Aluminium alloy continuous extrusion temperature control method

A technology of extrusion temperature and control method, which is used in metal extrusion control equipment, metal extrusion, manufacturing tools, etc. Production efficiency and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

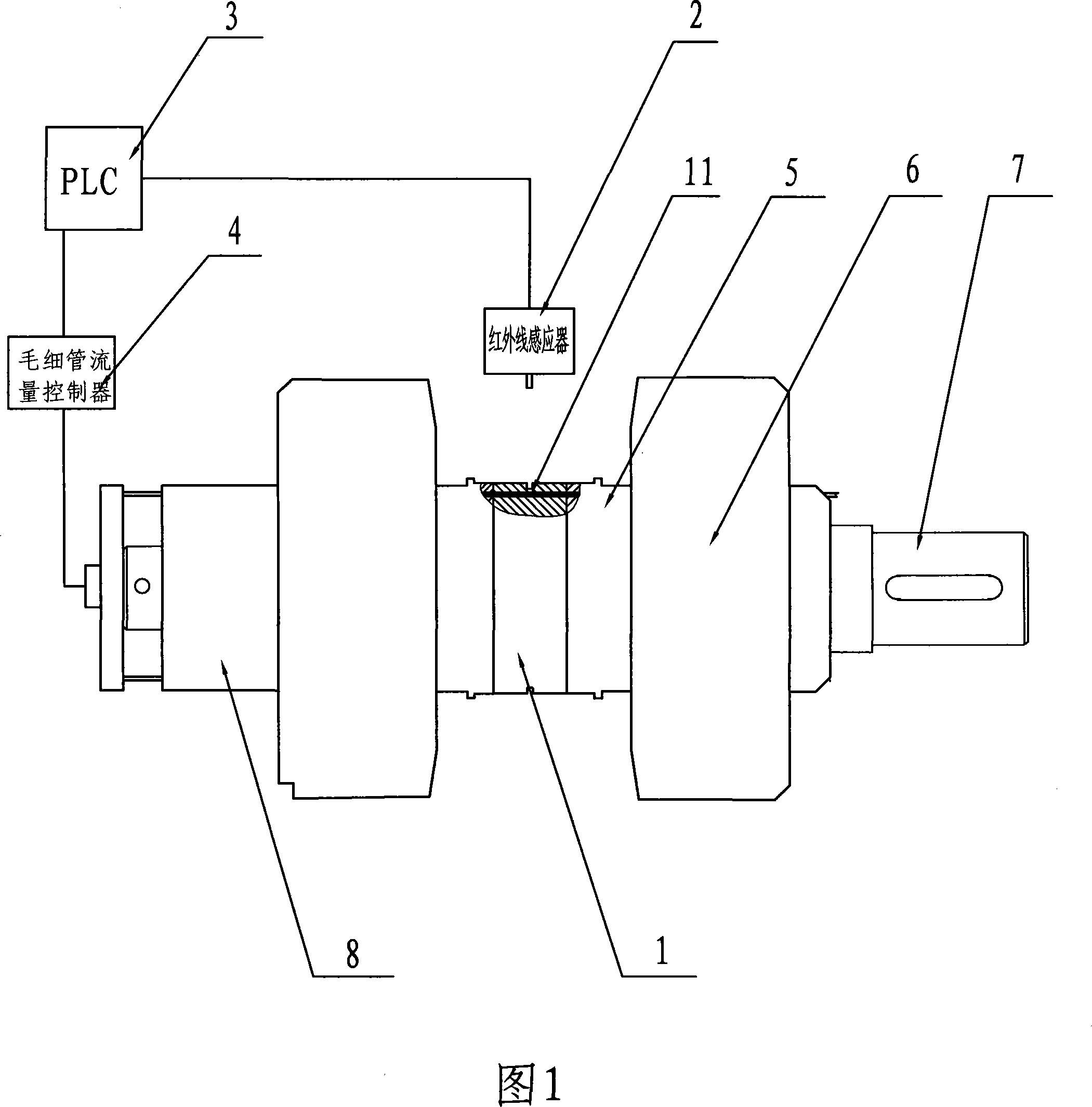

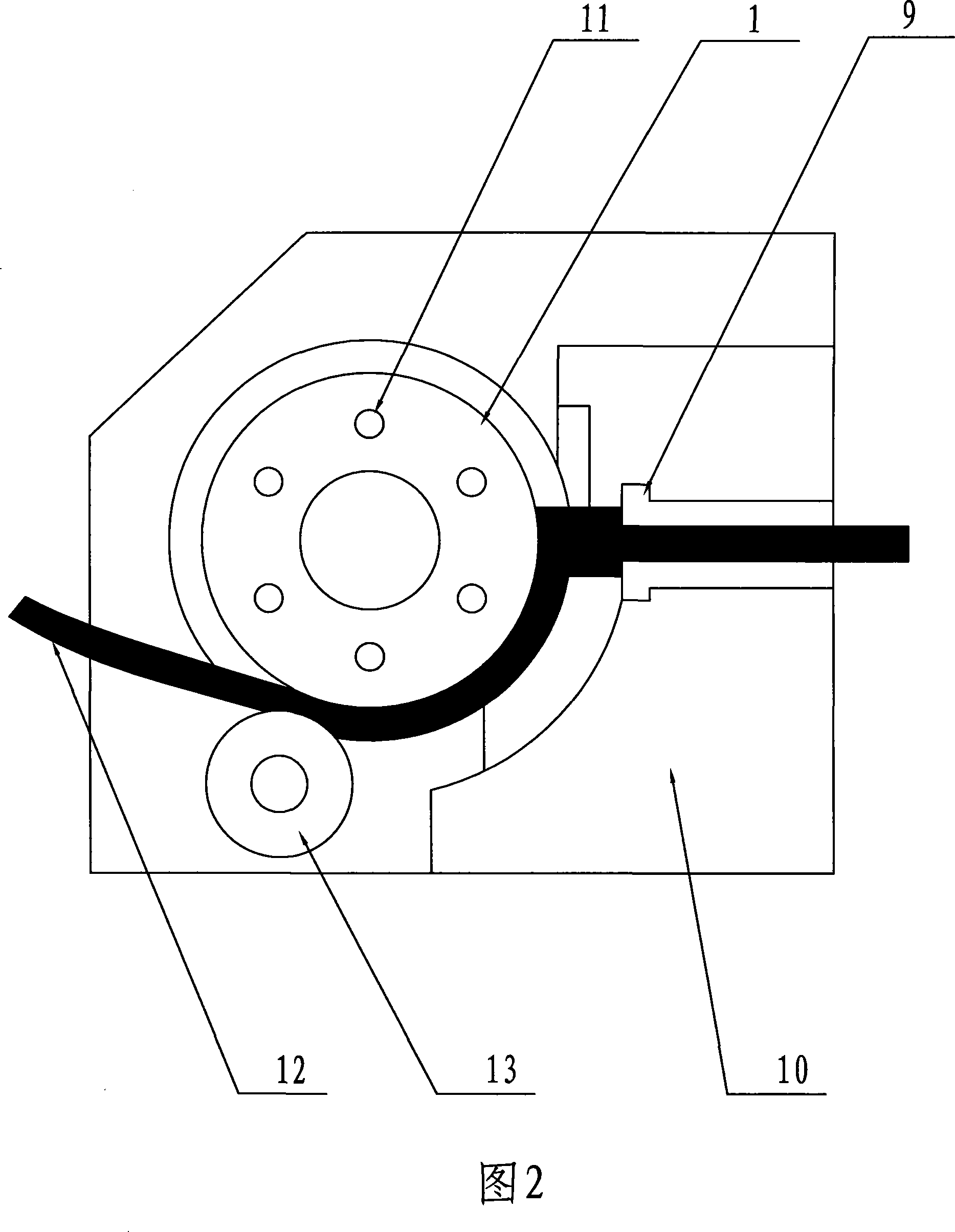

[0018] As shown in FIG. 1 and FIG. 2 , the extrusion wheel 1 is erected on the shoe body 10 , and the extrusion wheel 1 includes a main shaft 7 , an extrusion wheel 1 , a guard wheel 5 , a support wheel 6 and a hydraulic nut 8 . Described squeeze wheel 1 is installed in the middle part of main shaft 7, and guard wheel 5 is installed on the both sides of squeeze wheel 1, and support wheel 6 is all installed on the side of two guard wheels 5, next to support wheel 6 on the left side A hydraulic nut 8 is installed, and the extrusion wheel 1, the guard wheel 5 and the support wheel 6 are symmetrical with the extrusion wheel 1 at the center. Inside the extrusion wheel 1, six capillary tubes 11 are evenly arranged around the center of the extrusion wheel 1, and the capillary tubes 11 are used for cooling water to pass through, and the capillary tubes 11 run through the extrusion wheel 1, the protection Wheel 5 and supporting wheel 6. An infrared sensor 2, a PLC device 3 and a capil...

Embodiment 2

[0022] The heat generated by extrusion makes the temperature of the extrusion wheel reach 500°C-520°C, the temperature of the die mouth is 420°C-450°C, and the temperature of the shoe body is less than 450°C. The extrusion wheel speed is 9.5r / min. The extrusion speed of aluminum alloy products is 60m / min.

[0023] All the other are identical with embodiment 1.

Embodiment 3

[0025] The heat generated by extrusion makes the temperature of the extrusion wheel reach 510°C-530°C, the temperature of the die mouth is 430°C-440°C, and the temperature of the shoe body is less than 440°C. The extrusion wheel speed is 8.5r / min. The extrusion speed of aluminum alloy products is 55m / min.

[0026] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com