Continuous preparation method of chlorosulfonate

A technology for chlorosulfonate and chloride salt, which is applied in the field of continuous preparation of chlorosulfonate, can solve the problems of waste of energy consumption, large area of equipment, long production cycle, etc., so as to avoid the possibility of material leakage , Improve the production site environment, the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

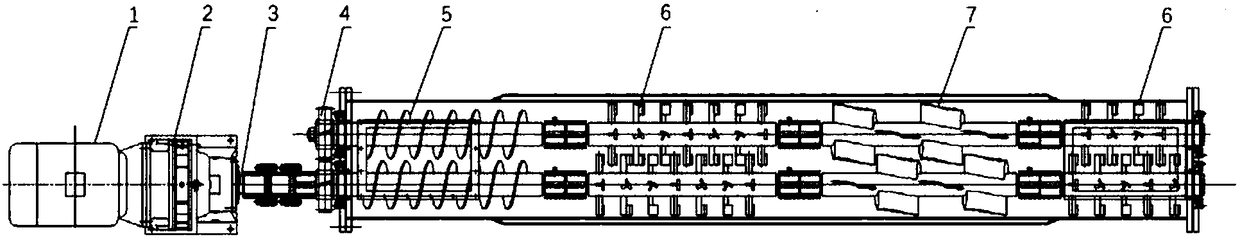

Image

Examples

Embodiment 1

[0029] Sodium chloride is stably and continuously input from the equipment inlet at a speed of 10Kg / min, sulfur trioxide is sprayed out through the dripping port on the equipment at a speed of 13.68Kg / min, the cooling water flow rate is 8m3 / h, and the cooling water temperature is 50°C, keep the reaction stable at 110-130°C, the frequency of the auger is 35HZ, and the reaction time is 15min to obtain sodium chlorosulfonate with a purity of 99.7% and a yield of 97.64%.

Embodiment 2

[0031] Sodium chloride is stably and continuously input from the equipment inlet at a rate of 15Kg / min, sulfur trioxide is sprayed out through the dripping port on the equipment at a rate of 20.51Kg / min, the cooling water flow rate is 7m3 / h, and the cooling water temperature is 45°C, keep the reaction stable at 110-130°C, the frequency of the auger is 30HZ, and the reaction time is 18min to obtain sodium chlorosulfonate with a purity of 99.5% and a yield of 98.37%.

Embodiment 3

[0033] Potassium chloride is stably and continuously input from the equipment inlet at a rate of 15Kg / min, sulfur trioxide is sprayed out at a rate of 20.51Kg / min through the dripping port on the equipment, the cooling water flow rate is 7m3 / h, and the cooling water temperature is 47°C, keep the reaction stable at 110-130°C, the frequency of the auger is 32HZ, and the reaction time is 17min to obtain potassium chlorosulfonate with a purity of 99.8% and a yield of 98.12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com