Preparation method of 5A molecular sieve adsorbent

A molecular sieve and adsorbent technology, which is applied in the field of preparation of 5A molecular sieve adsorbent, can solve the problems of low molecular sieve strength and molecular sieve forming difficulties, and achieve the effects of increasing calcium ion exchange degree, reducing waste water discharge, and improving mass transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

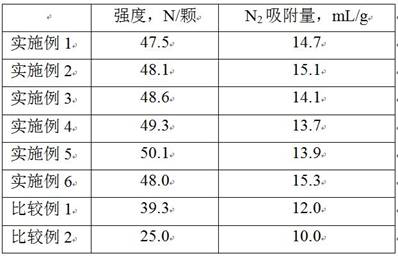

Examples

Embodiment 1

[0025] Mix 85g of NaA molecular sieve raw powder, kaolin with a mass fraction of 9g, 5g of sodium carbonate and 2g of starch, then knead the uniformly mixed material with 55g of water, and add the kneaded uniform mass into the extruder Extrude to obtain strip-shaped particles, put the strip-shaped particles into a spheronizer for spheronizing to obtain spherical particles; then dry the obtained spheres at 100° C. for 4 hours. The dried spherical adsorbent was roasted at 730°C for 3 hours once, and the roasted adsorbent was placed in a constant temperature and humidity box at a temperature of 95°C and a relative humidity of 90% for 3 hours, and then in 1mol / L CaCl 2 The solution was exchanged at 90°C for 3h, dried at 100°C for 4h, and then calcined at 350°C for 3h to obtain a spherical 5A molecular sieve adsorbent.

Embodiment 2

[0027] Mix 81g of NaA molecular sieve raw powder, 11g of kaolin, 10g of sodium carbonate and 3g of scallop powder, then knead the uniformly mixed material with 58g of water, and add the uniformly kneaded dough into the extruder Carry out extruding, and put the obtained strip-shaped particles into a spheronizer for spheronizing to obtain spherical particles, and then dry the obtained spherical particles at 120° C. for 1.5 hours. The dried spherical adsorbent was roasted once at 680°C for 7 hours, and the roasted adsorbent was placed in a constant temperature and humidity box at a temperature of 70°C and a relative humidity of 100% for 7 hours, and then heated at 0.5mol / L Ca solution (where, OH - :Cl - =1:100), exchanged at 70°C for 6h, dried at 120°C for 1.5h, and then calcined at 320°C for 4h to obtain spherical 5A molecular sieve adsorbent.

Embodiment 3

[0029] Mix 75g of NaA molecular sieve raw powder, 14g of kaolin, 13g of sodium carbonate, 2g of starch and 0.5g of tannin extract, then fully knead the uniformly mixed material with 54g of water, and add the kneaded uniform mass to the extruder Extrude the strips in the strip machine, put the obtained strip-shaped particles into a spheronizer for spheronizing to obtain spherical particles, and then dry the obtained spherical particles at 70°C for 12 hours. The dried spherical adsorbent was once calcined at 630°C for 7h, put the calcined adsorbent into deionized water at a temperature of 98°C for 3h, and then in 2mol / L Ca solution (wherein, OH - :Cl - =1:1000), exchanged at 95°C for 1.5 h, dried at 130°C for 1 h, and then calcined at 370°C for 2 h to obtain a spherical 5A molecular sieve adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com