Process for preparing uropium-doped yttrium oxide @ silicon dioxide bean-shaped nano-cables

A nanocable, europium yttrium oxide technology, applied in nanostructure manufacturing, cable/conductor manufacturing, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

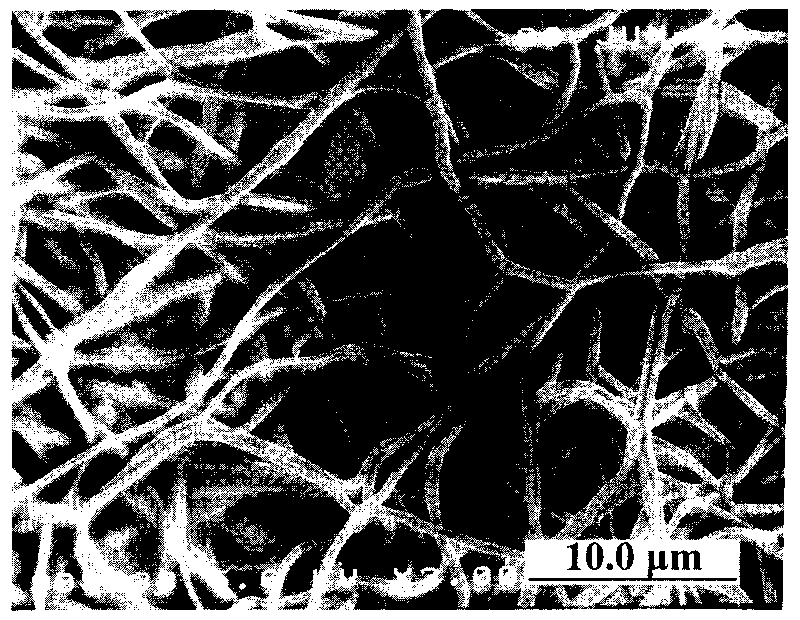

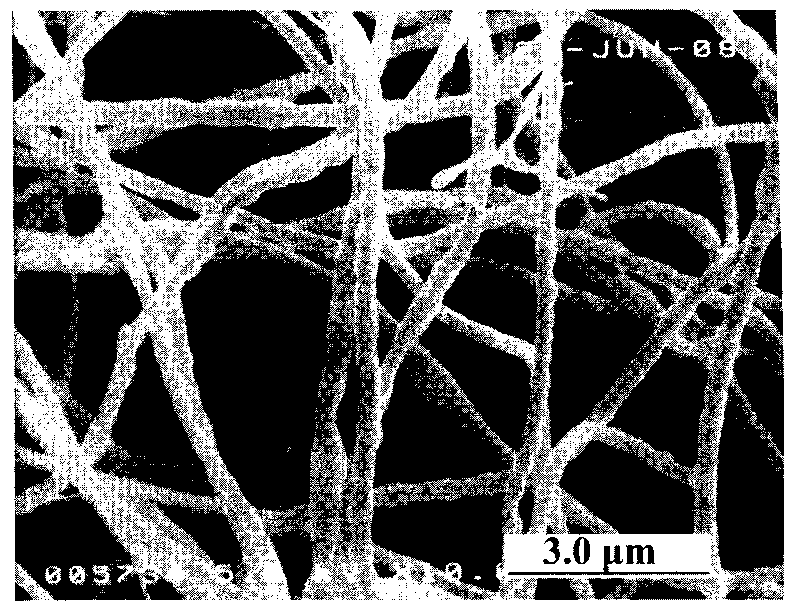

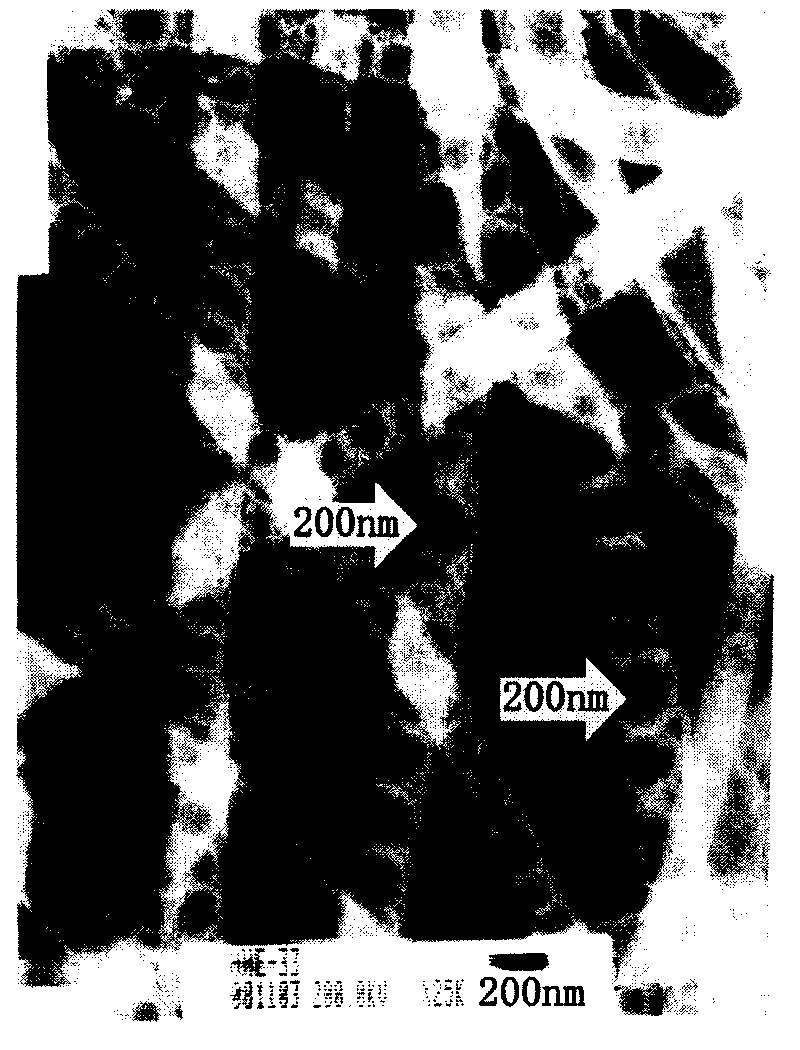

Image

Examples

Embodiment 1

[0018] Example 1: Weigh a certain amount of PVP (Mr=1300000), add it to the mixture (4:1) of absolute ethanol (AR) and tetraethylorthosilicate (AR), and stir it magnetically for 6 hours at room temperature After standing still for 3 hours, a uniform and clear shell spinning solution was obtained. The mass percentages of the substances in the shell spinning solution were: 12% of PVP, 68% of ethanol, and 20% of ethyl orthosilicate. Weigh a certain amount of Y 2 o 3 (99.99%), and then dissolve it with concentrated nitric acid, which should be gradually added dropwise and heated until completely dissolved to obtain transparent Y(NO 3 ) 3 solution, and then distill off excess concentrated nitric acid to obtain Y(NO 3 ) 3 Polycrystalline; then weigh a certain amount of PVP, add it to the mixed solution of DMF and glycerin (5:1), stir at room temperature for 3 hours, then add Y(NO 3 ) 3 , continue to stir for 6h and then leave it to stand for 3h to obtain a uniform core layer s...

Embodiment 2

[0019] Example 2: Weigh a certain amount of PVP (Mr=1300000), add it to the mixture (4:1) of absolute ethanol (AR) and tetraethylorthosilicate (AR), and stir it magnetically for 6 hours at room temperature After standing still for 3 hours, a uniform and clear shell spinning solution was obtained. The mass percentages of the substances in the shell spinning solution were: 12% of PVP, 68% of ethanol, and 20% of ethyl orthosilicate. Weigh a certain amount of Y 2 o 3 and Eu 2 o 3 (where Eu 3+ The mole fraction is 5%), then dissolve it with concentrated nitric acid, concentrated nitric acid should be gradually added dropwise and heated until completely dissolved to obtain transparent Y (NO 3 ) 3 and Eu(NO 3 ) 3 Mix the solution, then distill off the excess concentrated nitric acid to get Y(NO 3 ) 3 and Eu(NO 3 ) 3 Mix the polycrystals; weigh a certain amount of PVP again, add it to the mixed solution of DMF and glycerin (volume ratio is 5:1), stir at room temperature for...

Embodiment 3

[0020] Embodiment 3: take a certain amount of Y 2 o 3 and Eu 2 o 3 (where Eu 3+ The mole fraction is 5%), then dissolve it with concentrated nitric acid, concentrated nitric acid should be gradually added dropwise and heated until completely dissolved to obtain transparent Y (NO 3 ) 3 and Eu(NO 3 ) 3 Mix the solution, then distill off the excess concentrated nitric acid to get Y(NO 3 ) 3 and Eu(NO 3 ) 3 Mix the polycrystals; weigh a certain amount of PVP again, add it to the mixed solution of DMF and glycerin (volume ratio is 5:1), stir at room temperature for 3h, add Y(NO 3 ) 3 and Eu(NO 3 ) 3 The mixture was left to stand for 2 hours after continuing to stir for 4 hours to obtain a uniform core layer spinning solution, and the mass percentage of each substance in the core layer spinning solution was: Y(NO 3 ) 3 and Eu(NO 3 ) 3 8%, PVP 9%, Glycerin 18%, DMF 65%. Weigh a certain amount of PVP (Mr=1300000), add it into the mixture (4:1) of absolute ethanol (AR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com