Retaining seal material and production method thereof

A sealing material and fastening technology, which is applied in the field of preparation of alumina fiber aggregates, can solve the problems of not being able to obtain quality stable fastening sealing materials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

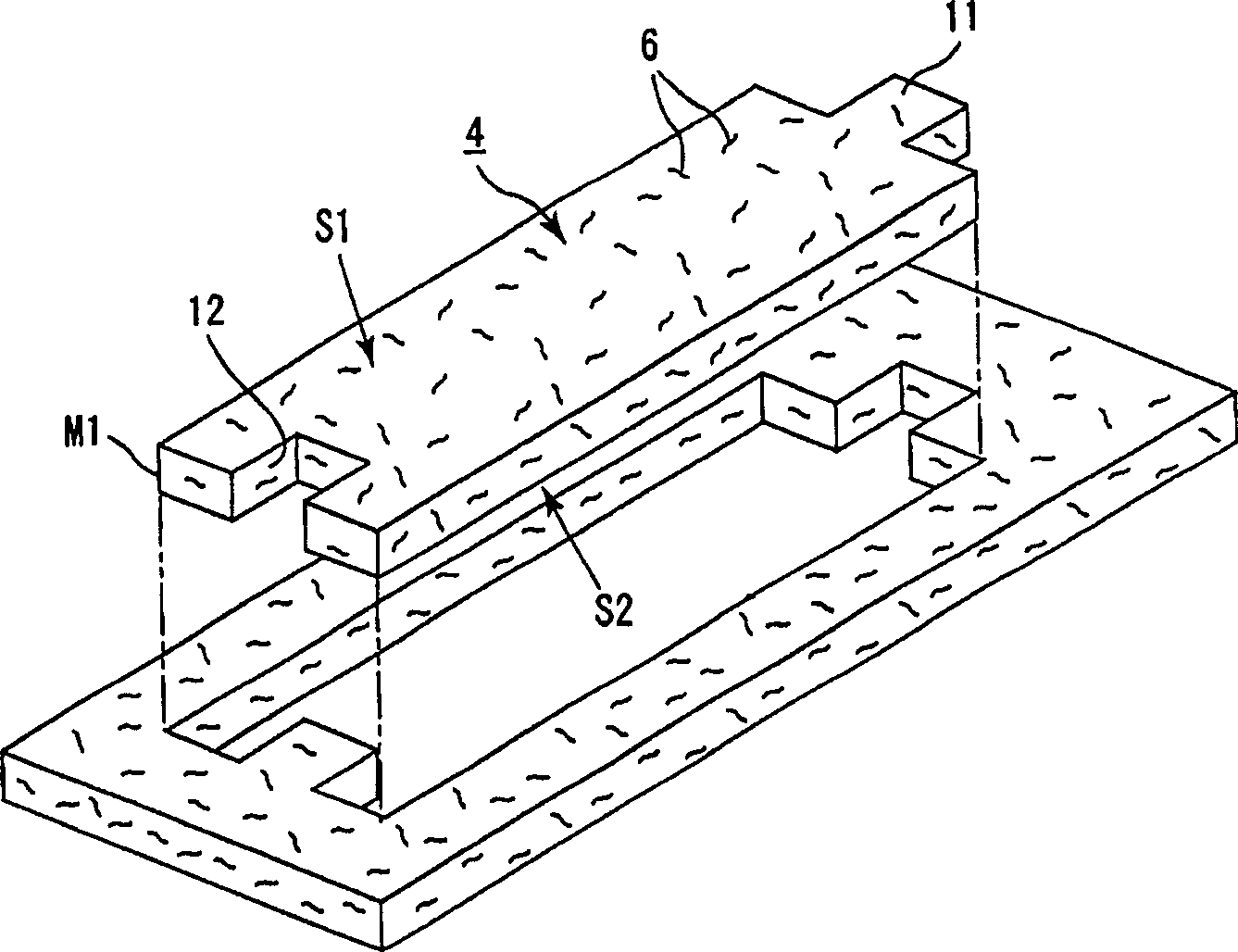

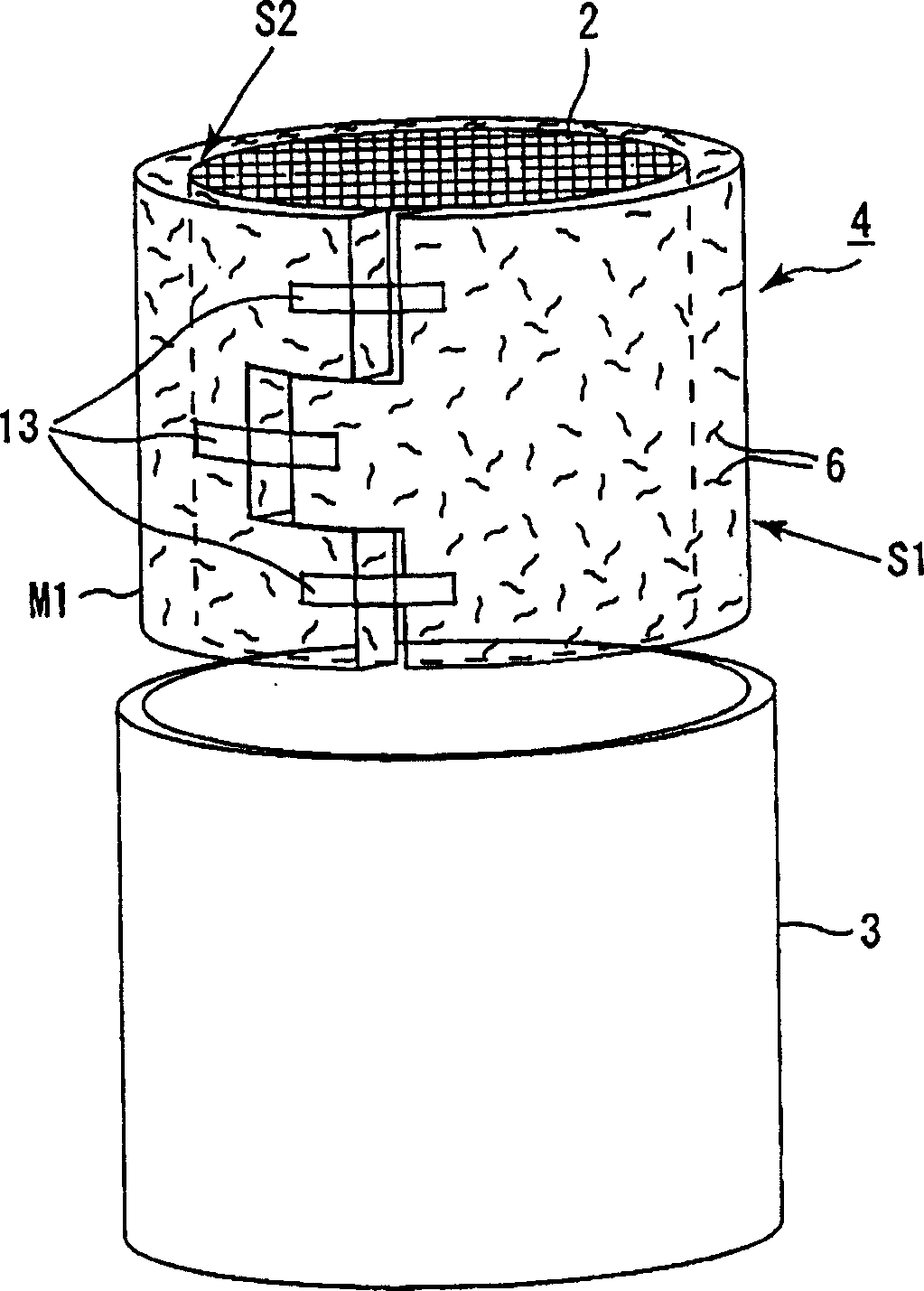

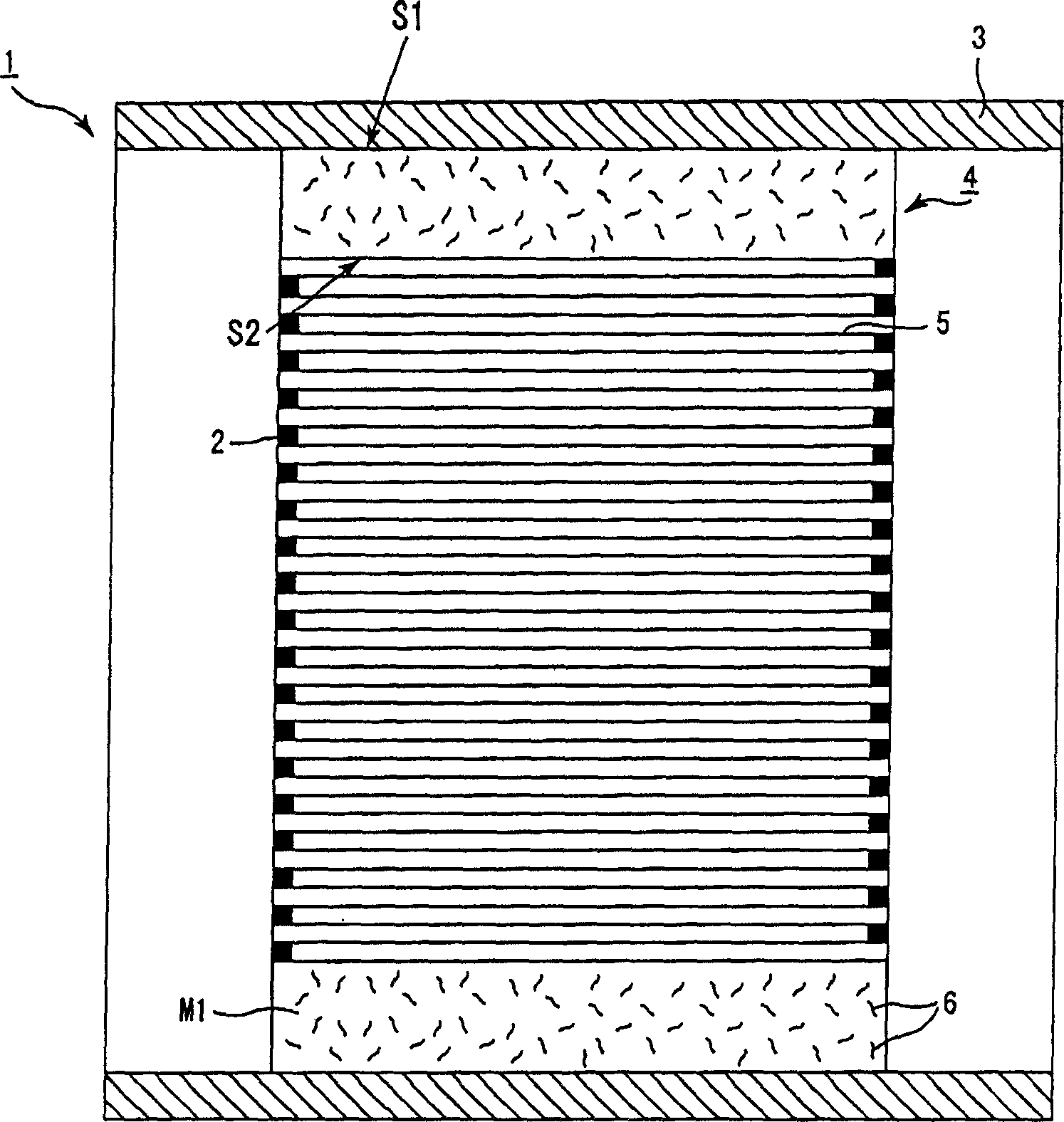

[0273] According to the production method of the embodiment of the first group of the present invention, the calcination step of sintering the precursor fibers is performed by heating the precursor fibers in an environment where the oxidation reaction of the carbon component contained in the precursor fibers is difficult to occur. Therefore, this makes it possible to retain a large amount of carbon components in the alumina-silica fiber 6, thus ensuring that the alumina-silica fiber 6 excellent in mechanical strength is easily obtained.

[0274] According to the preparation method of the first embodiment of the present invention, the environment for the calcination step adopts an inexpensive nitrogen atmosphere. Therefore, this can reduce the production cost of the fastening sealing material 4 . In addition, since the heating step is performed within the preferred calcination temperature range, this can stably obtain high-strength aluminum-silicon fibers 6 .

[0275] Accordin...

Embodiment 1

[0534] In Example 1, first, an alkaline aqueous solution of aluminum chloride (23.5% by weight), silica sol (20% by weight, the particle size of silica is 15 nm) and polyvinyl alcohol (10% by weight) were mixed so that A spinning stock solution is prepared, and the polyvinyl alcohol is a spinning performance imparting agent. Then, the resulting spinning stock solution was concentrated using an evaporator under vacuum at 50° C. to prepare a spinning stock solution having a concentration of 38% by weight and a viscosity of 1500 poise.

[0535] After the spinning stock solution is prepared, the spinning stock solution is continuously discharged into the air through the nozzles (perfect circular cross-section) of the spinning equipment, and the obtained precursor fiber is taken up while stretching.

[0536] Next, carry out heating step (pretreatment) to described precursor fiber, heat 30 minutes with electric furnace in 250 ℃, normal pressure and nitrogen atmosphere, then in the s...

Embodiment 2 and 3

[0545] In Examples 2 and 3, Al-Si fibers 6 were prepared in substantially the same order as in Example 1, except that the temperature and time of calcination were changed as shown in Table 1. As a result, aluminum silicon fibers 6 excellent in mechanical strength can be obtained.

[0546] In addition, when the samples for the surface pressure test were formed, the initial surface pressure, the surface pressure after the durability test, and the rate of decrease in the surface pressure with time were measured for these samples, and the optimal pressure was obtained in the same manner as in Example 1. results (see Table 1).

[0547] Of course, no changes in color and residual carbon content were observed.

[0548] In addition, a fastening sealing material 4 was prepared to manufacture a catalytic converter 1 , and a continuous running test was carried out after the catalytic converter 1 was equipped. As a result, during running, no noise was generated, and the catalyst carrier...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com