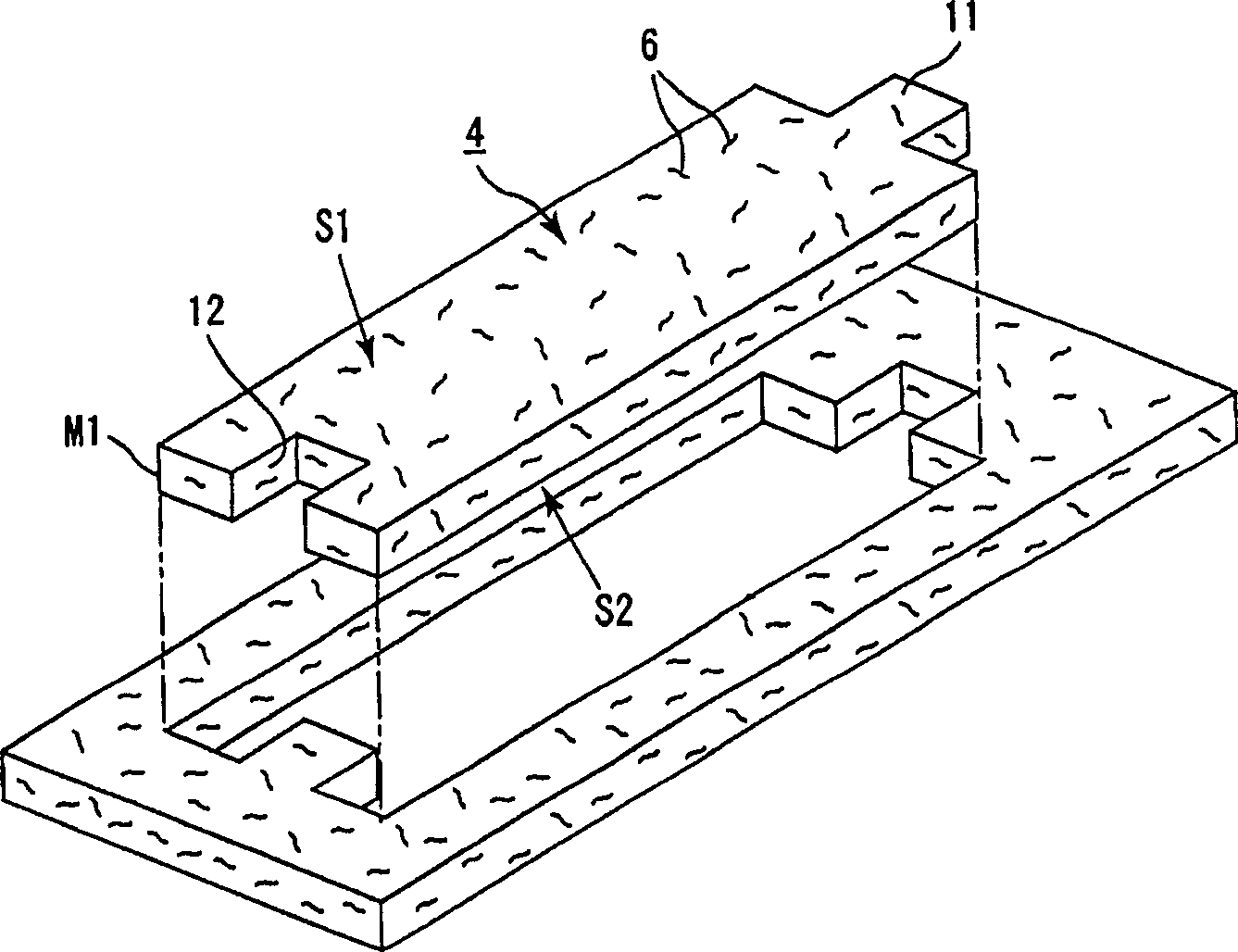

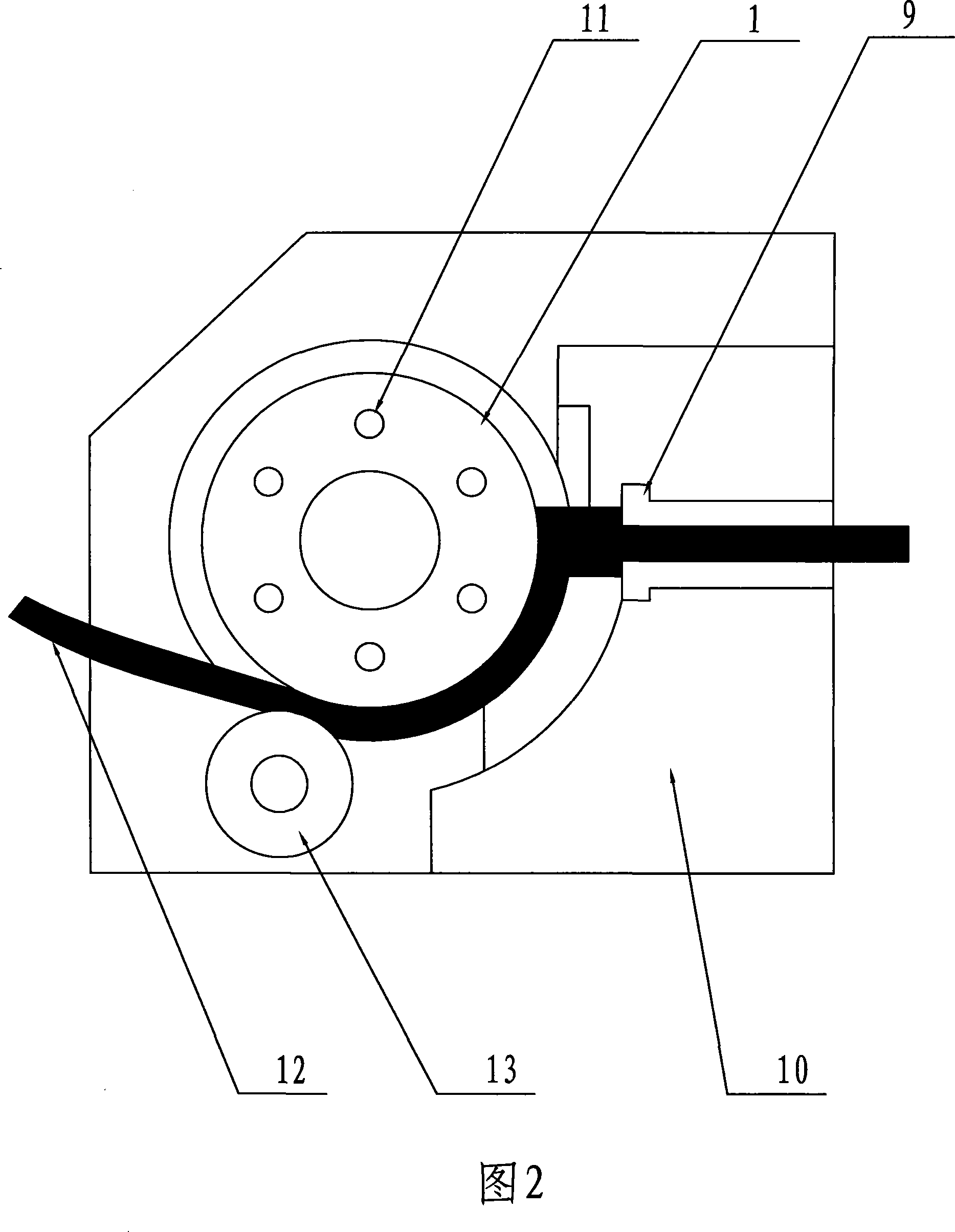

Method of preparing coupler yoke frame

InactiveCN101214602AManufacturing Method AdvantagesReduce heating stepsMetal-working apparatusMechanical pressUltimate tensile strength

The invention discloses a method for manufacturing a coupler yoke which includes the following technical steps: selecting a rod material and heating to 1200 to 1500 DEG C; forging and pressing on the heated rod material to lead the rod material to contract diameter and draw out to form a mechanical press forging material; a roll forging pressure of a roll forging machine is 300 to 700 tons; mechanical pressing and forging the forged mechanical press forging material in a die cavity to a platy material; the scrap rubbers generated in a cutting mechanical press forging finally heats the platy material to bend and form. Compared with the prior art, the invention adopts roll forging processing on the forging and pressing of the rod material; the roll forging speed has quickened, one time heating can finish the requirement of deformation dimension and the material fell caused by oxidation on the surface of the rod material is fewer and simultaneously adopting the roll forging can realize automatic operation with no needing of a worker or only one worker; thereby greatly reducing the working intensity of the worker ; adopting the roll forging leads the time for the rod material to be forged into the mechanical press forging material in the roll forging to be greatly shortened; thereby the temperature of the rod material is still in the temperature range of the mechanical press forging, thus saving the heating step before the mechanical press forging and simultaneously reducing the energy consumption compared with a free forging of an air hammer.

Owner:曾德文

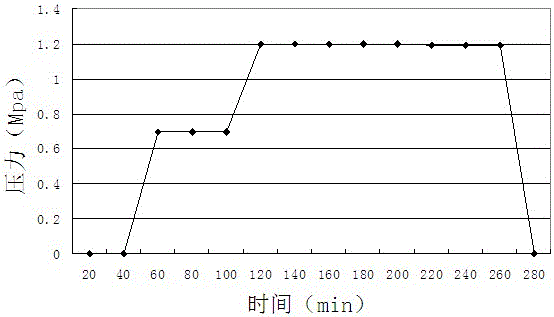

Novel dry laminated glass production process

ActiveCN105109179AReduce heating stepsReduce energy consumptionLaminationLamination apparatusPolyesterEngineering

The present invention provides a novel dry laminated glass production process, which comprises: 1) forming a laminated glass module in a sheet laminating chamber; 2) taking two pieces of high temperature polyester films, respectively coating on the upper surface and the lower surface of the laminated glass module, sealing the peripheries of the high temperature polyester films with sealing strips to form a flexible sealing cavity, and arranging at least a gas sucking port for vacuumizing on the surface of the flexible sealing cavity; and 3) conveying into an autoclave, carrying out pressurization and heating treatment through the autoclave, carrying out vacuumizing treatment through a vacuumizing device, discharging the pressure, taking out, and removing the flexible sealing cavity so as to obtain the finished product laminated glass. According to the present invention, the gas discharge of the process is performed through the vacuumizing in the closed environment, and the vacuum gas discharge and the step 2 are combined to achieve the laminated glass product production in the one step; and the vacuumizing gas discharge is performed in the autoclave so as to complete the laminated glass production process in the one-step manner and efficiently produce the high-quality laminated glass.

Owner:TAICANG YAOHUA GLASS

Photo-cured heat-conductive film and production method thereof

The invention relates to a photo-cured heat-conductive film. The photo-cured heat-conductive film is composed of the following components in percentage by weight: 9.26-20.44% of modified acrylate oligomer, 9.37-32.58% of acrylic monomer, 2.11-5. 82% of a photoinitiator, 0.3-5% of auxiliaries and 55.75-78.96% of a heat-conductive filler, and prepared by a production method comprising the steps of mixing raw materials, moulding by casting, and curing. The photo-cured heat-conductive film disclosed by the invention has the following advantages: the heat-conductive film is prepared by mixing modified acrylate oligomer, the acrylic monomer, the photoinitiator, the auxiliaries and the heat-conductive filler, thus improving the existing production process of films, improving the running efficiency of equipment, reducing the volatilization phenomena of organic solvents in the existing metal material thermal control and solvent moulding process, improving the use effect, simplifying the existing processing process, reducing heating steps, avoiding ingredient volatilization, and achieving a good use effect.

Owner:PINGHU ALLIED IND

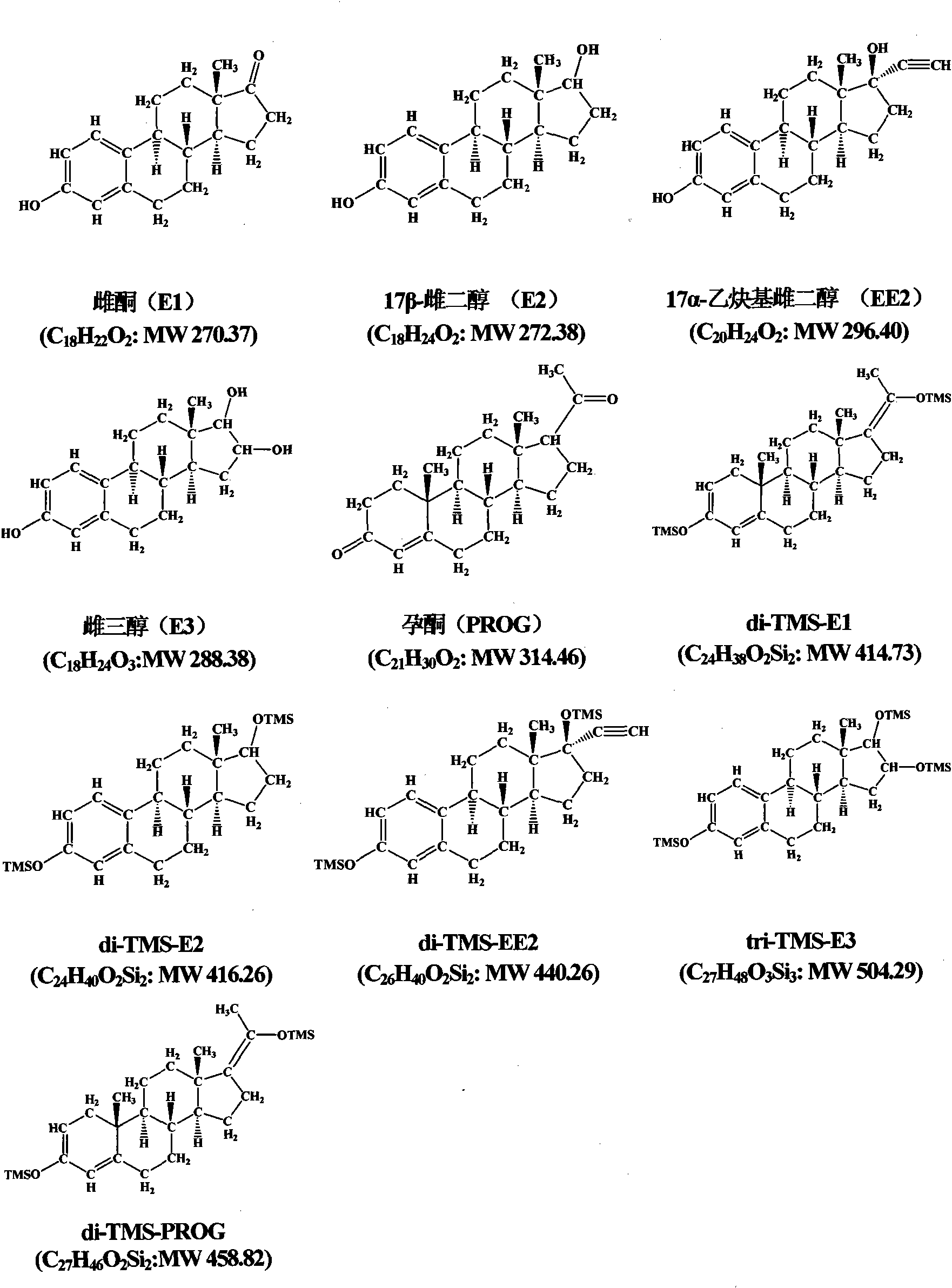

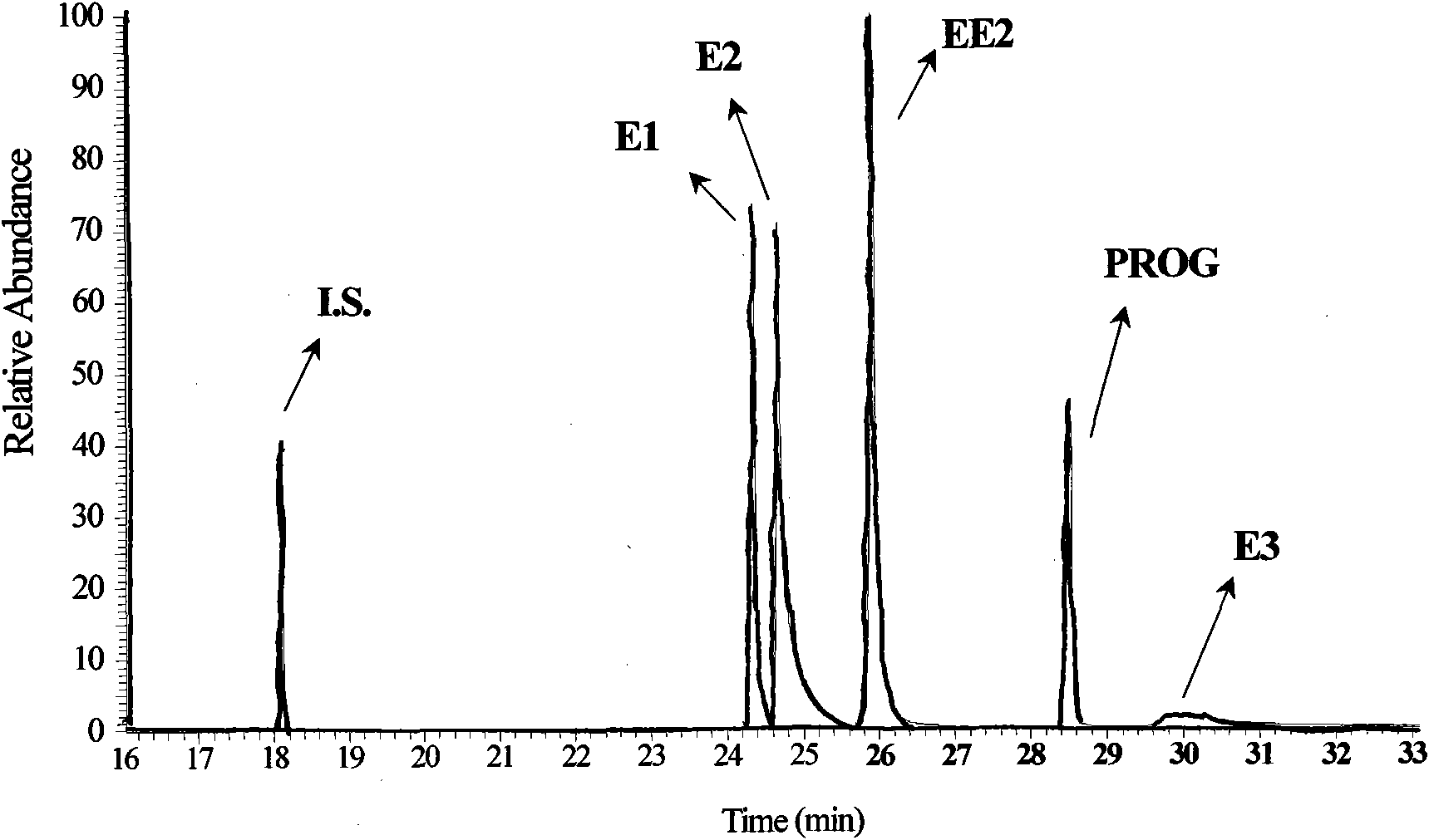

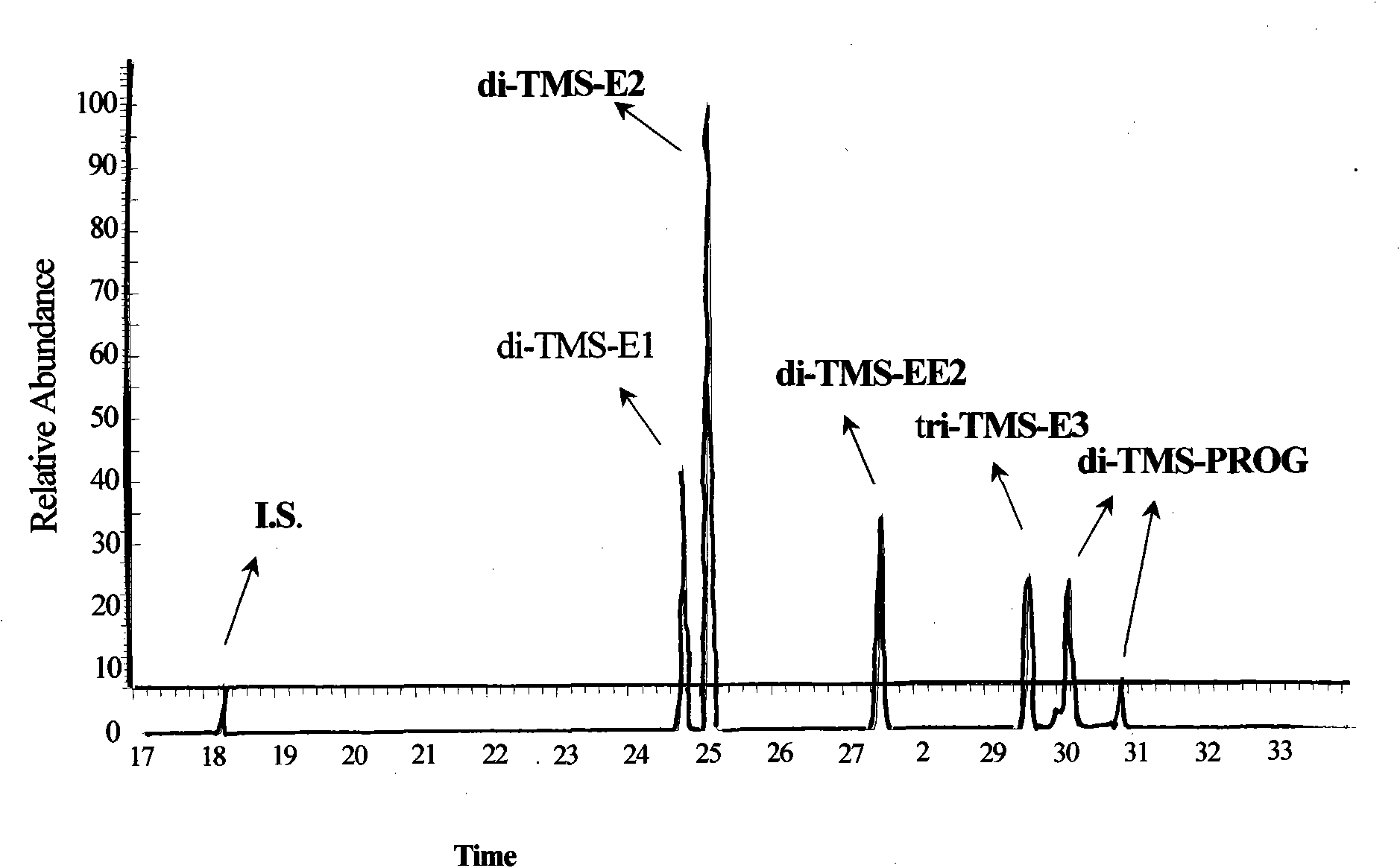

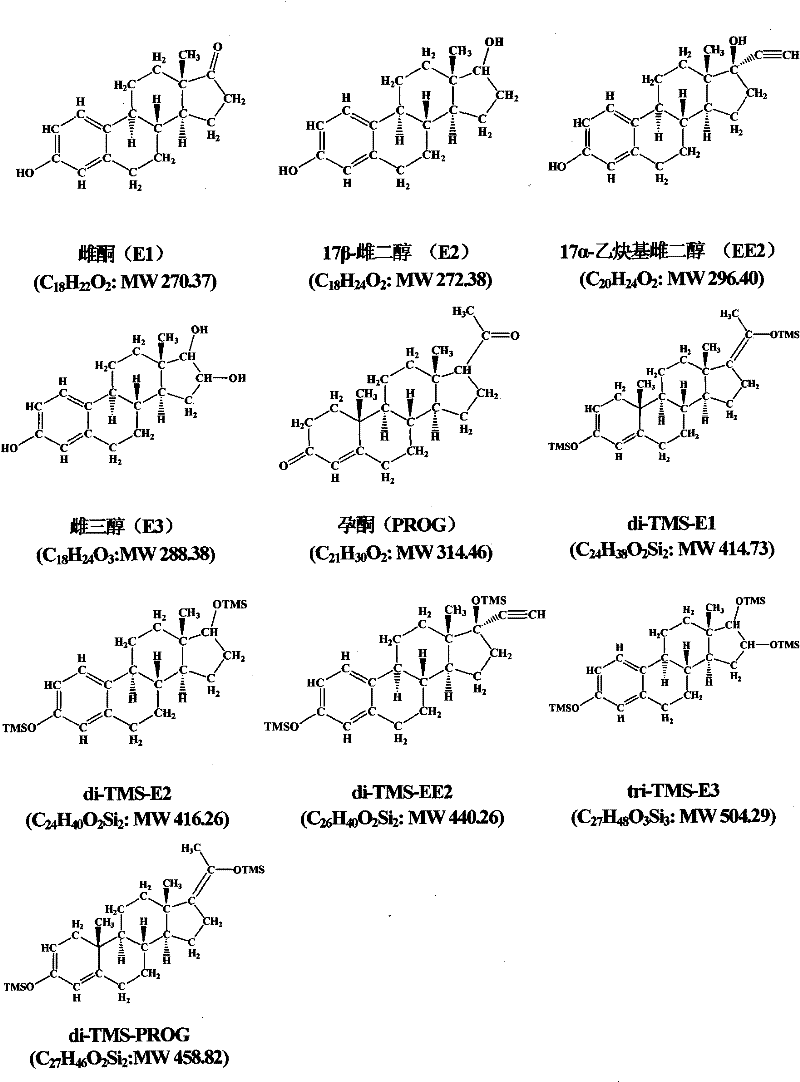

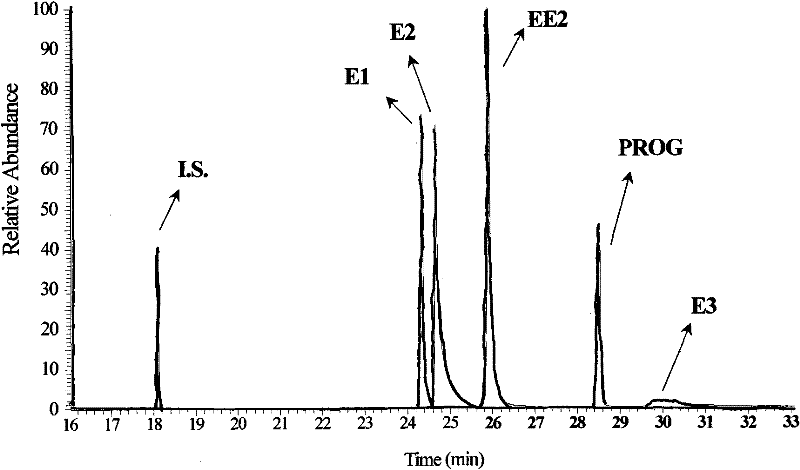

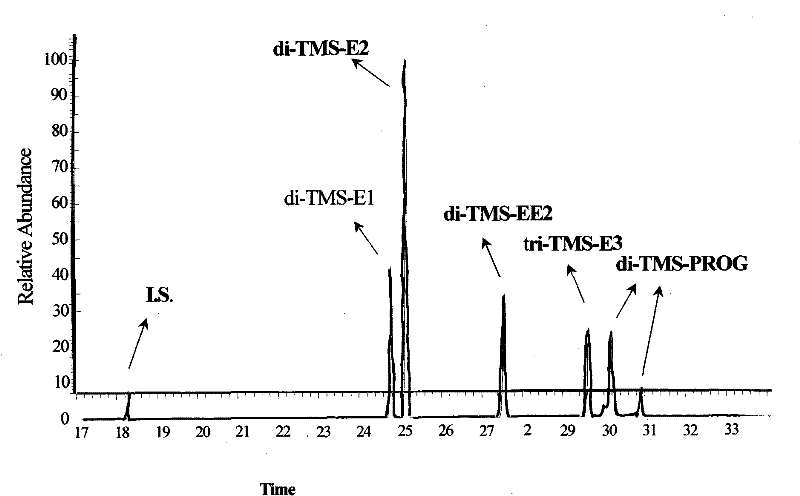

Hydroxyl group/keto group synchronous derivatization method of steroid environment endocrine disturbing chemicals

InactiveCN101942006AImplementing Synchronous DerivatizationReduce polarityComponent separationSteroids preparationEstriolLinear correlation

The invention discloses a steroid environment endocrine disturbing chemicals hydroxyl group / keto group synchronous derivatization method of steroid environment endocrine disturbing chemicals (oestrone, 17 beta-estradiol, 17 alpha-ethinyl estradiol, estriol and progesterone). The method comprises the following steps: first fetching standard mixed solution containing the steroid environment endocrine disturbing chemicals and internal standard and introducing high-purity nitrogen at normal temperature so as to dry the standard mixed solution; and adding derivatization reagent prepared from N-methyl-N-trimethylsilyl trifluoroacetamide, iodotrimethylsilane and dithiothreitol based on a proportion of 1,000 muL:5 to 10 muL:5 mg and reacting at 20 to 60 DEG C for 5 to 10 min so as to obtain the derivatization product shown in figure. The method has the advantages of simple and time-saving operation, low energy consumption and cost and the like. The hydroxyl group and the keto group can be derivatized synchronously, the linear correlation among the derivatization products is good, and the detection limit of instrument can reach 0.01 to 1 pg / mu L. The method can be used for the GC-MS detection of the steroid environment endocrine disturbing chemicals in samples such as water, bottom sediment, organisms and the like.

Owner:KUNMING UNIV OF SCI & TECH

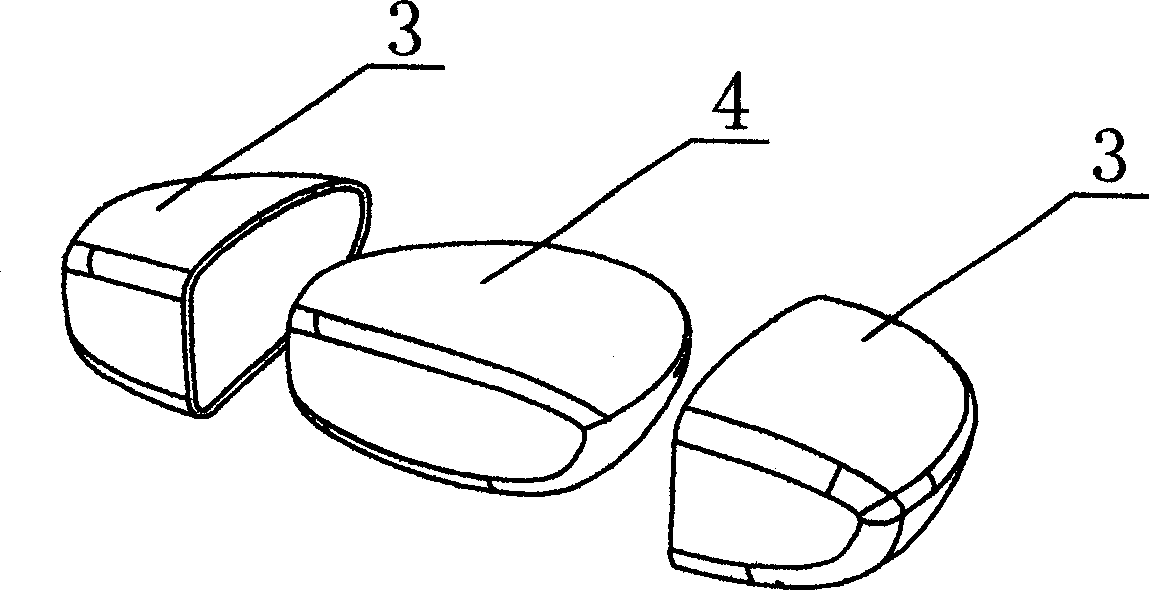

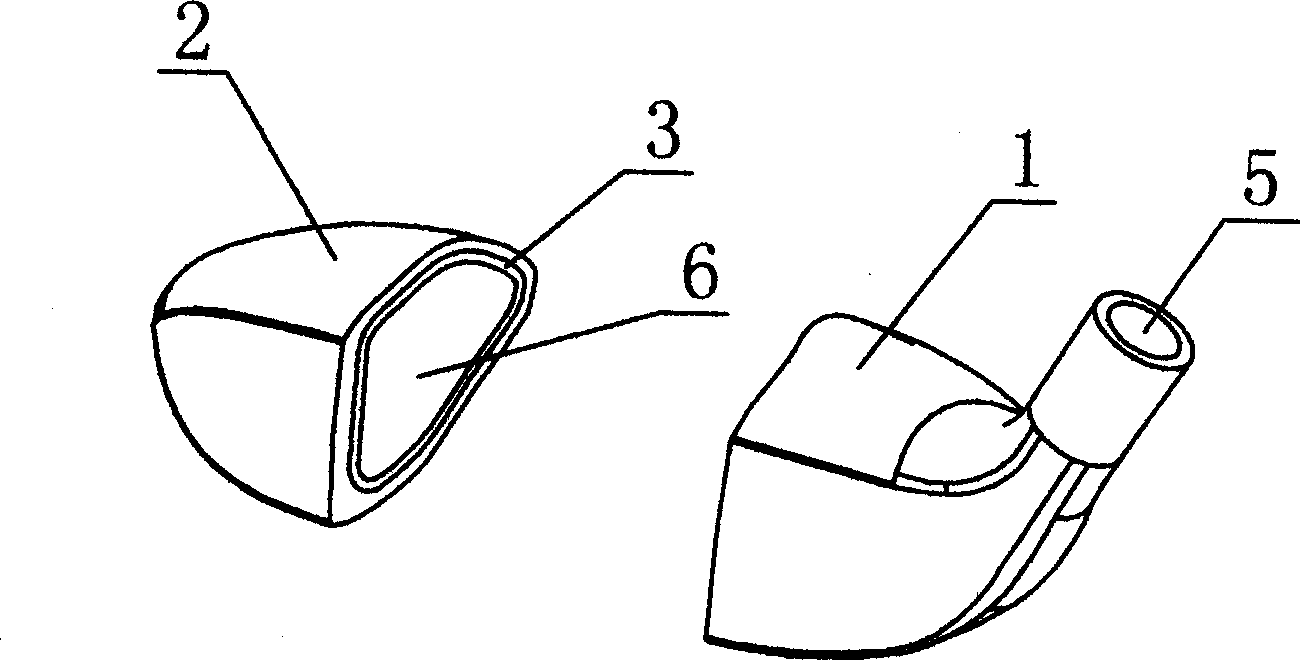

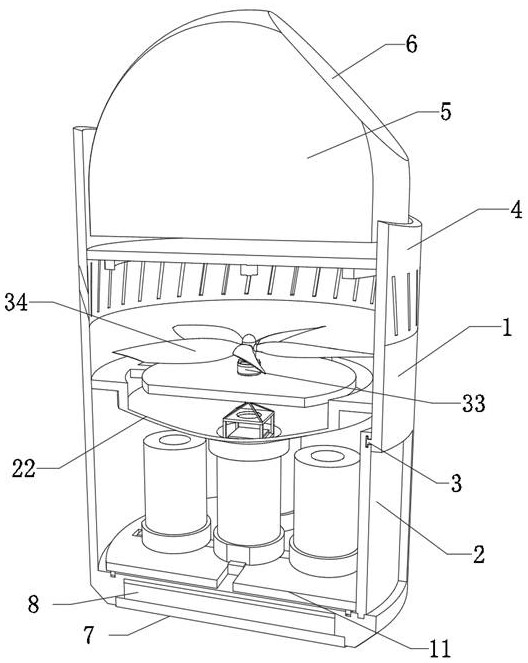

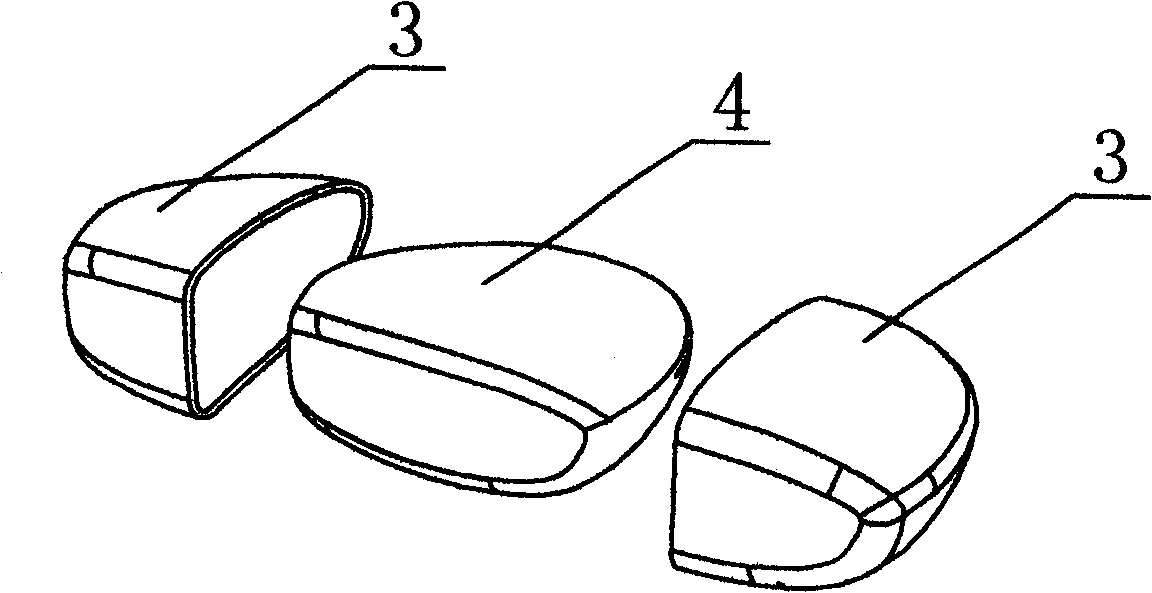

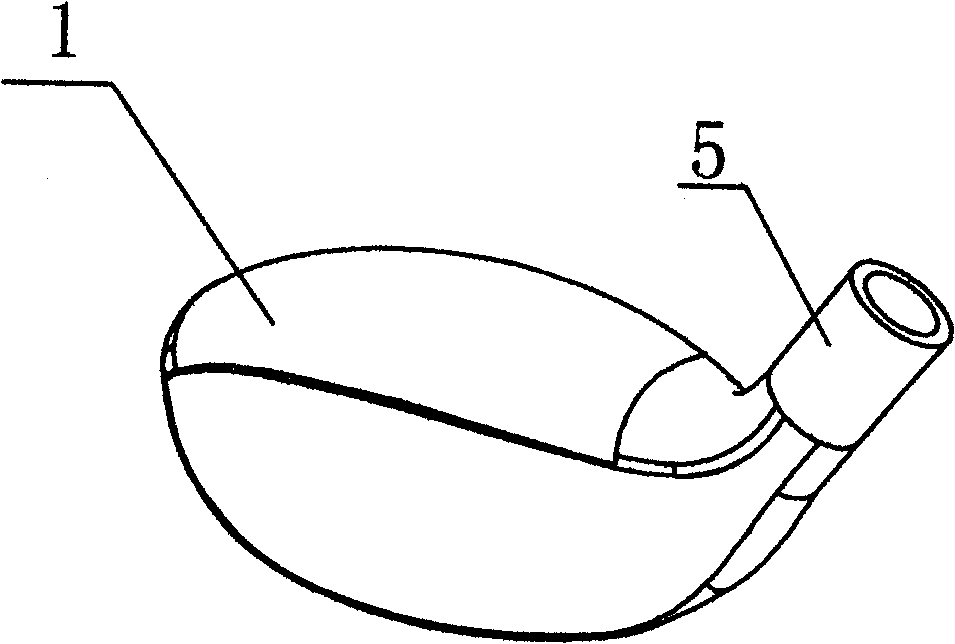

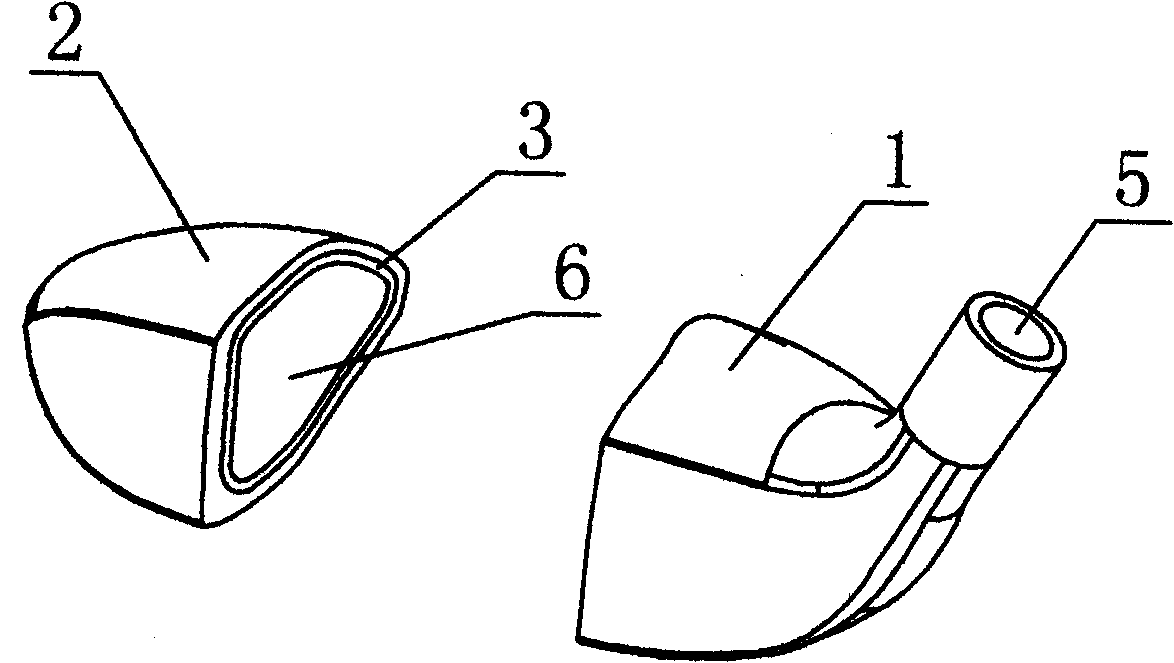

Improved manufacture method of one-piece golf bar head and products thereof

InactiveCN101362197AReduce distortionReduce consumptionFoundry mouldsFoundry coresMetallic materialsGolf club

The invention discloses a manufacturing method for improving an integral golf club head, which includes the following steps: (1) precasting an internal sleeve, the outer contour of which is the same with the shape of an inner cavity of the golf club head, and at least one opening is arranged in the internal sleeve; (2) preparing granular filling materials for the internal sleeve and placing the filling materials into the inner cavity of the internal sleeve through the opening; (3) precasting a die-casting die of the club head; (4) fixing the entity of the internal sleeve in the die-casting die; (5) casting metal liquid, the casting melting point of which is not higher than the melting point of the metal material of the internal sleeve, into the die, and the die is cast and formed; (6) preparing a club head embryo which consists of a shell layer, an internal sleeve layer and filling materials after die de-molding; (7) drilling a bore hole which permeates the shell layer and the internal sleeve layer on the embryo club head; and (8) manufacturing the golf club head by arranging the opening of the bore hole downward to cause the filling materials to flow out automatically from the bore hole. The method also discloses a product made by adopting the method.

Owner:LONGHUI SPORTS GOODS +1

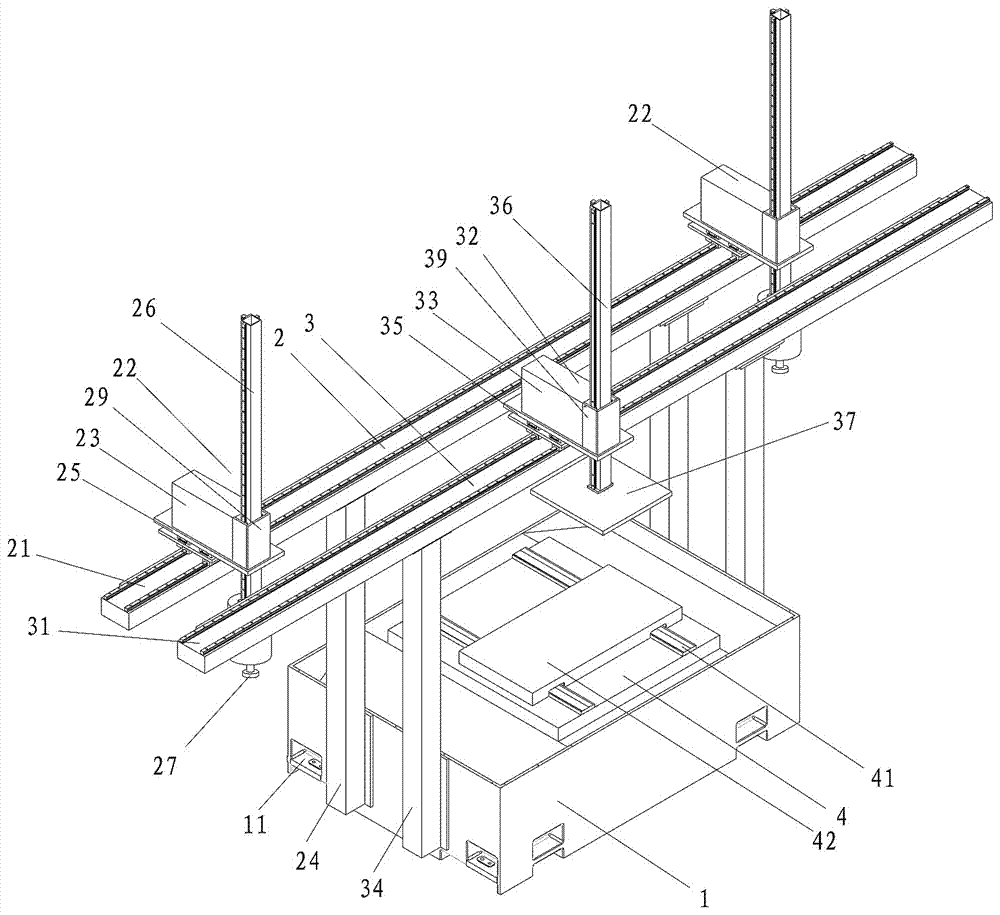

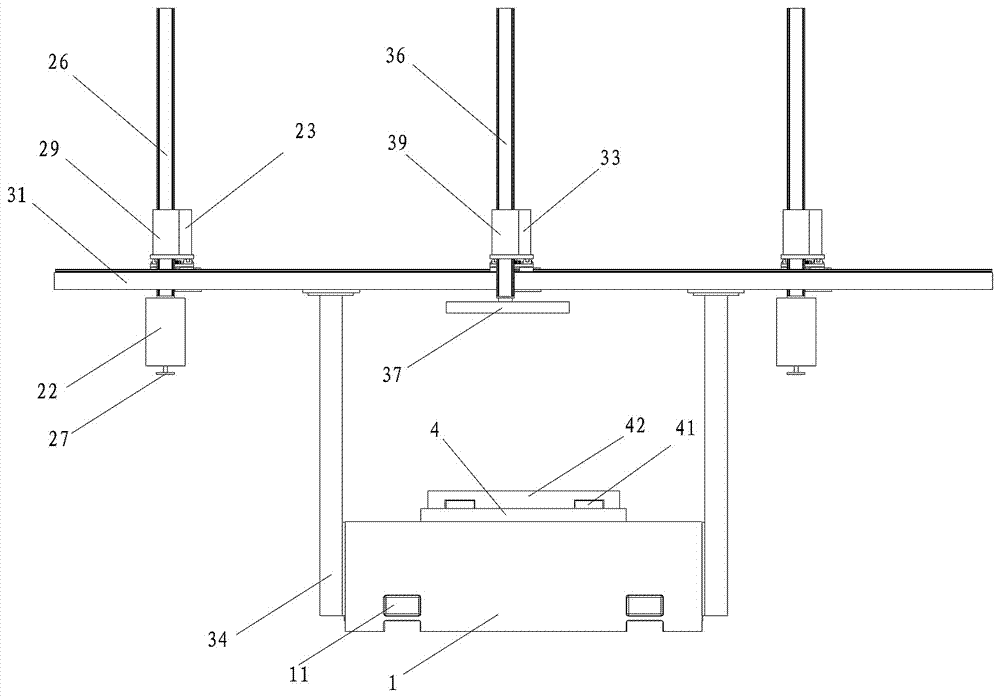

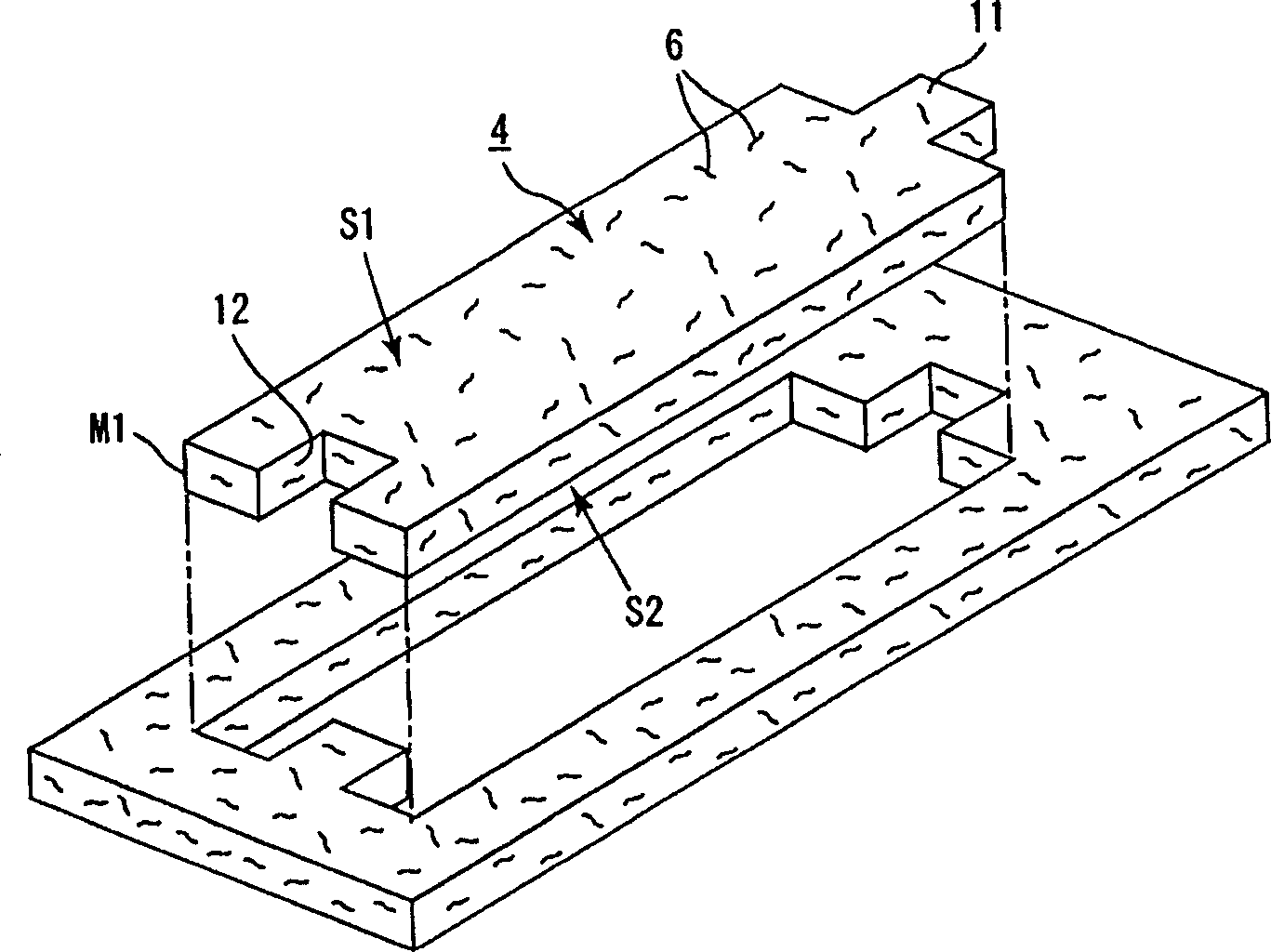

Accessory processing mechanism and method

InactiveCN107234916AReduce lossExtended service lifeSpecial ornamental structuresModel makingThermal energyEngineering

The invention relates to the field of accessory production and processing, in particular to an accessory processing mechanism and method. The mechanism comprises a base, a fixing device, an accurate carving device and a film pressing device, wherein the fixing device, the accurate carving device and the film pressing device are fixed to the base. The accurate carving device comprises a first sliding rail, a tool set and a first driving device. The lower end of the first sliding rail is provided with a first sliding rail support. The tool set comprises a first sliding plate, a first sliding strip and a tool. A first fixing plate is fixed to the first sliding plate. A first sliding groove is formed in the first fixing plate. The first driving device is installed on the first sliding plate. The film pressing device comprises a second sliding rail, a pressing block assembly and a second driving device. The lower end of the second sliding rail is provided with a second sliding rail support. The pressing block assembly comprises a second sliding plate, a second sliding strip and a pressing plate. A second fixing plate is fixed to the second sliding plate. A second sliding groove is formed in the second fixing plate. A second driving device is installed on the second sliding plate. Design is scientific, the structure is compact, the equipment occupied area is small, the heat utilization rate is improved, and processing time is saved.

Owner:义乌市富佳饰品有限公司

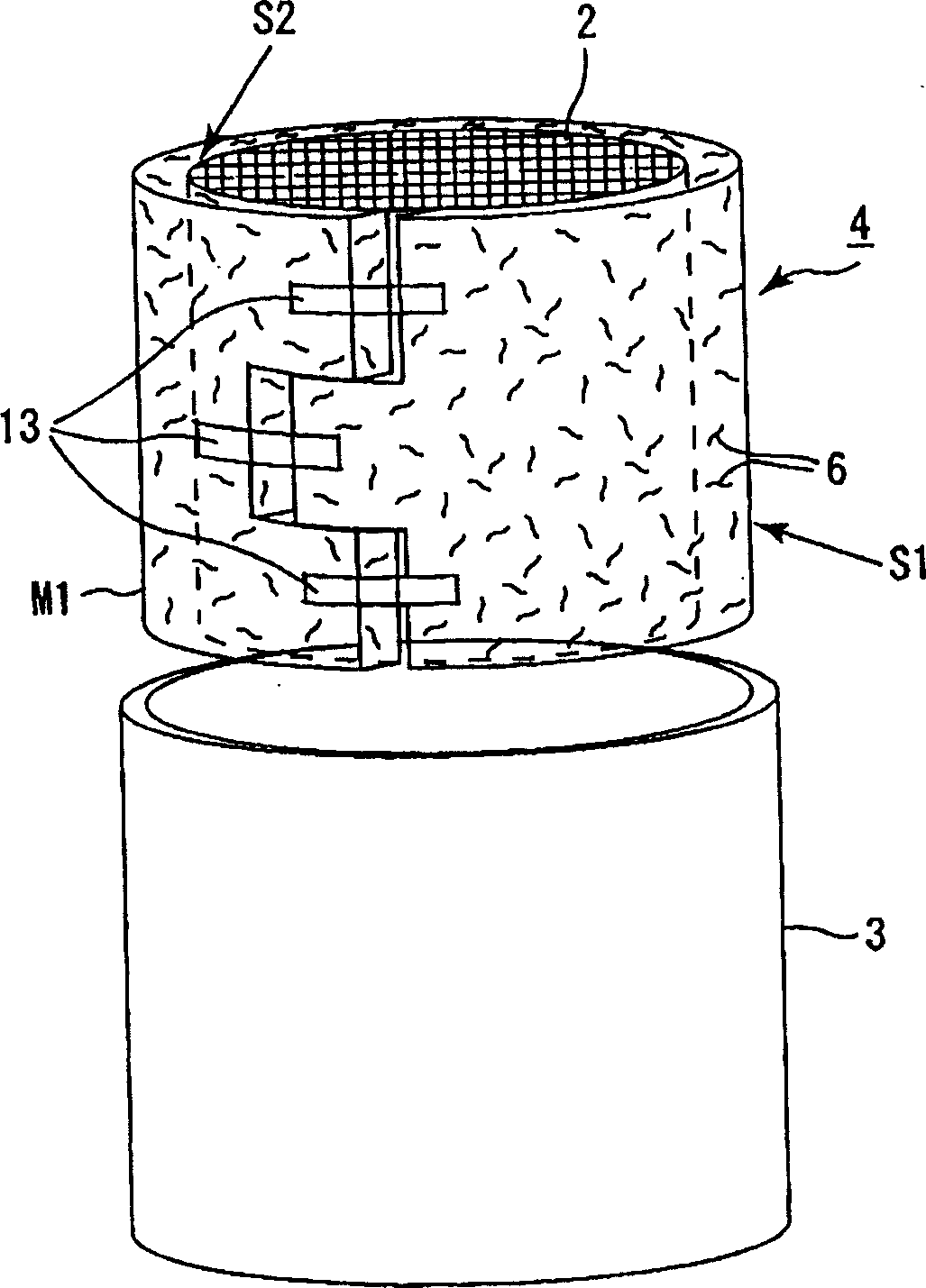

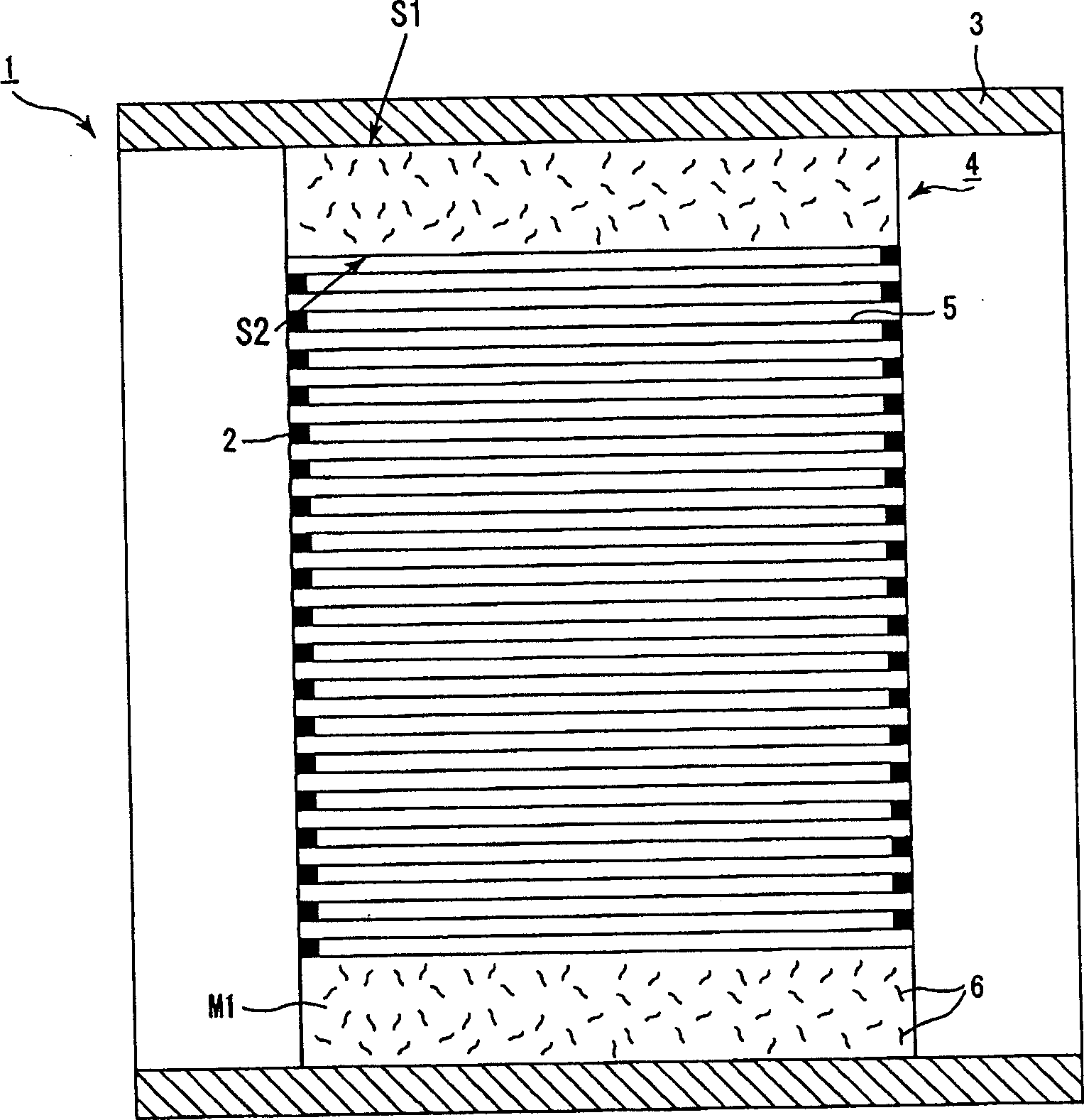

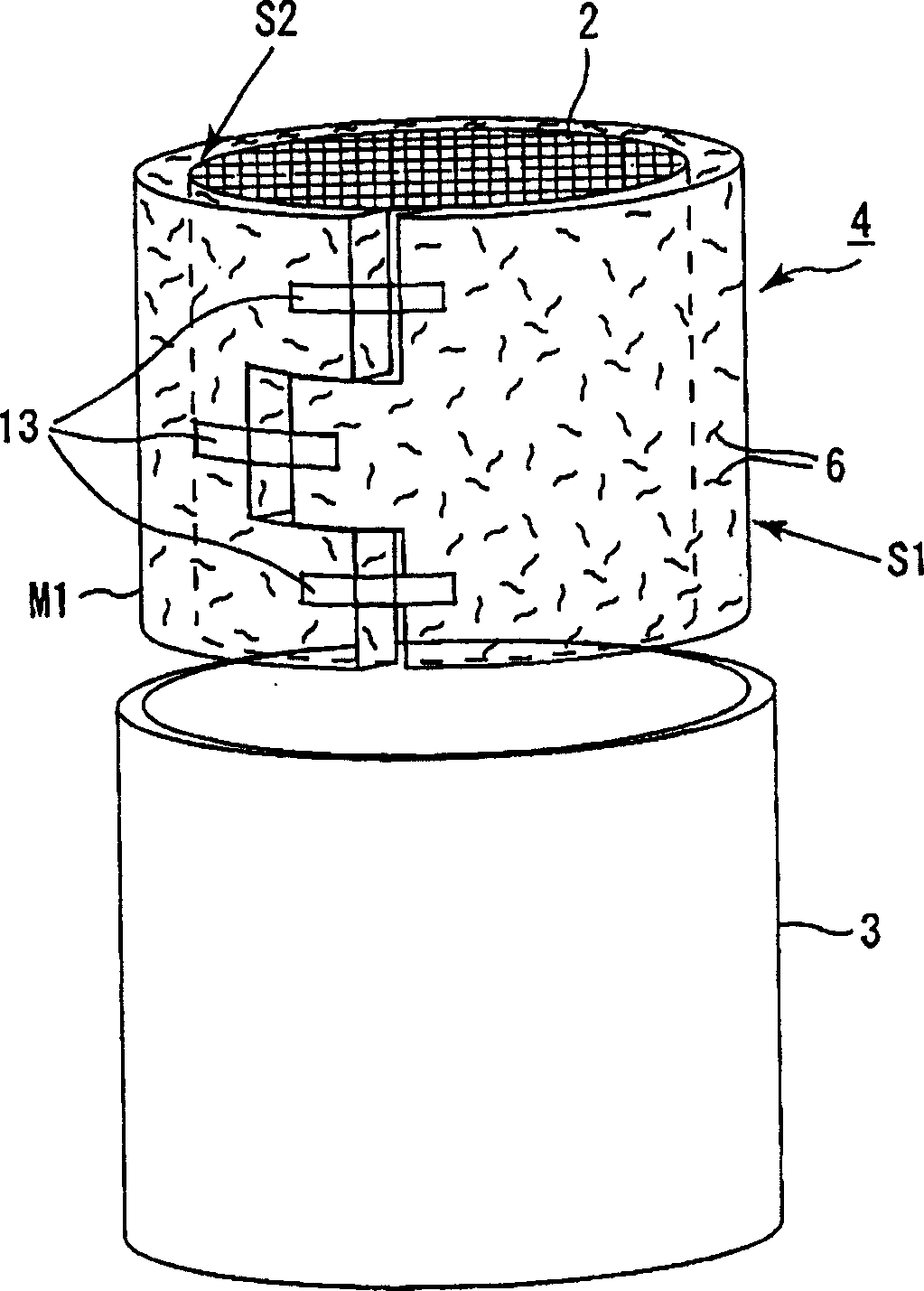

Catalytic cracking device

InactiveCN1693683ASurface pressure is not easy to reduceReduce heating stepsMaterial nanotechnologyCatalyst protectionFiberInorganic salts

An object of the present invention is to provide a manufacturing method by which alumina-silica based fibers excellent in mechanical strength can be readily and securely obtained, and the present invention obtains precursor fibers as a material by using an alumina-silica based fiber spinning stock solution for use in an inorganic salt method. Next, the precursor fibers are heated under an environment which makes it difficult to carry out an oxidizing reaction on the carbon component contained in the precursor fibers. Thus, the precursor fibers are sintered to obtain alumina-silica based fibers.

Owner:IBIDEN CO LTD

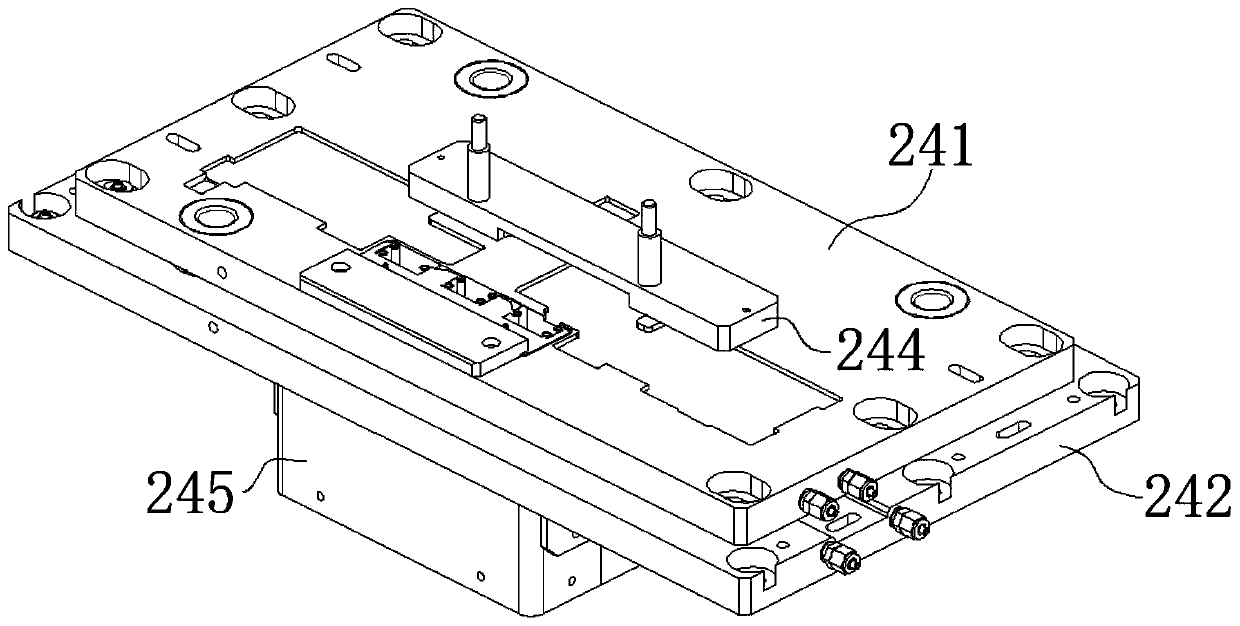

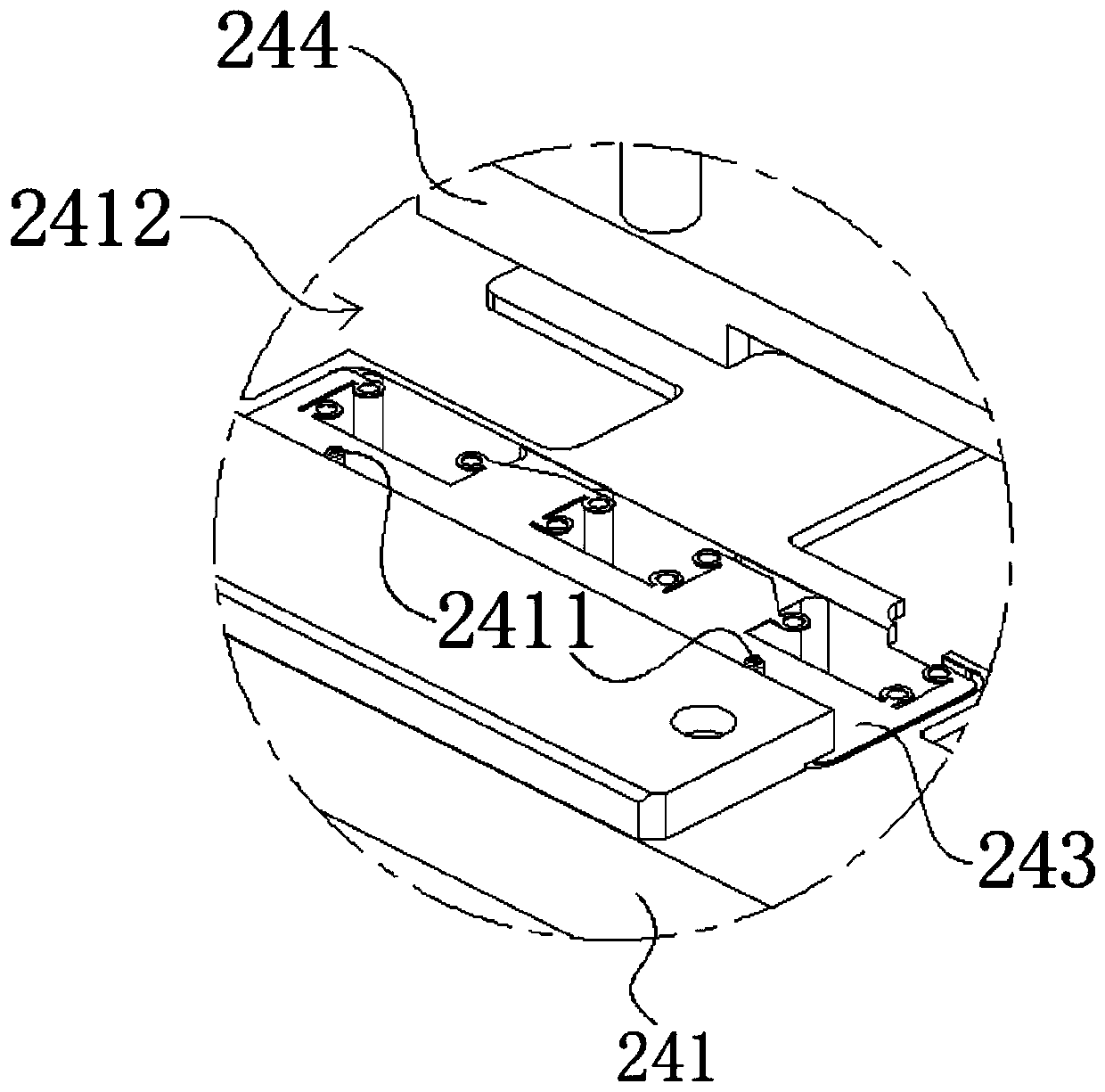

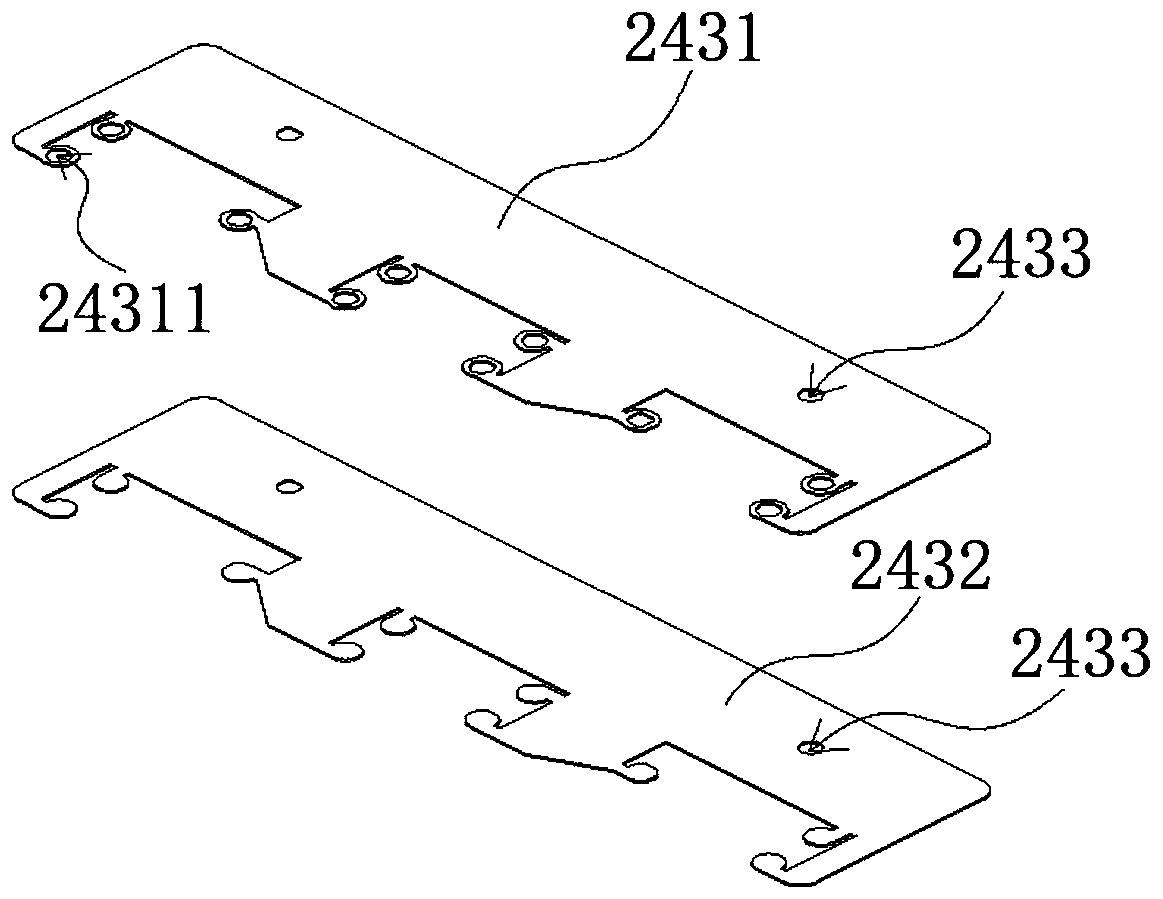

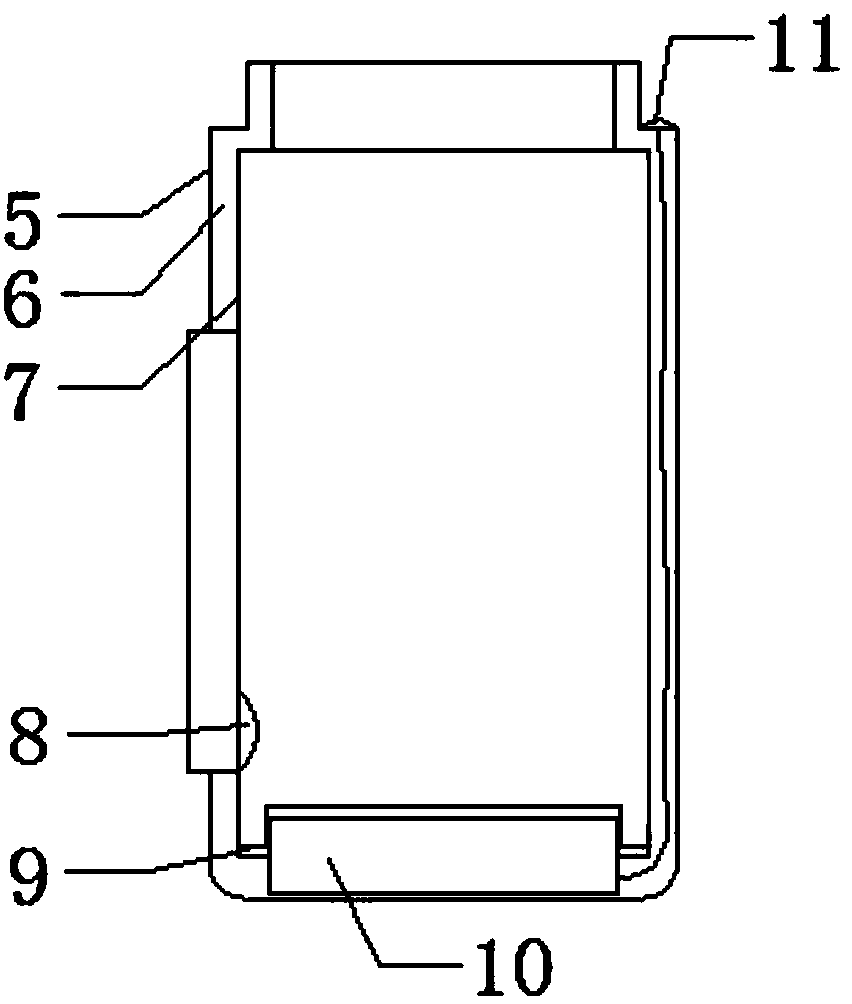

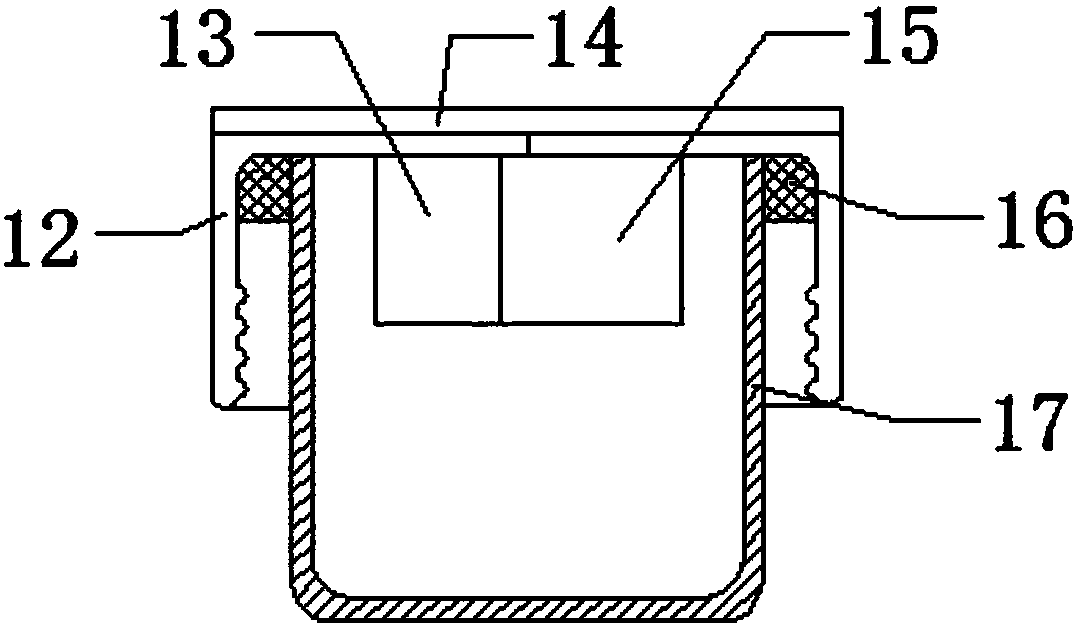

Jig assembly used for hot melting and hot-melting mechanism

The invention provides a jig assembly used for hot melting. The jig assembly used for hot melting comprises a jig body. The jig body comprises a bearing plate and a forming sheet, wherein the formingsheet is mounted on the bearing plate and comprises a heat-conduction layer and a shaping layer, and the forming sheet is mounted on the bearing plate; forming holes which are consistent with a forming shape are formed in the shaping layer; the heat-conduction layer is attached to one sides of the forming holes, and an external heat source is arranged on the side close to the heat-conduction layer; a pressure device is arranged on the side close to the shaping layer; and the forming sheet is heated through the external heat source, and a workpiece is fixed to the bearing plate through the pressing device, so that a to-be-hot melted part of the workpiece is melted and then solidified to be in the shape of the shaping holes. A hot-melting mechanism comprises a hot-melting device body, wherein the hot-melting device body comprises a jig body, a die set, a pressing assembly serving as the pressure device, and a hot-melting assembly serving as the external heat source, and in the hot-melting process, the pressing assembly, the hot-melting assembly and the jig body are combined. The hot-melting mechanism is simple and convenient to maintain.

Owner:SUZHOU RS TECH

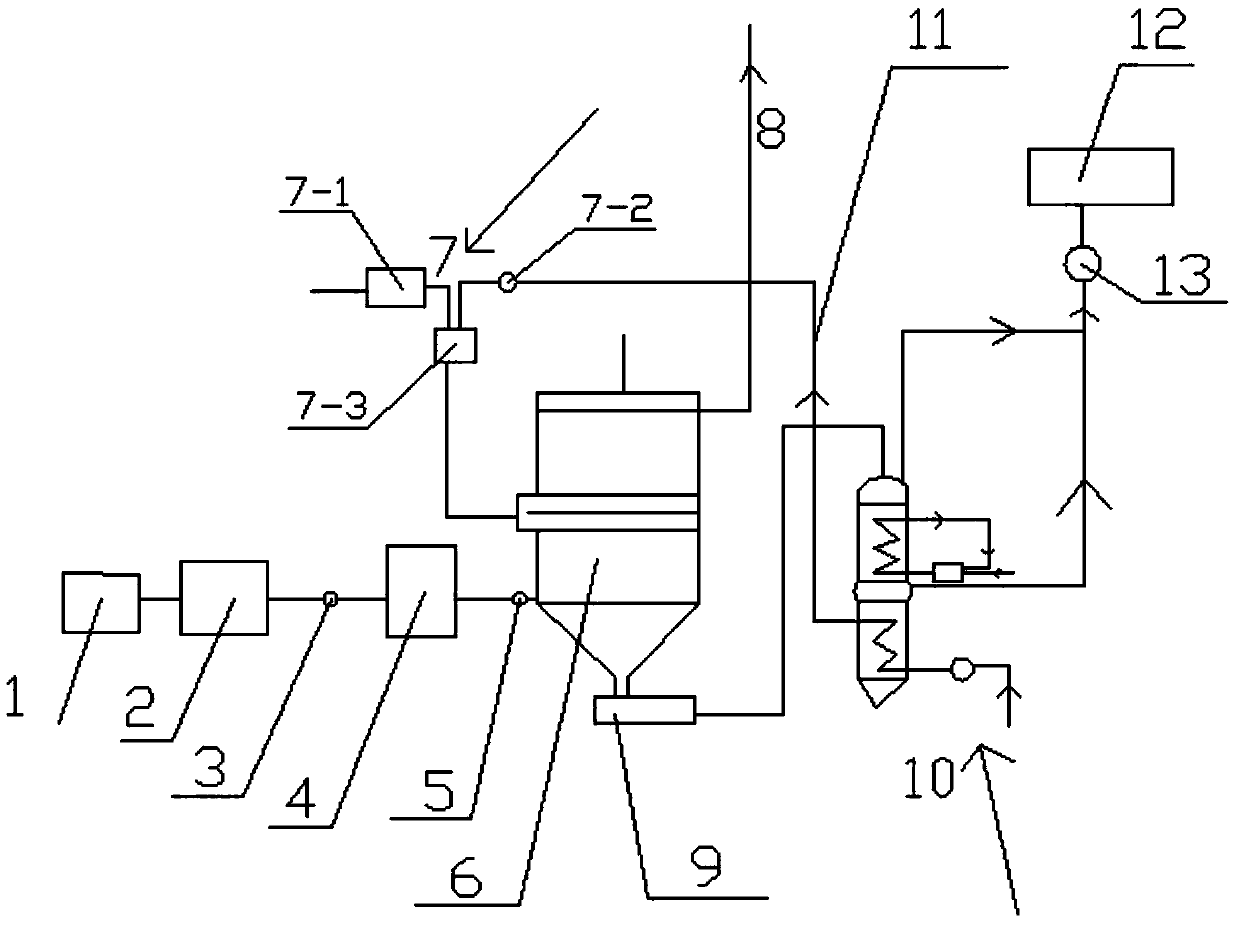

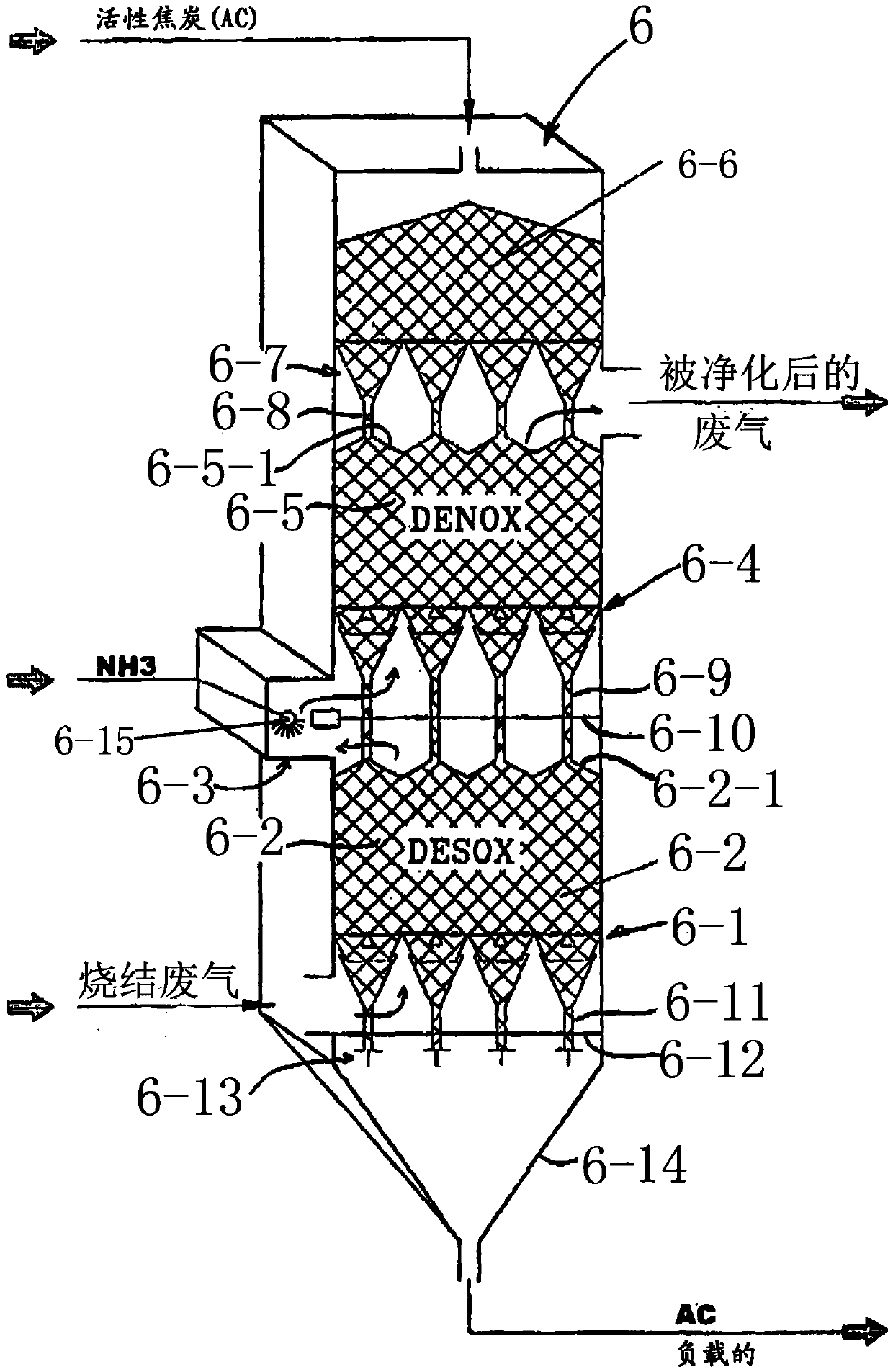

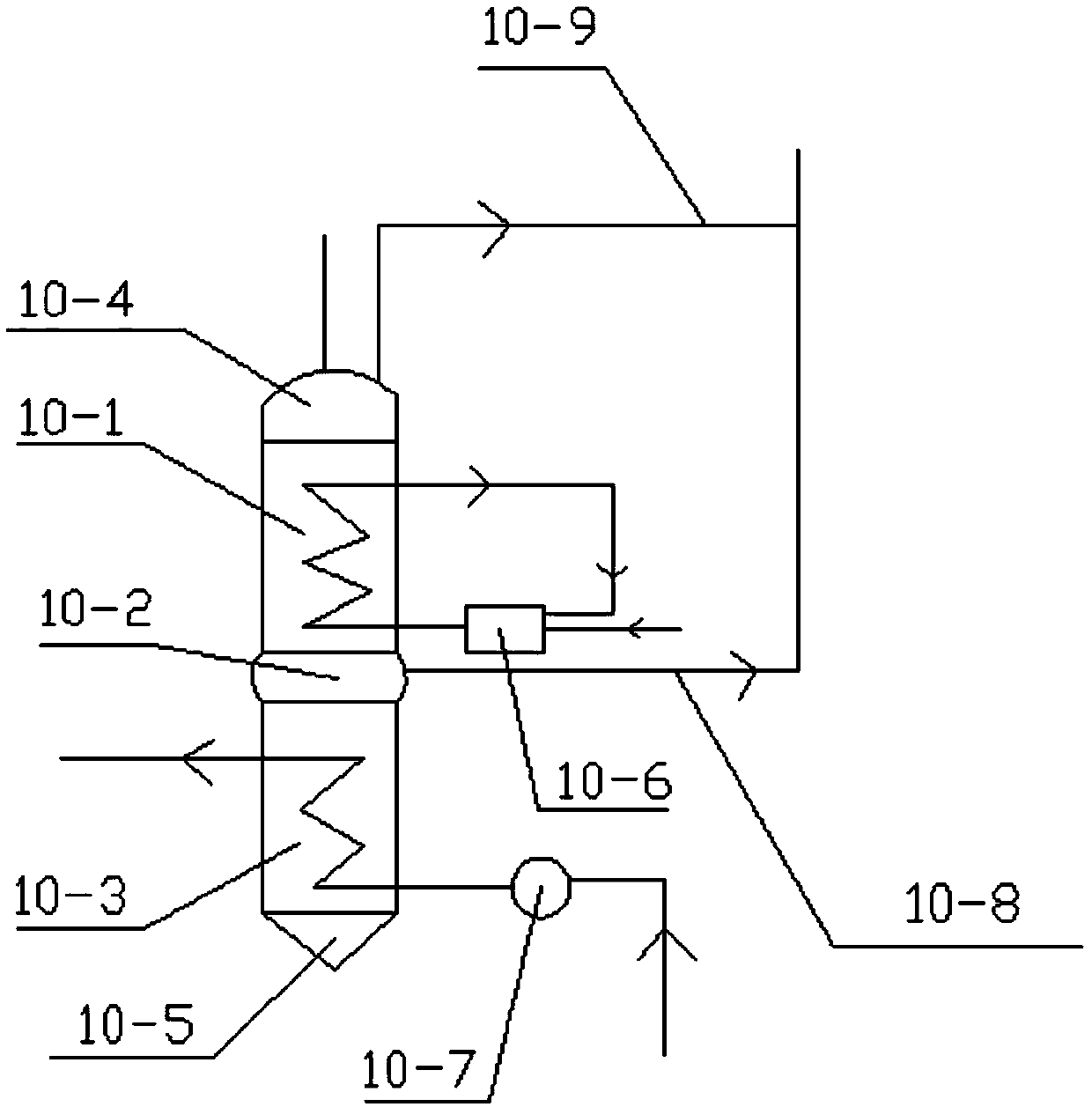

Method and device for treating solid combustion exhaust gas

PendingCN110813050AEasy to provideTo offer comfortCombination devicesGas treatmentExhaust gasExhaust fumes

The invention discloses a method and device for treating solid combustion exhaust gas. The method for treating the solid combustion exhaust gas includes the steps of removing at least major amount ofSOX and possibly other pollutants, pre-removing of NOX and removing of NOX and / or other reaction products. The device for treating the solid combustion exhaust gas includes a moving bed reactor for removing SOX, NOX and possibly other pollutants in the solid combustion exhaust gas, a NH3 supply unit and a regeneration unit for an adsorbent; and after air cooled by the adsorbent in the regenerationunit flows out of a cooling section of the regeneration unit, the air can be introduced into a dilution fan in the NH3 supply unit. According to the method and device for treating the solid combustion exhaust gas, simple and convenient production of NH3 can be realized, recycle of gas during the regeneration of the adsorbent is realized, and the gas during regeneration of the adsorbent can be used in the NH3 supply unit.

Owner:BEIJING ZHTD ENVIRONMENTAL PROTECTION TECH CO LTD

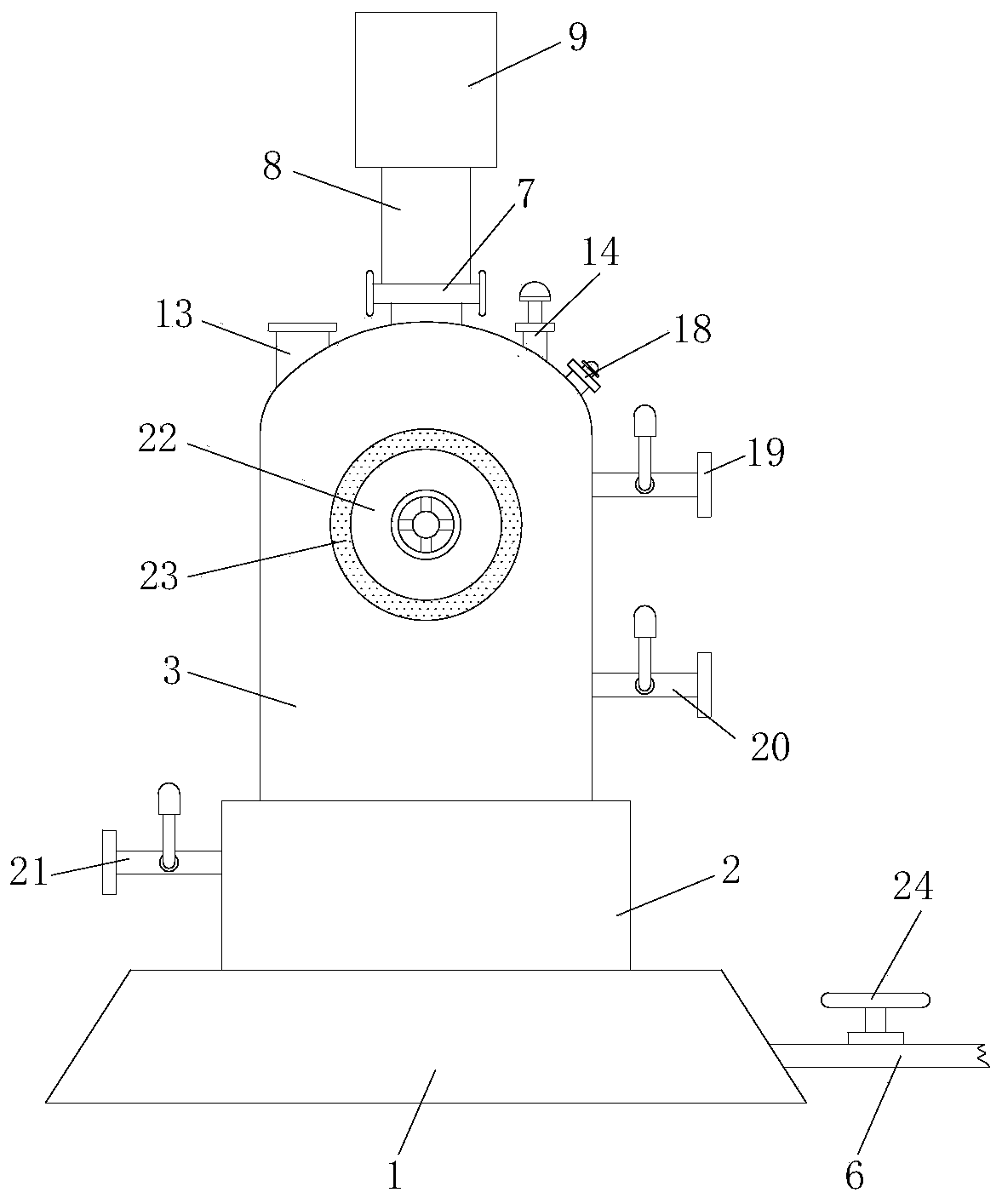

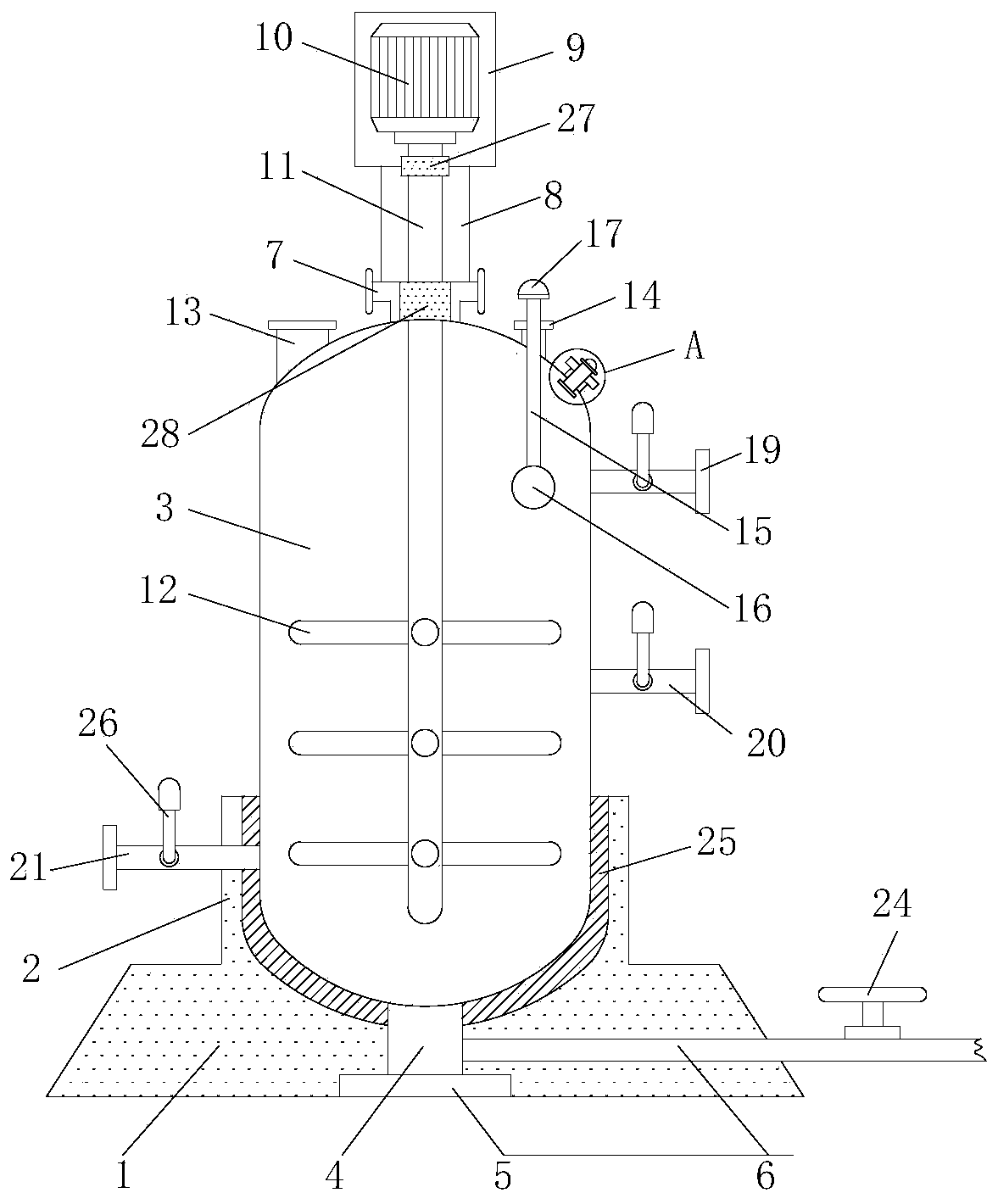

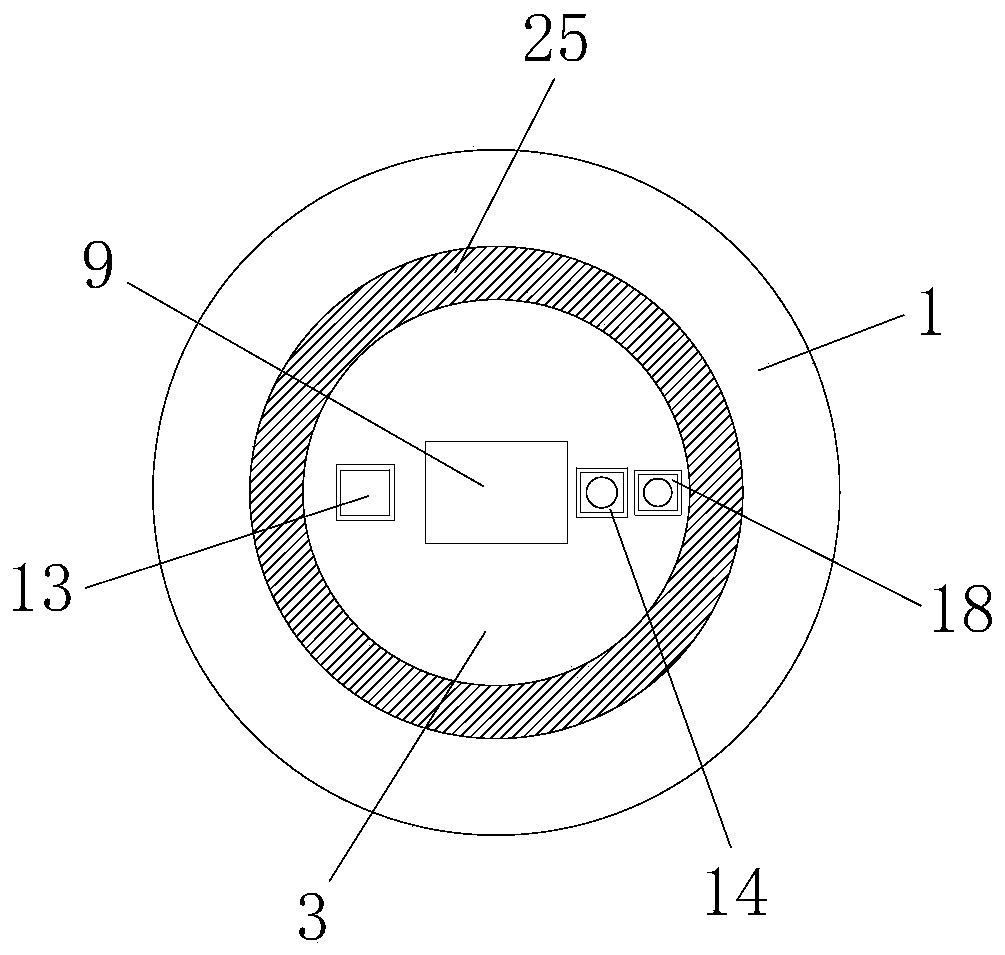

Corrosion-resistant glass-lined reaction kettle

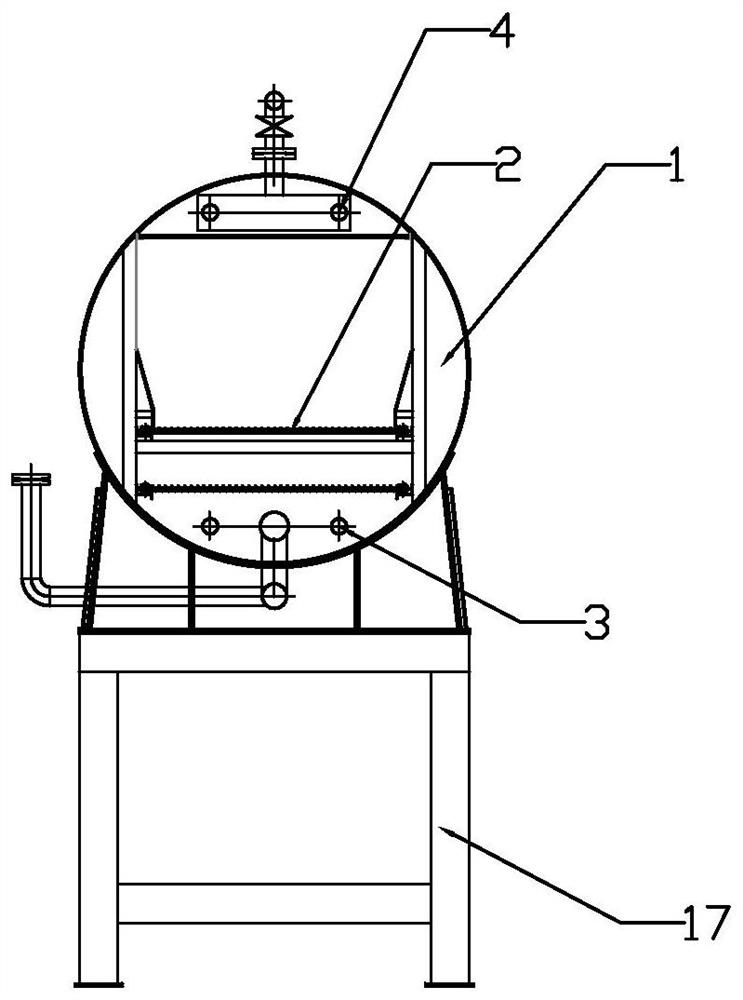

InactiveCN110975779AEasy to detect concentrationMaster the degree of responseProcess control/regulationChemical/physical/physico-chemical stationary reactorsEngineeringCircular cavity

The invention discloses a corrosion-resistant glass-lined reaction kettle, belonging to the field of corrosion-resistant glass-lined reaction kettles. The corrosion-resistant glass-lined reaction kettle comprises a support base, wherein the top end of the support base is fixedly connected with a circular cavity plate; a glass-lined reaction kettle is arranged in an inner cavity of the circular cavity plate in a sleeving manner; the bottom end of the glass-lined reaction kettle is fixedly connected with a liquid discharging pipe; the bottom end of the liquid discharging pipe is fixedly connected with a fixed valve; a flow guide pipe is fixedly connected to the right end of the liquid discharging pipe; one end of the flow guide pipe penetrates through the support base and extends to the outside; an opening valve is fixedly connected to the middle part of the top end of the glass-lined reaction kettle; a stirring rod protection box is fixedly connected to the top end of the opening valve;and a motor box is fixedly connected to the top end of the stirring rod protection box. The corrosion-resistant glass-lined reaction kettle is high in stability, can realize automatic pressure relief, improves the safety of the glass-lined reaction kettle, realizes layered sampling of a reagent, and facilitates detection of the reaction degree of the reagent.

Owner:日照正源化工机械制造有限公司

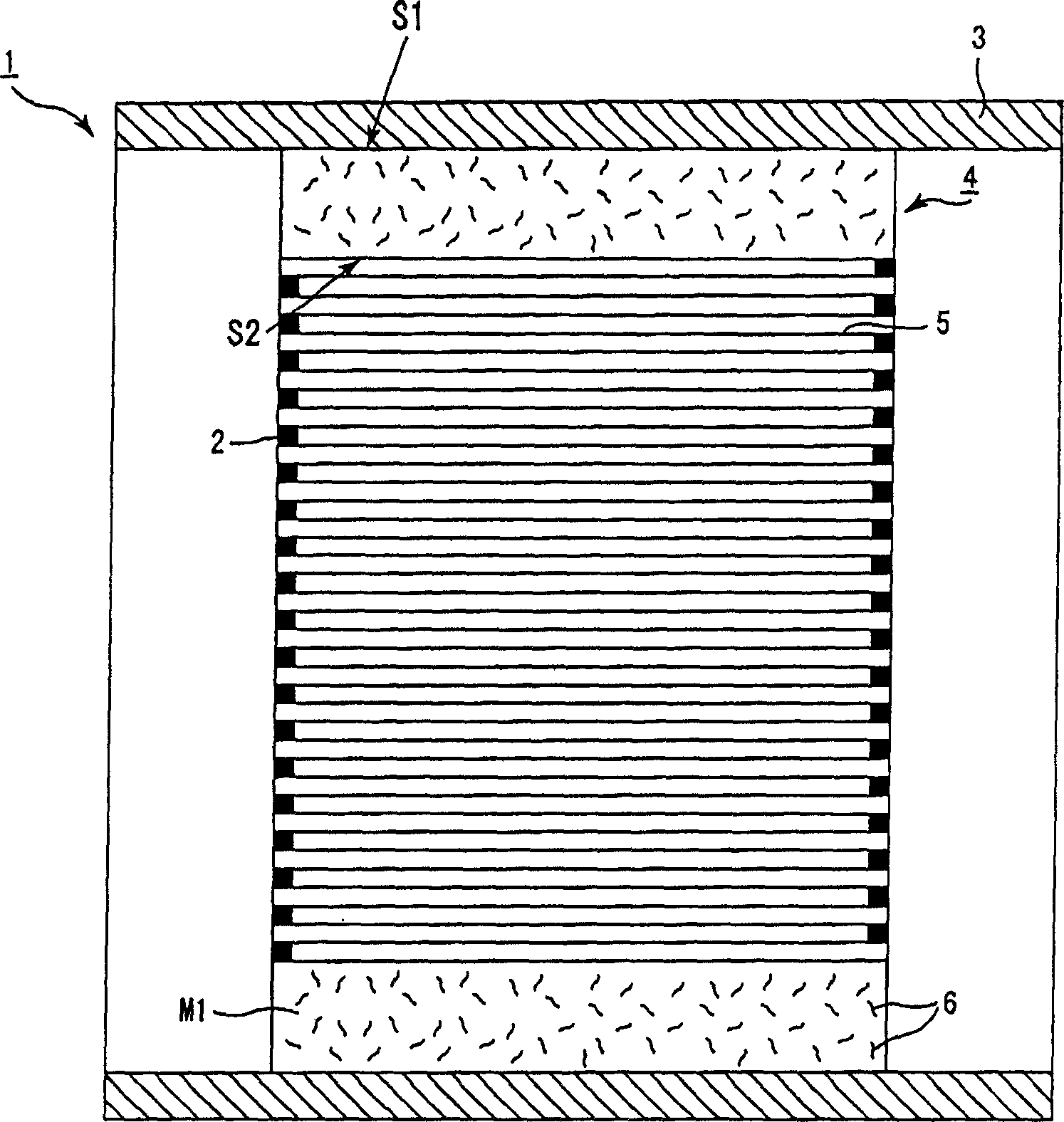

Retaining seal material and production method thereof

InactiveCN1690377ASurface pressure is not easy to reduceReduce heating stepsMaterial nanotechnologyCatalyst protectionInorganic saltsStock solution

An object of the present invention is to provide a manufacturing method by which alumina-silica based fibers excellent in mechanical strength can be readily and securely obtained, and the present invention obtains precursor fibers as a material by using an alumina-silica based fiber spinning stock solution for use in an inorganic salt method. Next, the precursor fibers are heated under an environment which makes it difficult to carry out an oxidizing reaction on the carbon component contained in the precursor fibers. Thus, the precursor fibers are sintered to obtain alumina-silica based fibers.

Owner:IBIDEN CO LTD

Energy-saving environment-friendly vacuum cup capable of performing self-heating

InactiveCN107638037AReduce heating stepsSimple structureDrinking vesselsHeat conductingDisplay device

Owner:成都濠溱科技有限公司

A new dry-process laminated glass production process

ActiveCN105109179BReduce heating stepsReduce energy consumptionLaminationLamination apparatusPolyesterEngineering

The present invention provides a novel dry laminated glass production process, which comprises: 1) forming a laminated glass module in a sheet laminating chamber; 2) taking two pieces of high temperature polyester films, respectively coating on the upper surface and the lower surface of the laminated glass module, sealing the peripheries of the high temperature polyester films with sealing strips to form a flexible sealing cavity, and arranging at least a gas sucking port for vacuumizing on the surface of the flexible sealing cavity; and 3) conveying into an autoclave, carrying out pressurization and heating treatment through the autoclave, carrying out vacuumizing treatment through a vacuumizing device, discharging the pressure, taking out, and removing the flexible sealing cavity so as to obtain the finished product laminated glass. According to the present invention, the gas discharge of the process is performed through the vacuumizing in the closed environment, and the vacuum gas discharge and the step 2 are combined to achieve the laminated glass product production in the one step; and the vacuumizing gas discharge is performed in the autoclave so as to complete the laminated glass production process in the one-step manner and efficiently produce the high-quality laminated glass.

Owner:TAICANG YAOHUA GLASS

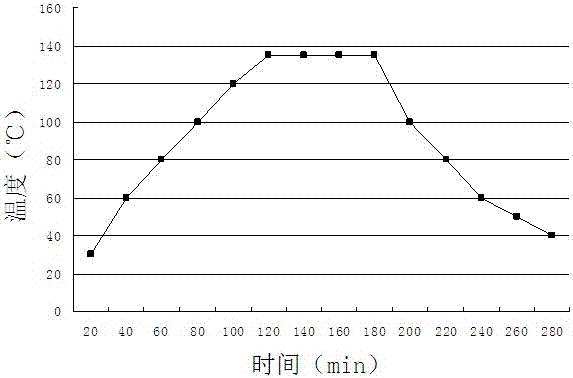

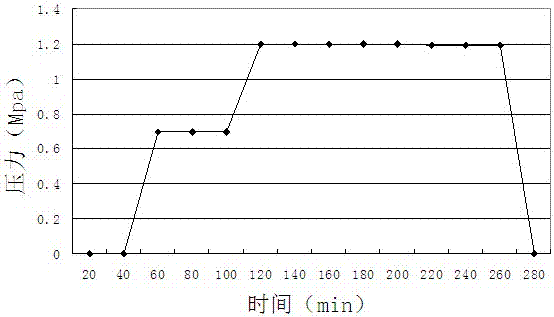

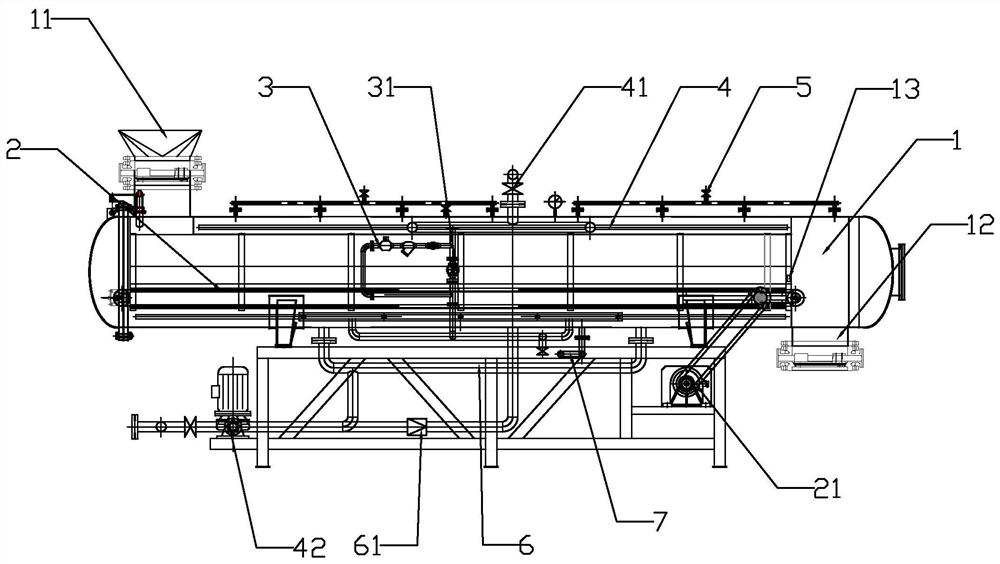

Automatic corn cob steamer

PendingCN111671035ARealize automatic controlHigh precision of speed regulationProgramme control in sequence/logic controllersSimultaneous control of multiple variablesAutomatic controlAgricultural engineering

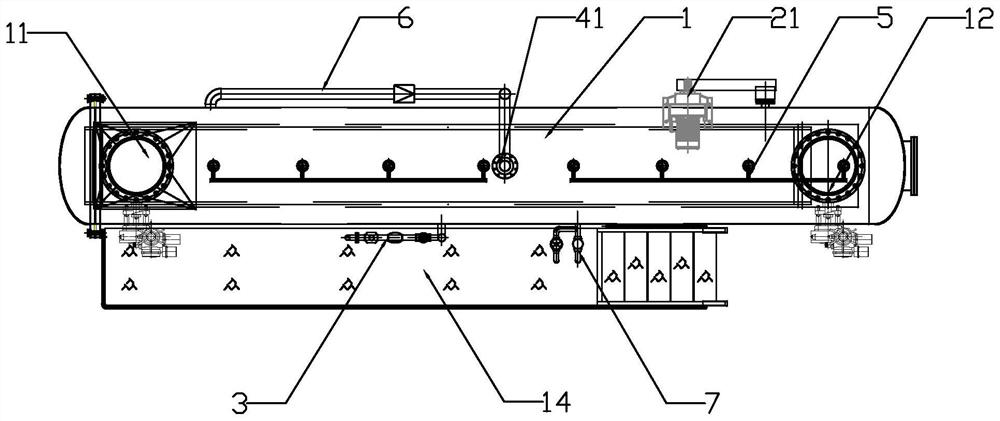

The invention discloses an automatic corn cob steamer. A conveying belt is arranged in a pot body; a feeding opening is formed in the position, corresponding to the front end of the conveying belt, ofthe top of the pot body; a feeding executing mechanism is arranged on the feeding opening; a discharging opening is formed in the position, corresponding to the tail end of the conveying belt, of thebottom of the pot body; a discharging executing mechanism is arranged on the discharging opening; the automatic corn cob steamer further comprises a steam pipeline and a spraying pipeline; pressurized steam is led into the pot body through the steam pipeline; a steam valve group is arranged on the steam pipeline; a spraying valve group is arranged on the spraying pipeline; an air release valve group is arranged at the top of the pot body; the feeding executing mechanism, the discharging executing mechanism, the conveying belt, the steam valve group, the spraying valve group and the air release valve group are all controlled through a PLC; a temperature sensor is arranged in the pot body; and steam in the pot body is the pressurized steam. Pre-cooking is not needed, so that the steaming efficiency is high; and full-automatic control is achieved, so that the steaming effect is good, and the labor cost and the equipment cost are saved.

Owner:SHANGYU GUANFENG FOOD MACHINERY

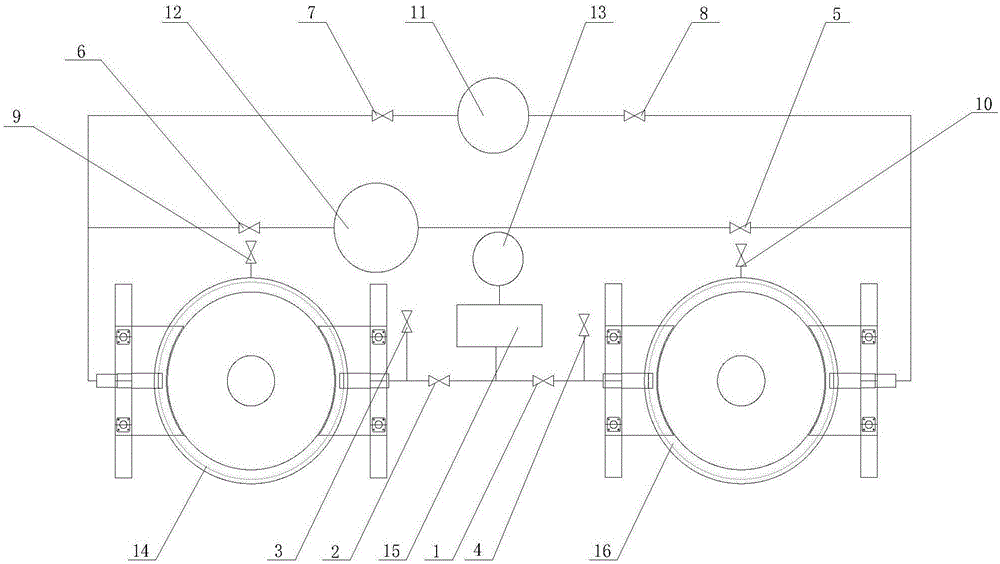

Vacuum oil-frying production technology

InactiveCN106561772AReduce heating stepsReduce usageOil/fat bakingDeep-fried productsStopped workEngineering

The present invention discloses a vacuum oil-frying production technology. The vacuum oil-frying production technology comprises the following steps: (1) pot A oil-frying: materials are added, a vacuum pump is turned on, and corresponding valves are opened, so that an oil storage tank is connected with the pot A via the fourth valve, the vacuum pump is connected with the pot A via the second valve, the vacuum pump vacuumizes the pot A, oil in the oil storage tank enters into the pot A, when oil level in the pot A reaches a setting position of the pot A, the fourth valve stops working, and a heating device of the pot A is turned on to conduct a heated oil-frying; and (2) pot B oil-frying: the materials are added, corresponding valves are opened and closed, the vacuum pump is turned on, a first relief valve connected to the pot A is intermittently opened, the oil in the pot A is pumped into a pot B, and after the finishing of the oil pumping, a heating device of the pot B is turned on to conduct the oil-frying. The two pots are used to conduct the oil-frying work, after the finishing of the oil-frying work of one of the pot, the oil in the pot is transferred into the other pot to conduct the oil-frying work, and due to the fact that the oil has a certain temperature, the vacuum oil-frying production technology reduces the use of energy and improves the production efficiency.

Owner:李庆新

Aluminium alloy continuous extrusion temperature control method

InactiveCN101249525ASave energyReduce heating stepsExtrusion control devicesThermal deformationEnergy consumption

The invention belongs to the manufacturing method of aluminum alloy, and particularly relates to an aluminum alloy continuous extrusion temperature control method for an air conditioner. The invention mainly solves the problems of prior art such as large production energy consumption and low discharging speed, and provides the aluminum alloy continuous extrusion temperature control method capable of saving energy resources and having high extrusion discharging speed. The aluminum alloy continuous extrusion temperature control method comprises the following steps of: feeding normal-temperature aluminum alloy blank into a mold, and extruding the aluminum alloy blank by an extrusion wheel to generate heat so as to improve the temperature of the aluminum alloy blank to the extrusion temperature, so that the aluminum alloy blank can generate thermal deformation during extrusion.

Owner:ZHEJIANG KANGSHENG CO LTD

Treatment method of (meth)acrylic acid wastewater

The invention discloses a treatment method of (meth)acrylic acid wastewater. The method comprises the following steps: adding a vinyl monomer and an initiator into the (meth)acrylic acid wastewater, the wastewater is illuminated to form a gel-form polymer, and the polymer is dehydrated and dried to obtain a high-water-absorptivity material. The treatment method of acrylic acid wastewater has the advantages of low energy consumption, high efficiency and simple process, and can realize recycling of (meth)acrylate production wastewater.

Owner:SICHUAN UNIV

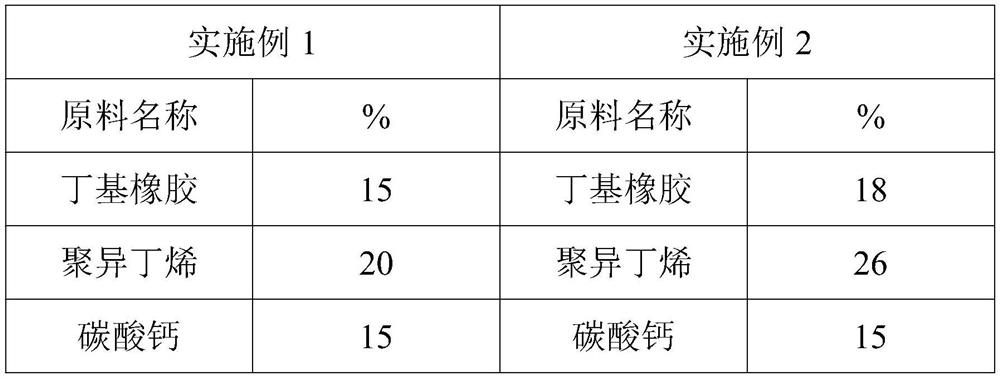

Gluing-free environment-friendly odorless damping plate and preparation method thereof

PendingCN112358690AImprove heat aging resistanceGood weather resistanceProcess engineeringButyl rubber

The invention discloses a gluing-free environment-friendly odorless damping plate which comprises rubber and a polyisobutene component, and the rubber is butyl rubber; wherein the content of the polyisobutene is higher than that of the butyl rubber in percentage by mass, and the content of the polyisobutene accounts for more than 18% of the total component content of the damping plate. In the formula of the damping plate, the content of polyisobutene is higher than that of butyl rubber, and the content of polyisobutene accounts for more than 18% of the total component content of the damping plate. By adding polyisobutene with a high proportion, the material can wet various base materials difficult to adhere to improve the adhesion performance of the base materials, the damping plate is endowed with high viscosity, and therefore the damping plate can be directly used for later application of products, the heating step in the product gluing or attaching process is reduced, and energy consumption is reduced. And the gluing process is reduced, and the labor cost is reduced.

Owner:佛山市德麟新材料科技有限公司

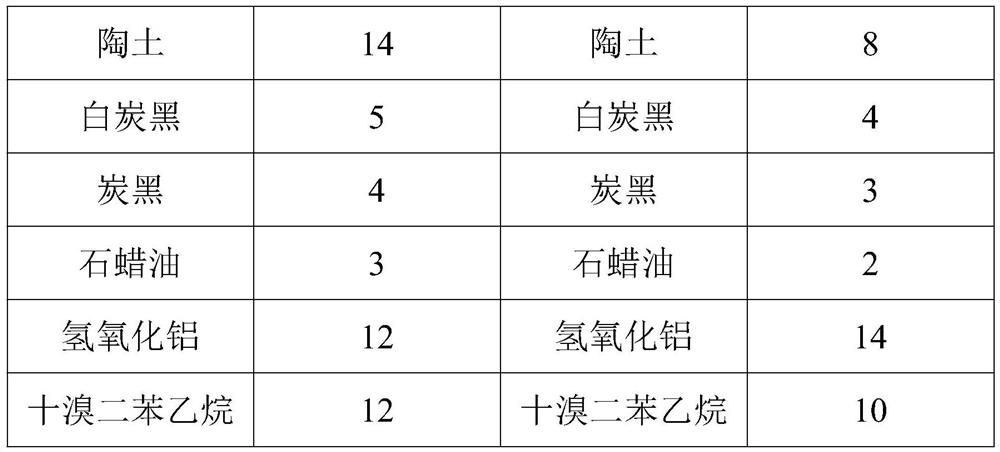

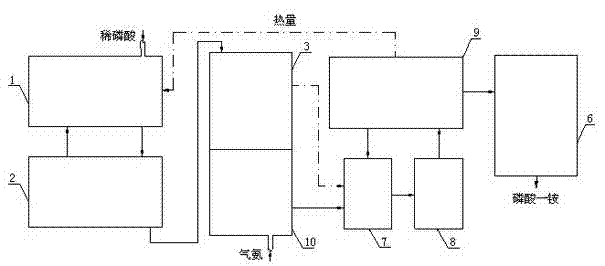

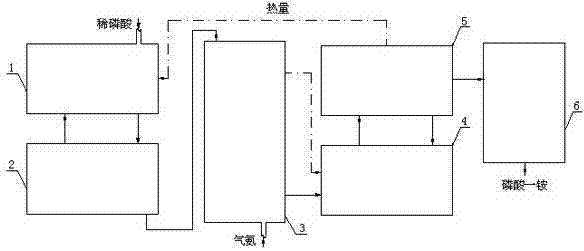

New technology of applying double-effect forced circulation concentration method in production of ammonium phosphate

InactiveCN102020257BReduce in quantityReduce the overall heightPhosphatesThermal energyFluidized bed drying

Owner:GANSU WENGFU CHEM

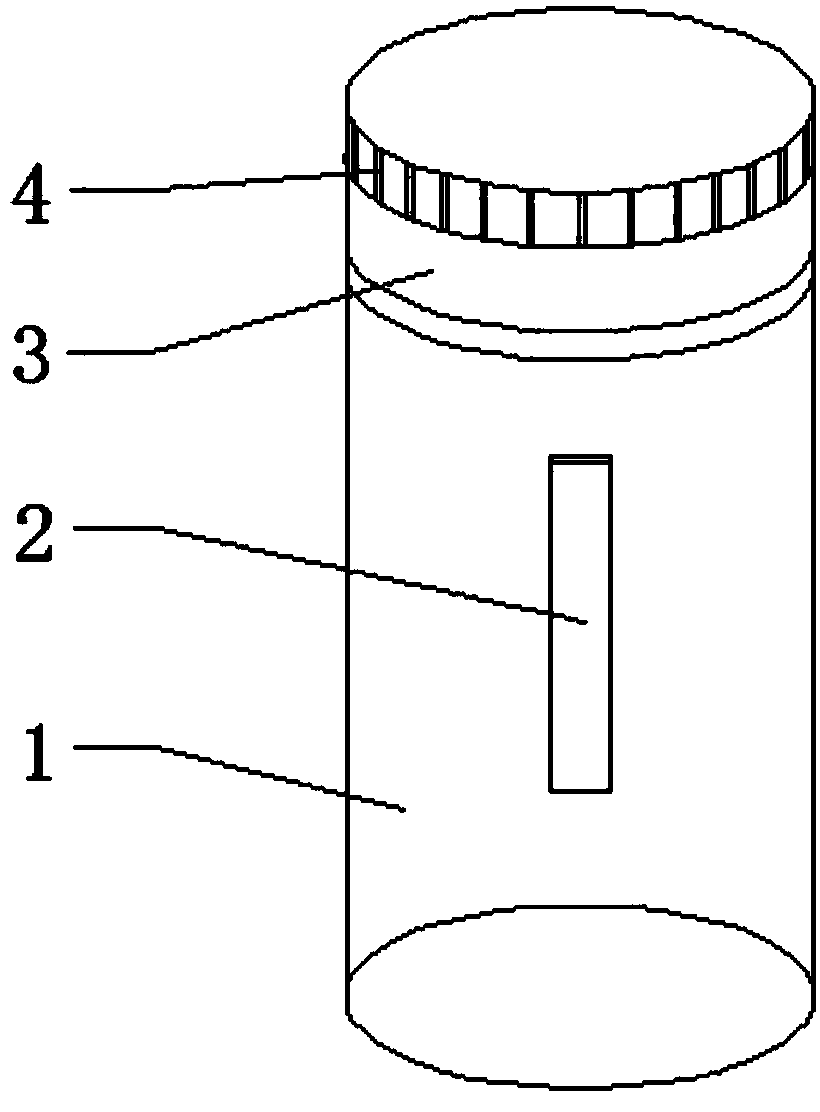

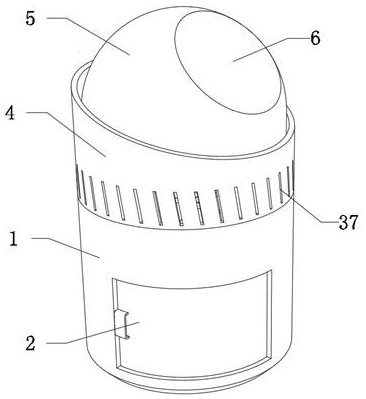

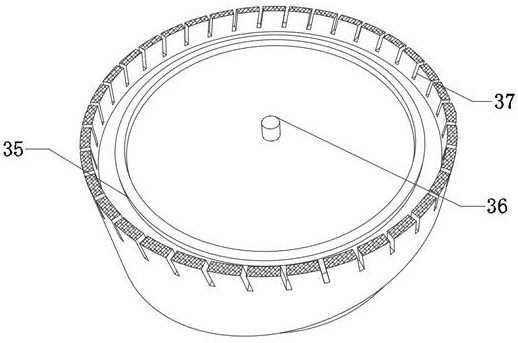

An active mist ion generating device for vehicle interior air purification

ActiveCN114379333BNo spillageCompact designAir-treating devicesAtomized substancesAir purifiersControl system

The invention relates to an active mist ion generating device for air purification inside a vehicle, which relates to the technical field of air purification. The invention includes a vehicle-mounted air purifier and a control system. The control system is used to control the operation of the vehicle-mounted air purifier. The vehicle-mounted air purifier includes a casing, a replacement component and a movable component are arranged inside the casing, and a liquid supply component and a movable component are arranged inside the replacement component. An atomization component is fixed inside, and a humidity sensor is fixedly connected to the inside of the shell; the replacement component includes a turntable, a power connection block, a second slider fixing groove and a heating plate; the liquid supply component includes a liquid bottle, a fixed rod, a telescopic block, and a spring and a sliding cover; the movable components include electric telescopic rods, connecting rods and push blocks; the control system includes a processing unit, an atomizing unit and a monitoring unit. The invention solves the problem that the existing active mist ion generating device for vehicle-mounted air purification is too cumbersome to replace the liquid bottle, and the vehicle-mounted air purifier is small in size, which may cause the liquid inside the liquid bottle to be spilled during replacement, and the difference in humidity in the vehicle is also possible This leads to the problem that the generation of mist ions is insufficient and the effect of air purification cannot be achieved.

Owner:BEIJING FULE CLOUD INSPECTION TECH

Improved manufacture method of one-piece golf bar head

InactiveCN101362197BReduce distortionRelieve pressureFoundry mouldsFoundry coresFilling materialsDie casting

Owner:LONGHUI SPORTS GOODS +1

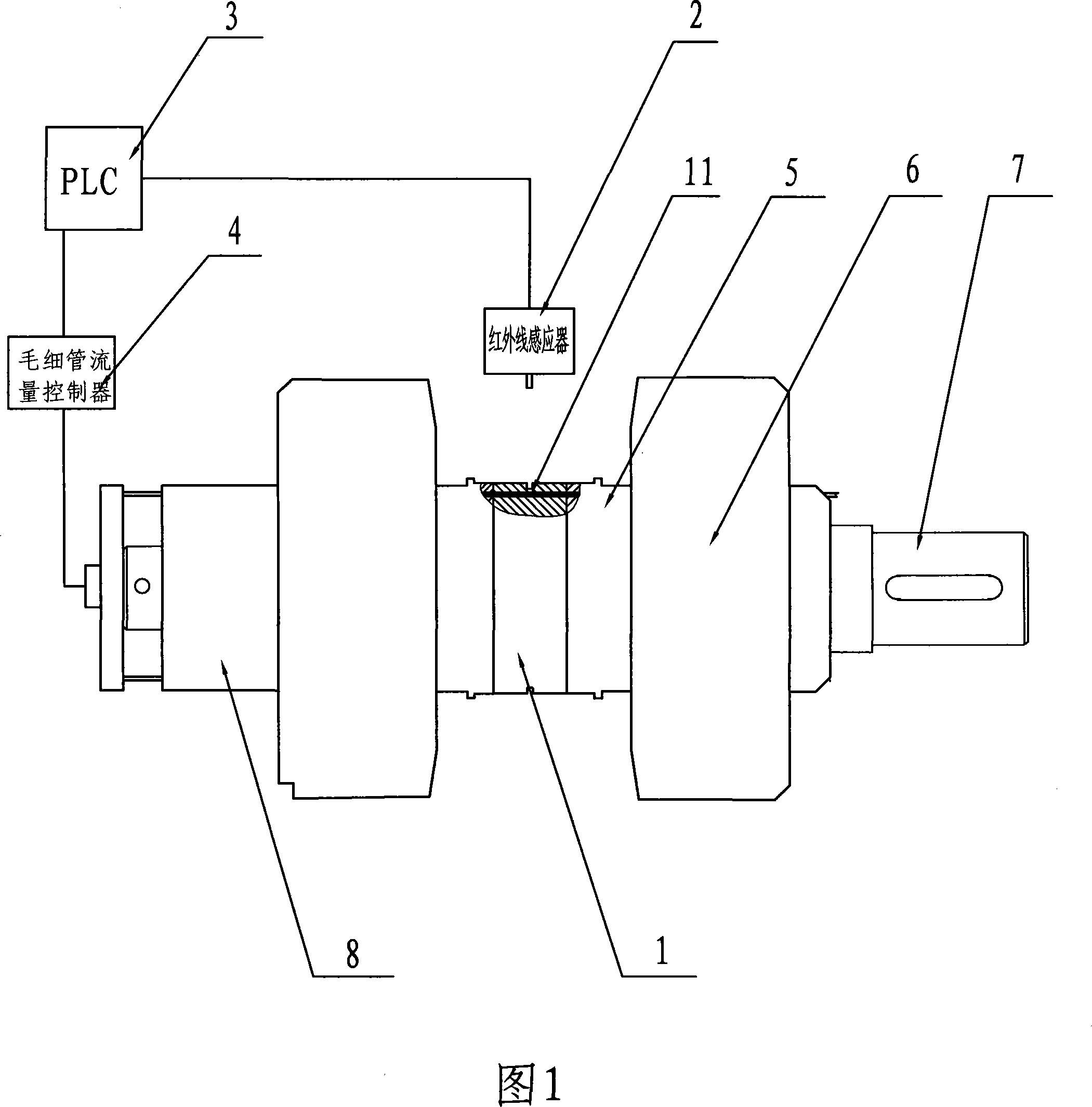

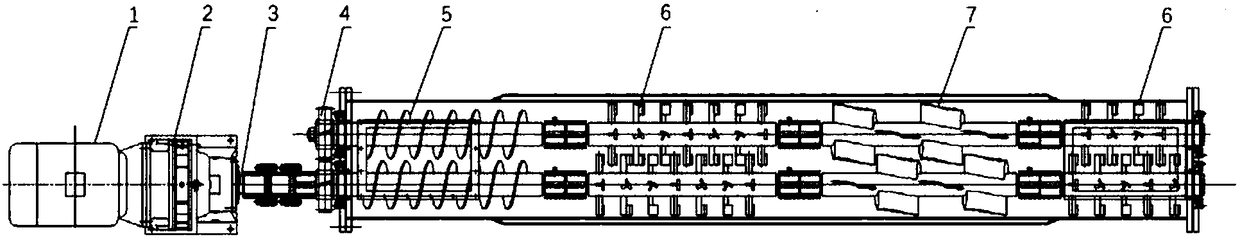

Continuous preparation method of chlorosulfonate

InactiveCN108946679APrevent leakageSmall footprintSodium/potassium compoundsChlorosulfonic acidContinuous reactorChloride salt

The invention provides a continuous preparation method of chlorosulfonate, wherein the preparation method comprises the following steps: carrying out reaction of chloride salt and liquid sulfur trioxide in a gas-solid continuous reactor, and making the mixed material continuously pushed forward by a motor, a speed reducer and a differential speed machine. A continuous liquid-solid reaction deviceis used for continuous production of sodium chlorosulfonate; the solid material sodium chloride makes full contact with liquid sulfur trioxide under the mixing and shearing action of a stirrer, the two materials are subjected to reaction by controlling the heating temperature, the material is continuously pushed forward during the reaction, and the reaction time is controlled by the material pushing speed in the device, so as to ensure that the two materials are subjected to total overall reaction to produce sodium chlorosulfonate when the material is pushed out from the other end of the device.

Owner:SHANDONG RUNBO BIOTECH CO LTD

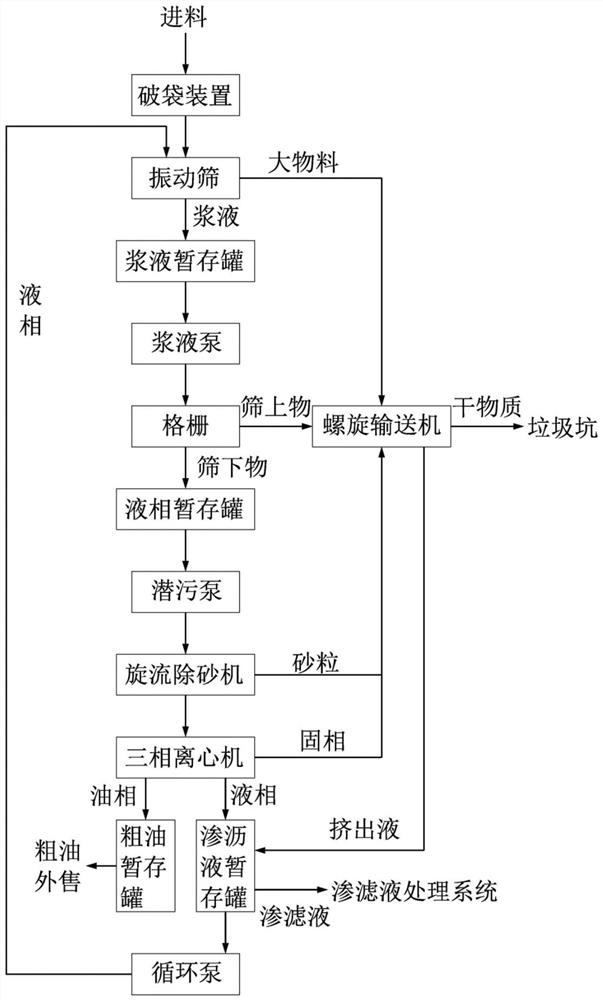

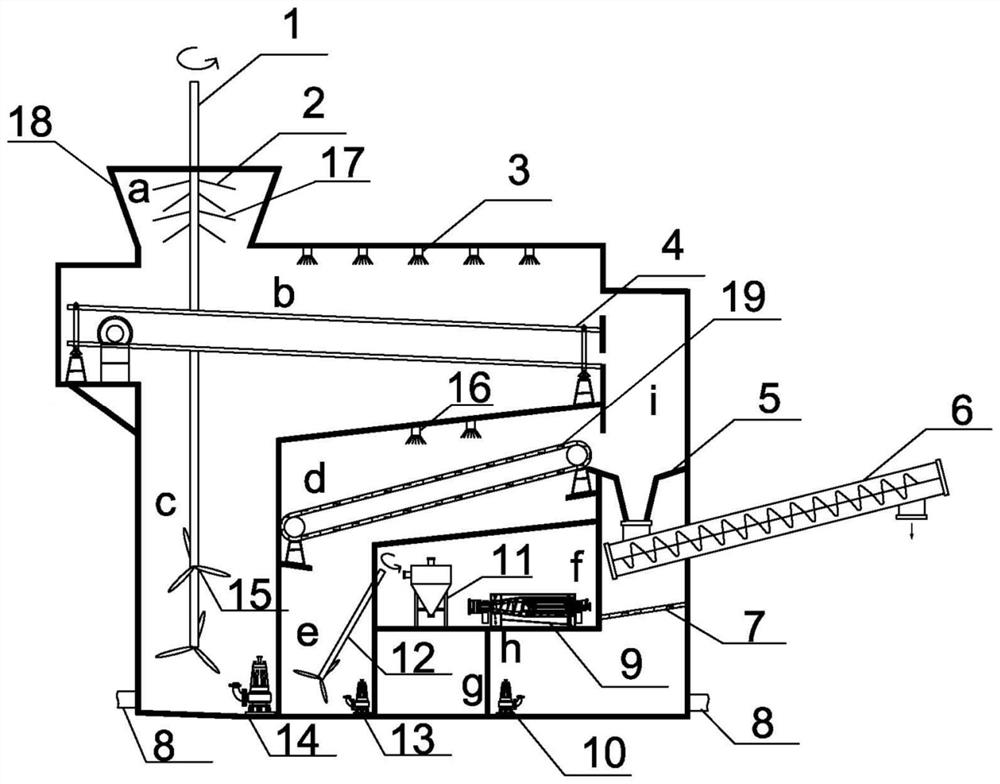

Kitchen waste pretreatment system and pretreatment method thereof

ActiveCN113319101AReduce churnReduce difficultySolid waste disposalTransportation and packagingPretreatment methodProcess engineering

The invention discloses a kitchen waste pretreatment system. The kitchen waste pretreatment system comprises a bag breaking chamber, a coarse separation chamber, a fine separation chamber, an oil extraction chamber and a solid phase collecting and conveying system; the coarse separation chamber is positioned below the bag breaking chamber; the fine separation chamber is arranged on the side of the coarse separation chamber; the oil extraction chamber is positioned below the coarse separation chamber; the solid phase collecting and conveying system is positioned on the sides of the coarse separation chamber, the fine separation chamber and the oil extraction chamber; a vibrating screen and a leachate spraying device are arranged in the coarse separation chamber; the vibrating screen is obliquely arranged; the leachate spraying device is arranged above the vibrating screen; a slurry temporary storage tank is positioned below the vibrating screen; a solid phase collecting chamber is positioned at the tail of the vibrating screen; the solid phase collecting and conveying system comprises a collecting hopper and a spiral conveying device; the spiral conveying device is obliquely arranged; the collecting hopper is connected above a feeding hole of the spiral conveying device; and the leachate temporary storage tank is positioned below the solid phase collecting chamber. The kitchen waste pretreatment system have the advantages of good solid-liquid separation degree and high crude oil extraction rate. The invention further discloses a pretreatment method of the kitchen waste pretreatment system.

Owner:龙净能源发展有限公司

Method for sealing a heat transfer unit

ActiveUS10307874B2Shorten the lengthImprove thermal efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat pipe

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Hydroxyl group/keto group synchronous derivatization method of endocrine disturbing chemicals in steroid environment

InactiveCN101942006BImplementing Synchronous DerivatizationReduce polarityComponent separationSteroids preparationEstriolLinear correlation

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com