High-safety diaphragm as well as preparation method and application thereof

A high-safety, diaphragm technology, applied in the battery field, can solve the problems of reducing the flexibility of the diaphragm, limited thermal stability improvement, internal short circuit, etc., to reduce the probability of thermal runaway and combustion, good thermal stability and tensile strength. , the effect of good mechanical toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

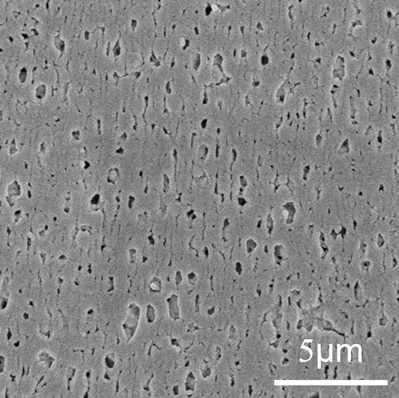

[0093] Mix polytetrafluoroethylene (molecular weight 30,000) and granular alumina (particle size 50nm) at a ratio of 40% and 60%, and after uniform dispersion for 60 minutes, add a plasticizer (volume ratio of paraffin oil to dichloromethane 3:1), control the solid content (polytetrafluoroethylene and alumina content) at 65%. After continuing to heat (50 °C) and stirring for 60 min, the solvent was evaporated to form mixed pellets. At this time, the mass proportion of the plasticizer was 20%.

[0094] The lamination is carried out by a hydraulic press, and the lamination pressure is 20MPa. The thickness of the primary sheet-shaped blank after the first lamination is 1mm; 4 layers of the primary sheet-shaped blank are stacked and laminated to form a secondary sheet-shaped blank. is 1 mm, and the thickness of each layer of secondary sheet-shaped blanks is 0.25 mm; the secondary sheet-shaped blanks are trimmed to form the sheet-shaped blanks.

[0095] The sheet-shaped blank is r...

Embodiment 2

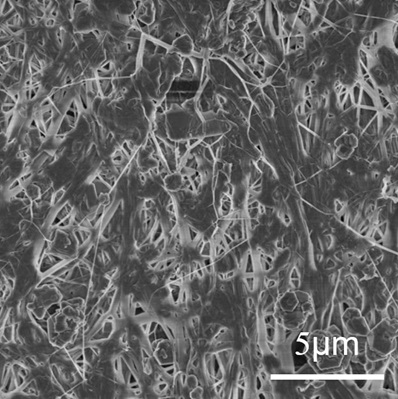

[0099] Mix polytetrafluoroethylene (molecular weight 30000) and fibrous alumina (particle size 200nm) at a ratio of 10% and 90%, and after uniform dispersion for 60 minutes, add plasticizer (volume ratio of paraffin oil and dichloromethane 3:1), control the solid content at 50%. After continuing heating (70 °C) and stirring for 60 min, the solvent was evaporated to form mixed pellets. At this time, the mass proportion of the plasticizer was 23%.

[0100] The lamination is carried out by a hydraulic press, and the lamination pressure is 20MPa. The thickness of the primary sheet-shaped blank after the first lamination is 1mm; 4 layers of the primary sheet-shaped blank are stacked and laminated to form a secondary sheet-shaped blank. is 1 mm, and the thickness of each layer of secondary sheet-shaped blanks is 0.25 mm; the secondary sheet-shaped blanks are trimmed to form the sheet-shaped blanks.

[0101] The sheet-shaped blank is rolled by a roller press to form a diaphragm, and...

Embodiment 3

[0105] Polytetrafluoroethylene (molecular weight 40,000), polyvinylidene fluoride (molecular weight 20,000), granular alumina (particle size 50nm) and flaky montmorillonite (particle size 2μm) at 40%, 20%, 25%, Mix at a ratio of 15%, and disperse evenly for 60 minutes, then add plasticizer (dichloromethane) to control the solid content at 50%. After continuing heating (70 °C) and stirring for 60 min, the solvent was evaporated to form mixed pellets. At this time, the mass proportion of the plasticizer was 15%.

[0106] Lamination is carried out by a hydraulic press, and the lamination pressure is 20 MPa. The thickness of the primary sheet-shaped blank after the first lamination is 1 mm; stack and laminate 4 layers of the primary sheet-shaped blank to form a secondary sheet-shaped blank. Its thickness is 1 mm, and the thickness of each layer of secondary sheet-shaped blanks is 0.25 mm; the secondary sheet-shaped blanks are trimmed to form the sheet-shaped blanks.

[0107] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com