Improved manufacture method of one-piece golf bar head and products thereof

A technique for golf club heads and manufacturing methods, applied to golf balls, golf clubs, manufacturing tools, etc., to achieve the effects of avoiding welding processes, reducing deformation, and small deformation coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

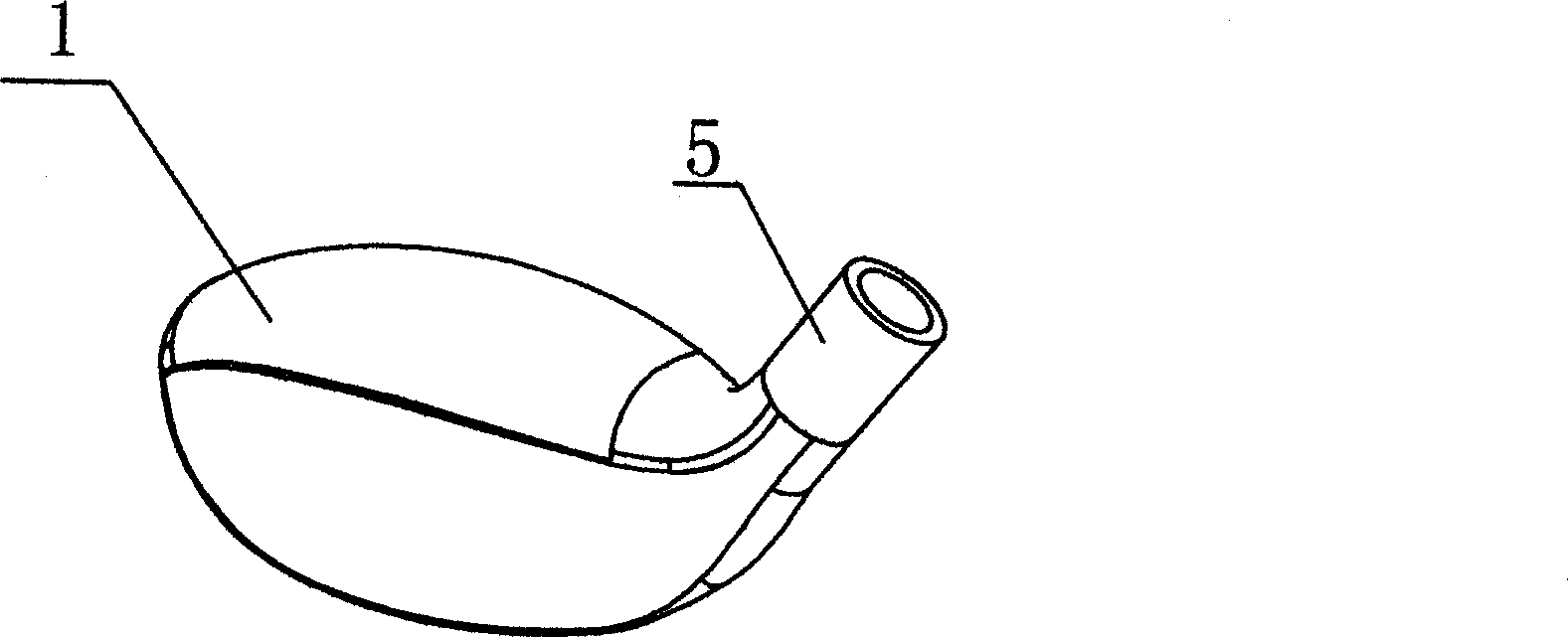

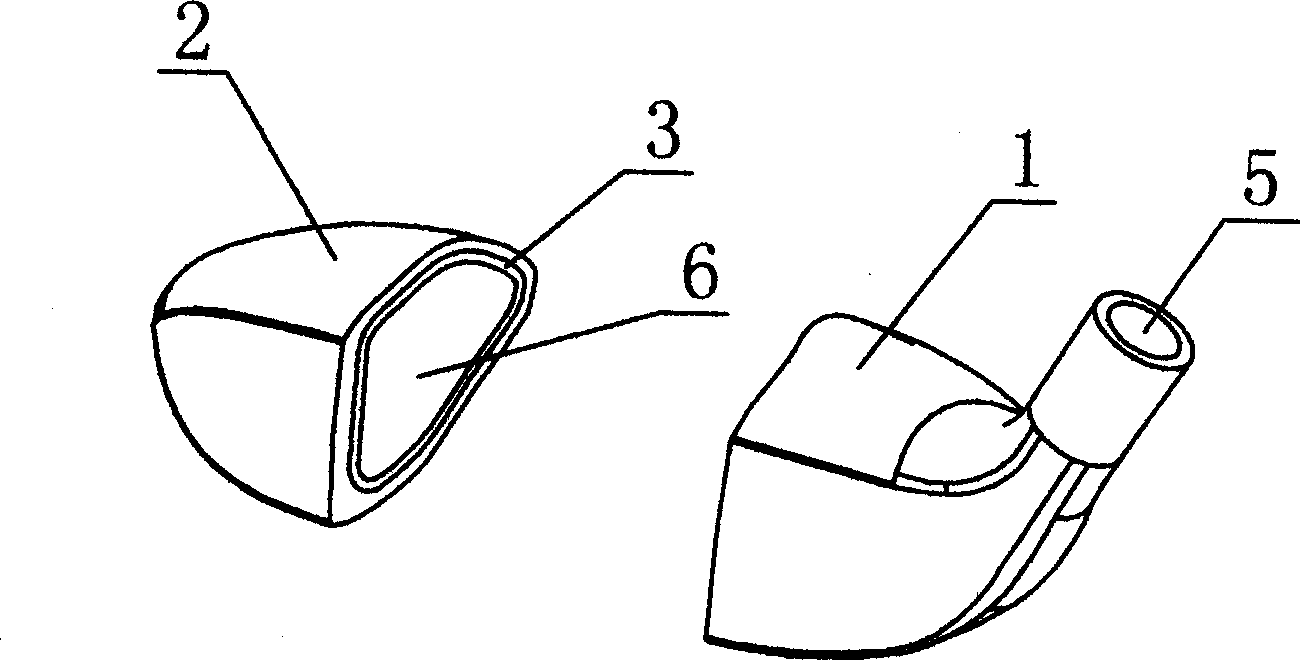

[0032] Example: see Figure 1 ~ Figure 4 , an improved manufacturing method for an integrated golf club head provided in this embodiment, comprising the following steps:

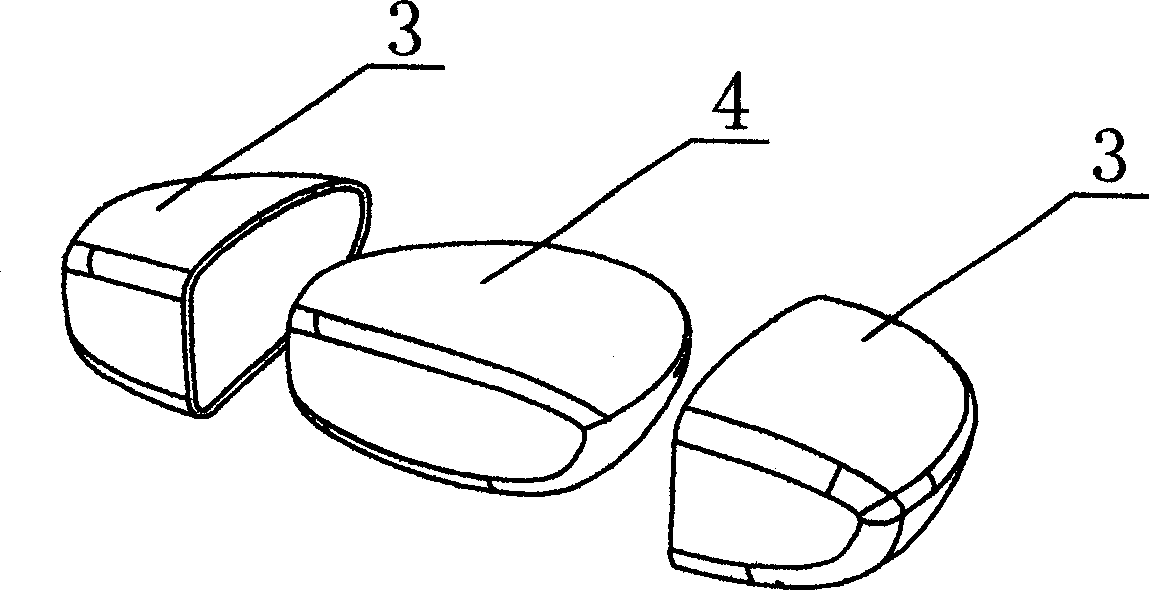

[0033] (1) Prefabricate an inner sleeve 3 with the same shape as the inner cavity of the golf club head 1 and a size approximately equal to the inner cavity of the golf club head by using a metal material with a higher melting point; and the inner sleeve 3 is provided with an opening ;

[0034] (2) Prepare the granular inner sleeve filler 4, put it into the inner cavity 6 of the inner sleeve 3 through the opening, and make it full and fill the inner sleeve cavity 6 to form a solid ;

[0035] (3) Prefabricate a club head die-casting mold 11;

[0036] (4) The inner sleeve 3 is physically fixed in the die-casting mold 11;

[0037] (5) Pouring metal liquid with a melting point not higher than the melting point of the metal material of the inner sleeve 3 into the mold 11 for die-casting; There is a cavity 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com