High-limestone-flour-adulterate-amount composite enhanced grinding aid for cement and preparation method of high-limestone flour-adulterate amount composite enhanced grinding aid

A technology of limestone powder and composite reinforcement, which is applied in the field of building materials, can solve the problems that high limestone powder cannot be satisfied, cement does not play a big role, and the performance is unstable, so as to improve the effect of grinding aid, prevent aggregation, and improve grinding aid. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

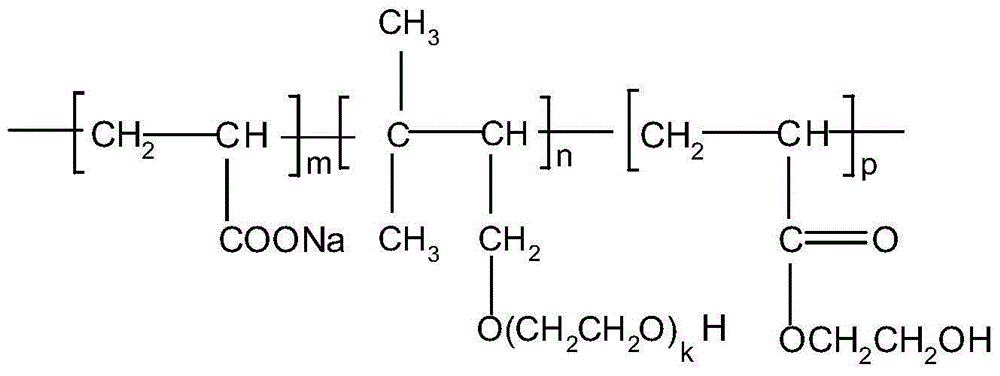

Method used

Image

Examples

Embodiment 1

[0022] A composite enhanced grinding aid suitable for cement with high limestone powder content. The raw materials are: 18% triethanolamine, 12% triisopropanolamine, 28% ethylene glycol, 8% molasses, Polycarboxylate superplasticizer is 6%, sodium sulfate is 8%, glacial acetic acid is 5%, water is 15%, pour water into a stirring pot, add sodium sulfate and stir until sodium sulfate is completely dissolved, add glacial acetic acid until completely dissolved After dissolving, add triethanolamine, triisopropanolamine, ethylene glycol, molasses and polycarboxylate superplasticizer in sequence, and continue stirring for 20 to 30 minutes to obtain the product, and then put it into the vapor deposition device according to 0.03% of the cement weight , in the process of ball milling, dispersed to the surface of cement clinker.

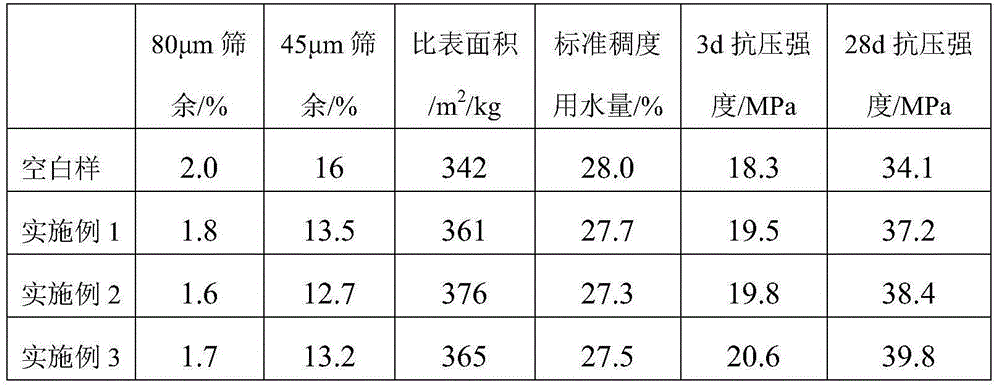

[0023] The raw material proportions of cement used in the examples are PC32.5R cement from Enshi Tenglong Cement Plant as an example, wherein: the obtained ceme...

Embodiment 2

[0026] A composite enhanced grinding aid suitable for cement with high limestone powder content. The raw materials are weighed: 20% triethanolamine, 10% triisopropanolamine, 25% ethylene glycol, 10% molasses, Polycarboxylate superplasticizer is 5%, sodium sulfate is 6%, glacial acetic acid is 8%, water is 16%, pour water into a stirring pot, add sodium sulfate and stir until sodium sulfate is completely dissolved, add glacial acetic acid until completely dissolved After dissolving, add triethanolamine, triisopropanolamine, ethylene glycol, molasses and polycarboxylate superplasticizer in sequence, and continue stirring for 20 to 30 minutes to obtain the product, and then put it into the vapor deposition device according to 0.03% of the cement weight , in the process of ball milling, dispersed to the surface of cement clinker.

[0027] The raw material proportions of cement used in the examples are PC32.5R cement from Enshi Tenglong Cement Plant as an example, wherein: the obta...

Embodiment 3

[0030] A composite enhanced grinding aid suitable for cement with high limestone powder content. The raw materials are: 24% triethanolamine, 13% triisopropanolamine, 20% ethylene glycol, 9% molasses, Polycarboxylate superplasticizer is 4%, sodium sulfate is 6%, glacial acetic acid is 6%, water is 18%, pour water into a stirring pot, add sodium sulfate and stir until sodium sulfate is completely dissolved, add glacial acetic acid until completely dissolved After dissolving, add triethanolamine, triisopropanolamine, ethylene glycol, molasses and polycarboxylate superplasticizer in sequence, and continue stirring for 20 to 30 minutes to obtain the product, and then put it into the vapor deposition device according to 0.03% of the cement weight , in the process of ball milling, dispersed to the surface of cement clinker.

[0031] The raw material proportions of cement used in the examples are PC32.5R cement from Enshi Tenglong Cement Plant as an example, wherein: the obtained ceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com