High-capacity mesoporous carbon nanofiber for lithium-ion battery and preparation method of high-capacity mesoporous carbon nanofiber

A lithium-ion battery and nanofiber technology, which is applied in the fields of nanomaterials and new energy, can solve the problems of complex process flow, maintain at 400mAh, and the pore structure is not obvious, and achieve the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

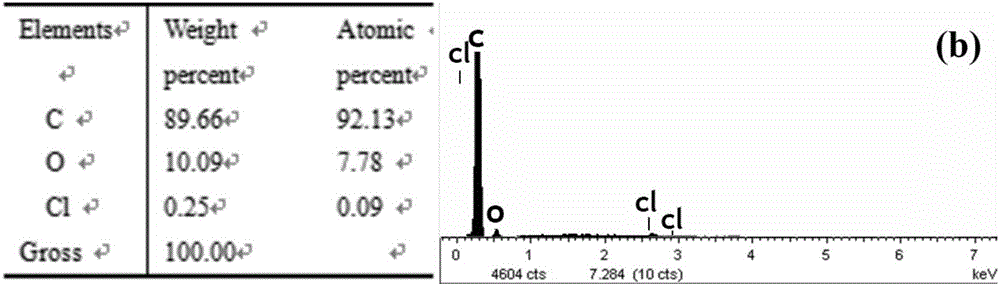

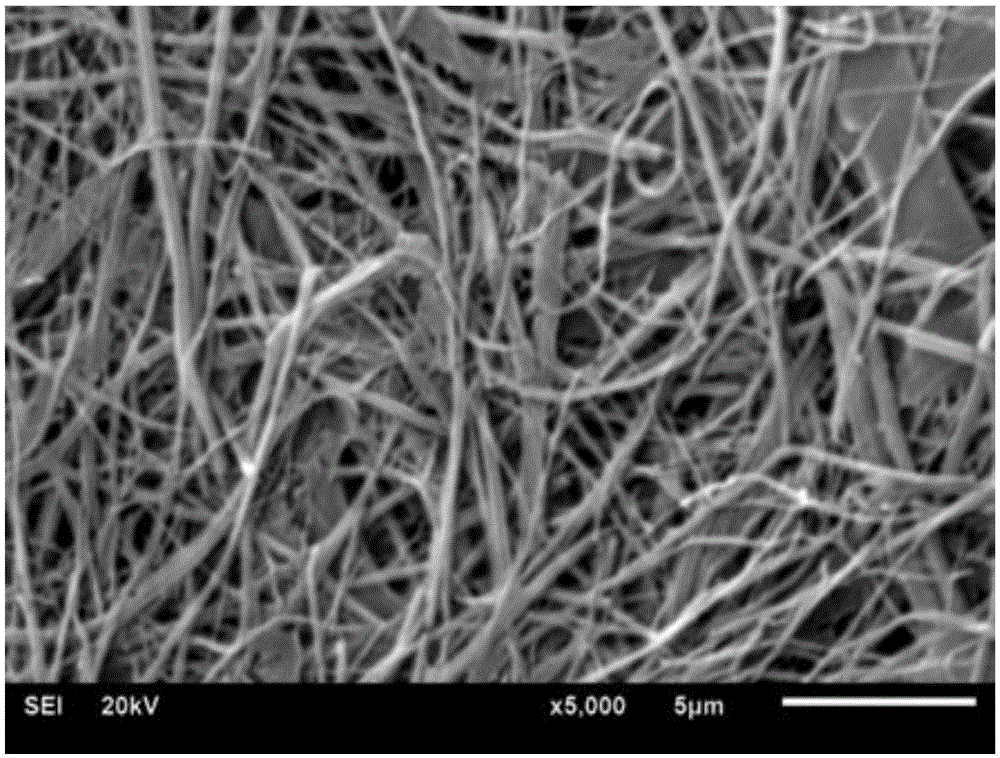

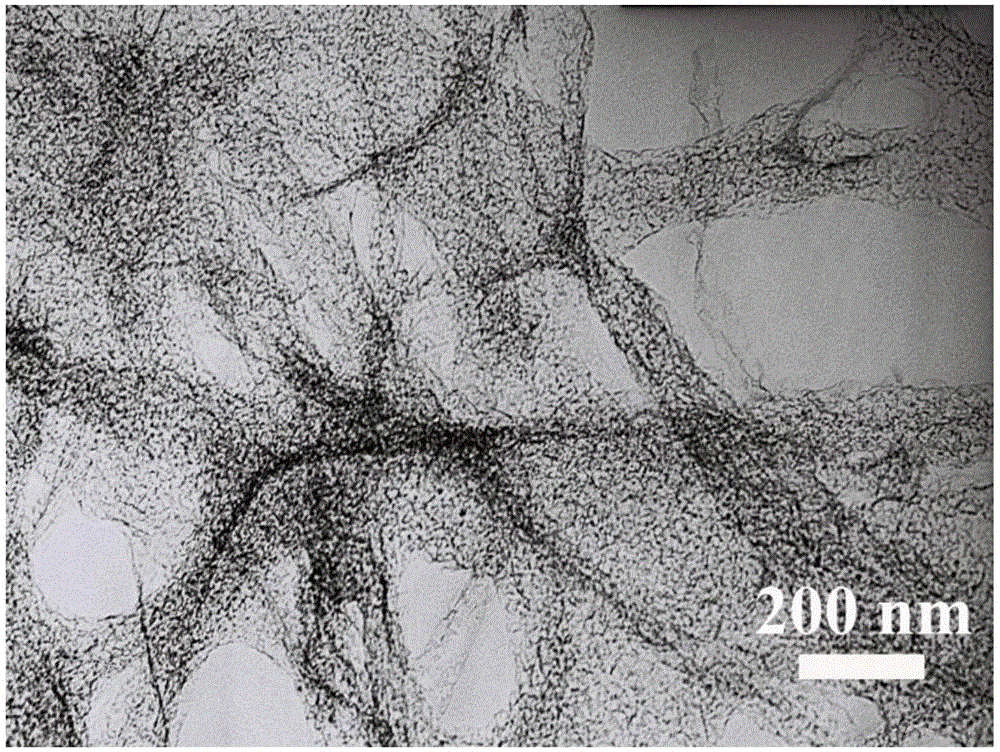

[0027] The uniformly dispersed fibrous calcium citrate was placed in a tube furnace, and under the protection of inert gas, the furnace temperature was raised to an activation temperature of 700 °C at a heating rate of 5 °C / min, and after holding for 2 hours, it was naturally cooled to room temperature; then The obtained carbonized product was taken out, and templates such as calcium oxide were removed by immersion in a 1 mol / L dilute hydrochloric acid solution, and washed with deionization for several times until neutral. The cleaned product was placed in a freeze dryer for drying, and finally obtained. mesoporous carbon nanofibers, and the obtained mesoporous carbon nanofibers were tested for physical and chemical properties such as morphology and structure.

[0028] Further, the mesoporous carbon nanofibers were used as the active material for battery assembly. First, the active material: the binder: the conductive agent was mixed uniformly at a mass ratio of 8:1:1, and then...

Embodiment 2

[0038] The uniformly dispersed fibrous calcium citrate was placed in a tube furnace, and under the protection of inert gas, the furnace temperature was raised to an activation temperature of 800 °C at a heating rate of 5 °C / min, and after holding for 2 hours, it was naturally cooled to room temperature; then The obtained carbonized product was taken out, and templates such as calcium oxide were removed by immersion in a 1 mol / L dilute hydrochloric acid solution, and washed with deionization for several times until neutral. The cleaned product was placed in a freeze dryer for drying, and finally obtained. mesoporous carbon nanofibers, and the obtained mesoporous carbon nanofibers were tested for physical and chemical properties such as morphology and structure.

[0039]Further, the mesoporous carbon nanofibers were used as the active material for battery assembly. First, the active material: the binder: the conductive agent was mixed uniformly at a mass ratio of 8:1:1, and then ...

Embodiment 3

[0042] The uniformly dispersed fibrous calcium citrate was placed in a tube furnace, and under the protection of inert gas, the furnace temperature was raised to an activation temperature of 700 °C at a heating rate of 5 °C / min, and after holding for 4 hours, it was naturally cooled to room temperature; then The obtained carbonized product was taken out, and templates such as calcium oxide were removed by immersion in a 1 mol / L dilute hydrochloric acid solution, and washed with deionization for several times until neutral. The cleaned product was placed in a freeze dryer for drying, and finally obtained. mesoporous carbon nanofibers, and the obtained mesoporous carbon nanofibers were tested for physical and chemical properties such as morphology and structure.

[0043] Further, the mesoporous carbon nanofibers were used as the active material for battery assembly. First, the active material: the binder: the conductive agent was mixed uniformly at a mass ratio of 8:1:1, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com