Ceramsite fired by doping high-silicon iron tailings and preparation method thereof

A technology of high-silicon iron tailings and ceramsite, which is applied to clay products, ceramic products, and other household appliances, can solve problems such as impacting the environment and hazards, and achieve the goals of reducing firing temperature, ensuring durability, and increasing fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

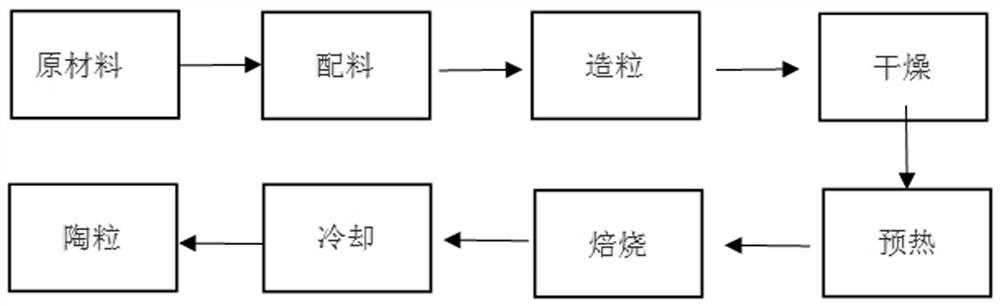

Image

Examples

Embodiment 1

[0051] A method for preparing ceramsite by using a high-silicon iron tailings firing process, the steps are as follows.

[0052] 1) Raw material pretreatment: Clean up sundries, mix and grind the raw materials in proportion, pass through a 100-mesh standard sieve, and put the materials in a dry place to dry to keep the moisture content at 10%-15%. 2) Ingredients: in parts by mass, 60 parts of high-silicon iron tailings, 15 parts of red mud, 12 parts of montmorillonite, 5 parts of pulverized coal, and 8 parts of kitchen waste. Mix the raw materials accurately according to the ratio. 3) Granulation: Mix and stir the raw materials for 5 minutes, add the mixed raw materials into the granulator, add an appropriate amount of water to humidify during the startup of the equipment, adjust the speed and inclination to roll the raw materials until they are formed, and screen out the granules with a sieve Raw balls with a diameter in the range of 15mm-20mm. 4) Drying: In order to ensure...

Embodiment 2

[0055] A method for preparing ceramsite by using a high-silicon iron tailings firing process, the steps are as follows.

[0056] 1) Raw material pretreatment: Clean up sundries, mix and grind the raw materials in proportion, pass through a 100-mesh standard sieve, and put the materials in a dry place to dry to keep the moisture content at 10%-15%. 2) Ingredients: in parts by mass, 65 parts of high-silicon iron tailings, 12 parts of red mud, 8 parts of montmorillonite, 7 parts of pulverized coal, and 8 parts of kitchen waste. Accurately weigh and mix the raw materials according to the ratio. 3) Granulation: Mix and stir the raw materials for 5 minutes, add the mixed raw materials into the granulator, add an appropriate amount of water to humidify during the startup of the equipment, adjust the speed and inclination to roll the raw materials until they are formed, and screen out the granules with a sieve Raw balls with a diameter in the range of 15mm-20mm. 4) Drying: In order ...

Embodiment 3

[0059] A method for preparing ceramsite by using a high-silicon iron tailings firing process, the steps are as follows.

[0060] 1) Raw material pretreatment: Clean up sundries, mix and grind the raw materials in proportion, pass through a 100-mesh standard sieve, and put the materials in a dry place to dry to keep the moisture content at 10%-15%. 2) Ingredients: in parts by mass, 70 parts of high-silicon iron tailings, 10 parts of red mud, 7 parts of montmorillonite, 8 parts of coal powder, and 5 parts of kitchen waste. Accurately weigh and mix the raw materials according to the ratio. 3) Granulation: Mix and stir the raw materials for 5 minutes, add the mixed raw materials into the granulator, add an appropriate amount of water to humidify during the startup of the equipment, adjust the speed and inclination to roll the raw materials until they are formed, and screen out the granules with a sieve Raw balls with a diameter in the range of 15mm-20mm. 4) Drying: In order to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com