Method for continuously producing polyester functional master batch and polyester functional master batch

A technology of functional masterbatch and polyester, which is applied in the field of polyester functional masterbatch and continuous production of polyester functional masterbatch, which can solve the problems of uniform dispersion of difficult functional powder and difficult application of functional masterbatch, and achieve the improvement of structural uniformity , improve the uniformity of the structure, achieve the effect of precise proportion addition and highly uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

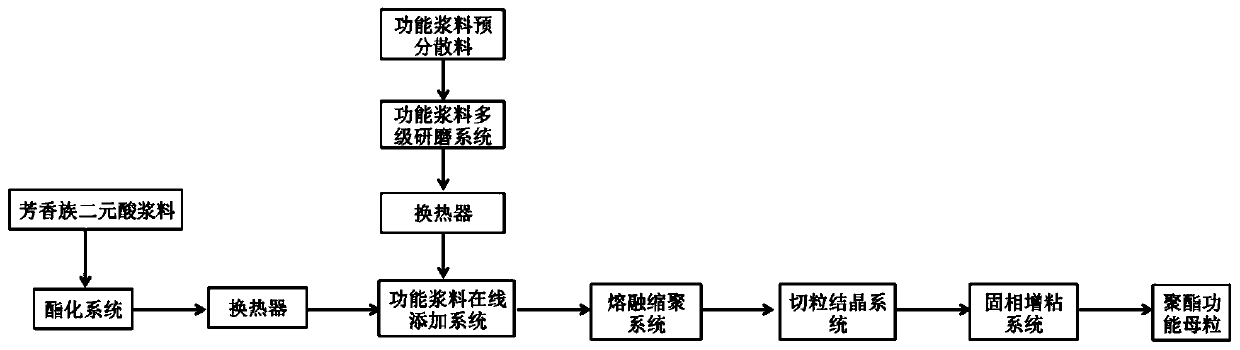

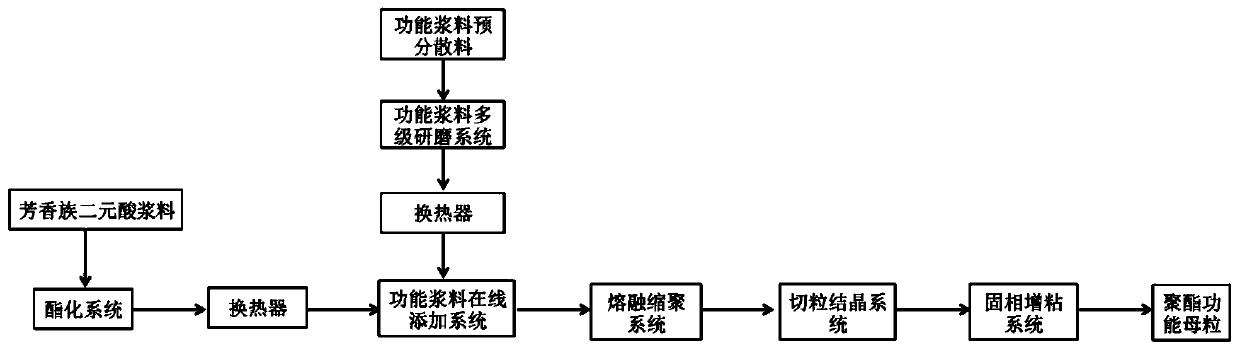

Method used

Image

Examples

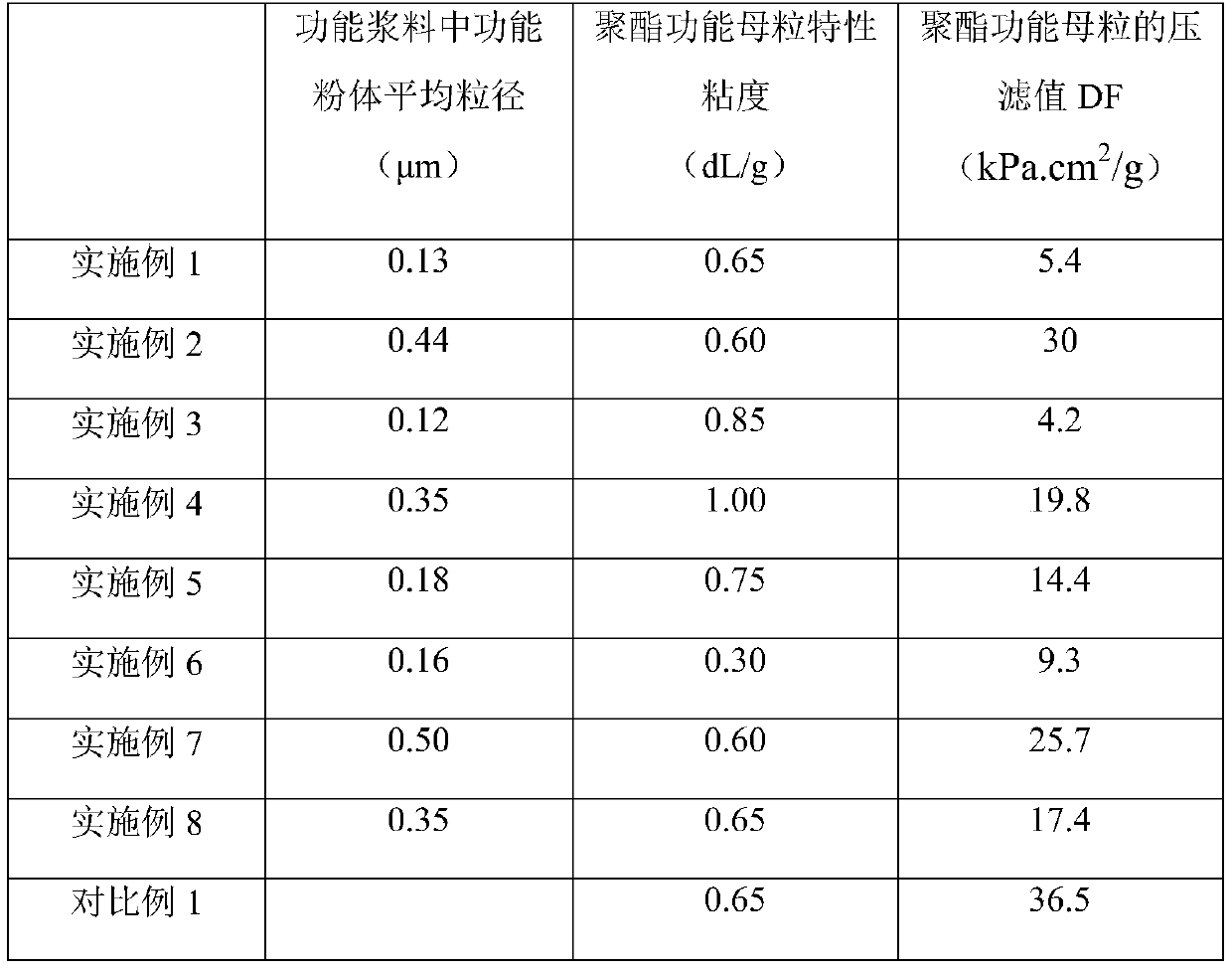

Embodiment 1

[0073] A method for continuously preparing polyester functional master batches, comprising the steps of:

[0074] A slurry prepared by preparing terephthalic acid, ethylene glycol and catalyst antimony ethylene glycol, the molar ratio of terephthalic acid to ethylene glycol in the slurry is 1:1.3, and the amount of antimony catalyst ethylene glycol is terephthalic acid 0.05% of the mass of formic acid; the obtained slurry is continuously and uniformly transported to an esterification system composed of a vertical esterification tank for esterification reaction, wherein the reaction temperature of the esterification tank is 280°C. When the acid value of the ethylene terephthalate oligomer reaches 30 mgKOH / g, the ethylene terephthalate oligomer is continuously and stably withdrawn from the esterification tank.

[0075] The antibacterial agent cuprous oxide and ethylene glycol are formulated into a functional slurry predispersion material at a mass ratio of 40:60. The obtained f...

Embodiment 2

[0080] A slurry formulated with terephthalic acid, ethylene glycol and catalyst tetraisopropyl titanate, the molar ratio of terephthalic acid to ethylene glycol in the slurry is 1:1.3, and the amount of catalyst tetraisopropyl titanate It is 0.004% of the mass of terephthalic acid; the obtained slurry is continuously and uniformly transported to an esterification system composed of a vertical esterification tank for esterification reaction, wherein the reaction temperature of the esterification tank is 260°C. When the acid value of the ethylene terephthalate oligomer reaches 40mgKOH / g, the ethylene terephthalate oligomer is continuously and stably withdrawn from the esterification tank.

[0081] The flame retardant zinc borate and ethylene glycol are formulated into a functional paste predispersion material at a mass ratio of 50:50. The obtained functional slurry pre-dispersed material is continuously and uniformly transported to a functional slurry multi-stage grinding system...

Embodiment 3

[0086] A slurry formulated with terephthalic acid, butanediol and catalyst tetrabutyl titanate, the molar ratio of terephthalic acid and butanediol in the slurry is 1:1.2, and the amount of catalyst tetrabutyl titanate is 0.4% of the mass of phthalic acid; the obtained slurry is continuously and uniformly transported to an esterification system composed of a vertical esterification tank for esterification reaction, wherein the reaction temperature of the esterification tank is 245°C. When the acid value of the butylene terephthalate oligomer reaches 10 mgKOH / g, the butylene terephthalate oligomer is continuously and stably withdrawn from the esterification tank.

[0087] The antibacterial agent silver oxide and butanediol were formulated into a functional paste predispersion at a mass ratio of 20:80. The obtained functional slurry pre-dispersed material is continuously and evenly transported to a functional slurry multi-stage grinding system formed by 5 grinding machines conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com