Method and device for treating solid combustion exhaust gas

A technology for burning waste gas and solids, which can be used in combination devices, gas treatment, separation methods, etc., and can solve the problems of different, complex units, and increasing the total cost of steel production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

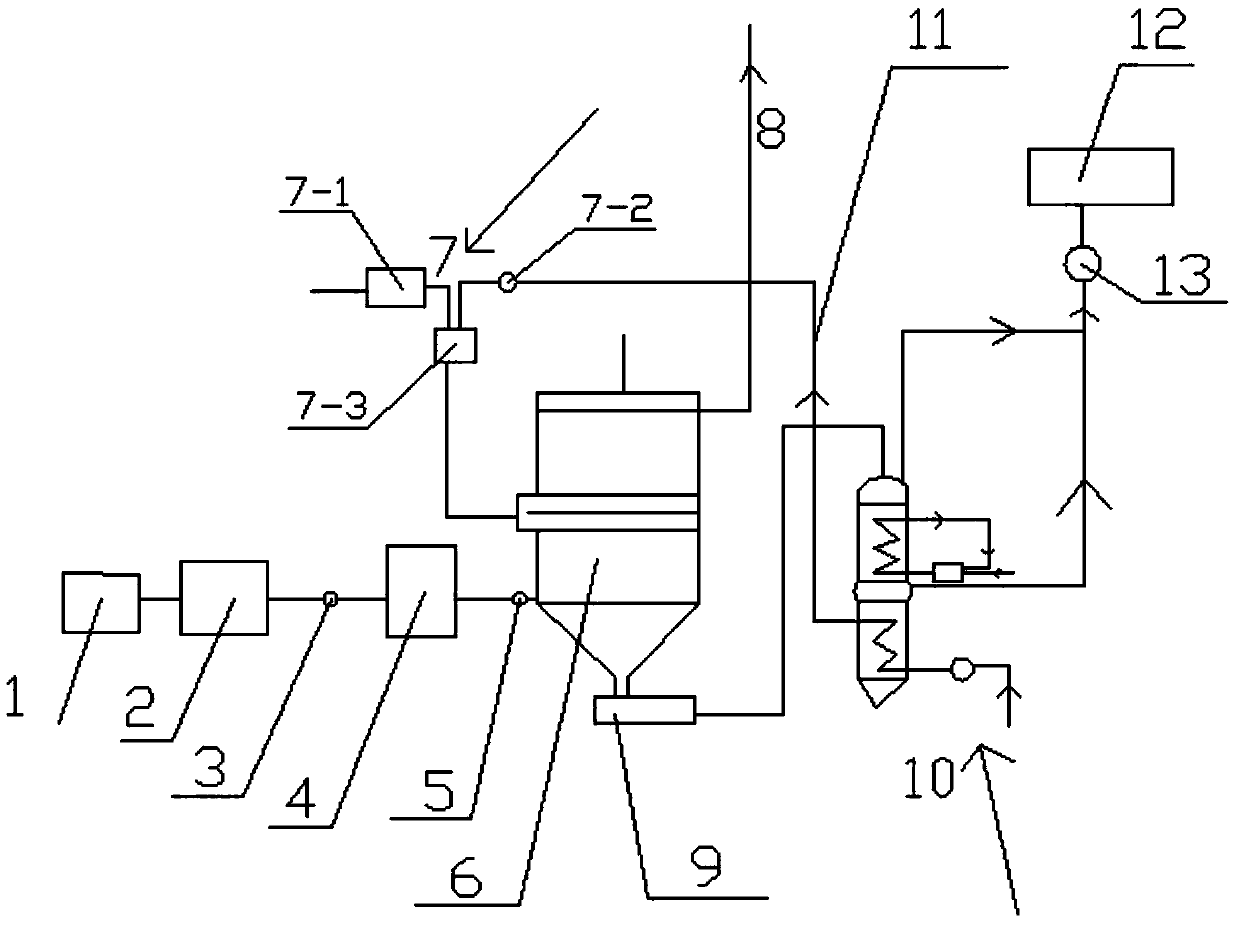

[0070] see figure 1 , the waste gas generated on the sintered belt 1 is transmitted to the electric filter (the prior art) through the pipeline, the dust generated by the electric filter 2 is transmitted back to the sintered belt through the pipeline, and the outflow from the electric filter 2 is about 150-165 ℃ The exhaust gas flows through the first blower 3 and enters the bag filter 4 in turn, wherein the blower 3 can provide sufficient boost pressure for the operation of the device. Calcium oxide, calcium hydroxide and / or similar alkali metal compounds or alkali metal compounds can also be added to the sintered waste gas before flowing out of the first blower 3 and into the bag filter 4 to be combined with SO in the sintered waste gas. X , HS and or HCl to significantly reduce consumption of more expensive sorbents.

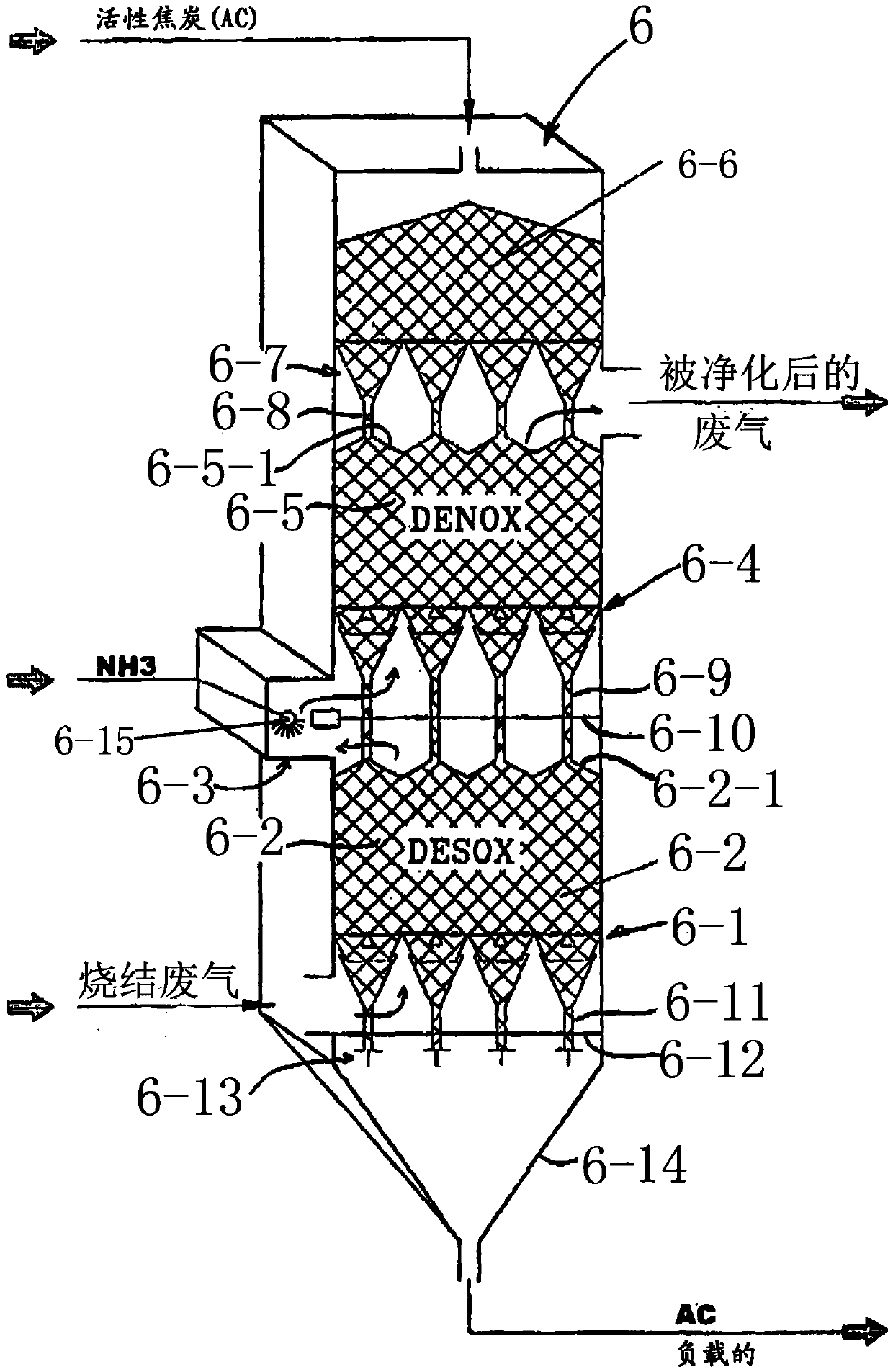

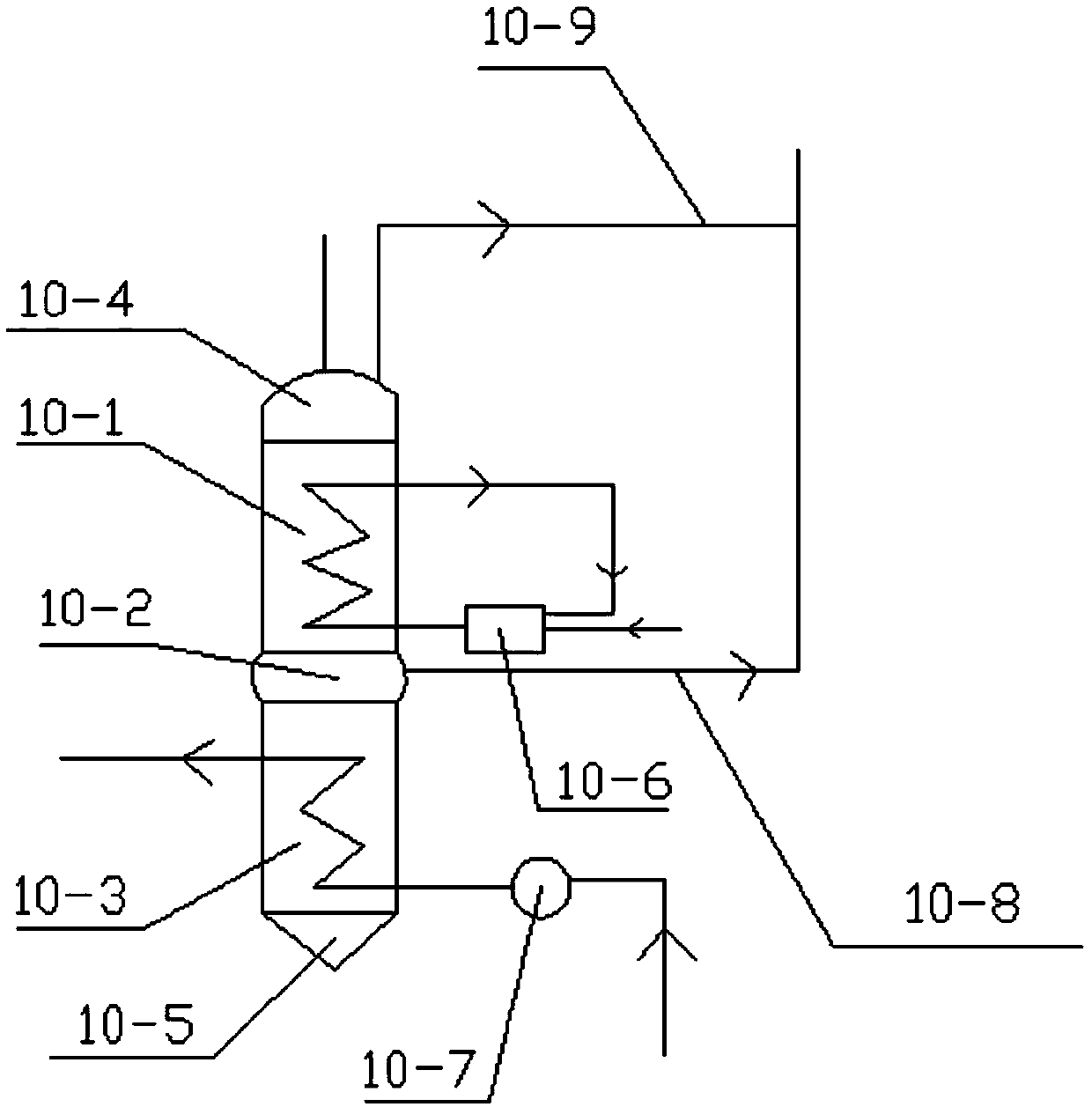

[0071] The sintering waste gas leaving through the bag filter 4 is first cooled to about 135° C. by water evaporation, and then introduced into the moving b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com