Manufacturing method of lightning-protection cable joint

A lightning protection cable and manufacturing method technology, applied in the assembly/disassembly of contacts, circuits, connections, etc., can solve problems such as damage to blades, and achieve the effects of good mechanical properties, excellent fire and heat insulation performance, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

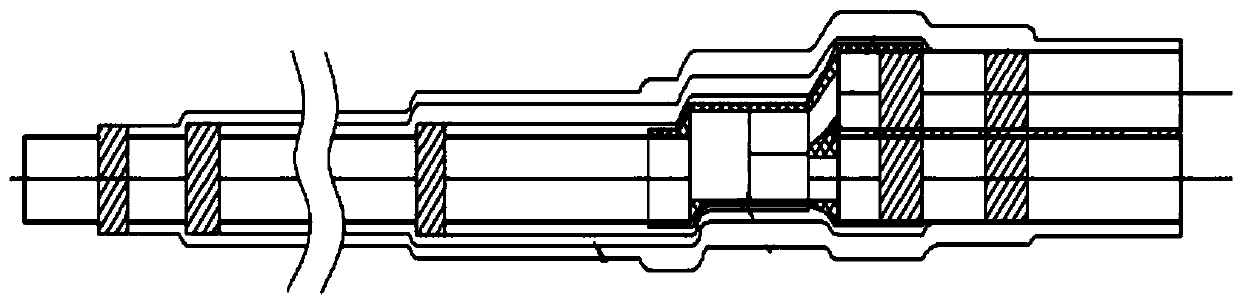

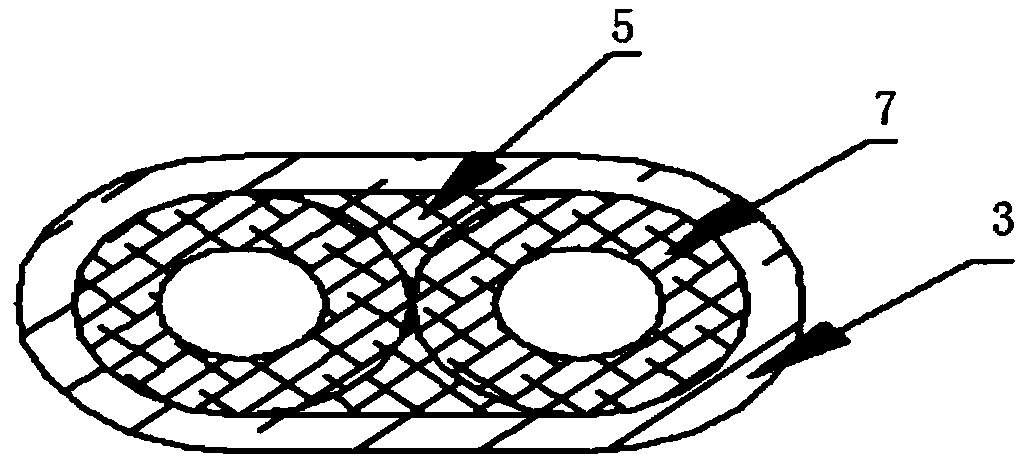

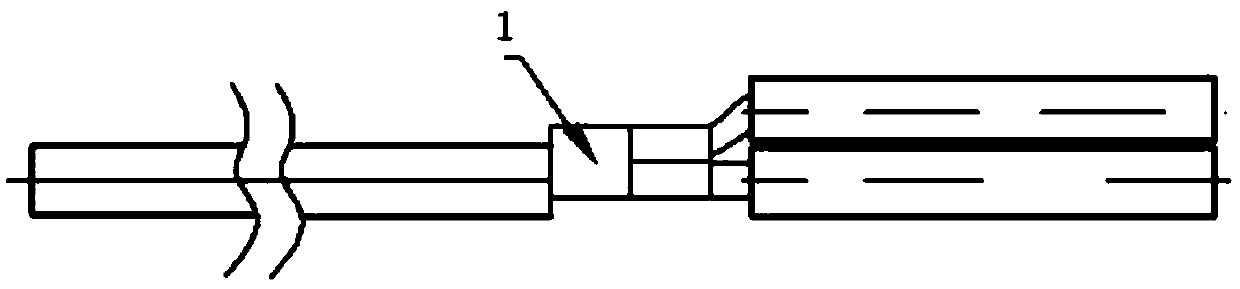

[0039] like Figures 3 to 5 Shown, the manufacturing method of lightning protection cable joint of the present invention, it comprises the following steps:

[0040] a, to lightning cable 7 and branch cable thereof, carry out the insulating layer stripping of fixed distance;

[0041] b. Pass the joint 1 of the branch cable together with the metal wire core of the lightning protection cable through the C-type clamp, first tighten it in the forward direction, and then tighten it in the opposite direction with the C-type clamp next to it;

[0042] c. Use a hydraulic crimping machine to start pressing from the branch cable joint 1. At least one-third of the molds need to be stacked. Each mold should be pressed above 70 MPa and held for 10 seconds; until it is clamped. The C-type clamp is fully pressed;

[0043] d. Apply cable structural adhesive 2 to the crimping part of the branch cable, wait for the cable structural adhesive 2 to solidify and fix, and then insert the Y-shaped h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com