Multi-layer macropore-mesopore-micropore polymer-derived ceramic adsorption material and preparation method thereof

A microporous polymer and adsorption material technology, applied in the field of porous ceramic materials, can solve the problems of single pore size distribution, narrow pore size distribution, and low specific surface area of porous PCDs, and achieve the effects of low cost, improved adsorption performance, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

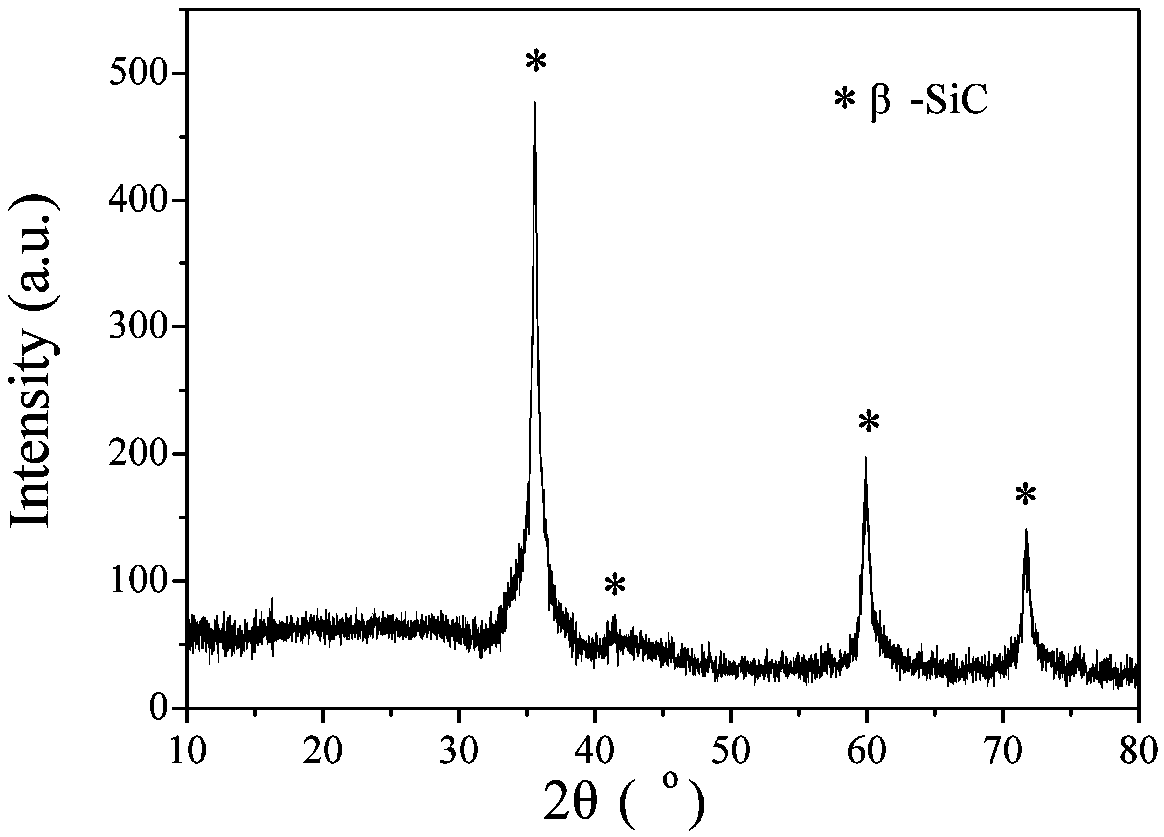

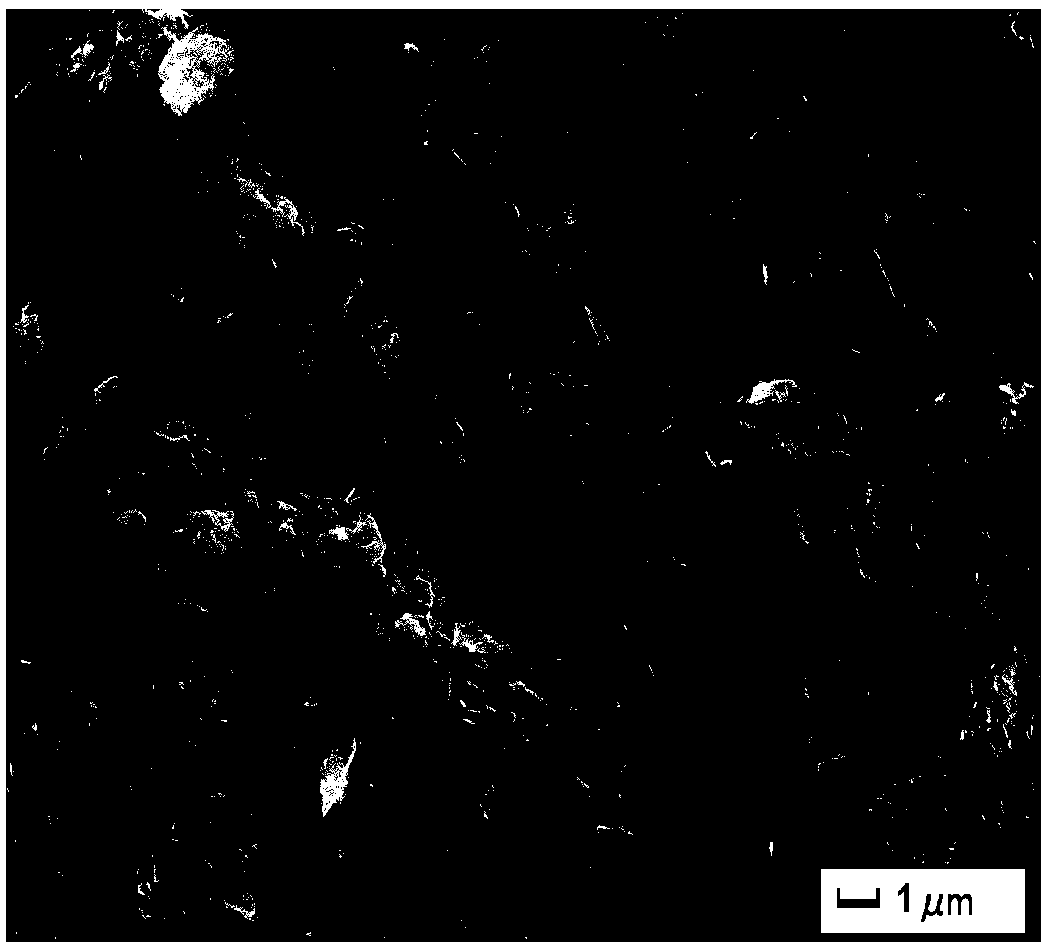

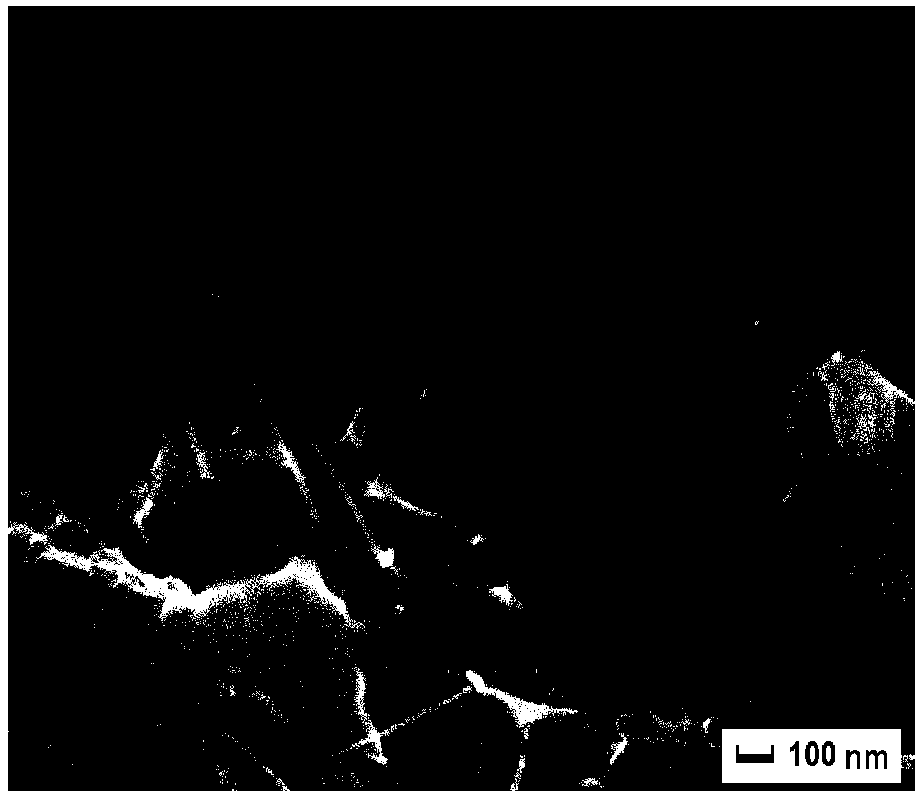

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0028] A method for preparing a multi-level macroporous-mesoporous-microporous polymer-derived ceramic adsorption material, comprising the following steps:

[0029] S01: Prepare solid polysiloxane; specifically: mix hydrogen-containing silicone oil, divinylbenzene, and chloroplatinic acid in a mass ratio of 6:3:1, and mix them uniformly by ultrasonic oscillation, then cross-link and solidify at 120°C to synthesize a solid Polysiloxane; wherein hydrogen-containing silicone oil is used as a polymer precursor, divinylbenzene is used as a crosslinking agent, and chloroplatinic acid solution is used as a catalyst; the concentration of the chloroplatinic acid solution is 11.3ppm; the crosslinking curing time is 12h.

[0030] S02: Sawdust and rice husks were crushed and screened...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com