Patents

Literature

39 results about "Ejecta" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ejecta (from the Latin: "things thrown out", singular ejectum) are particles ejected from an area. In volcanology, in particular, the term refers to particles including pyroclastic materials (Tephra) that came out of a volcanic explosion and magma eruption volcanic vent, or crater, has traveled through the air or under water, and fell back on the ground surface or on the ocean floor.

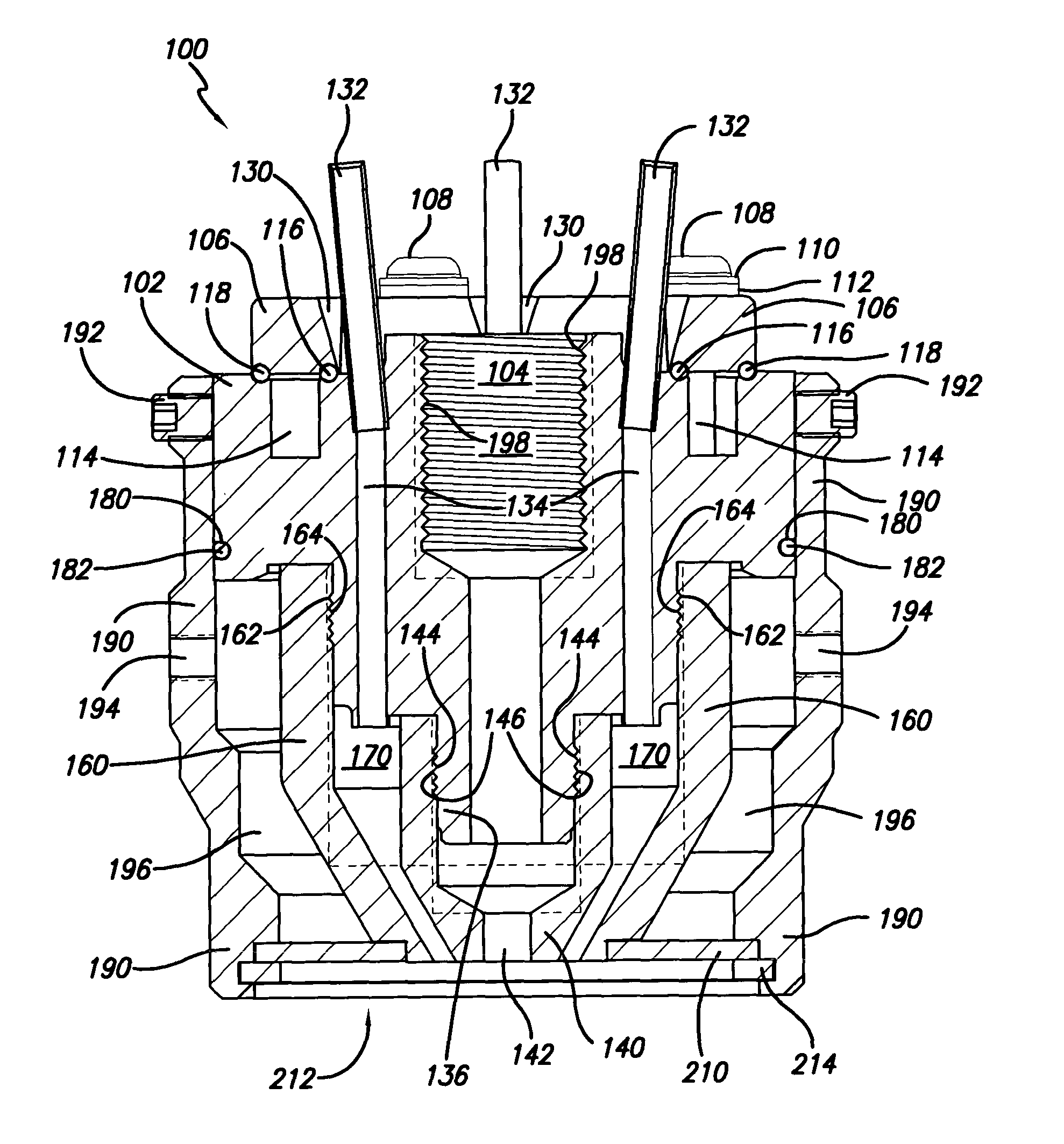

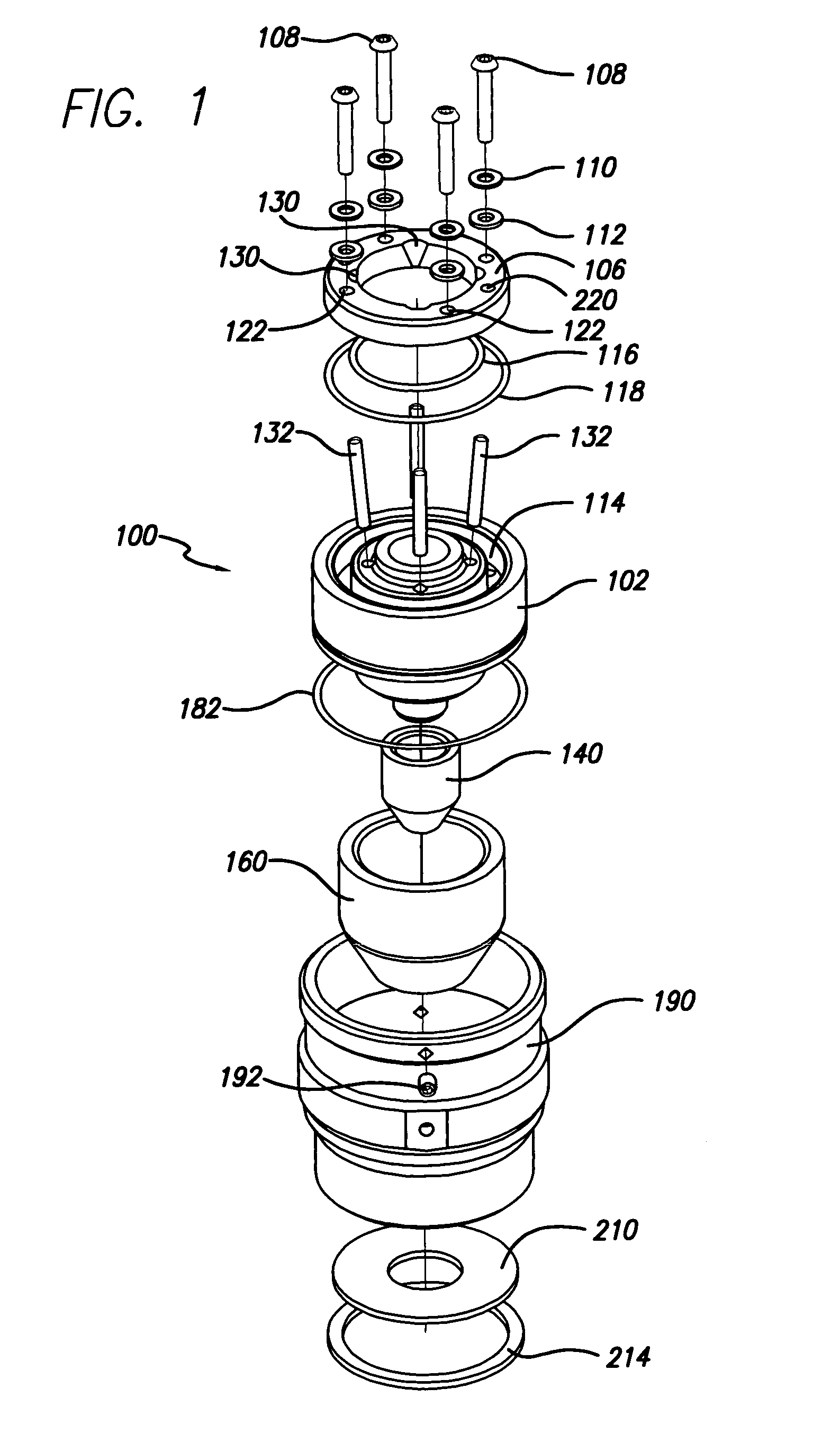

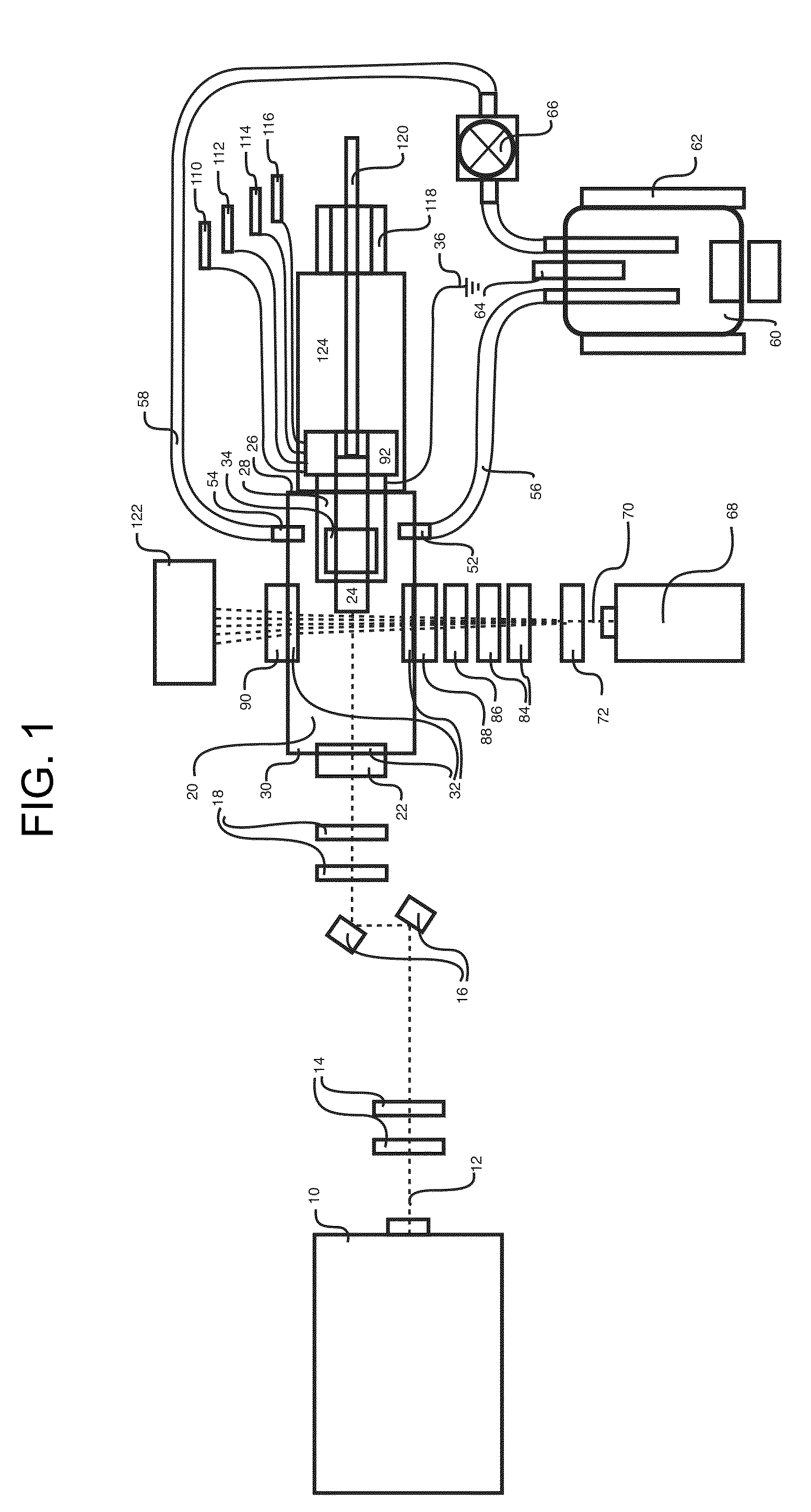

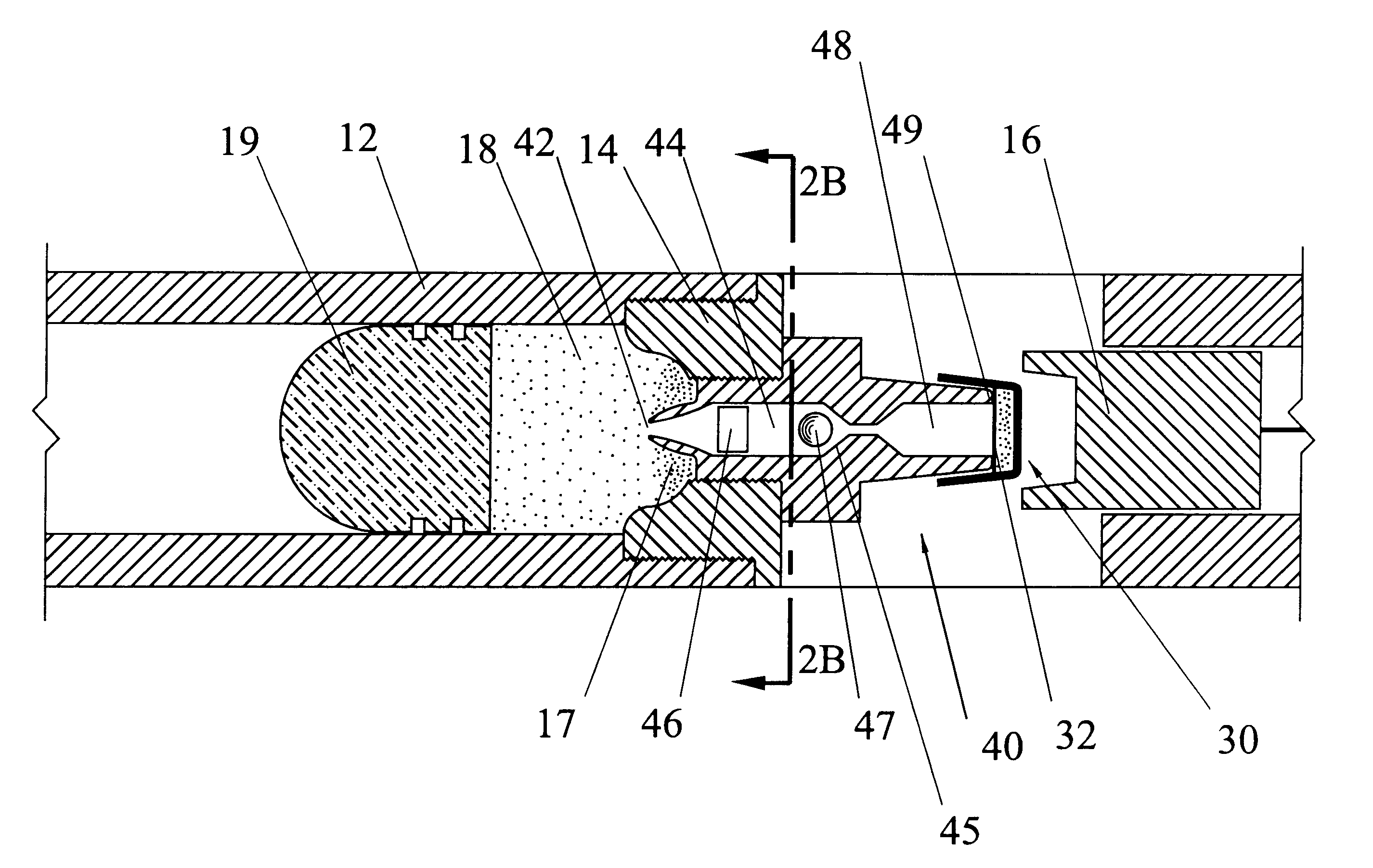

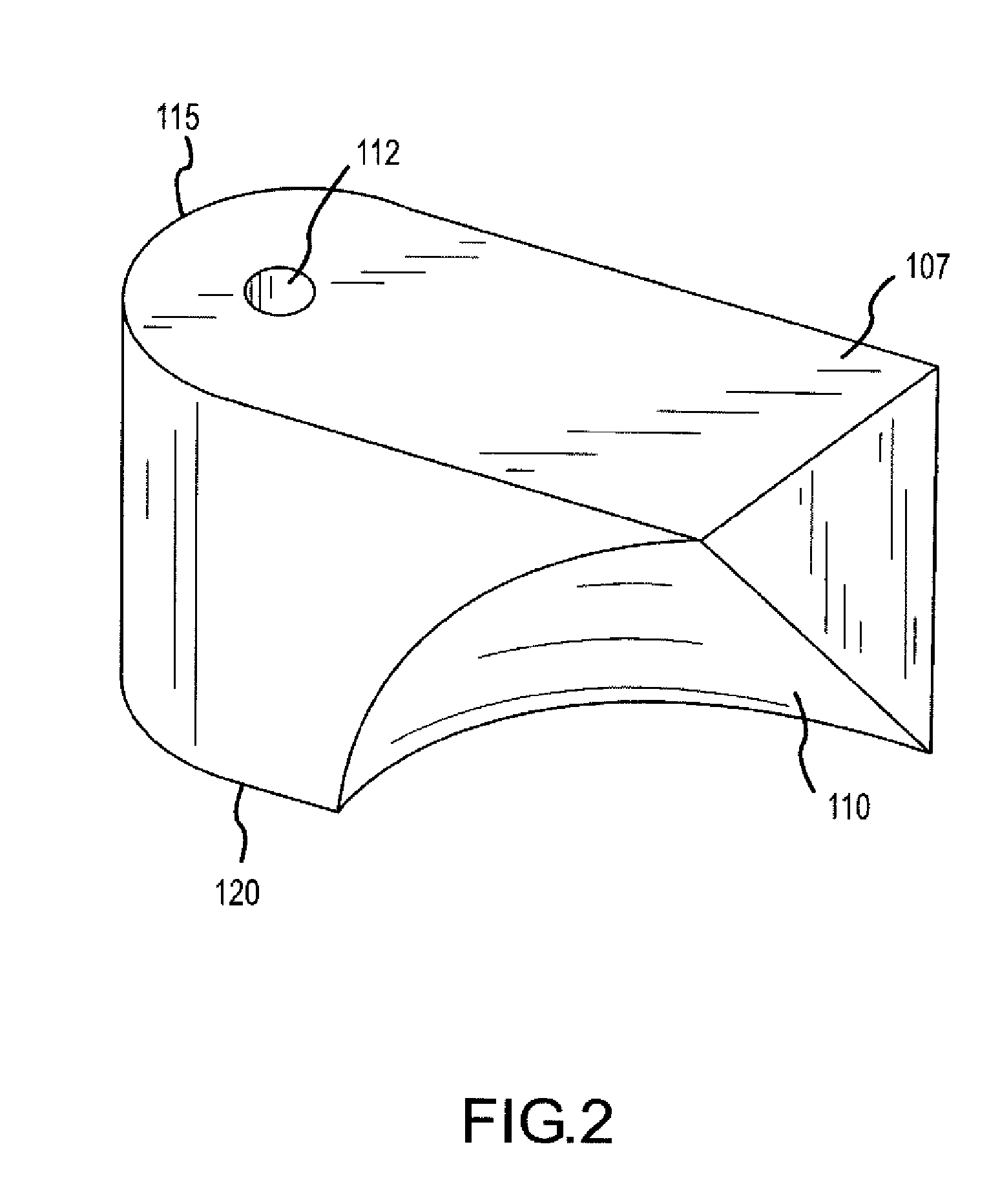

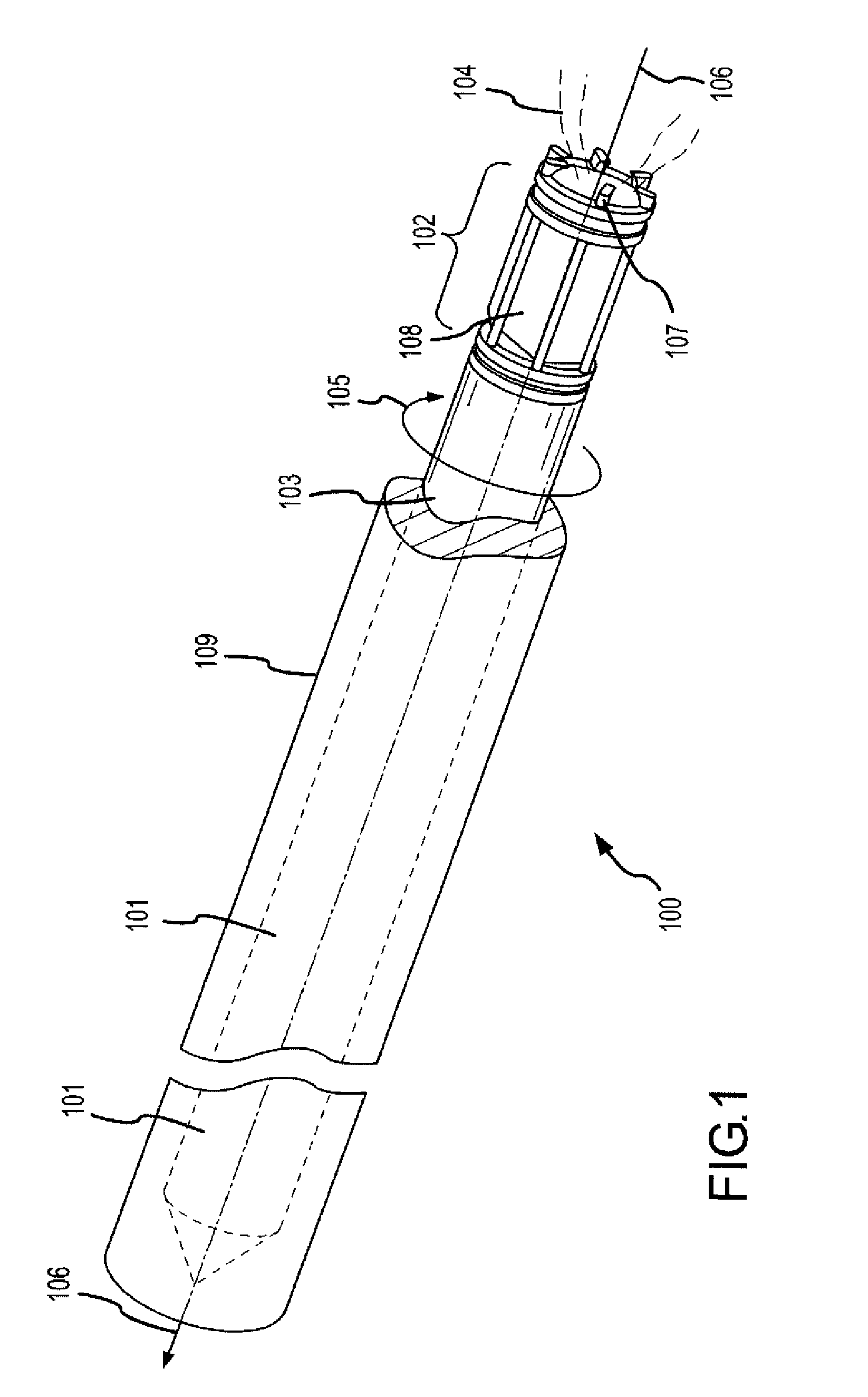

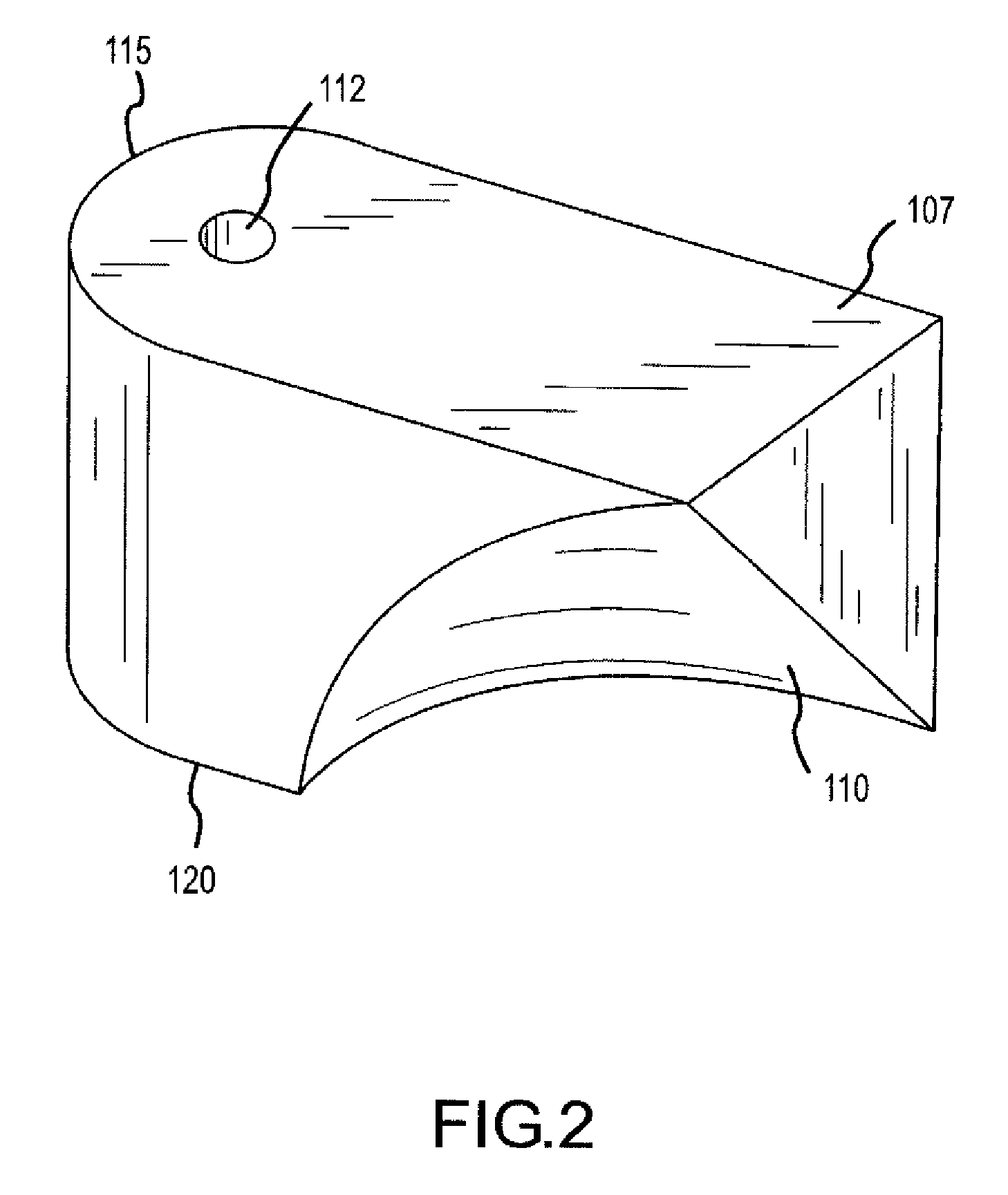

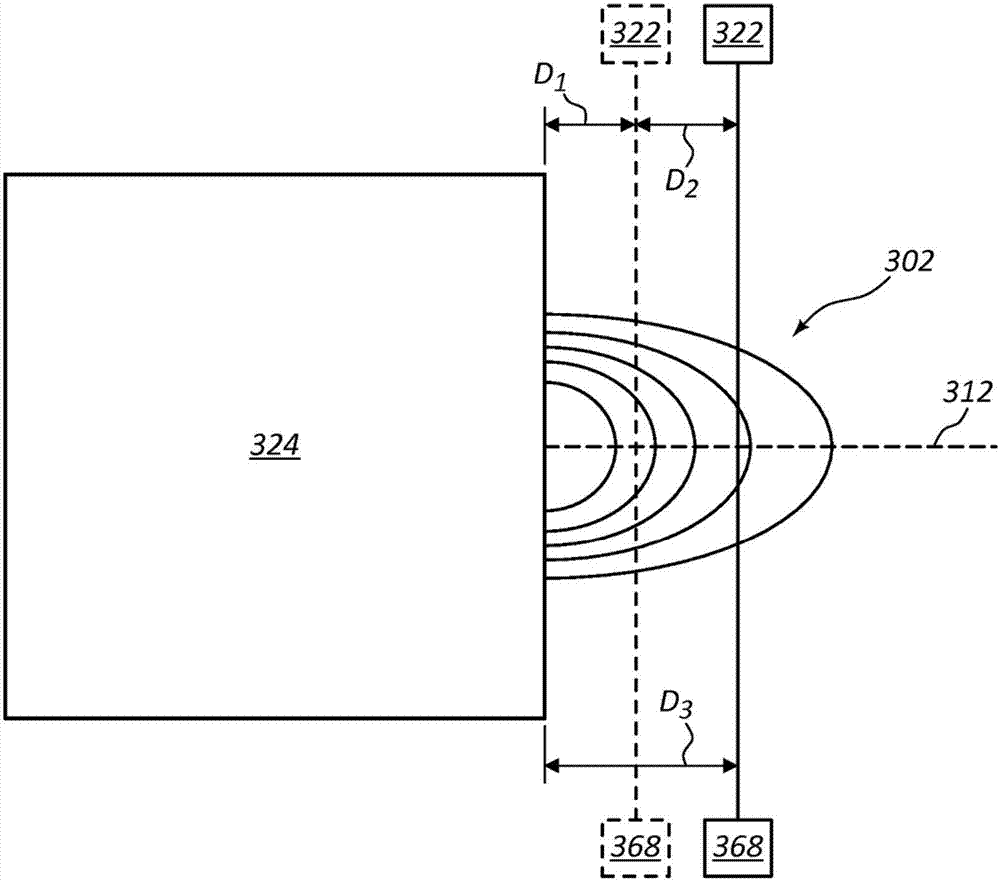

Coaxial nozzle design for laser cladding/welding process

InactiveUS20050056628A1Reliably-symmetric powder flowLong-term useLaser beam welding apparatusLaser NozzleShielding gas

A laser nozzle for use in a laser powder fusion (LPF) welding process provides longer service life and ease of maintenance. Eliminating the use of laser nozzle inserts, the laser nozzle uses an inner tip that is less subject to damage from the welding process. The laser beam travels down an open central passage to exit out the inner tip in focused alignment with a conical powder flow stream ending in a point generally coincident with the laser beam. The powder supply travels through a passage that is generally coaxial to the central laser passage. A circumscribing passage for inert shielding gas or the like is coincidentally coaxial with both the laser powder flow channel and the central laser channel. Coolant is circulated through a main body portion of the nozzle in order to keep the entire assembly cool. Both the laser and the flow of powder may be adjusted according to operating preferences. A porous shielding cover prevents ejecta and other materials from entering into the shielding gas flow channel. The entire assembly is easily constructed from readily available materials and is easily disassembled for cleaning. Reassembly is also easily achieved in order to enable rapid refurbishment and reconstitution of an optimal LPF welding nozzle.

Owner:HONEYWELL INT INC

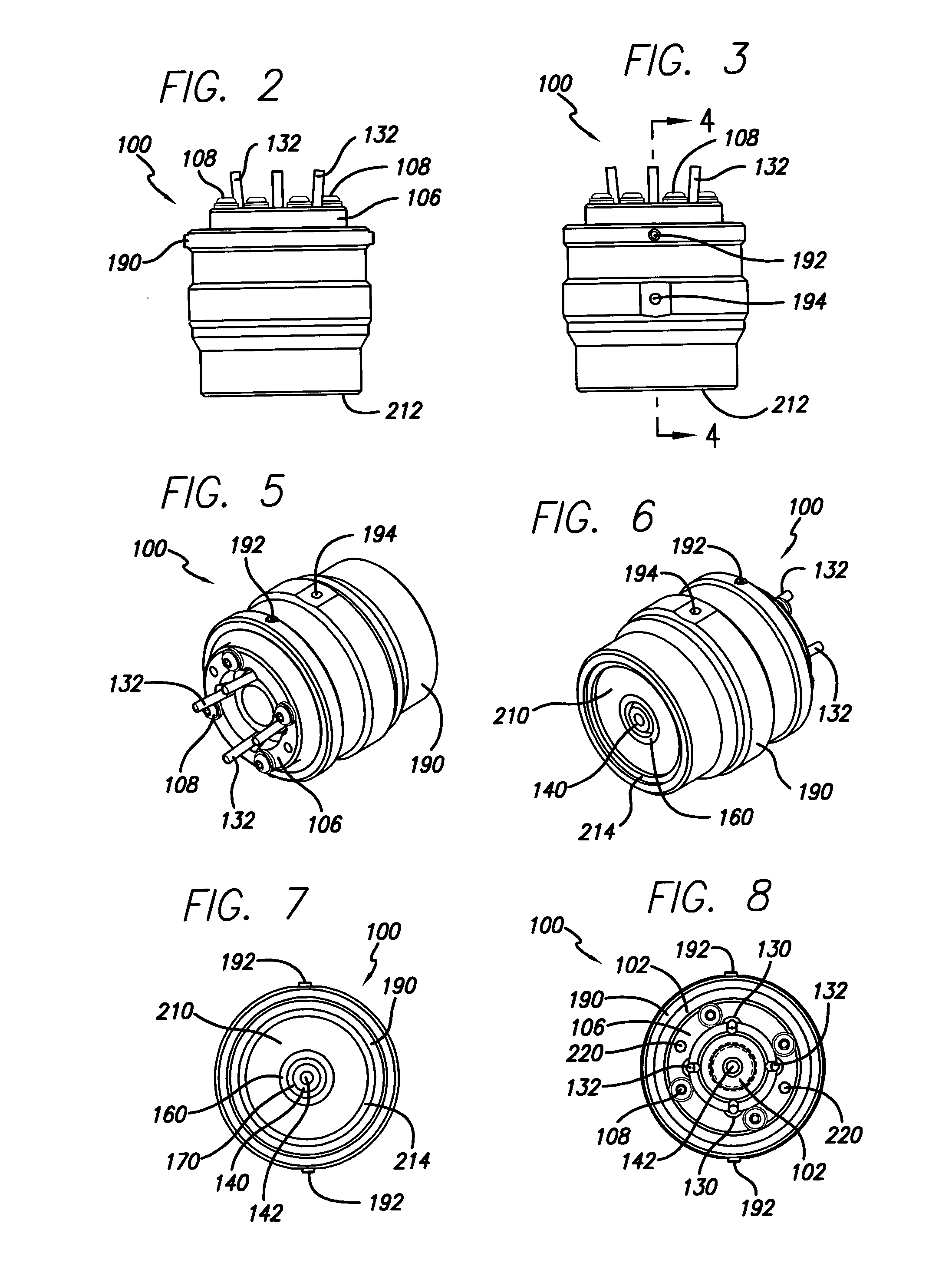

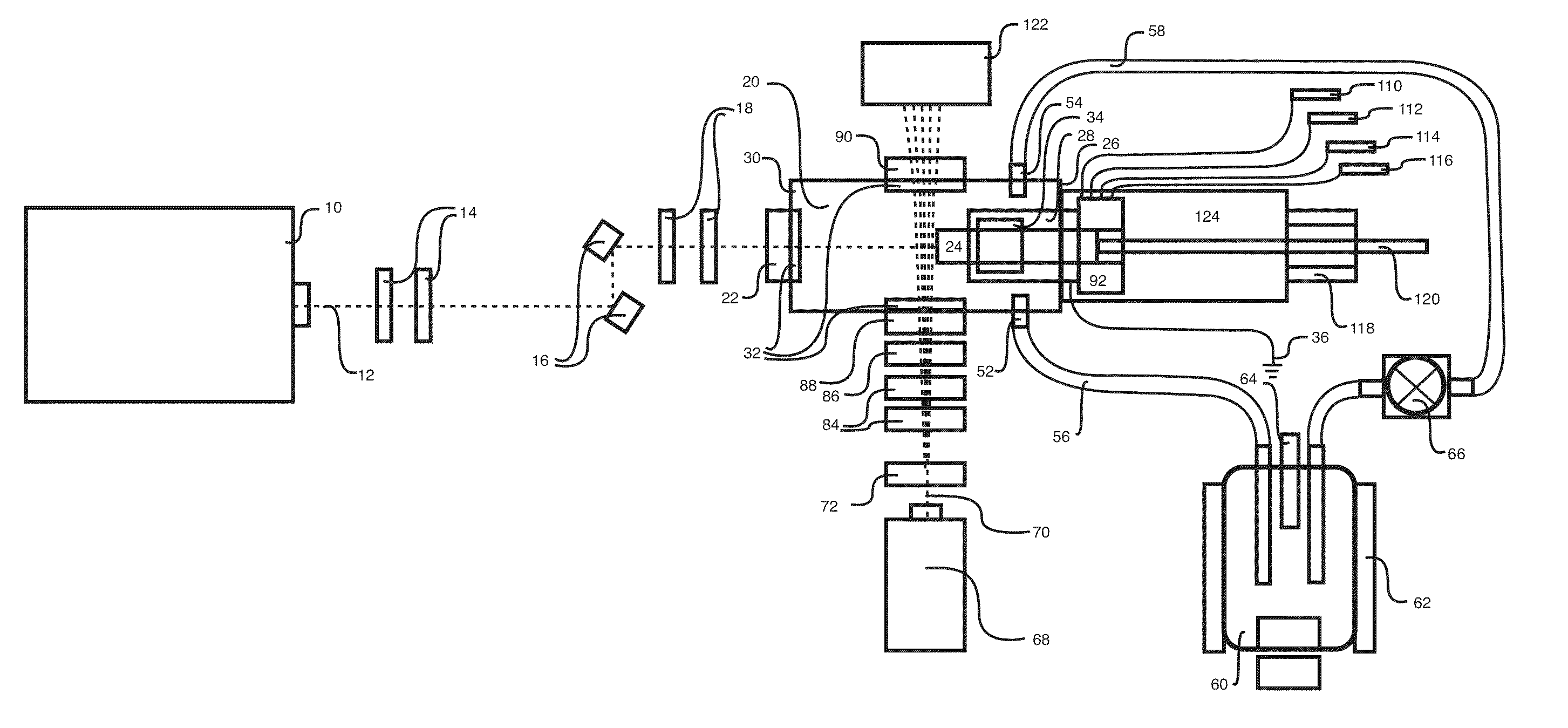

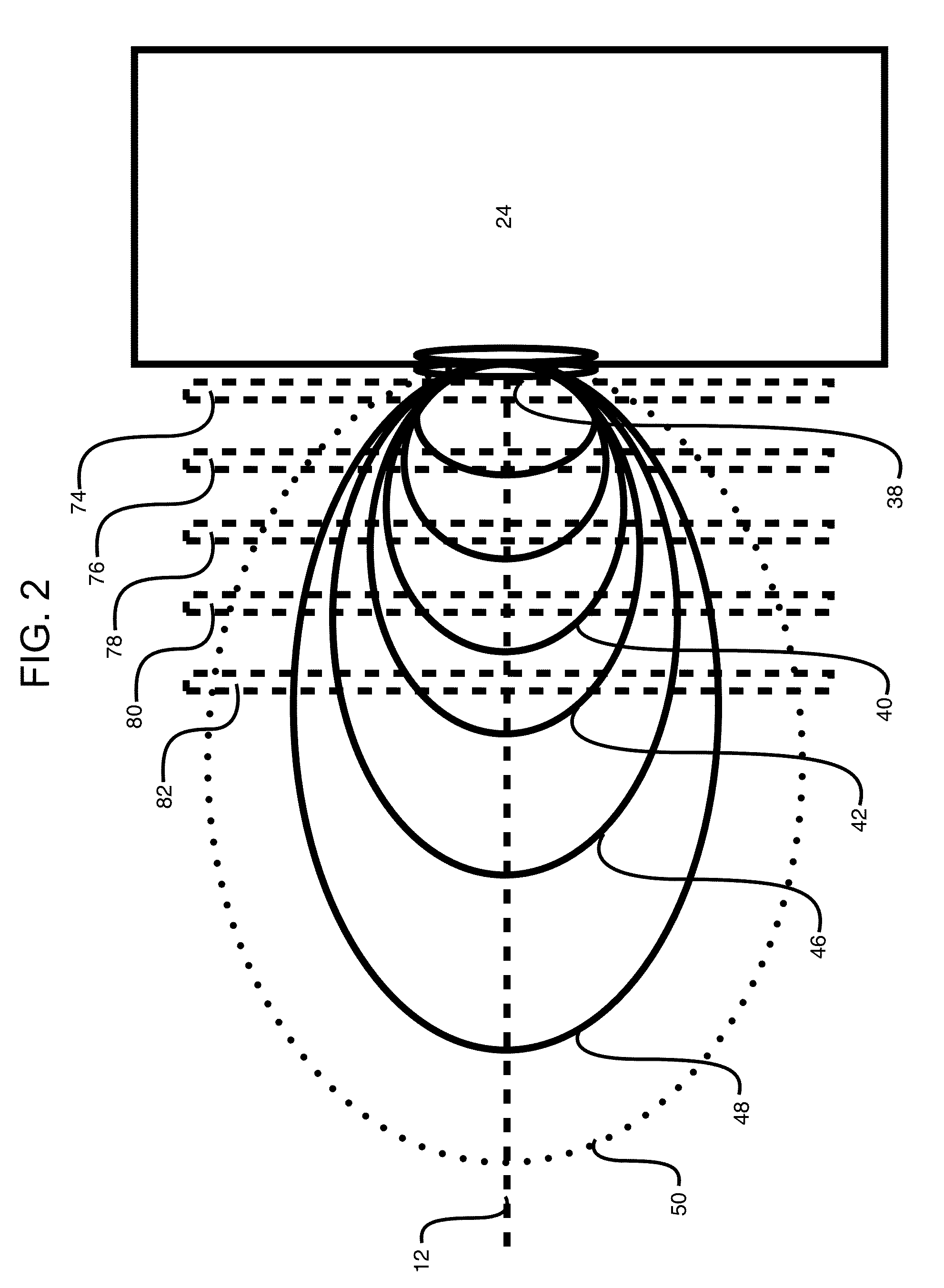

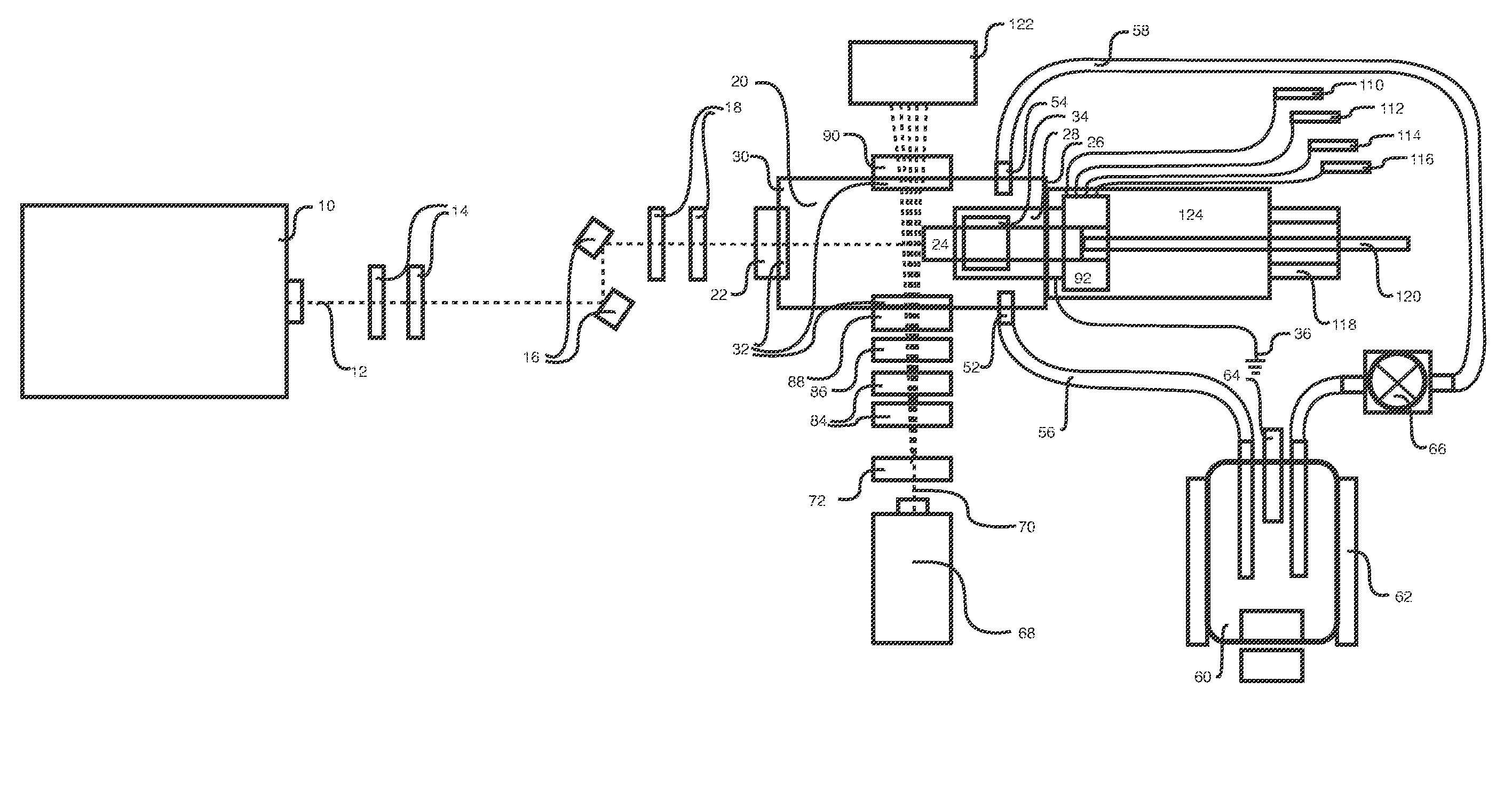

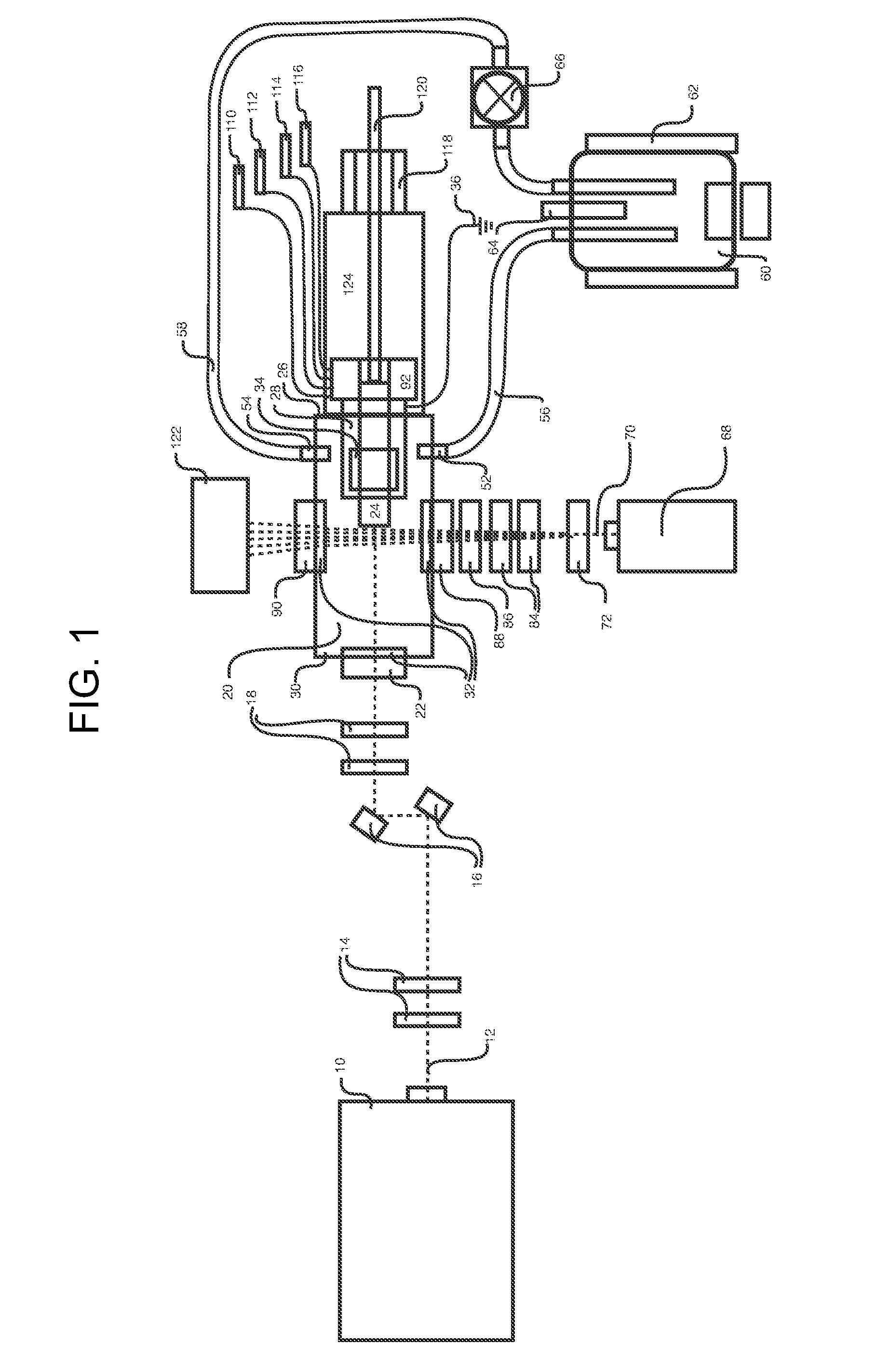

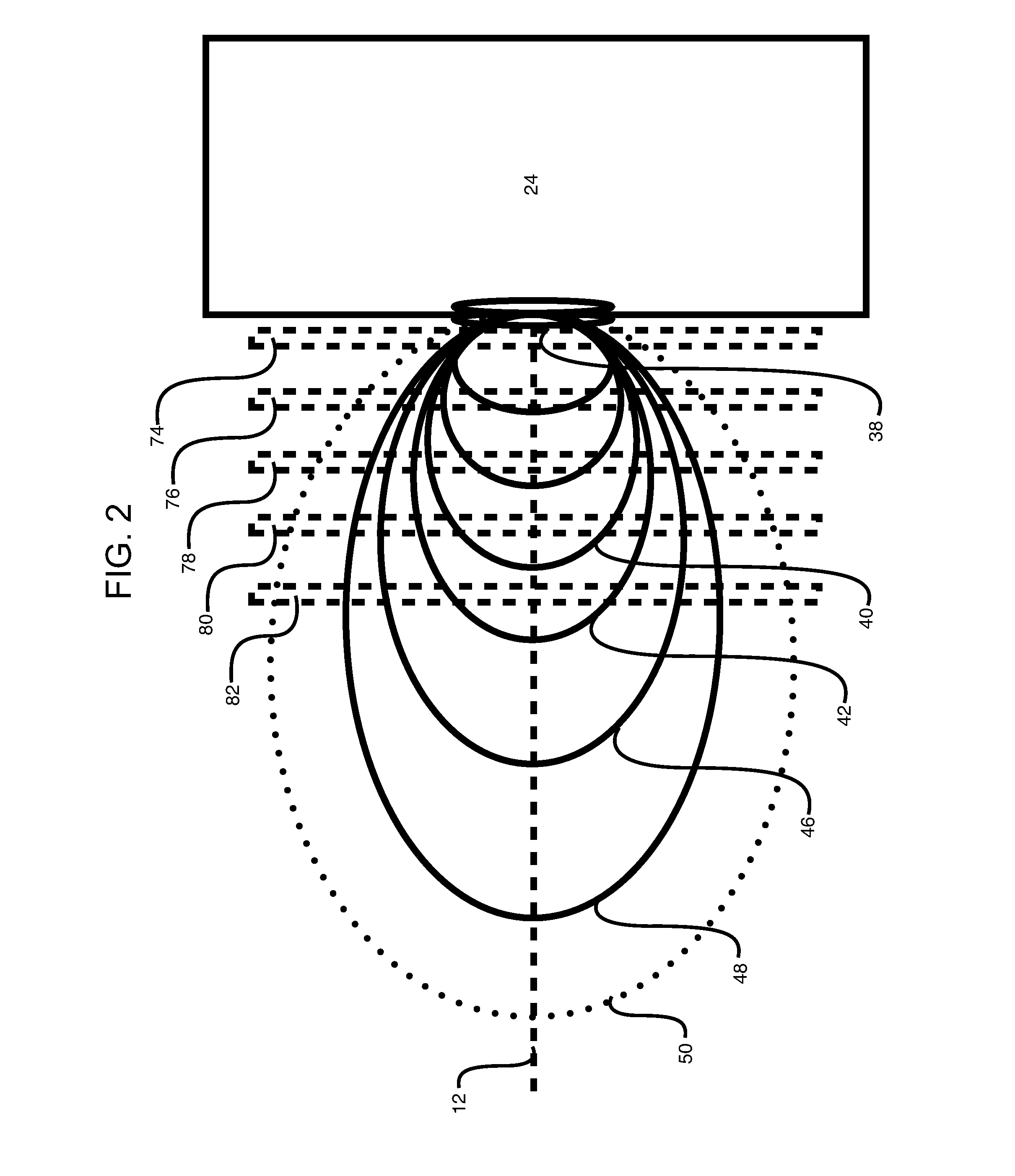

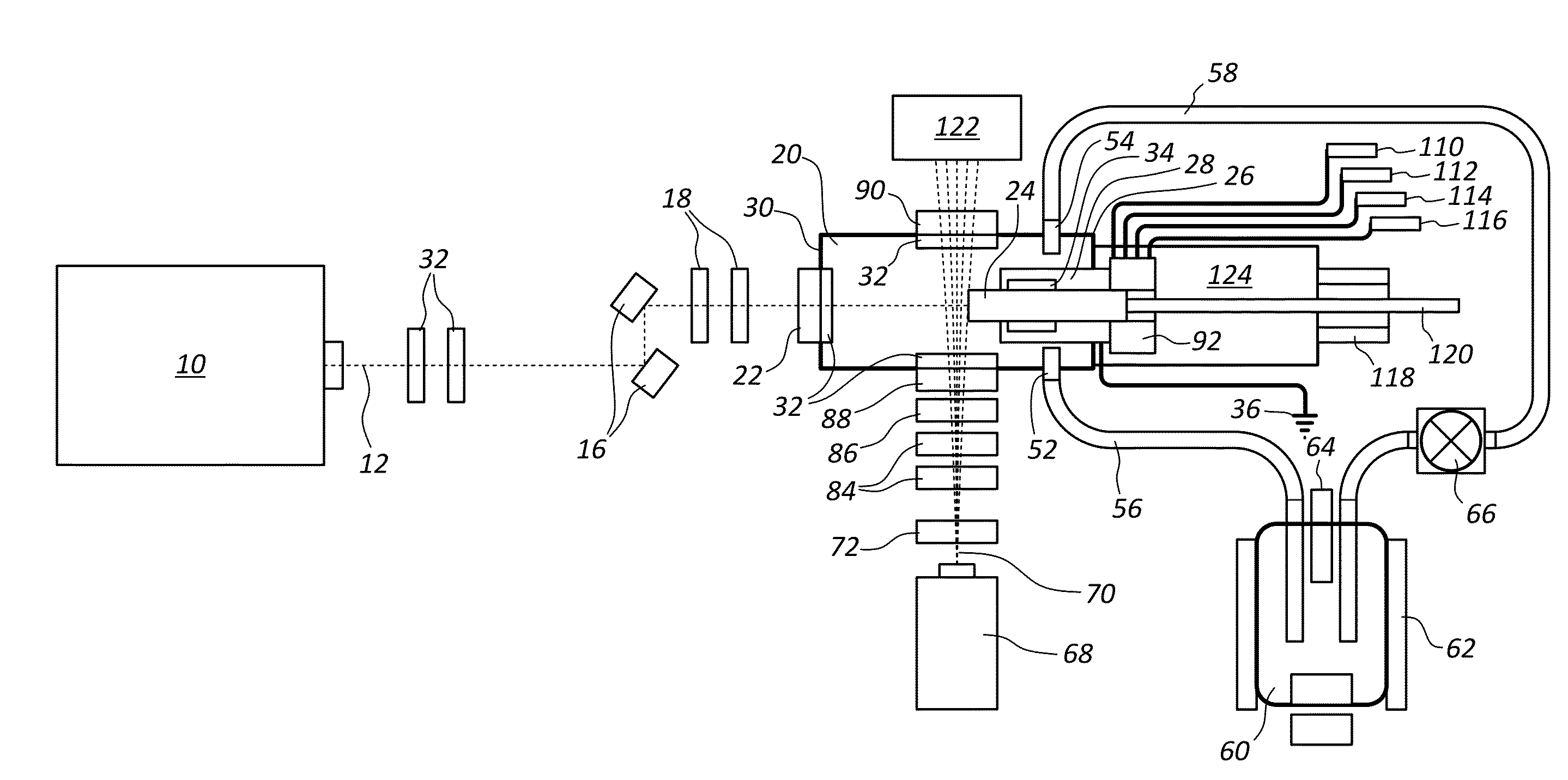

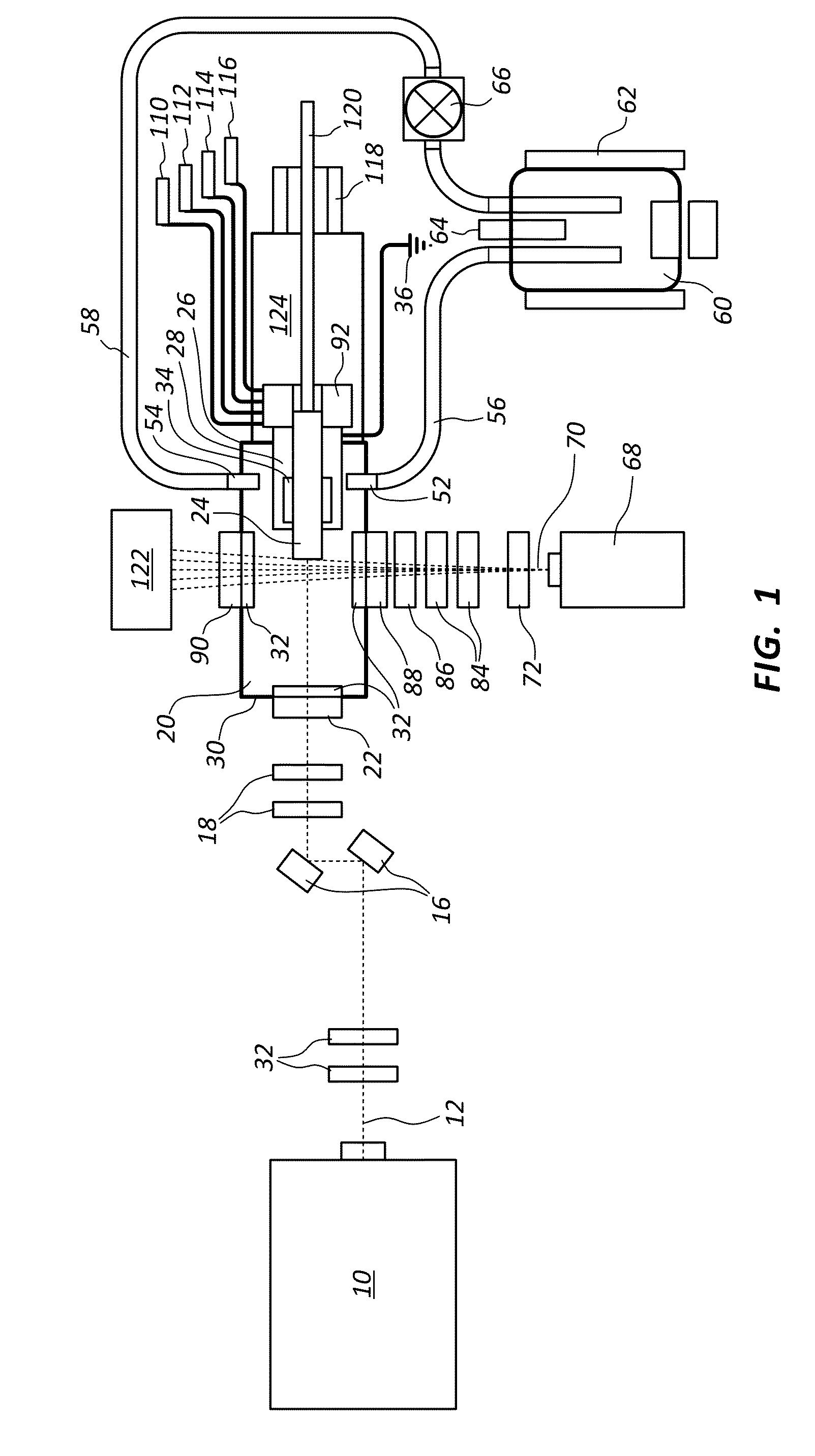

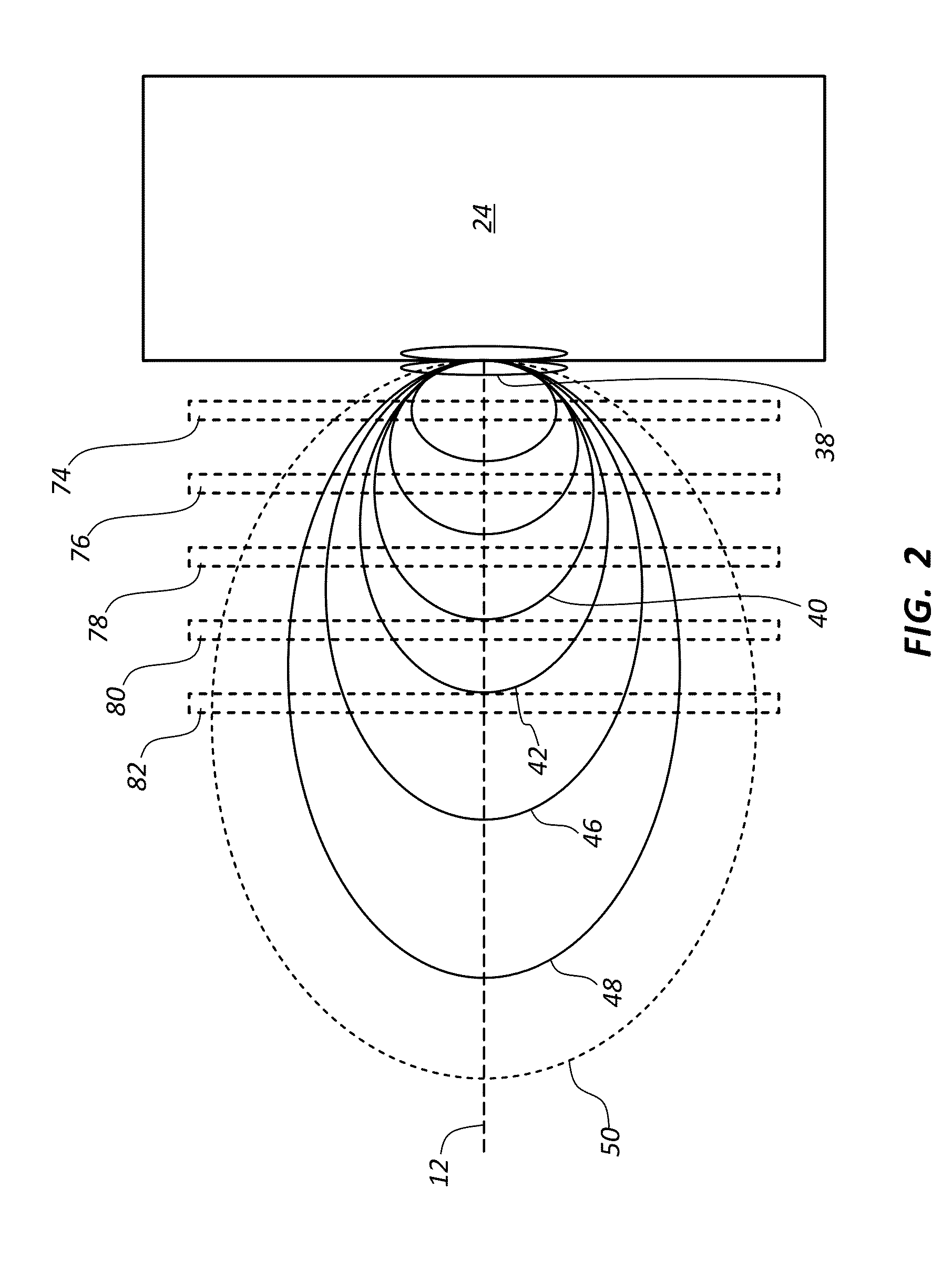

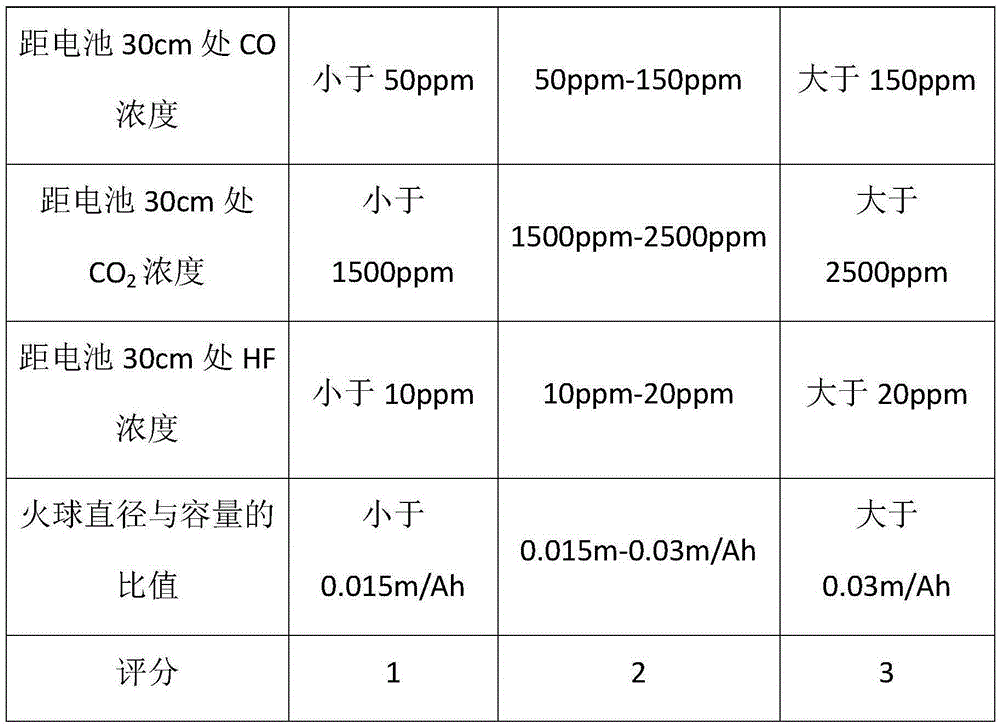

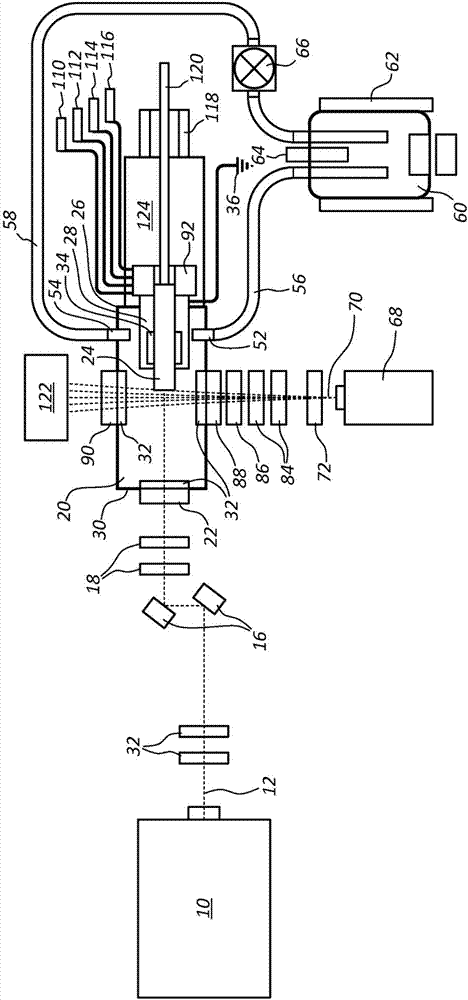

Method and apparatus for production of uniformly sized nanoparticles

ActiveUS20130001833A1Reduce in quantityLightweight productionMetal-working apparatusNanotechnologyTarget surfaceNanoparticle

An apparatus and process for creating uniformly sized, spherical nanoparticles from a solid target. The solid target surface is ablated to create an ejecta event containing nanoparticles moving away from the surface. Ablation may be caused by laser or electrostatic discharge. At least one electromagnetic field is placed in front of the solid target surface being ablated. The electromagnetic field manipulates at least a portion of the nanoparticles as they move away from the target surface through the electromagnetic field to increase size and spherical shape uniformity of the nanoparticles. The manipulated nanoparticles are collected.

Owner:EVOQ NANO INC

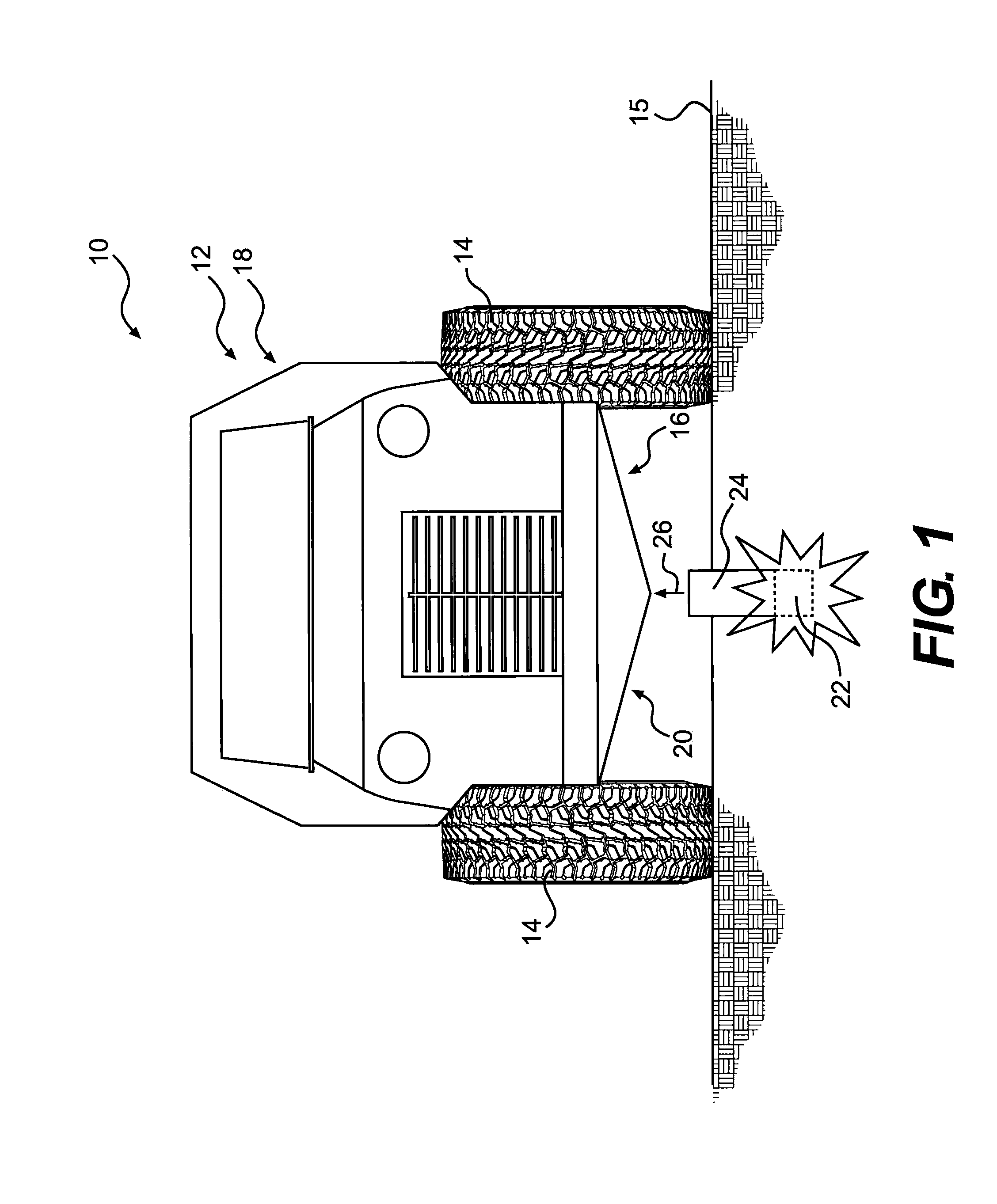

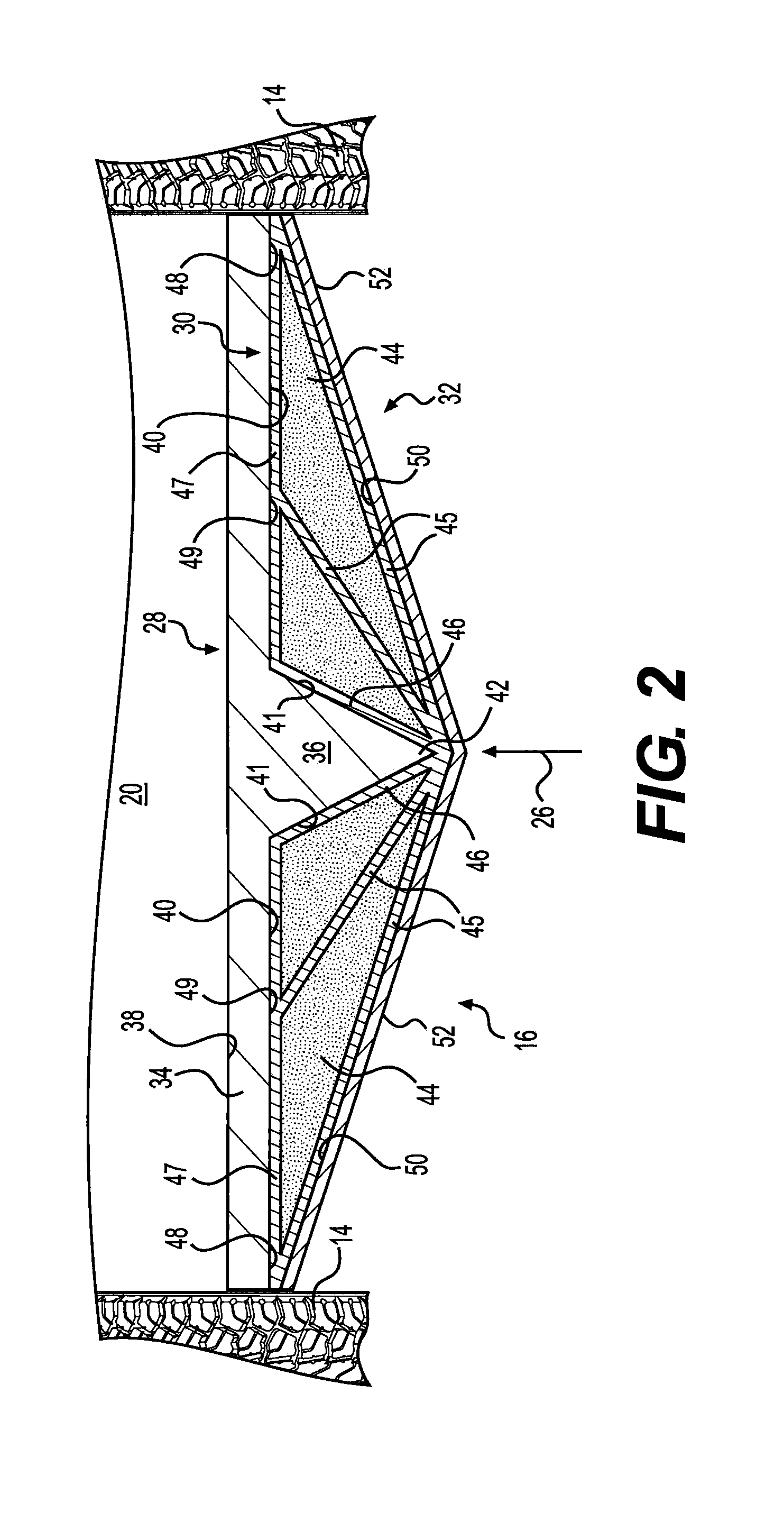

System For Protecting A Vehicle From A Mine

InactiveUS20110277621A1Increase speedArmoured vehiclesOther manufacturing equipments/toolsShock waveDetonation

In one aspect, the present disclosure is directed to a system for protecting a vehicle from a mine. Upon detonation the mine may yield ejecta having an expected trajectory. The system has a first layer of material disposed outside of an underbody of a hull of the vehicle. The first layer includes a base disposed in a direction substantially parallel to the underbody and a protrusion that narrows as it extends away from the base in a direction opposing the expected ejecta trajectory. The system also has a second layer including a material having a shock wave transmission velocity that is higher than a shock wave transmission velocity of the material of the first layer. The system further has an exterior layer substantially covering the first and second layers, and the exterior layer has an exterior surface that faces away from the underbody and toward the expected ejecta trajectory.

Owner:FORCE PROTECTION TECH

Method and apparatus for production of uniformly sized nanoparticles

ActiveUS20140288194A1Reduce in quantityLightweight productionMixing methodsMetal-working apparatusTarget surfaceNanoparticle

An apparatus and process for creating uniformly sized, spherical nanoparticles from a solid target. The solid target surface is ablated to create an ejecta event containing nanoparticles moving away from the surface. Ablation may be caused by laser or electrostatic discharge. At least one electromagnetic field is placed in front of the solid target surface being ablated. The electromagnetic field manipulates at least a portion of the nanoparticles as they move away from the target surface through the electromagnetic field to increase size and spherical shape uniformity of the nanoparticles. The manipulated nanoparticles are collected.

Owner:EVOQ NANO INC

System and method for making non-spherical nanoparticles and nanoparticle compositions made thereby

Systems and methods for selectively making non-spherical metal nanoparticles from a metal material. The metal target surface is ablated to create an ejecta event or plume containing nanoparticles moving away from the surface. Ablation may be caused by laser or electrostatic discharge. At least one electromagnetic field is placed in front of the solid target surface being ablated. The electromagnetic field manipulates at least a portion of the nanoparticles as they move away from the target surface through the electromagnetic field to create coral-shaped metal nanoparticles. The distance between the electromagnetic field and metal surface can be adjusted to yield metal nanoparticles of a desired size and / or shape.

Owner:EVOQ NANO INC

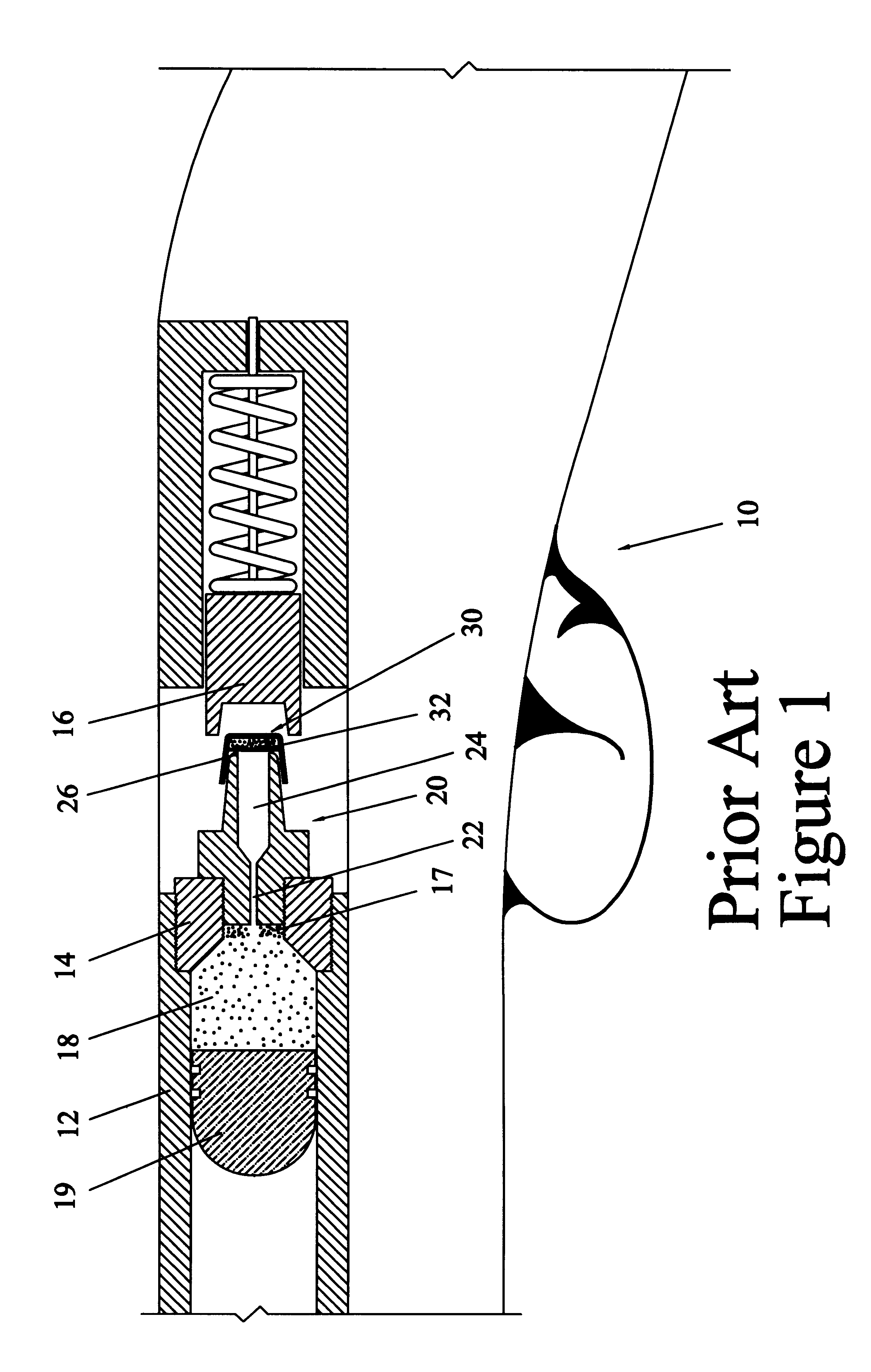

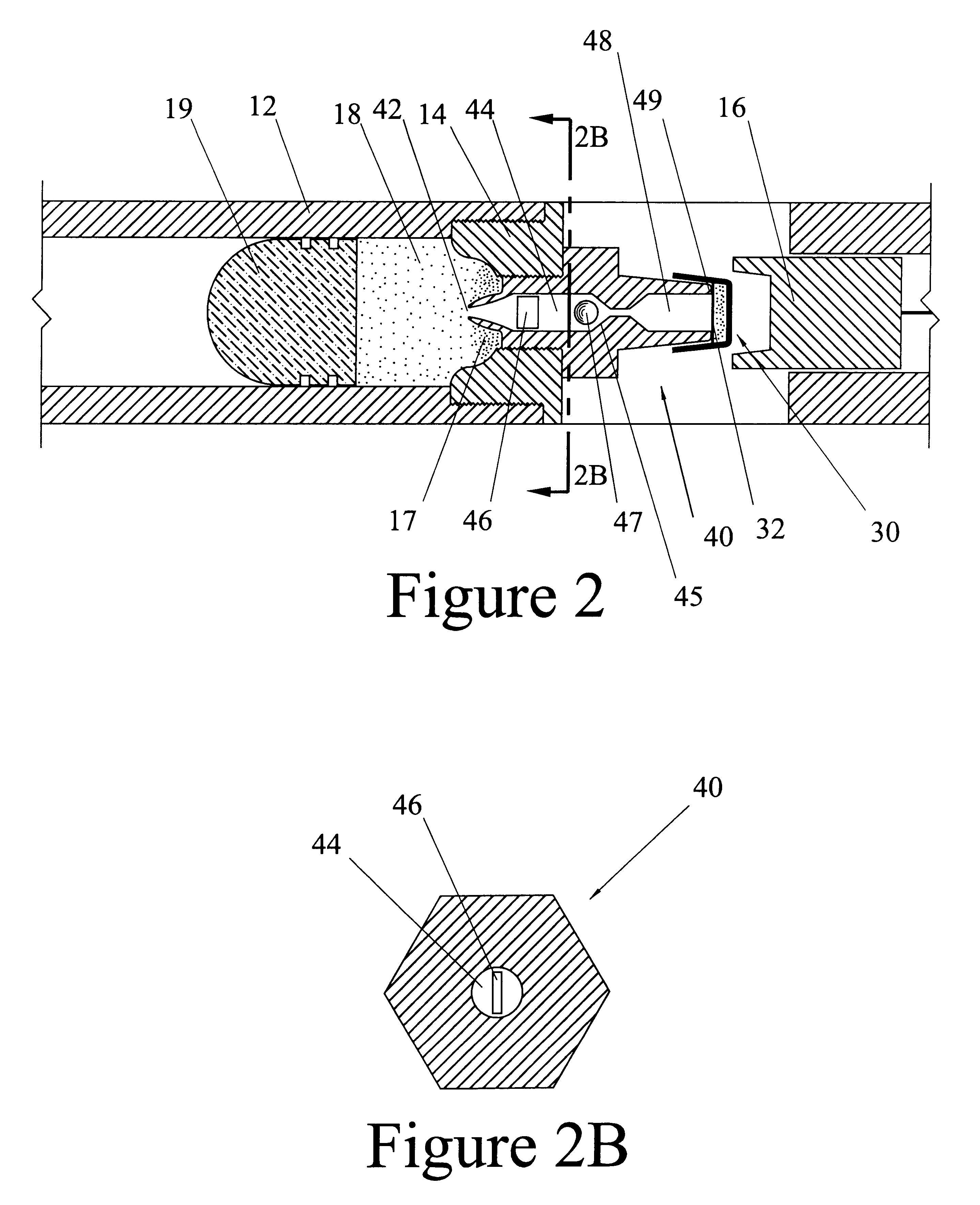

Back-flash check for muzzleloaders

InactiveUS6226916B1Minimize impactIncrease speedSafety arrangementMuzzle-loading smallarmsEngineeringEjecta

An improved nipple, used with a percussion cap to ignite the propellent of a muzzleloader without significant ejecta from the nipple (back-flash), is disclosed. A check valve, preferably using a spherical actuator that is loosely retained within the valve chamber, is used to preclude back-flash. Use of a check valve and use of a relatively mild percussion cap (compared to primers) revealed a set of new problems that are solved by the disclosed device. Difficulty in removing spent caps, because of the lack of cap removing back-flash, was solved by flash chamber structure within the nipple adjacent to the cap. A tendency for the protective membranes of percussion caps to lodge within a nipple not having back-flash was cured by the use of an actuator retainer that directs the actuator to the side of the valve chamber during ignition. Ignition was improved by the use of a flash jet orifice and by the use of a directing actuator retainer. The disclosed nipple may be constructed so as to be exchanged for existing nipples in side-hammer, and in-line, cap-fired muzzleloaders. The disclosed nipple may be constructed so as to convert primer fired in-line muzzleloaders to percussion cap fired muzzleloaders and thus avoid the strictures of BATF Industry Circular number 98-2 dated Nov. 9, 1997.

Owner:KENDALL STEVEN SCOTT

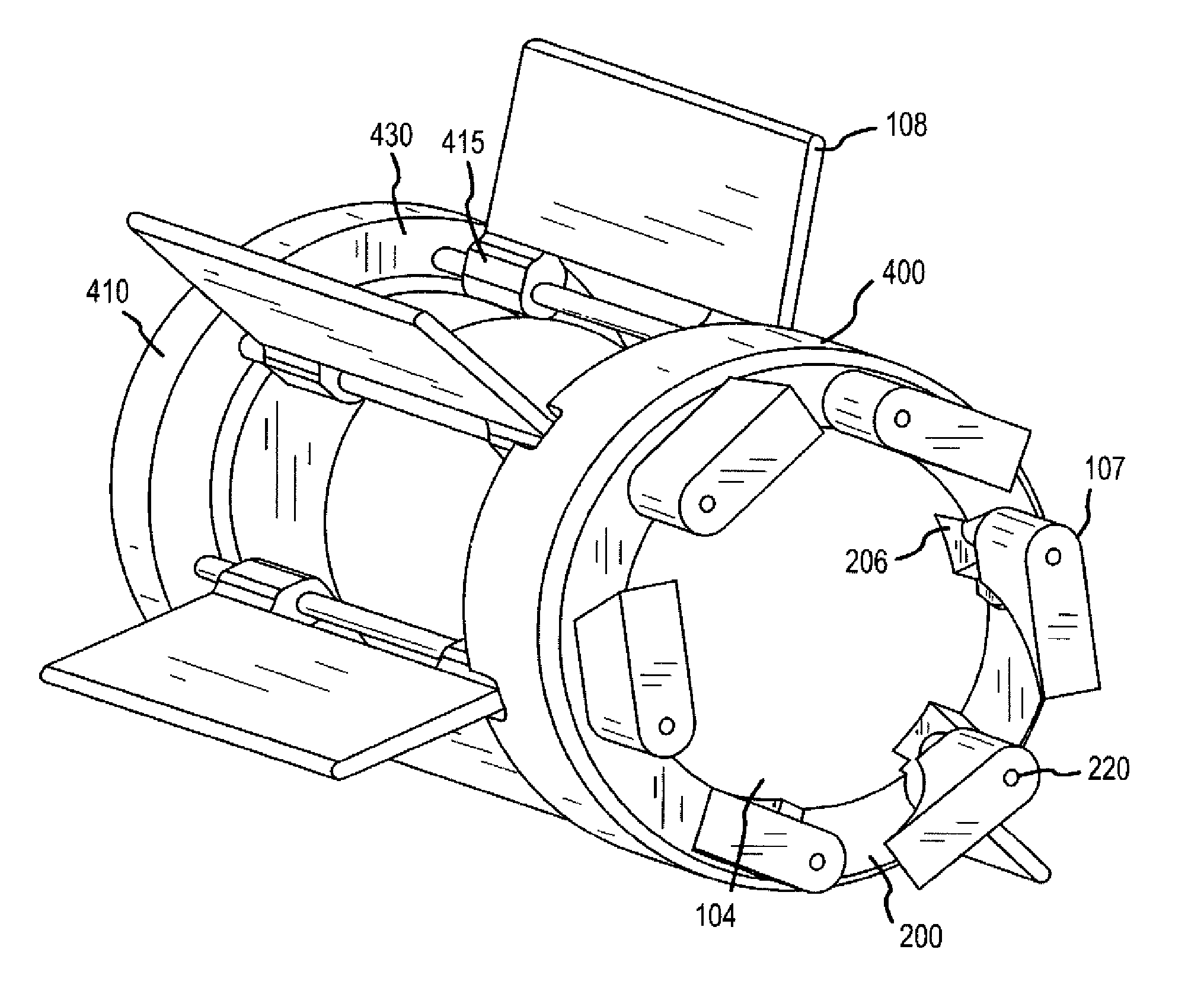

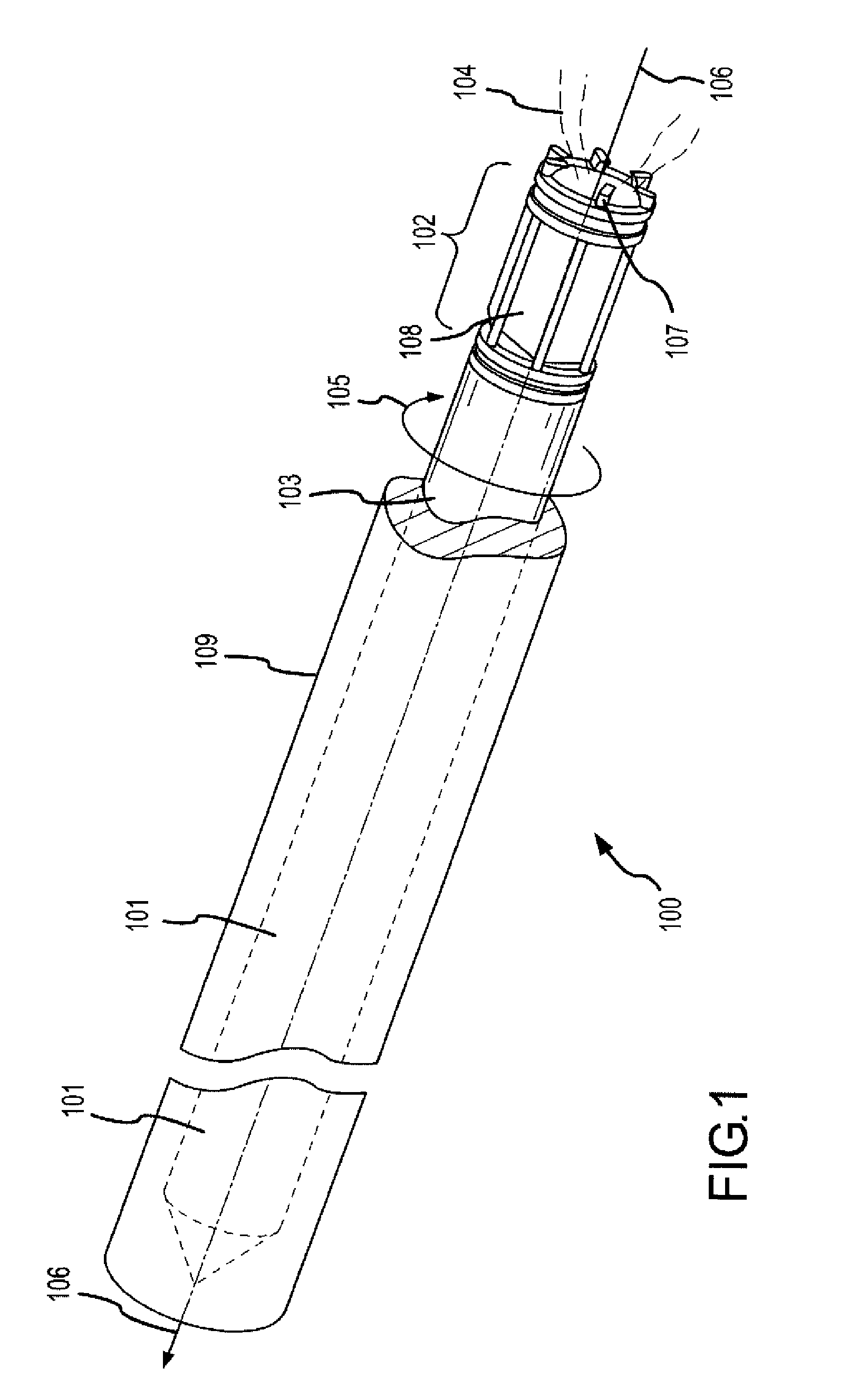

Exhaust assembly for mass ejection drive system

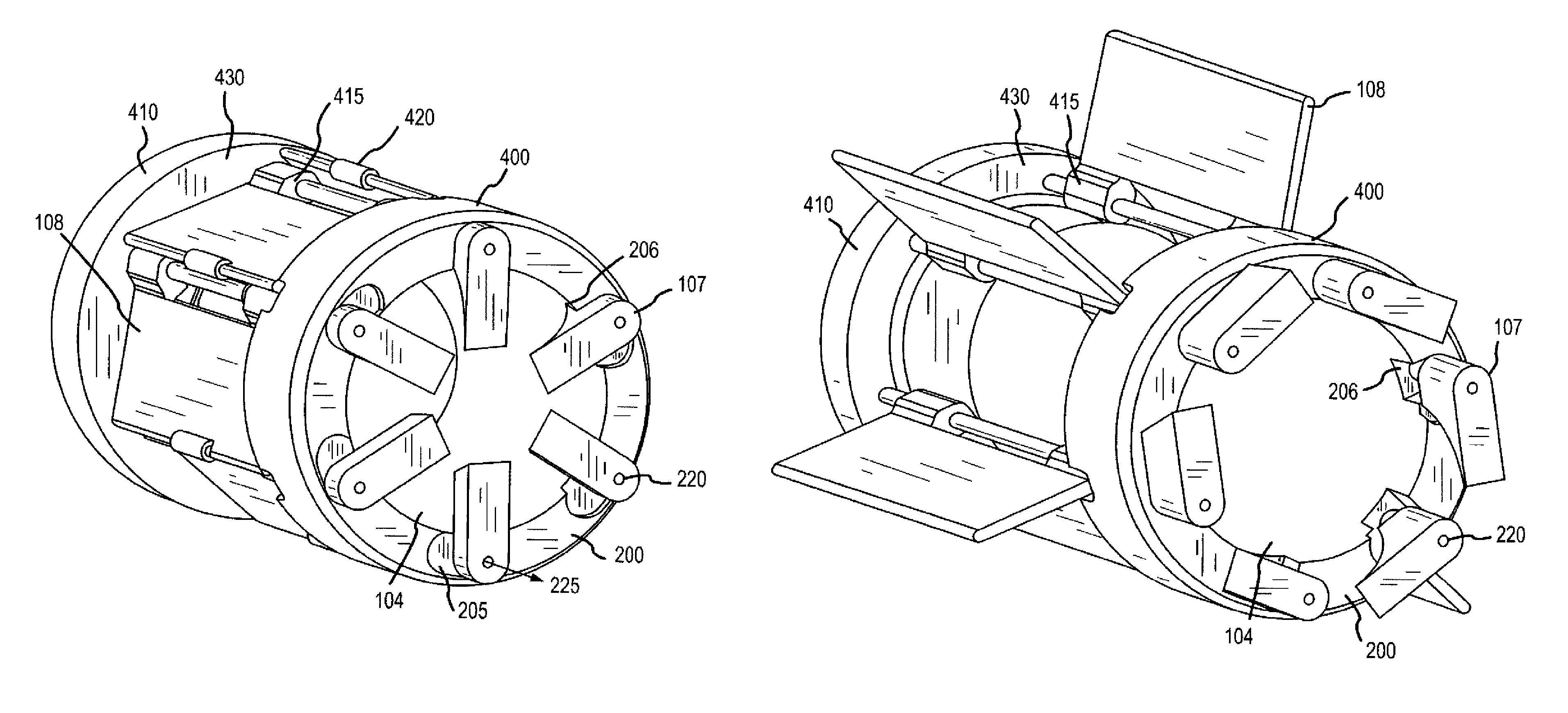

InactiveUS20070152097A1Make up for deficienciesDirection controllersEngine manufactureEngineeringEjecta

The present invention discloses a system, device and method for providing an exhaust assembly adapted for use with a mass ejection drive system to produce rotational torque about the principle axis of the drive system. Representative features generally include a vane suitably configured to at least partially engage a mass ejecta stream to apply a net rotational torque about the principal axis of the drive system, and a tailfin coupled to the at least one vane. The tailfin is configured to selectively deploy from an at least partially stowed position in order to decrease the application of net rotational torque about the principal axis of the drive system.

Owner:RAYTHEON CO

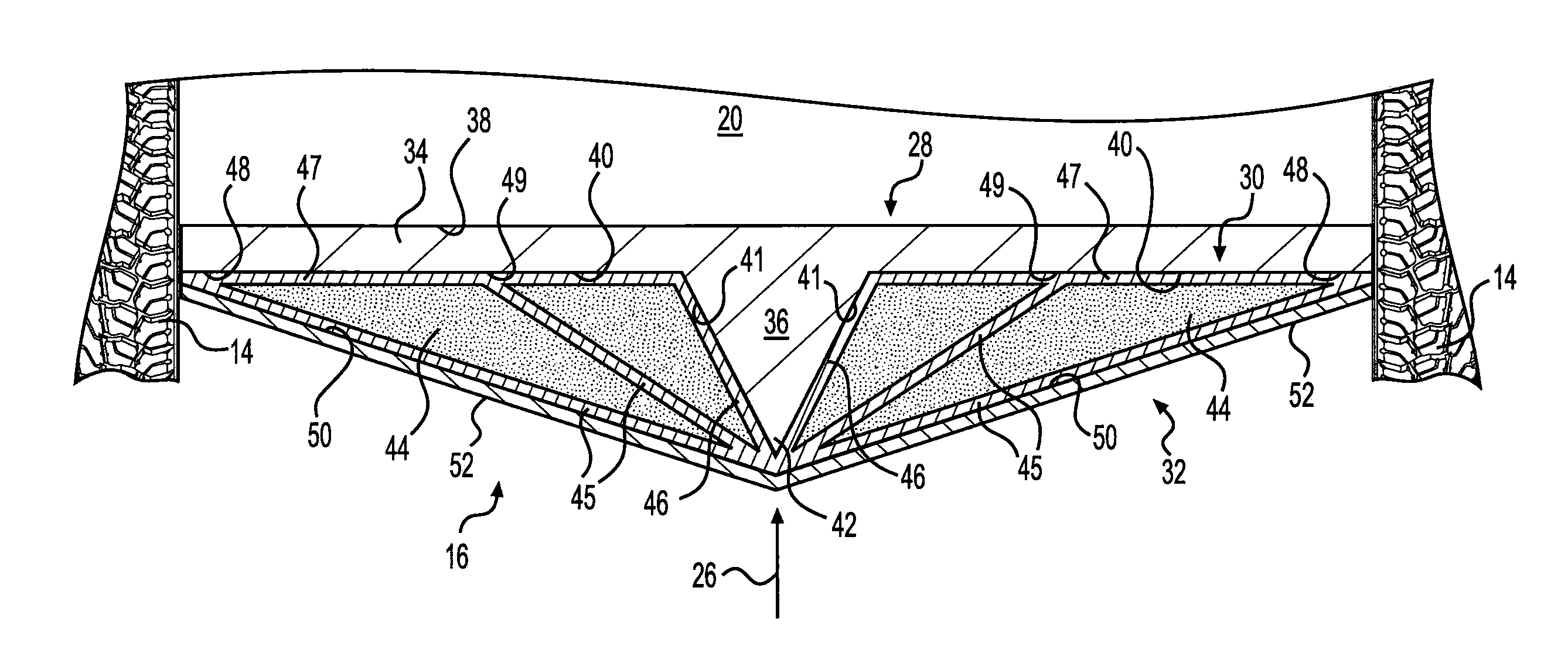

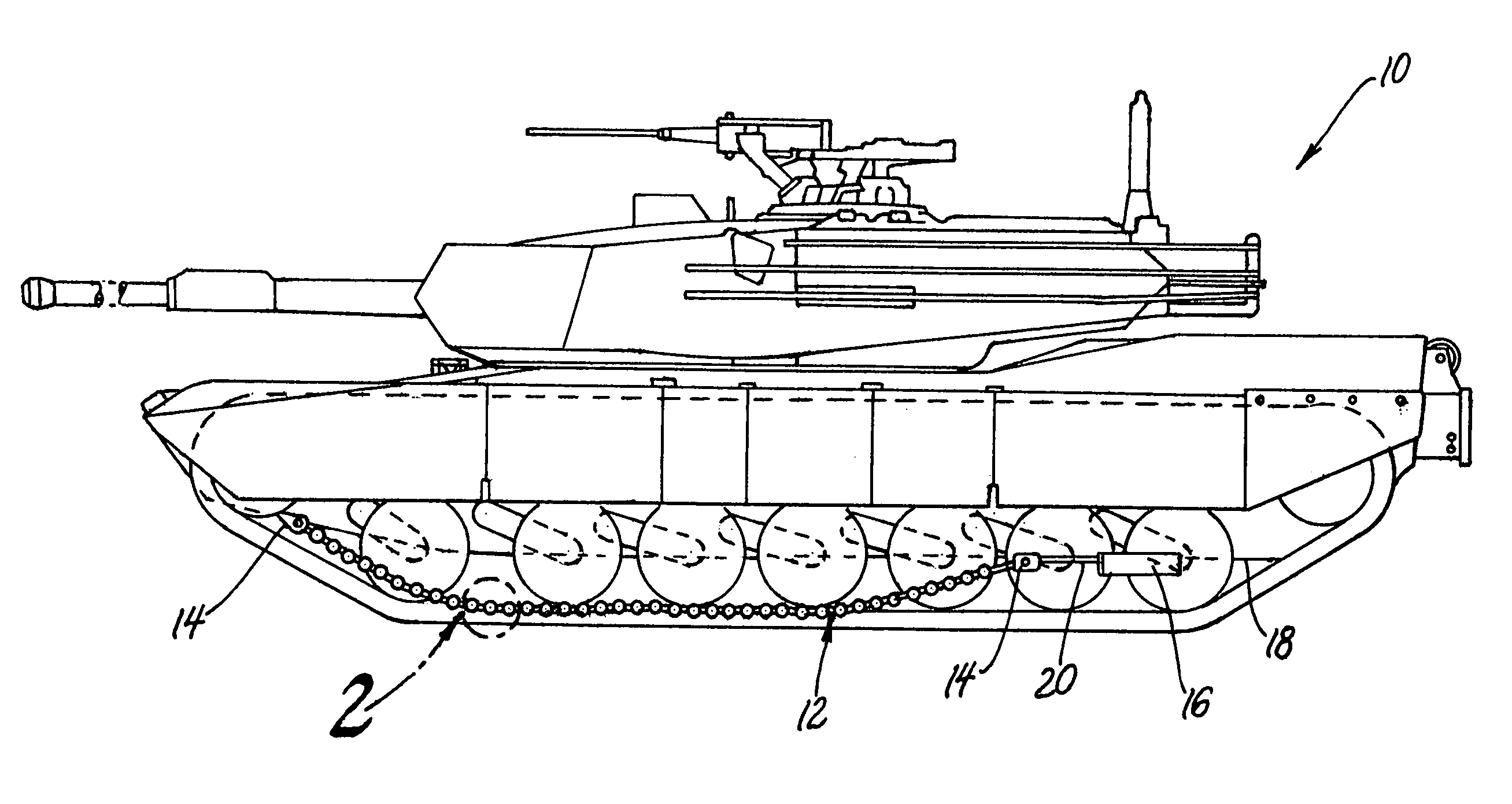

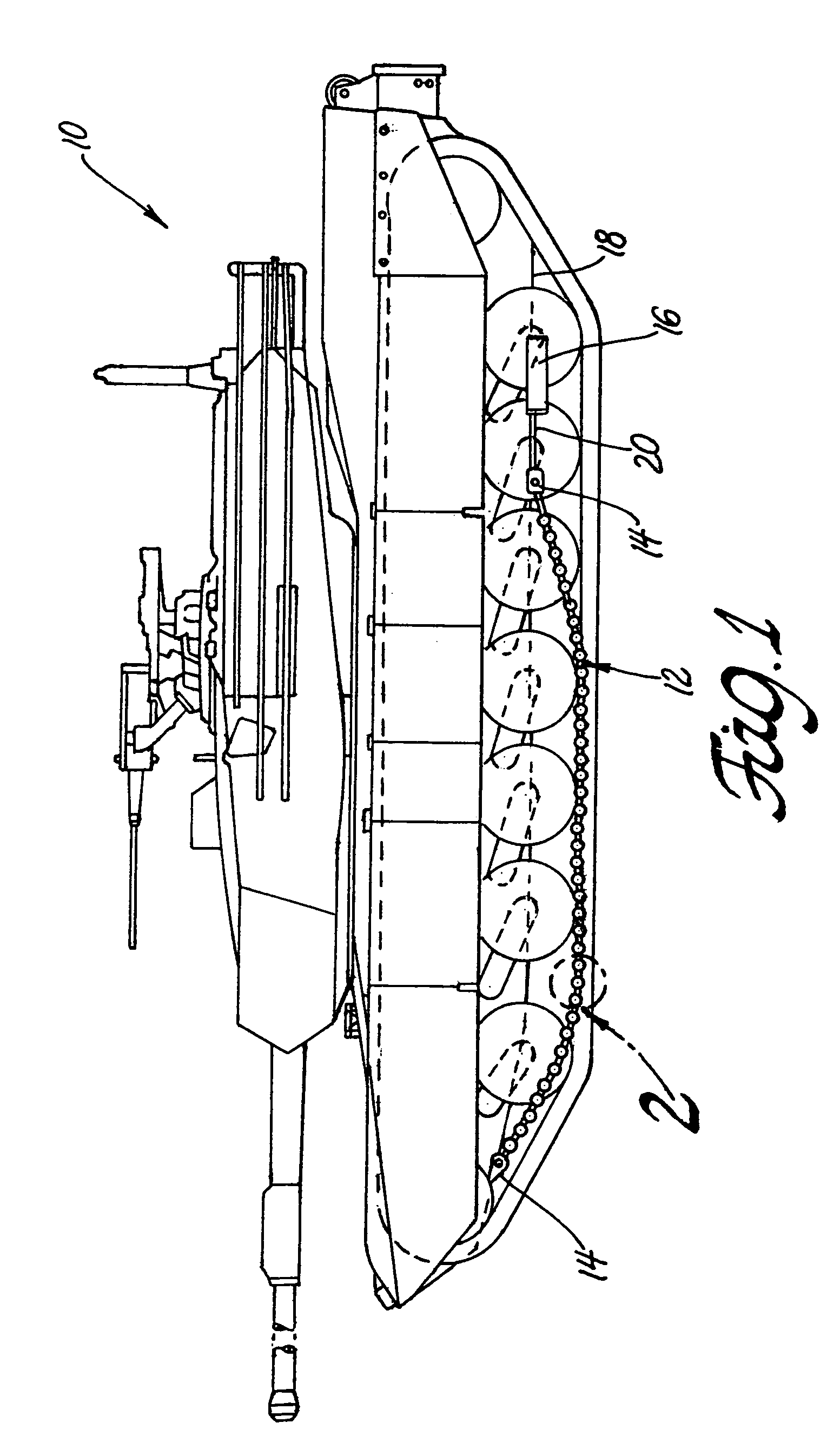

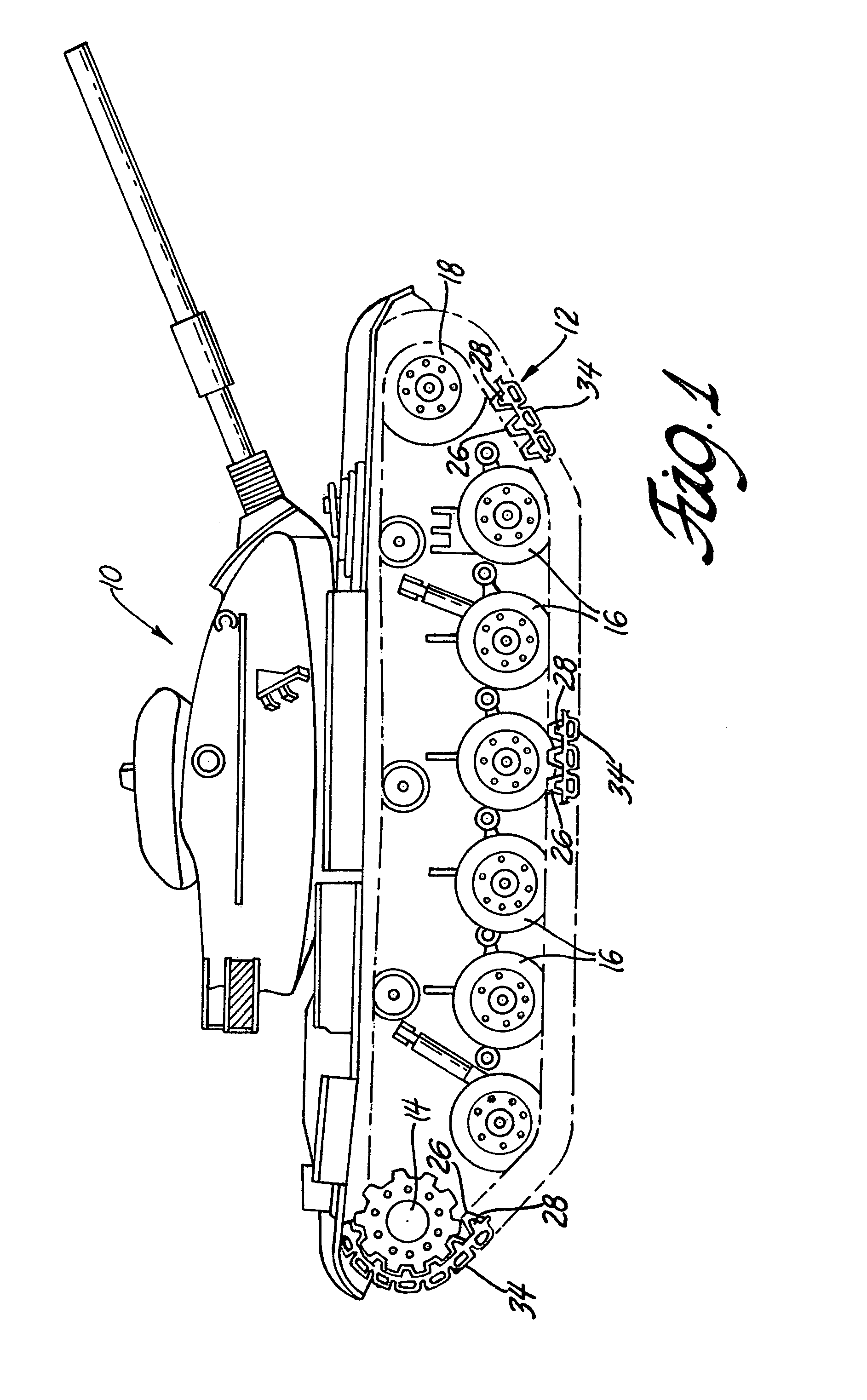

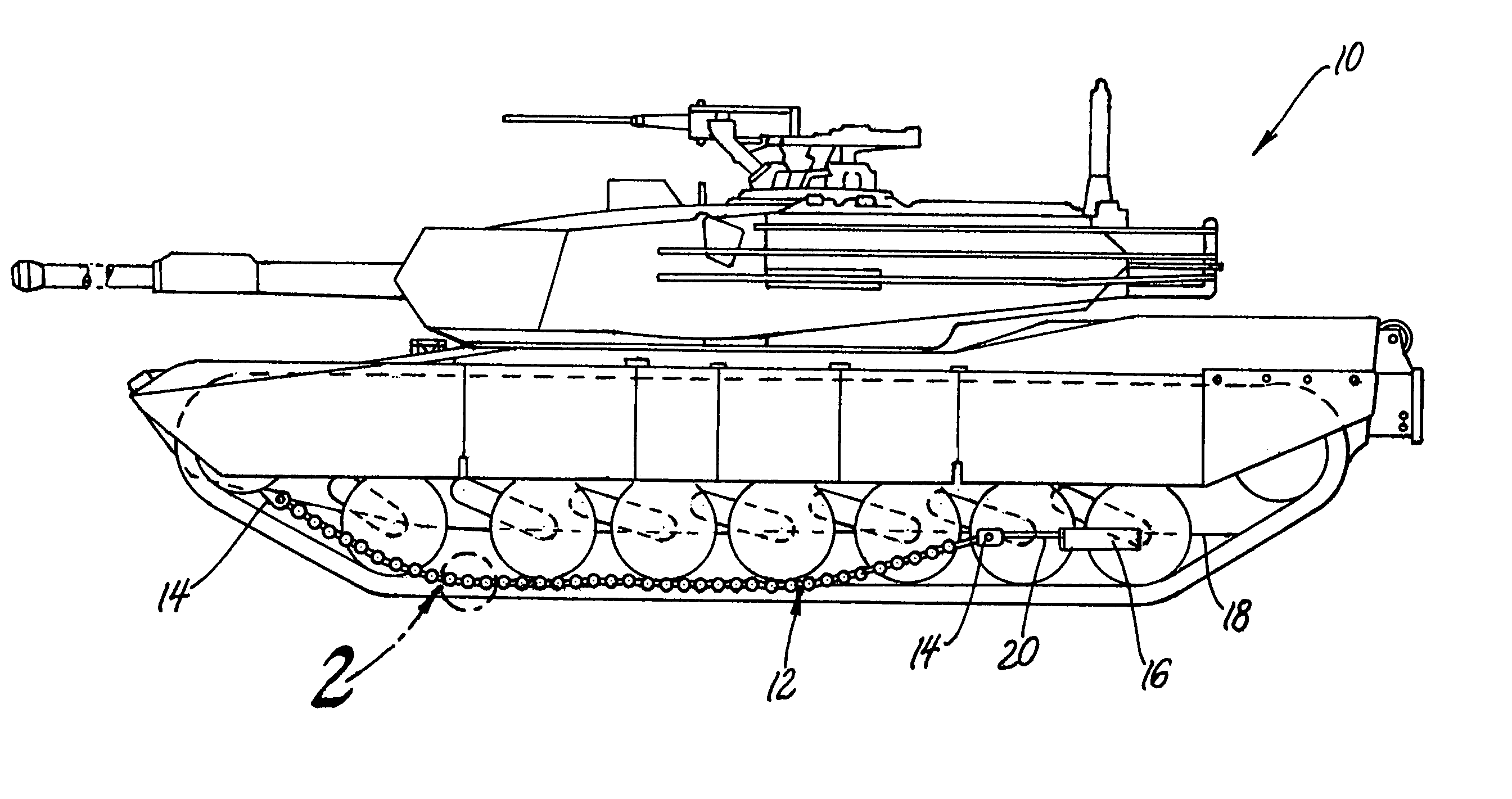

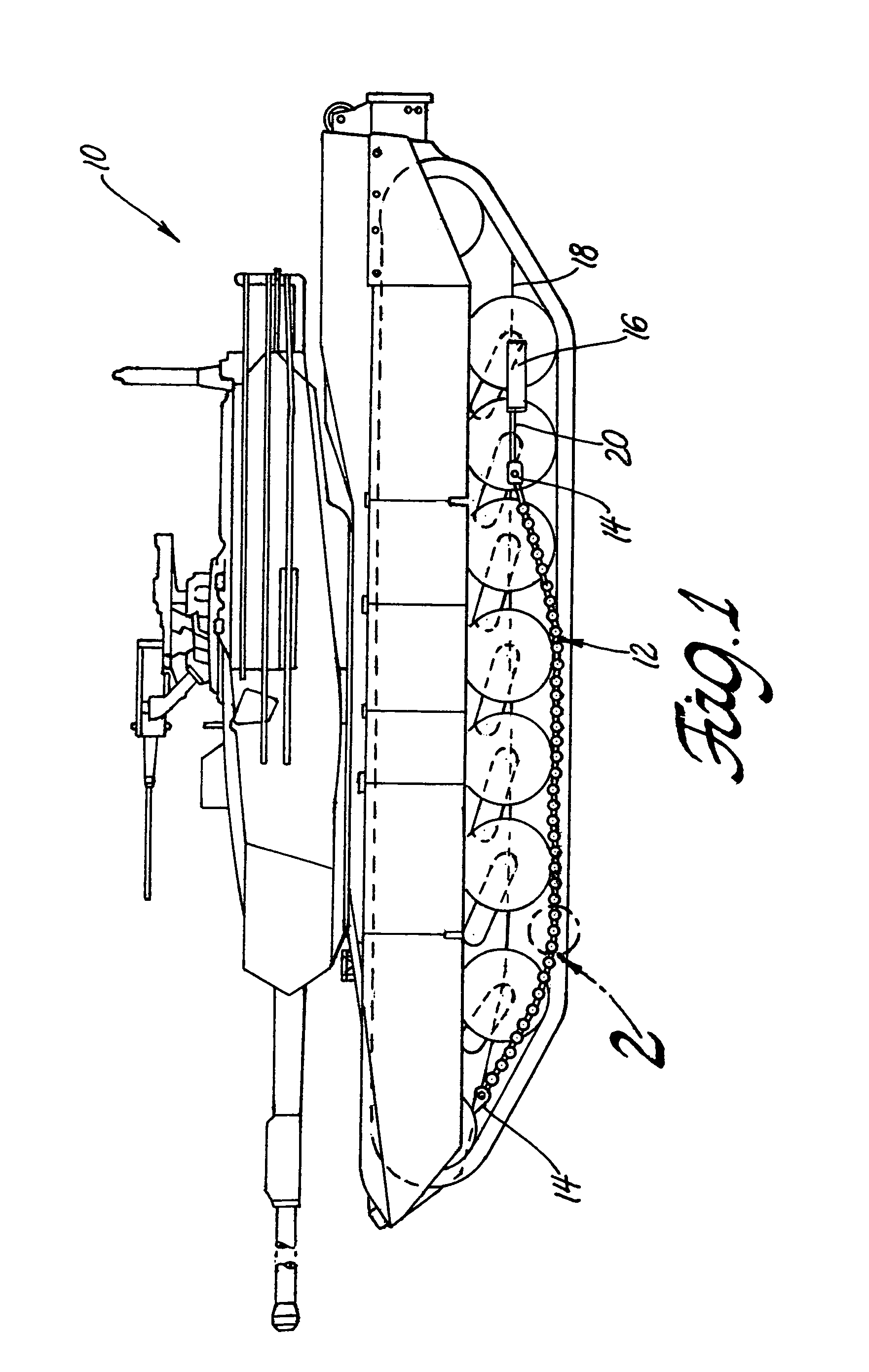

Apparatus and method for ballistic protection of vehicle undercarriages

InactiveUS20060048641A1Reduce chanceSimple and reliable and durableArmoured vehiclesTerrainEngineering

An elongate ballistic protection apparatus is described and claimed herein which has minimal weight and maximum flexibility to conform to the most contorted and undulating ground surfaces. In use, it is immediately positioned below a military vehicle to protect the crew compartment positioned above said apparatus by extending transversely between the propulsive means and laterally along the direction of travel for the vehicle. The apparatus may detonate mines while operated by driven engagement over mine bearing terrains, but it will do so in a manner sufficient to defeat them without inducing unacceptable damages to either the vehicle or crew. Thereby, this invention provides a means to effectively disrupt the firing sequence of the explosive charges in these mines by contact with my minimal weight roller link chain. Beneficially, the blast gasses and ejecta of the mine simply vents through the open areas of my chain. This is a substantial improvement over devices having solid configurations or geometries.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

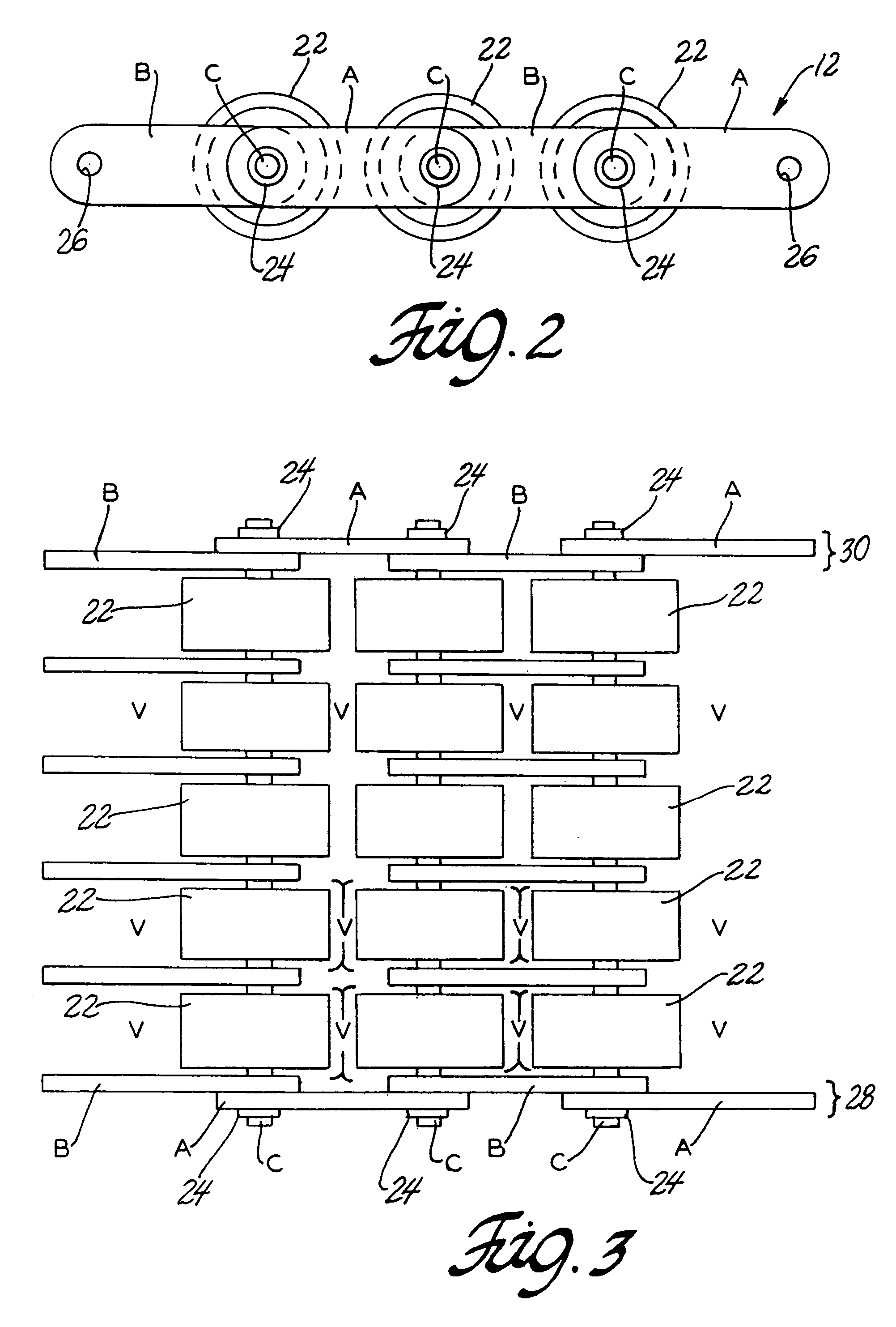

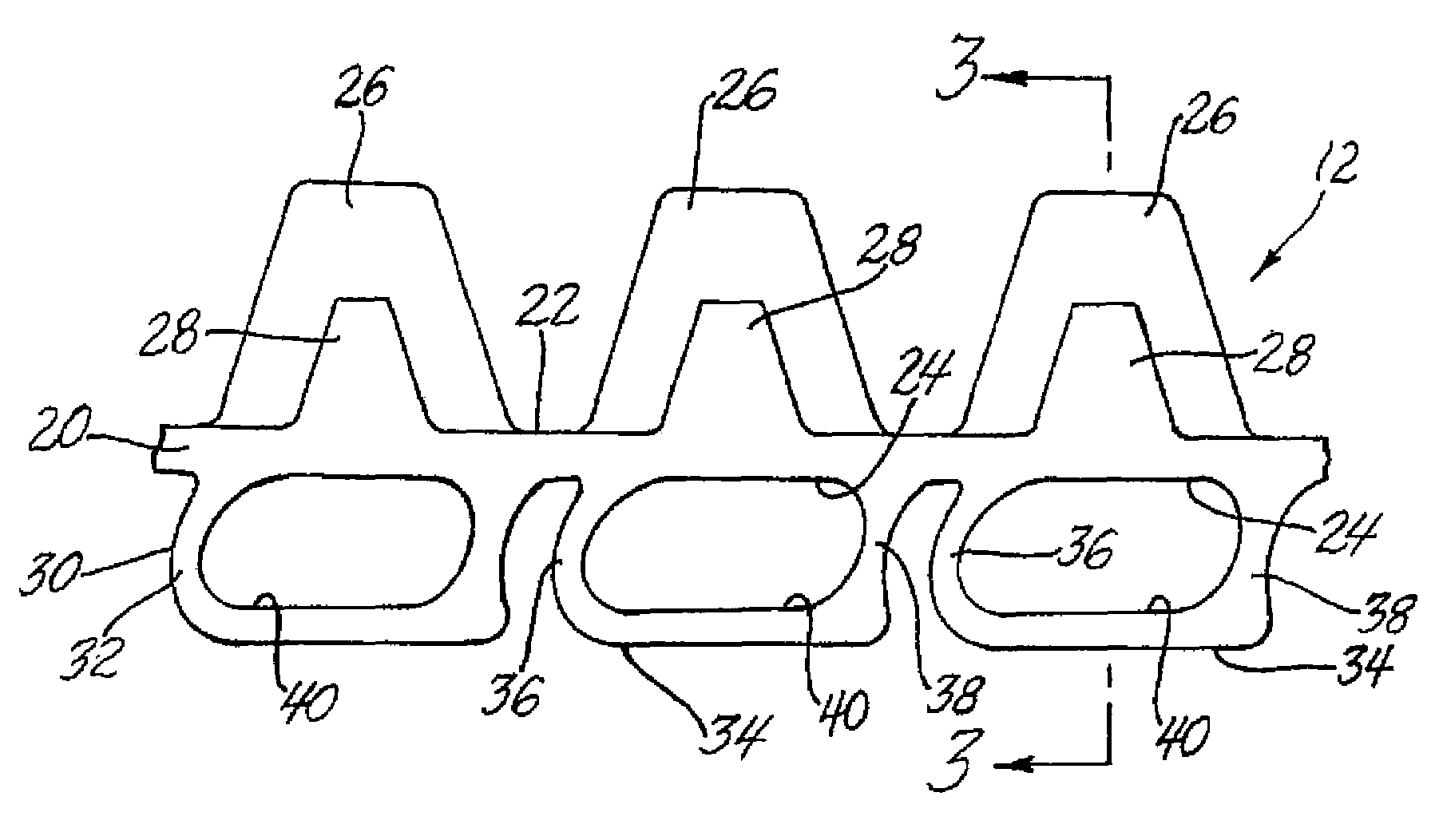

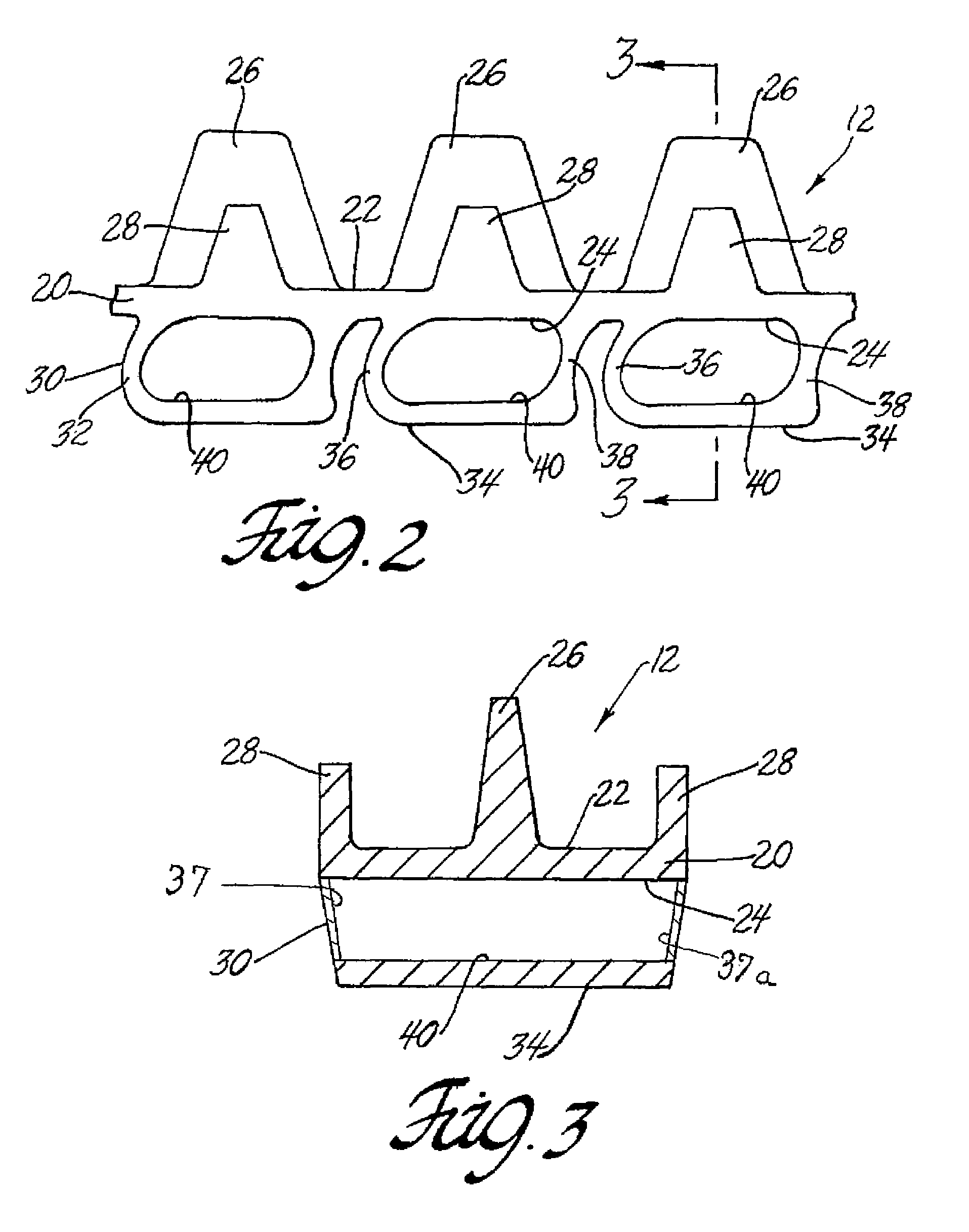

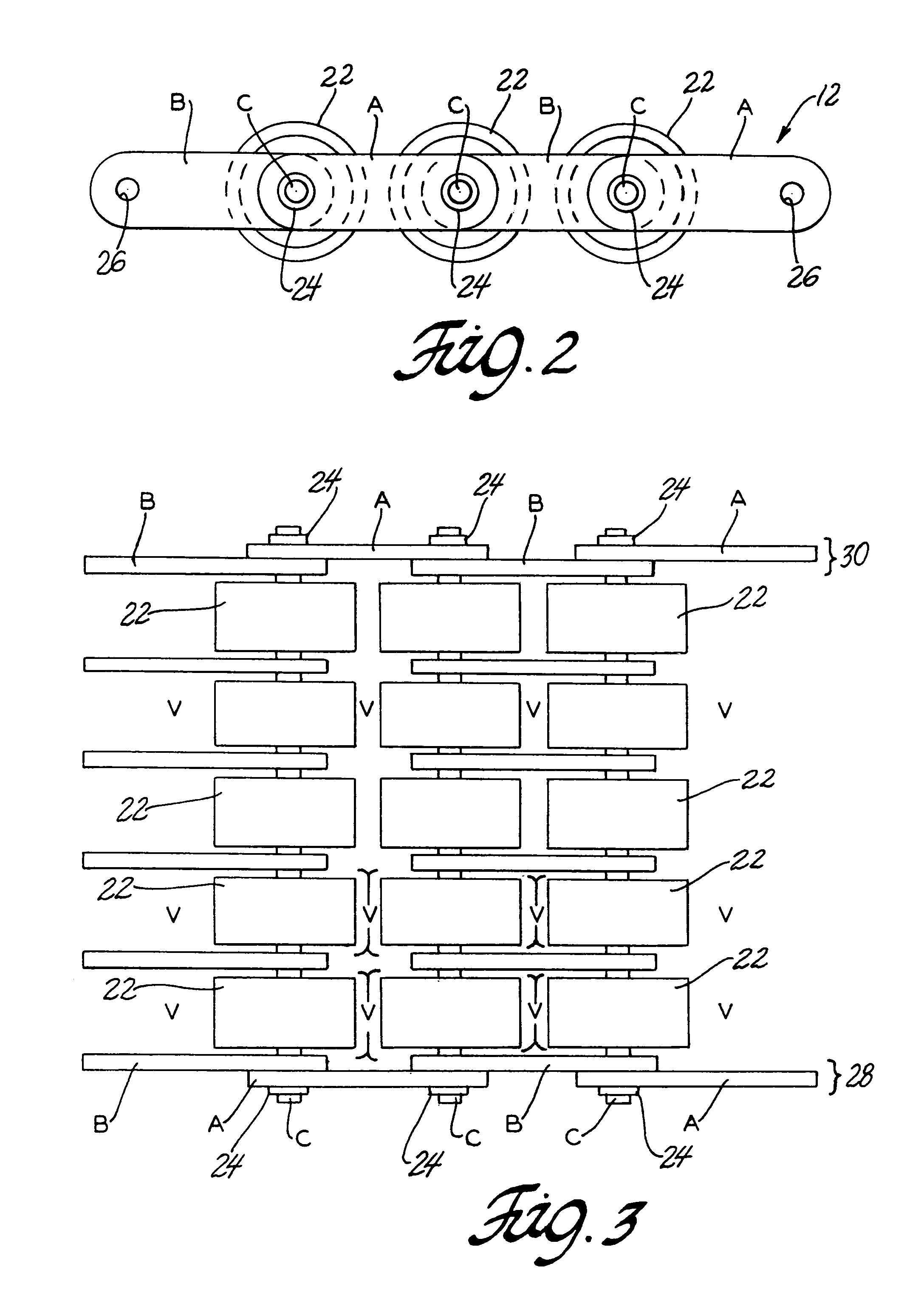

Mine resistant band track

InactiveUS7445299B2Avoid developmentAvoid insufficient thicknessArmoured vehiclesInflatable tyresTerrainControl manner

A band track for a tracked vehicle having enhanced resistance to mines includes a plurality of track pad units disposed on the bearing surface of the track band. The track pad units have extended end walls of sufficient height to distance the vulnerable portion of the band track from the shearing force of an exploding mine. These end walls are sufficiently strong to support the vehicle as it traverses terrain, but are configured to collapse in controlled manner under the force of an exploding mine. Such explosion forces a specifically configured front end wall of a trailing track pad to engage the matingly configured end wall of the leading track pad. The resulting mating juxtaposition of the adjacent end walls forms a relatively continuous physical barrier protecting the vulnerable section of the band track from shrapnel and other entrained ejecta of the explosion.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

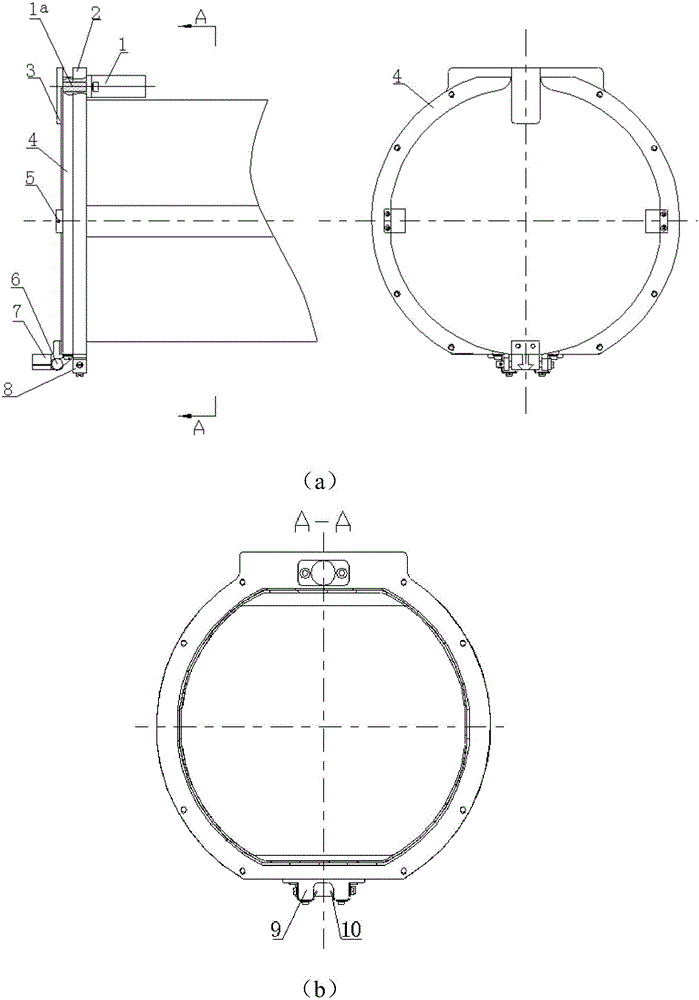

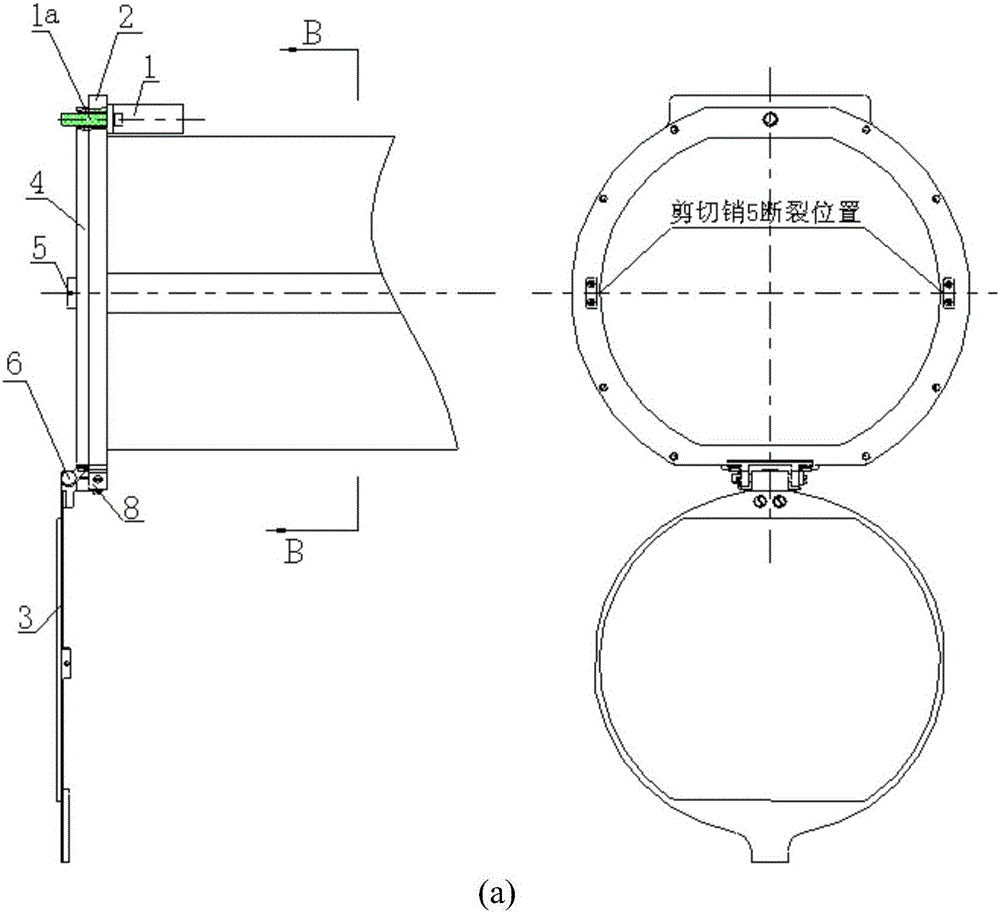

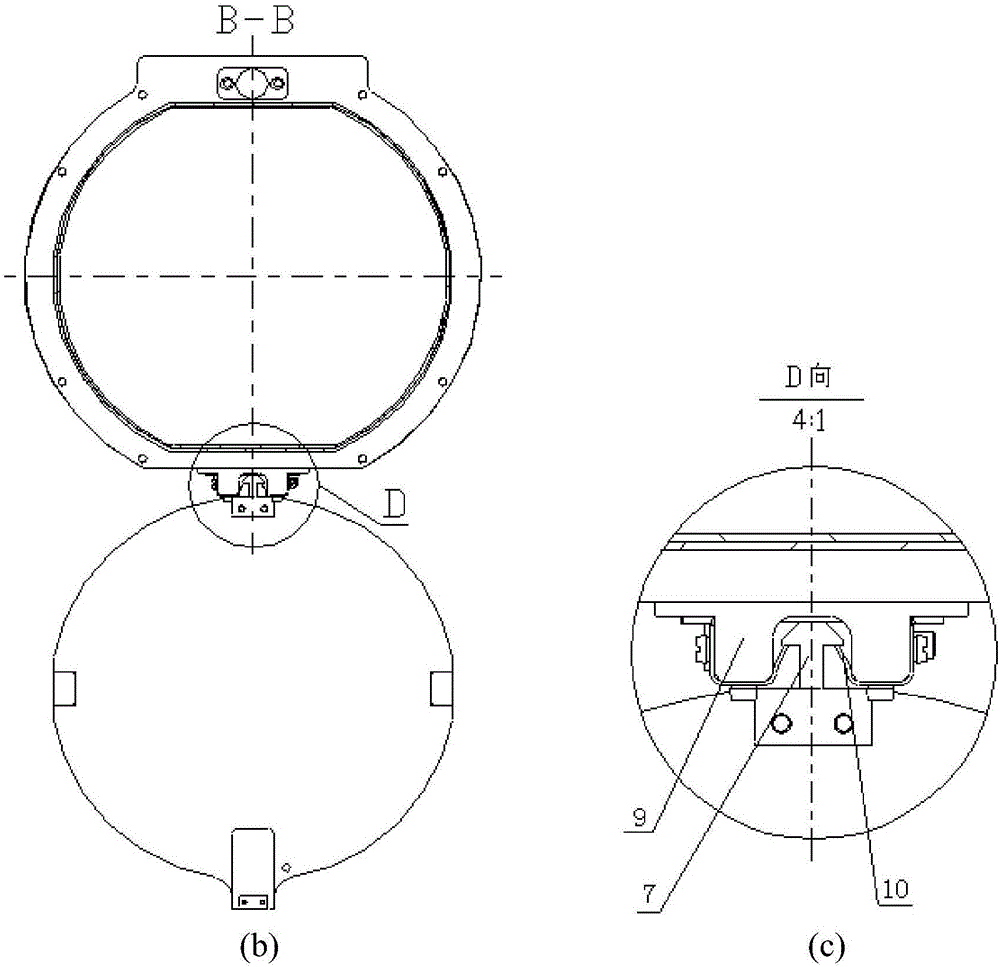

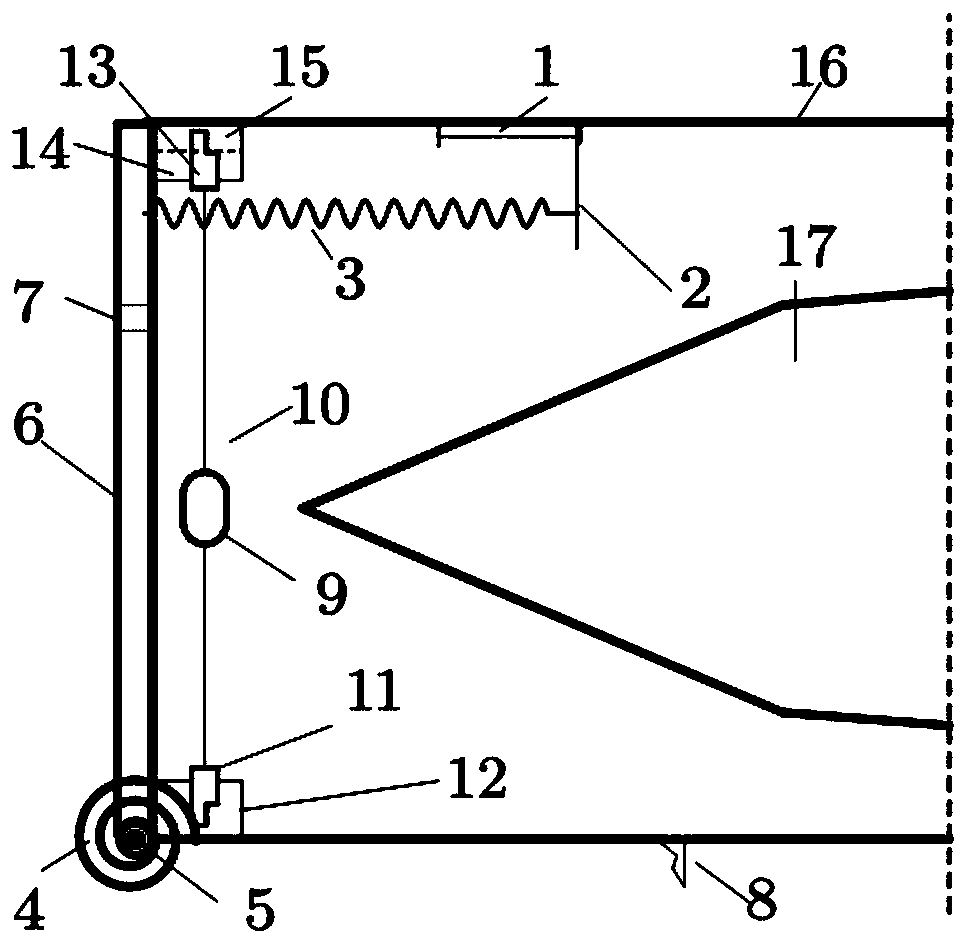

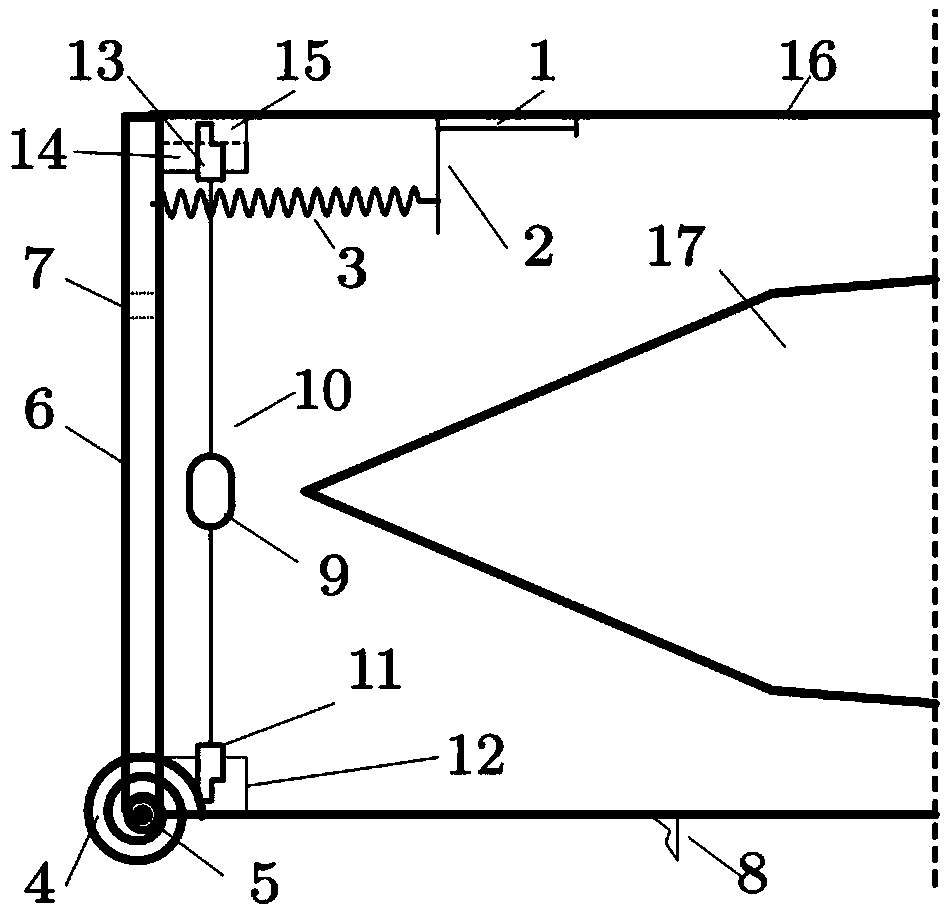

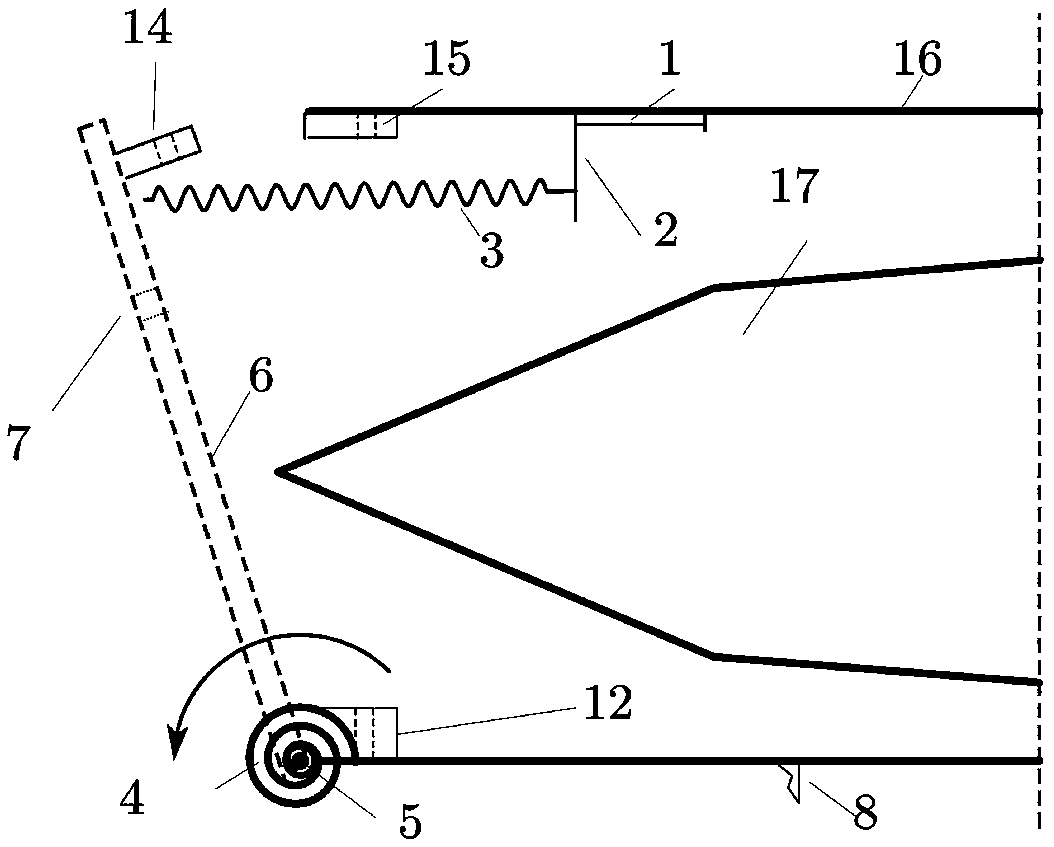

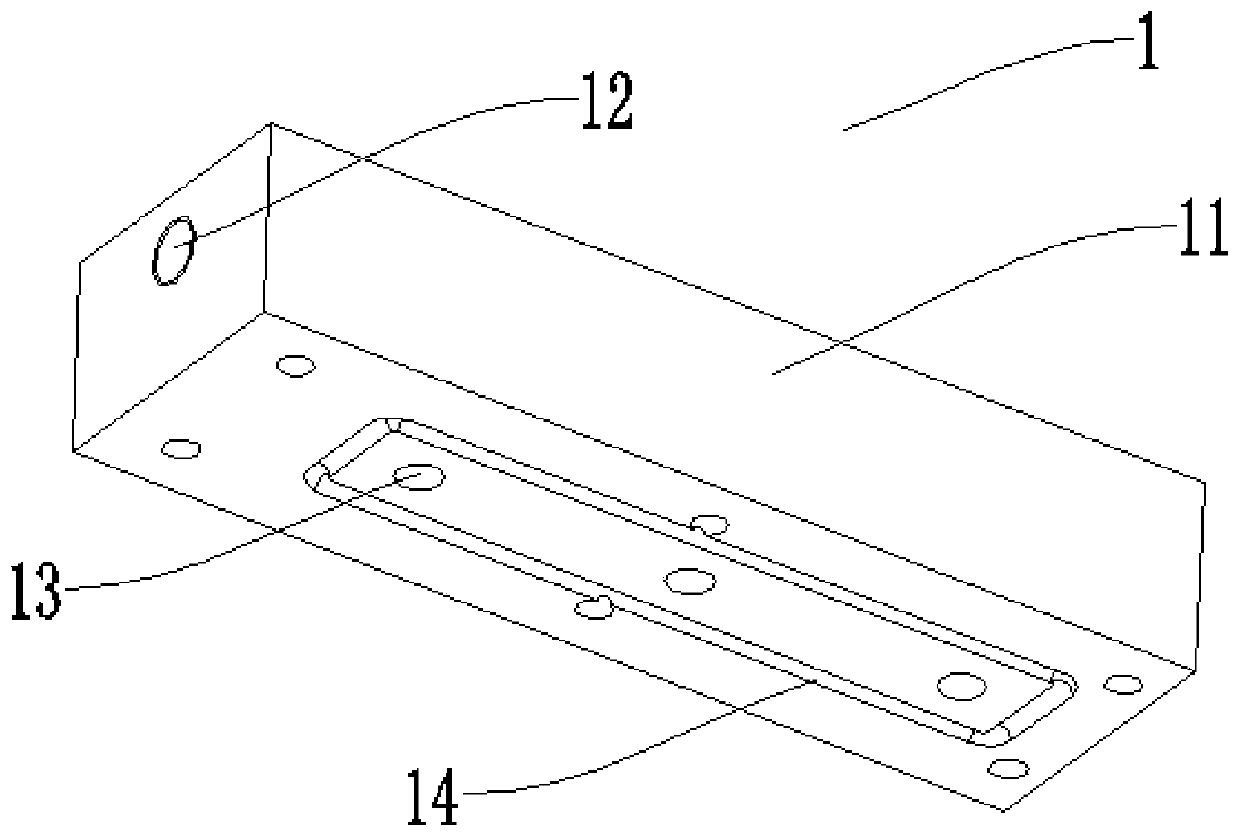

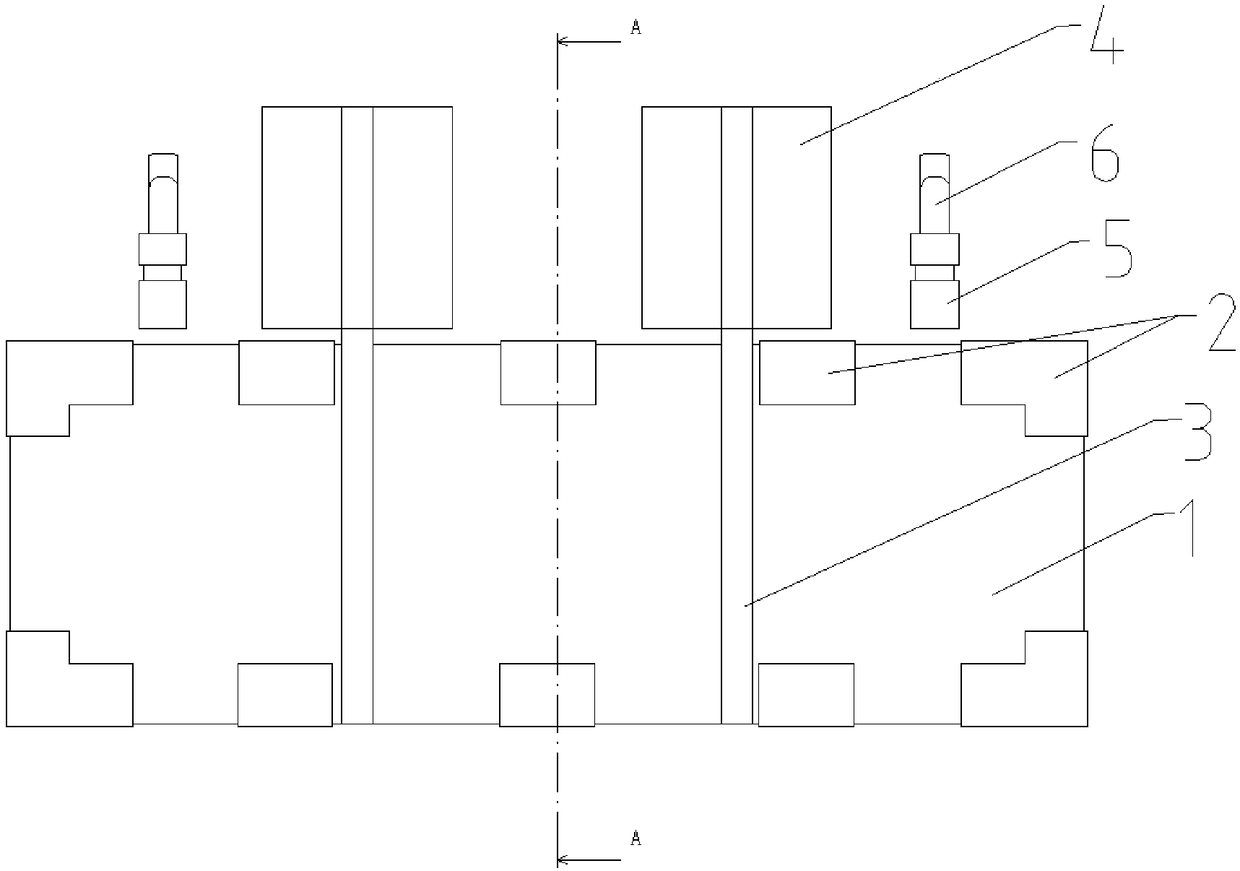

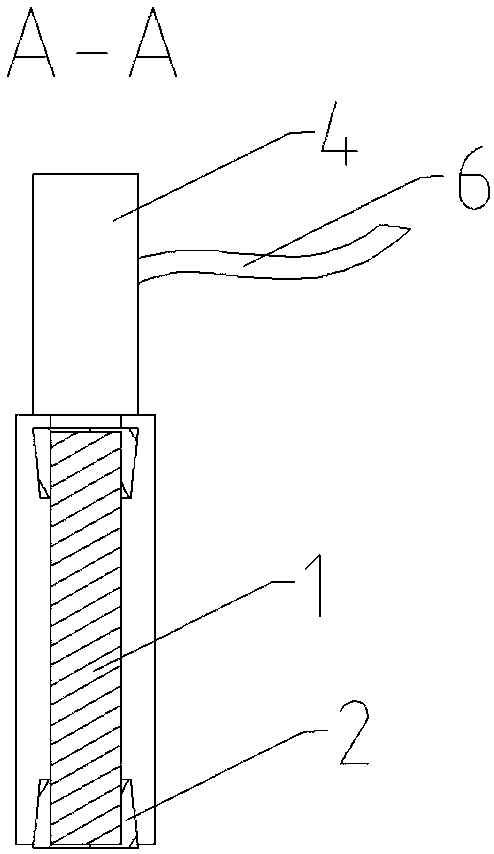

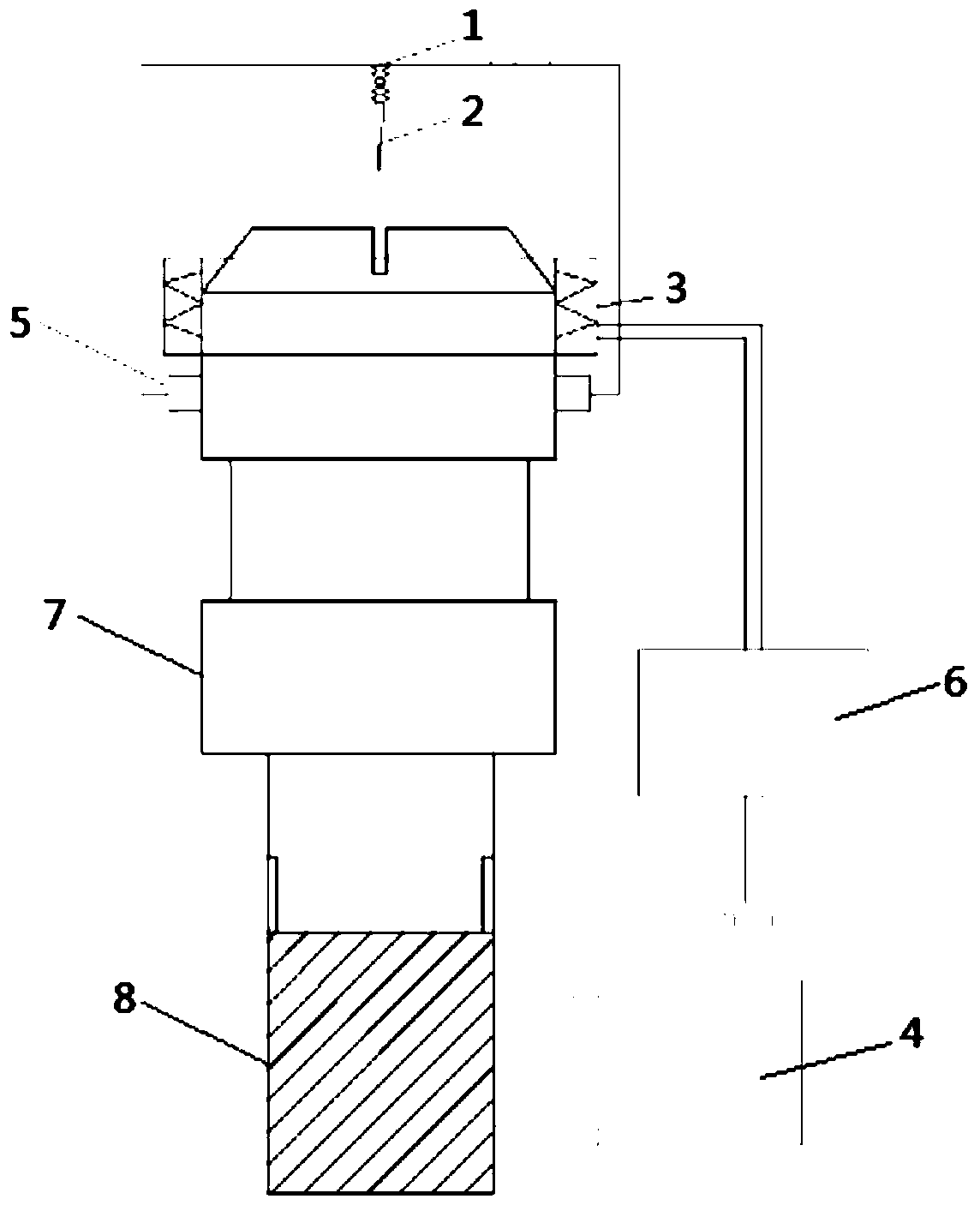

Non-pollution and non-ejecta rapid cover opening device for launcher container

The invention relates to a non-pollution and non-ejecta rapid cover opening device for a launcher container, and belongs to the field of launch technique. Before an aircraft is launched, under the trigger of the electric signal and the action of thrust produced by an electric actuator, a case cover can overcome weak link, and open quickly, and is locked to the box body after opening in place, the aircraft is out of the box after prelaunch preparation is completed. According to experimental verification, it is found that the achieved cover opening method has no smoke, and cannot produce any pollution to the seeker of the aircraft, and throws no debris, produce no damage to the other launching equipment on the ground, and is high in safety; the cover opening time is short, wherein the cover can be opened within 1 second; the device is simple in structure, strong in generalization, low in cost and good in practicability.

Owner:BEIJING INST OF SPECIALIZED MACHINERY

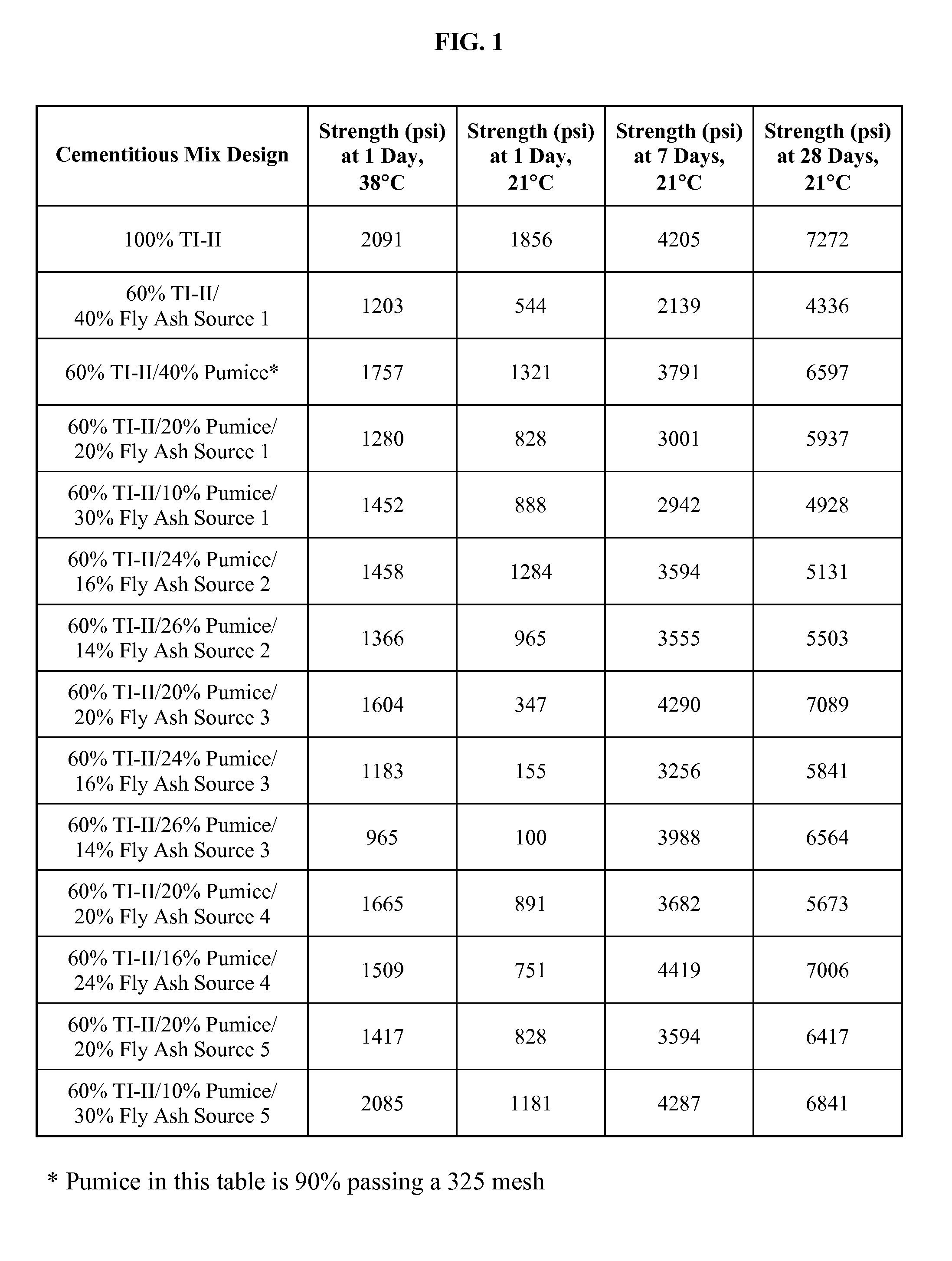

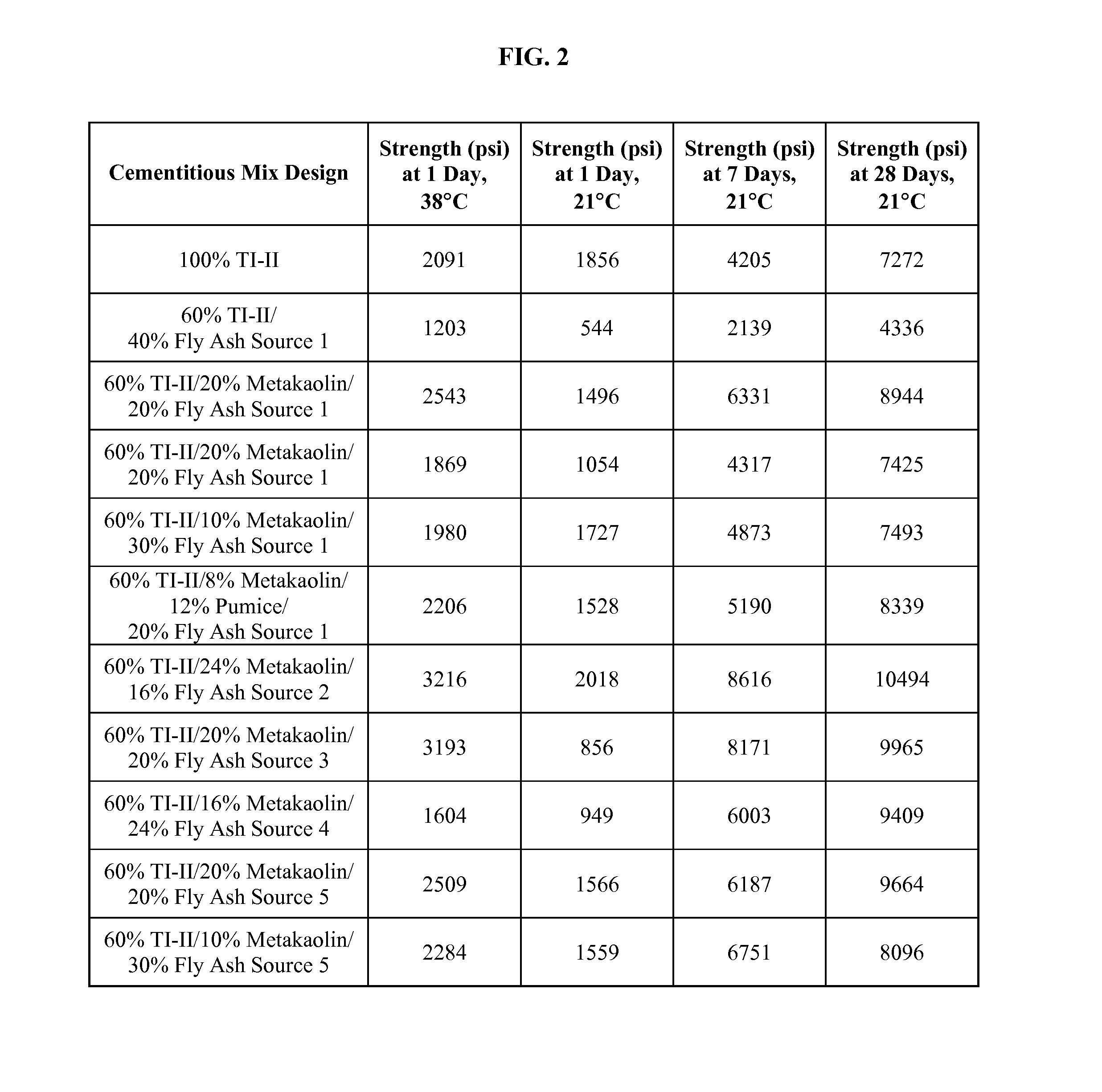

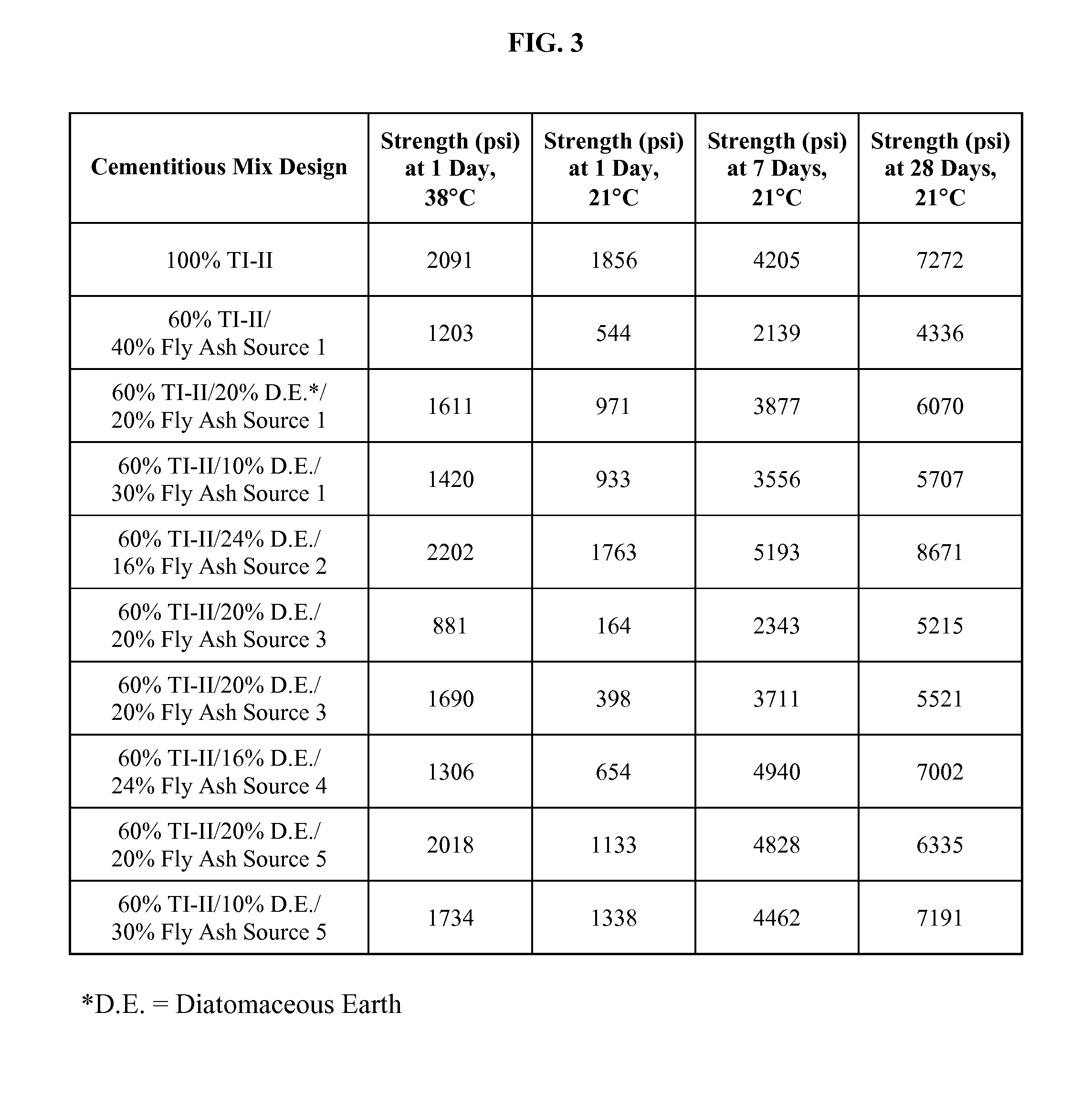

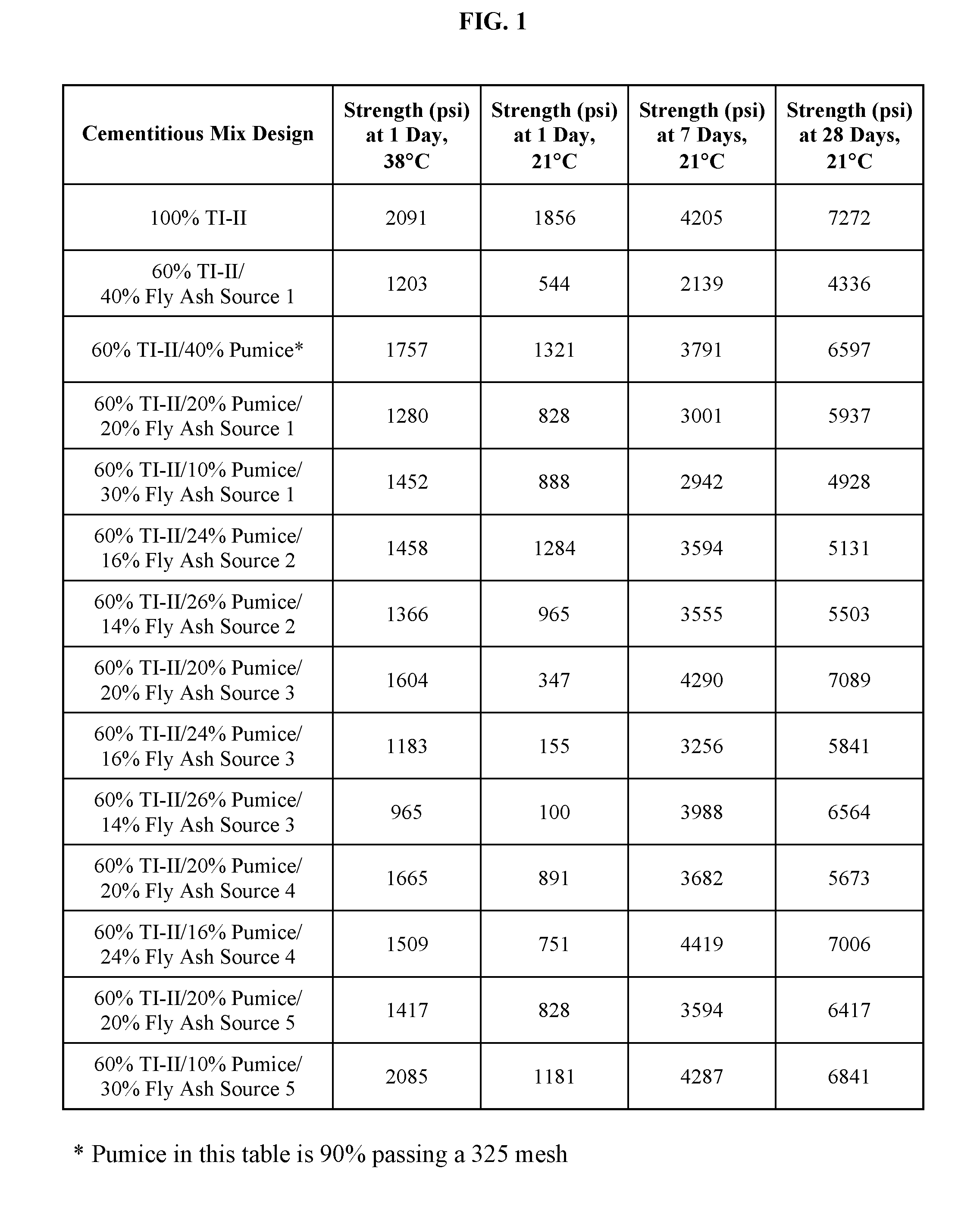

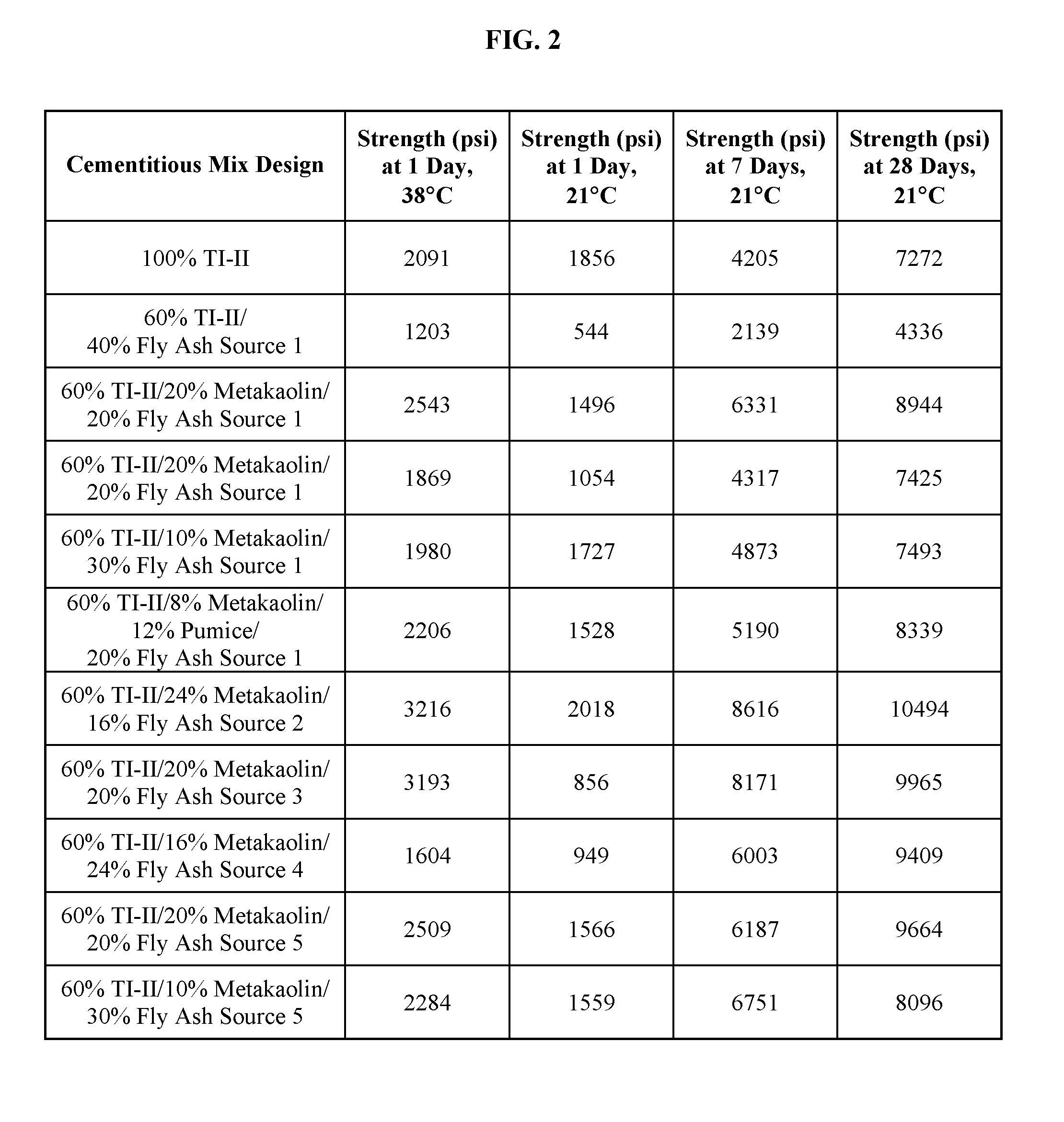

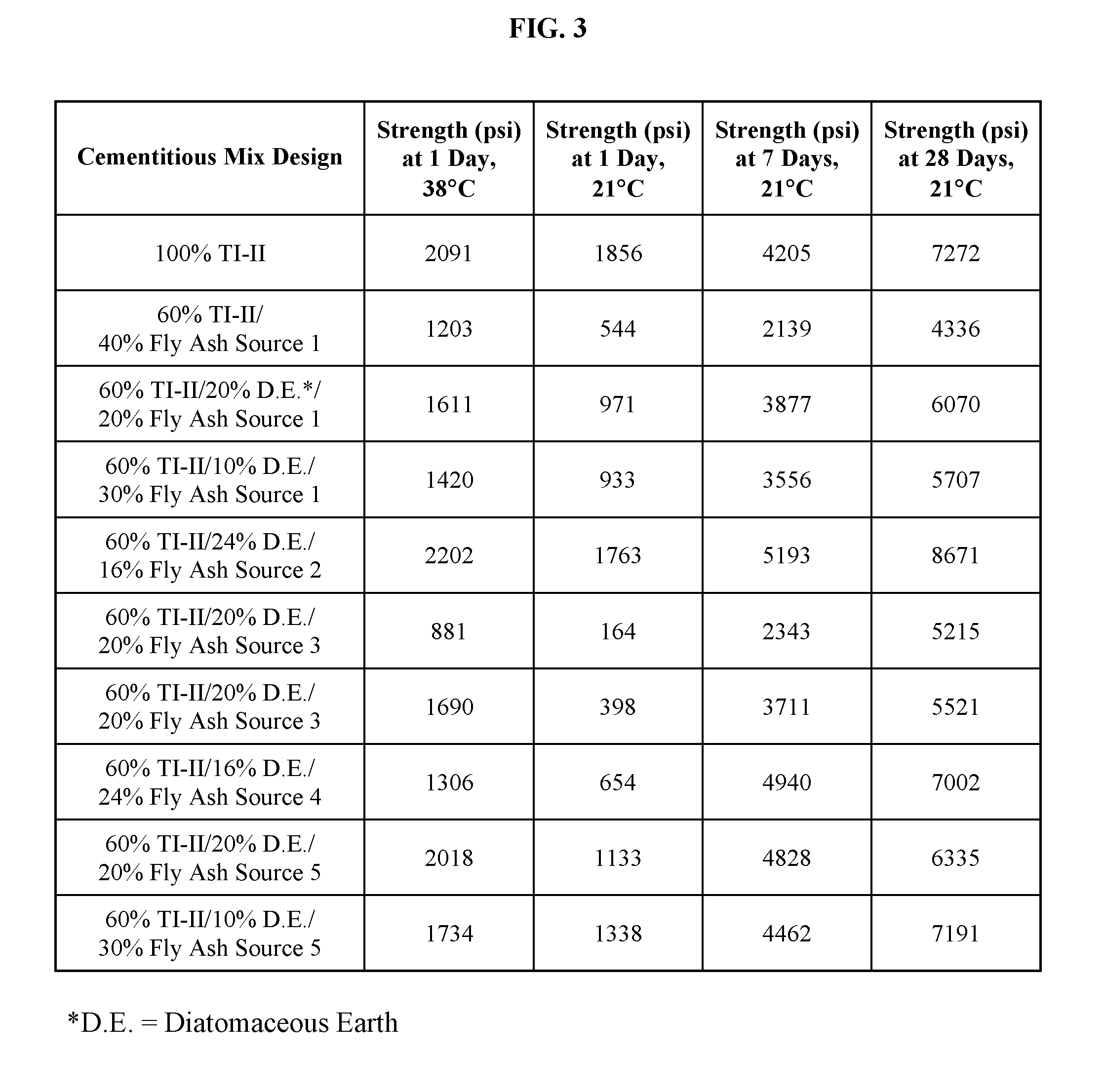

Pozzolanic compositions containing fly ash and remediation agents for use in cementitious materials

It has been unexpectedly discovered that the addition of a natural or other pozzolan to non-spec fly ash significantly improves the properties of the non-spec fly ash to the extent it can be certified under ASTM C618 and AASHTO 295, as either a Class F or Class C fly ash. The natural pozzolan may be a volcanic ejecta, such as pumice or perlite. Other pozzolans may also be used for this beneficiation process. Many pozzolans are experimentally tested and may be used to beneficiate non-spec fly ash into certifiable Class F fly ash. Additionally, this disclosure provides a method of converting a Class C fly ash to a more valuable Class F fly ash. This discovery will extend diminishing Class F fly ash supplies and turn non-spec fly ash waste streams into valuable, certified fly ash pozzolan which will protect and enhance concrete, mortars and grouts.

Owner:CR MINERALS COMPANY

Impact unlocking-spring potential energy driven launch box uncovering device

The invention relates to an impact unlocking-spring potential energy driven launch box uncovering device. During rocket missile storing and transporting, a locking stop block is inserted into a locking connector, and box cover locking is completed. When a rocket missile is launched, the head of the missile impacts an unlocking gasket, a flexible rope is pulled to draw the unlocking stop block out,box cover unlocking is completed, opening is quickly conducted under action of a thrust spring and a torsional spring, after a box cover is completely opened, the box cover is attached and fixed to alaunch box, and the windward area is effectively decreased. According to the uncovering mode, unlocking is achieved through impacting of the kinetic energy of the rocket missile, prefabricated springpotential energy driving is conducted, uncovering action does not need to be triggered by an electric signal, and reaction is rapid; and through reasonable design of parameters of the uncovering device, the effect that the rocket missile does not collide against the box cover in the box cover opening process can be ensured, and the launch safety is guaranteed. Ejecta do not exist in the box coveropening process, box cover disengagement is avoided, and damage to launch equipment and personnel on the ground is avoided; and the uncovering device is simple in structure, low in cost and good in practicality and has the universality.

Owner:NANJING UNIV OF SCI & TECH

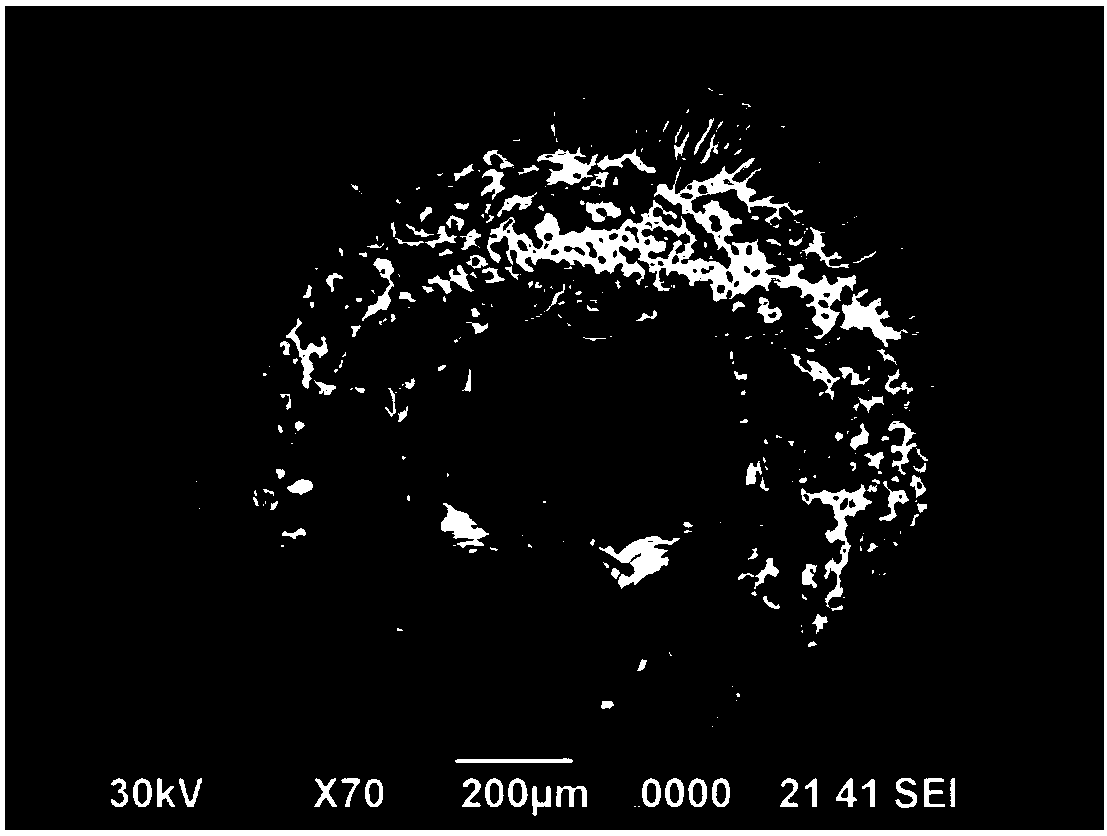

Mass based filtration devices and method of fabrication using bursts of ultrafast laser pulses

InactiveUS20150122656A1Easy to manufactureLow costCellsFatty/oily/floating substances removal devicesFiltrationEngineering

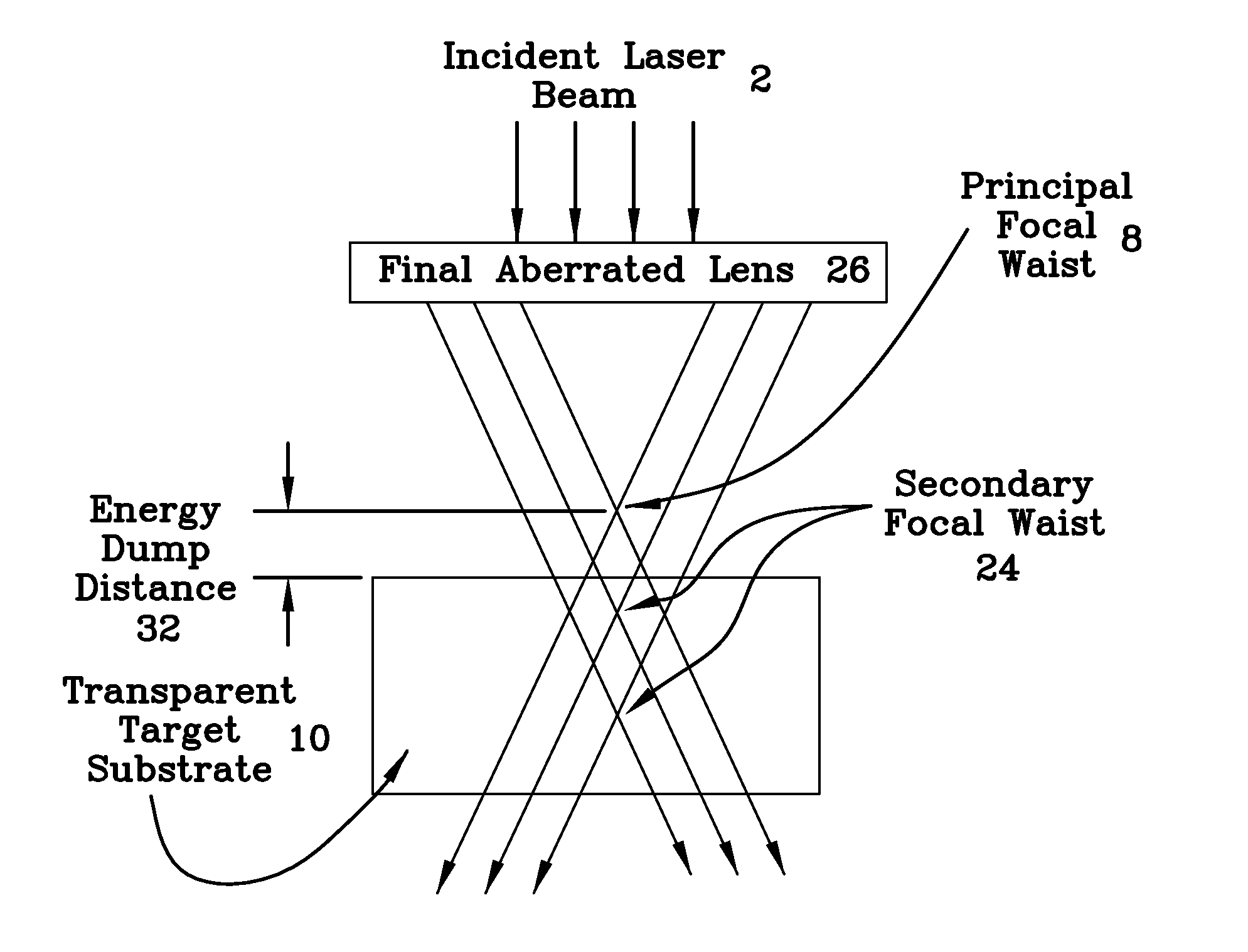

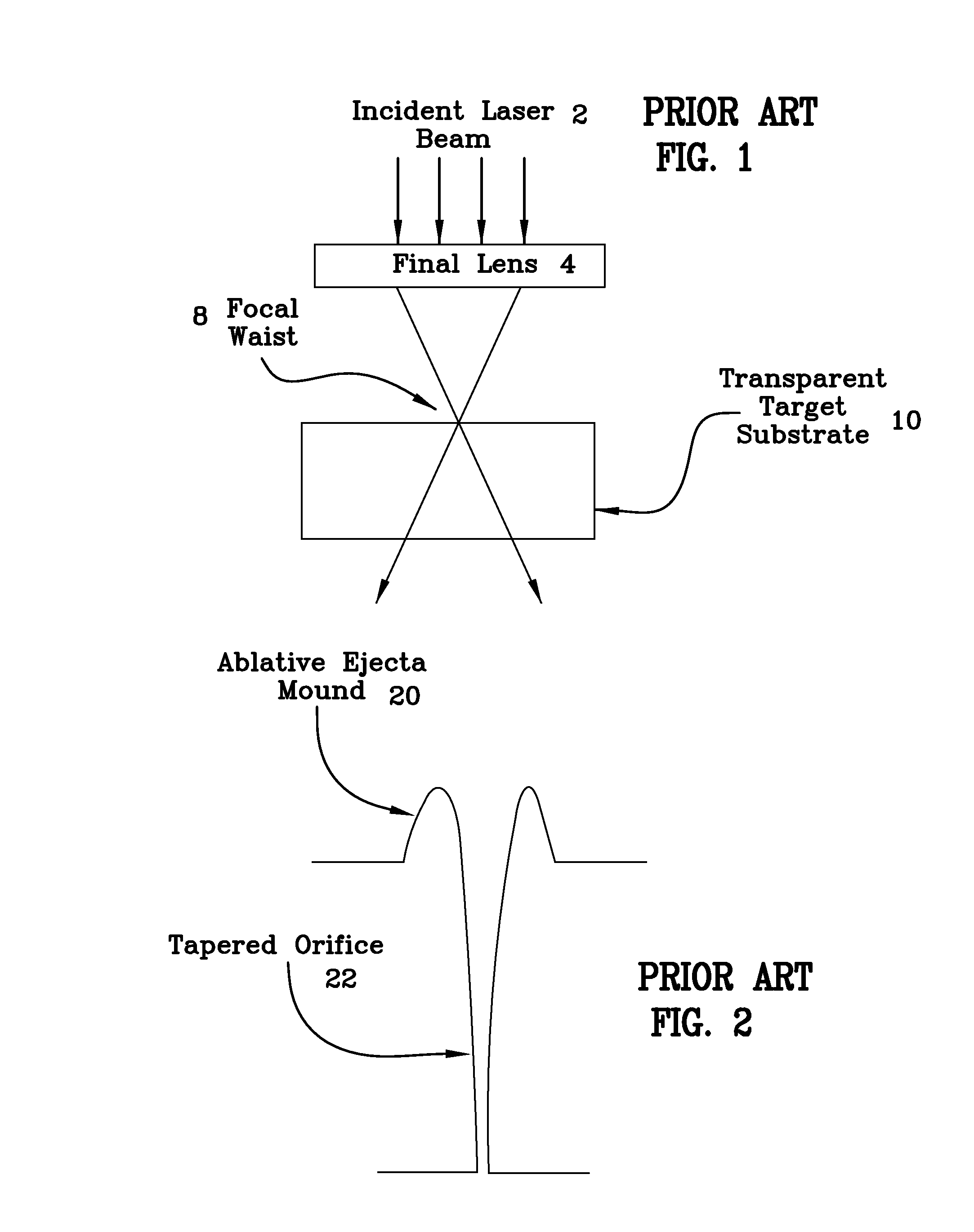

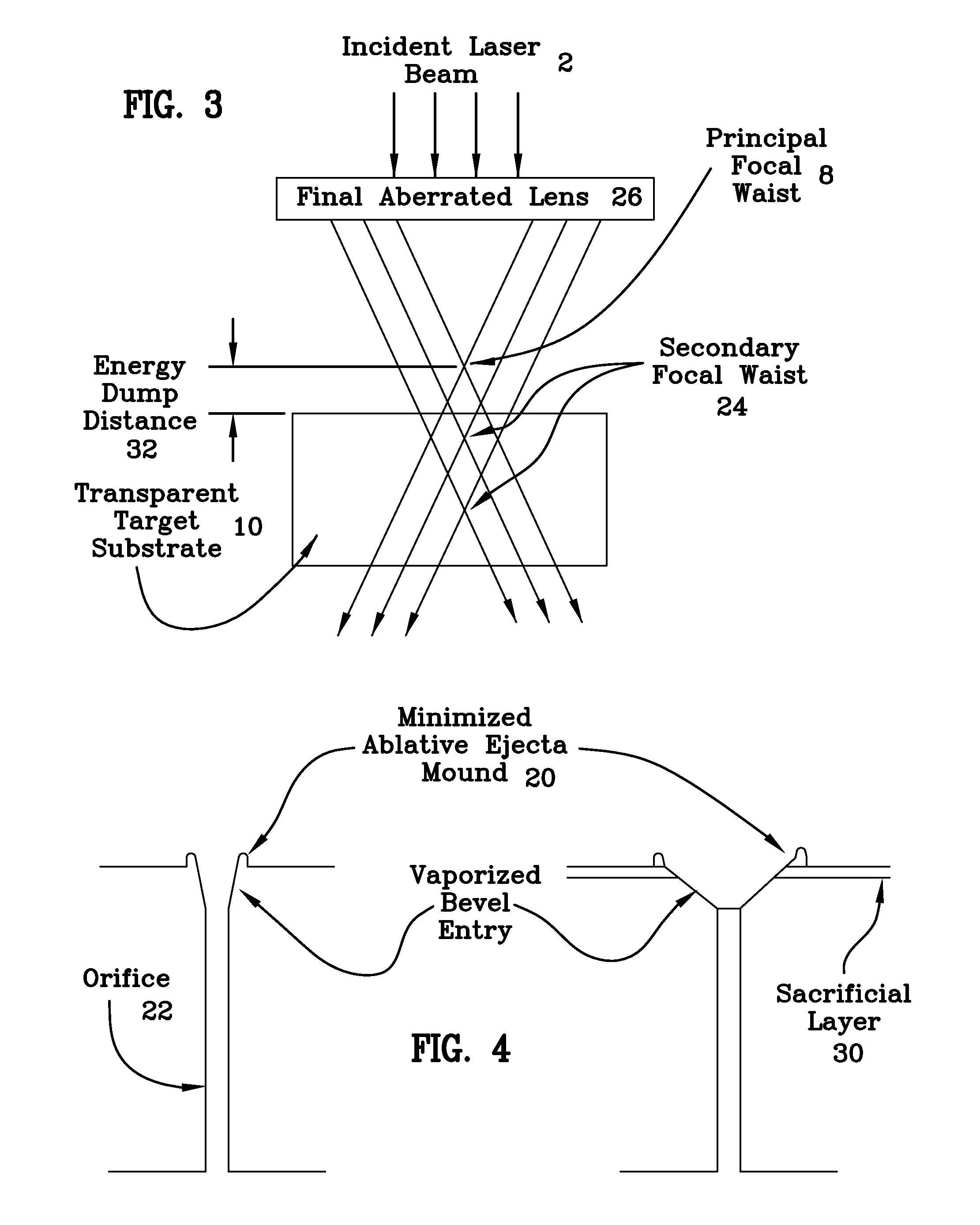

A mass separation device includes a transparent substrate and a plurality of small diameter cylindrically shaped orifices in the transparent substrate. The small diameter cylindrically shaped orifices include smooth wall surfaces and are not tapered. The small diameter cylindrically shaped orifices are drilled by photoacoustic compression and are clean and sharp and do not have ejecta mounds surrounding the orifice on the surface of the transparent substrate. The small diameter cylindrically shaped orifices in said transparent substrate are less than or equal to 1 μm in diameter. The transparent substrate is glass and preferably is borosilicate glass.

Owner:ROFIN SINAR TECH

Exhaust assembly for missile system, and method

A system, device and method provide an exhaust assembly adapted for use with a mass ejection drive system to produce rotational torque about the principle axis of the drive system. Representative features generally include a vane suitably configured to at least partially engage a mass ejecta stream to apply a net rotational torque about the principal axis of the drive system, and a tailfin coupled to the at least one vane. The tail fin is configured to selectively deploy from an at least partially stowed position in order to decrease the application of net rotational torque about the principal axis of the drive system.

Owner:RAYTHEON CO

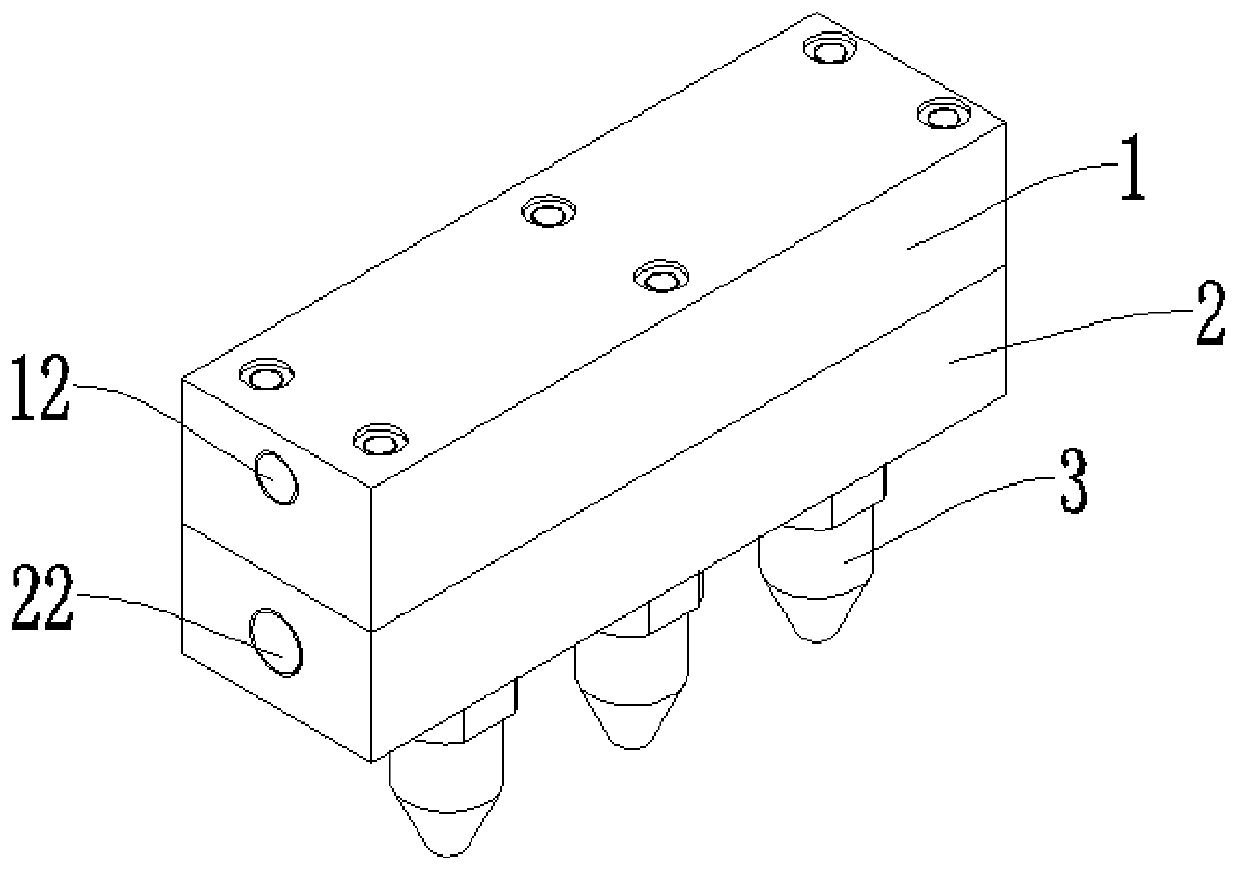

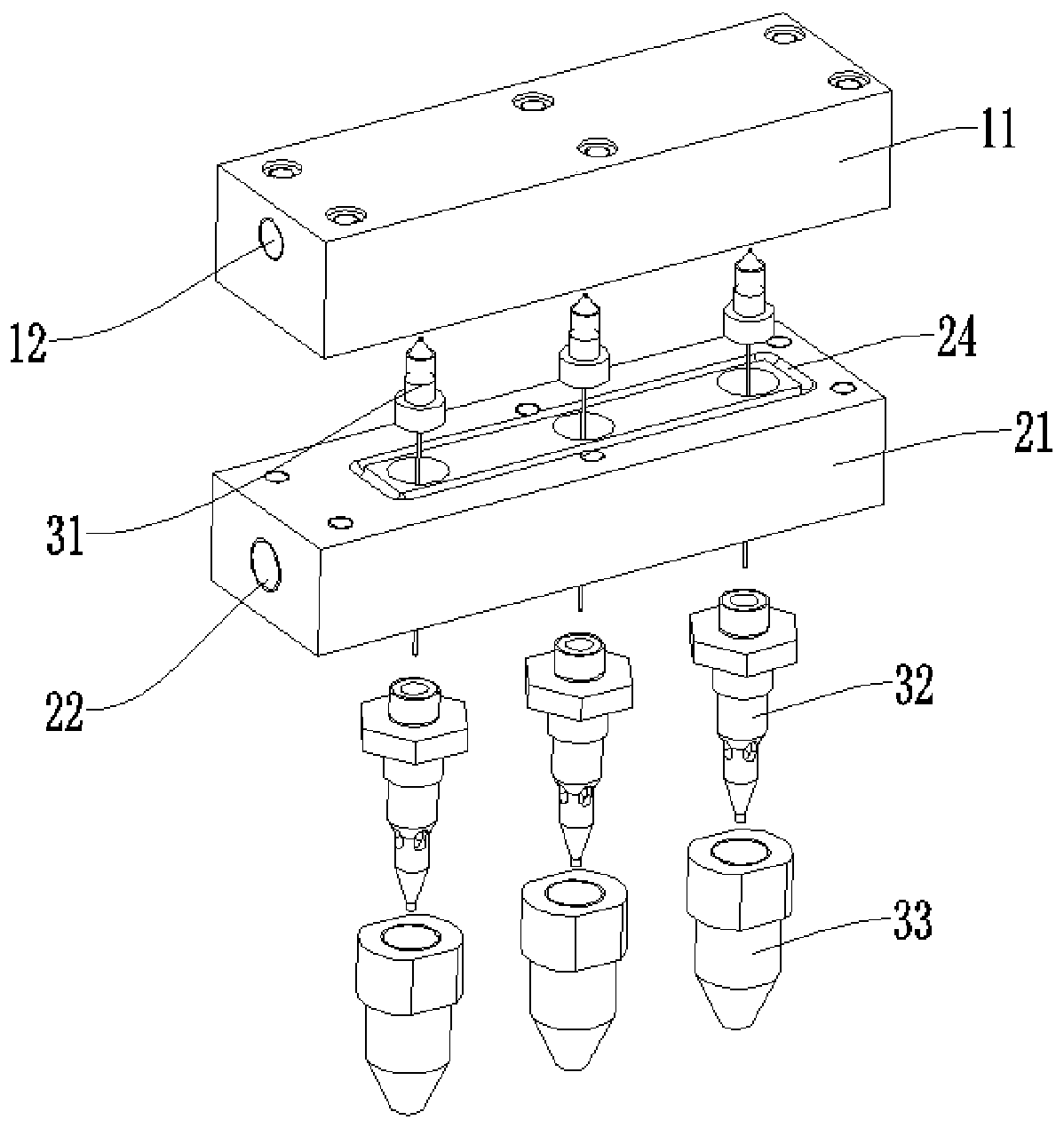

Array type dry ice spray head and gas-solid mixture generation method

InactiveCN110142160AReduce interfaceImprove air tightnessSpray nozzlesLiquid spraying apparatusSpray nozzleDry ice

The invention provides an array type dry ice spray head and a gas-solid mixture generation method. The array type dry ice spray head comprises an upper cavity, a lower cavity and a spray head assembly. The upper cavity comprises an upper cavity rack, a liquid inlet pipeline arranged on the upper cavity rack in a penetrating manner and a plurality of first branch pipes vertically arranged on the liquid inlet pipeline; the lower cavity comprises a lower cavity rack, an air inlet pipeline arranged on the lower cavity rack in a penetrating manner and a plurality of second branch pipes vertically arranged on the air inlet pipeline, and the first branch pipes communicate with the second branch pipes. The spray head assembly comprises throttlers connected to the first branch pipes in a sleeving manner, gas mixing devices connected to the second branch pipes and nozzles arranged on the gas mixing devices in a sleeving manner. Each gas mixing device is provided with a plurality of ventilating holes annularly, an annular cavity is formed between each gas mixing device and each nozzle, liquid carbon dioxide flows into the throttlers through the liquid inlet pipeline and is mixed with compressed gas at the outlets of the throttlers to be ejected through the gas mixing devices or the annular cavities. The array type dry ice spray head is few in port and is arranged in an array manner, and has relatively good air impermeability and gas mixing effect. The spraying direction and the flow rate of gas-solid mixed ejecta can be adjusted, so that the array type dry ice spray head can be suitable for different working occasions.

Owner:XIAMEN UNIV OF TECH

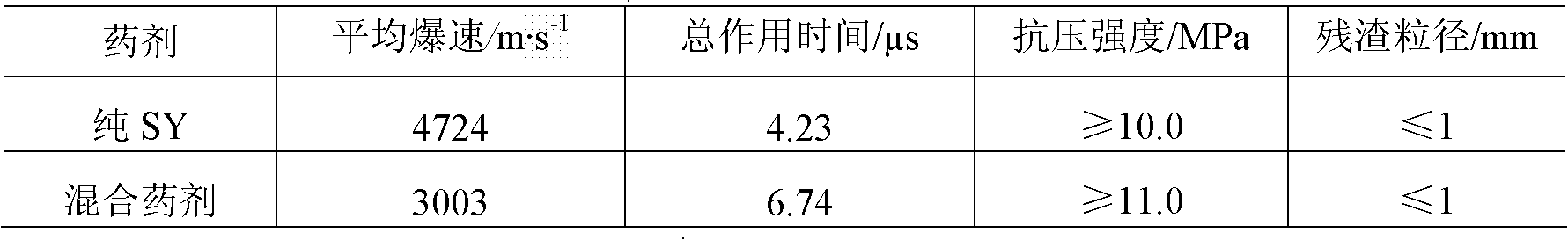

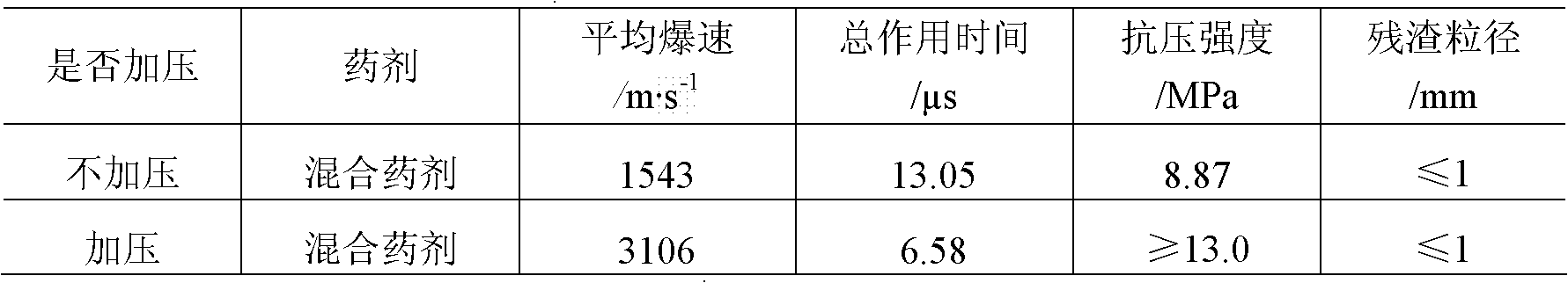

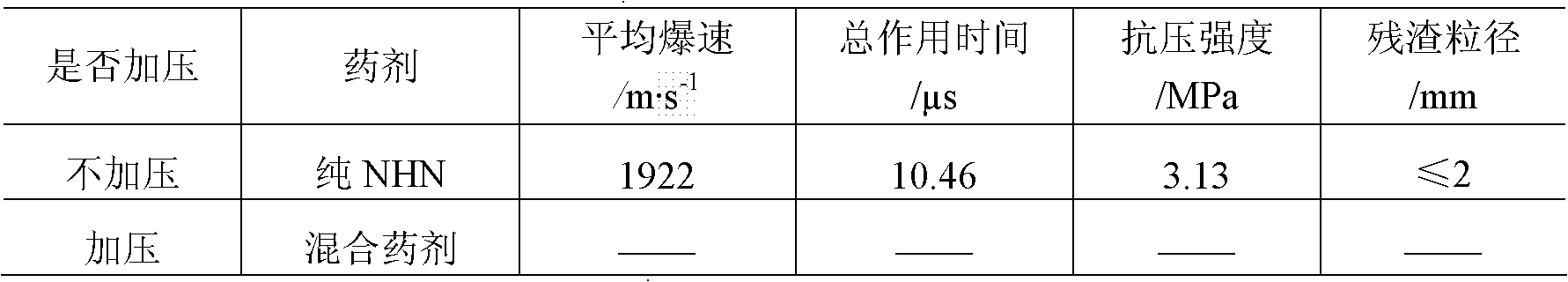

Novel energetic base material prepared from porous material and preparation method thereof

InactiveCN102659491AImprove performanceImprove ballistic performanceAmmonium perchlorate explosive compositionsRamjetDetonation

The invention provides a novel energetic base material prepared from a porous material and a preparation method thereof. The novel energetic base material and the preparation method thereof solve the problem that a closure material prepared in China at present has the defects of a large ejecta size, long action time and a complicated structure. The preparation method of the novel energetic base material comprises that an amine perchlorate eutectic compound (SY) or nickel hydrazine nitrate (NHN) as a reagent is added with additives and then the mixture is filled into porous ceramics or porous copper so that the novel energetic base material is obtained. The novel energetic base material obtained by the preparation method has excellent compressive properties, sealing properties and temperature resistance, can explode into fine fragments fast and reliably under the action of output energy from a miniature ignition / detonation device, and can be used as a closure material for a novel solid rocket ramjet air-intake duct.

Owner:NANJING UNIV OF SCI & TECH

Apparatus and method for ballistic protection of vehicle undercarriages

InactiveUS7059236B2Effectively and efficiently preventLittle strengthArmoured vehiclesShieldsTerrainEngineering

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

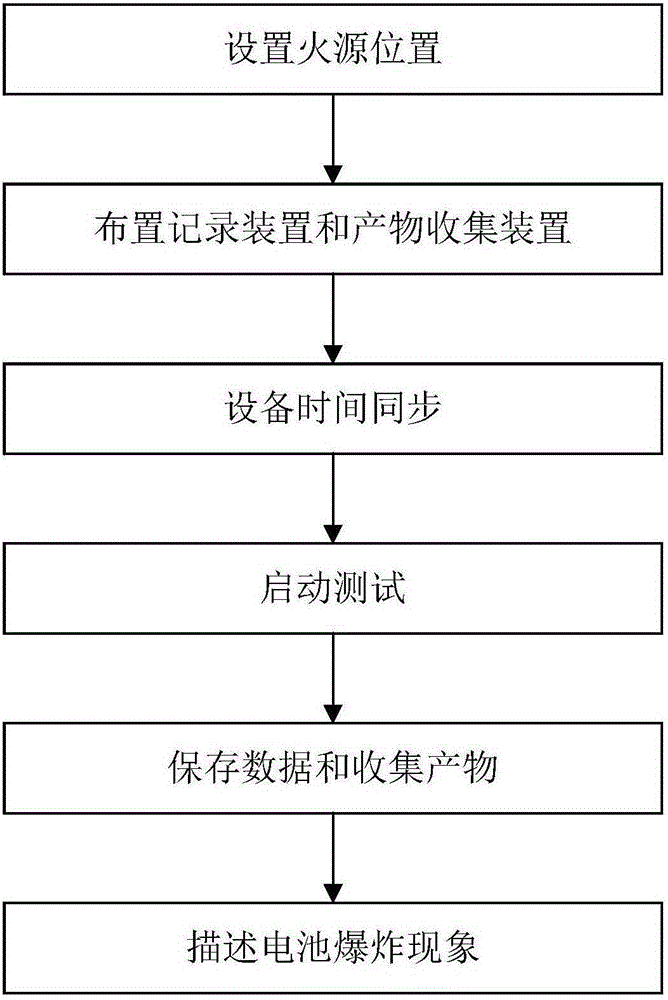

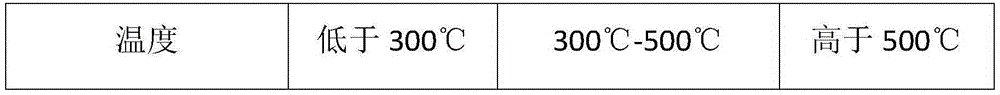

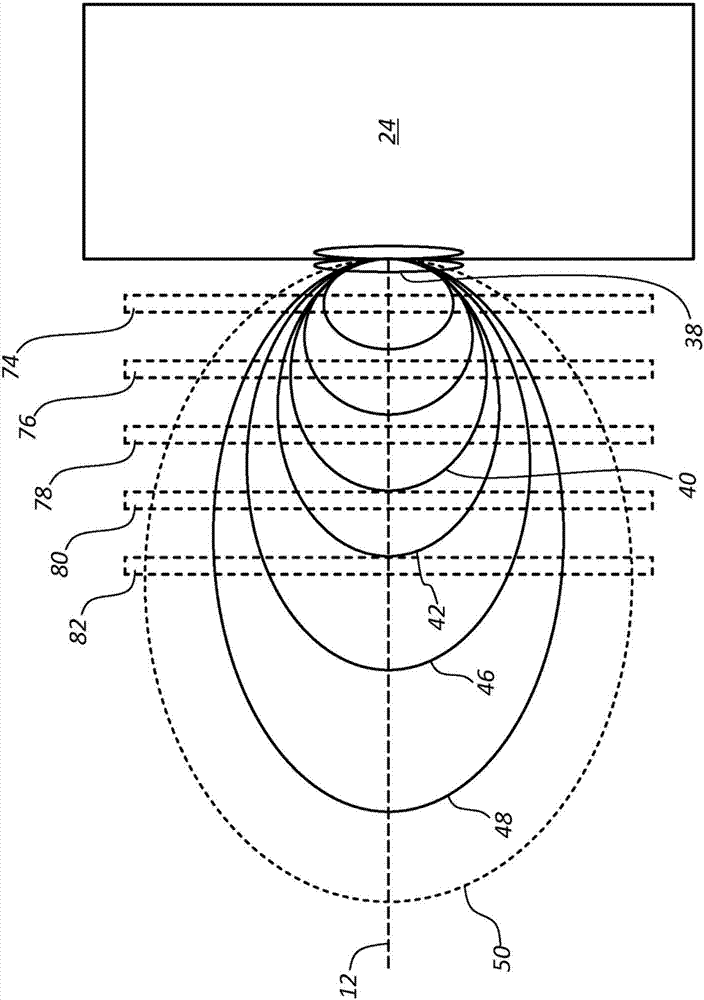

Lithium ion battery combustion detection method

InactiveCN105259298AImprove securityChemical analysis using combustionCritical conditionElectrical battery

The invention provides a lithium ion battery combustion detection method. The detection method comprises steps as follows: arranging a collection device; determining a trigger mode; starting a fire source to cause battery combustion; collecting data; clearing residues and ejecta. The lithium ion battery combustion detection method provided by the invention has the advantages that the method is used for detecting the excitation source critical condition for inducing lithium ion battery combustion, high-temperature resistance as well as firing and combustion process and products of a battery, targeted prevention and control are realized, and the safety of the lithium ion battery is greatly improved.

Owner:CHINA ELECTRIC POWER RES INST +2

System and method for making non-spherical nanoparticles and nanoparticle compositions made thereby

Systems and methods for selectively making non-spherical metal nanoparticles from a metal material. The metal target surface is ablated to create an ejecta event or plume containing nanoparticles moving away from the surface. Ablation may be caused by laser or electrostatic discharge. At least one electromagnetic field is placed in front of the solid target surface being ablated. The electromagnetic field manipulates at least a portion of the nanoparticles as they move away from the target surface through the electromagnetic field to create coral-shaped metal nanoparticles. The distance between the electromagnetic field and metal surface can be adjusted to yield metal nanoparticles of a desired size and / or shape.

Owner:伊沃克纳米公司

Cutting machine capable of controlling fracture by electrically controlled lasers

InactiveCN102310276AAvoid edge saggingIncrease profitLaser beam welding apparatusThermal deformationEngineering

The invention provides a cutting machine capable of controlling fracture by electrically controlled lasers. A control unit adopts alternating current to load electricity to realize the connection, identification and control functions of loaded electric appliances, and adopts intense magnetic fields to absorb integrally-fallen fragile waste materials, so that fragile materials which are easily destroyed through heating can be cut off fast and controllably by heating of laser beams; under the condition of heating of high-power intensity laser beams, the speed that a material surface temperature rises to a boiling temperature is fast, which is enough to avoid melt caused by heat conduction; a part of materials is vaporized into steam and disappears, and a part of materials is sucked back by auxiliary airflows from the bottom of a cutting slot as ejecta; the slot cut by the lasers is thin, the cutting surface is smooth, the cutting speed is fast, the thermal deformation is small, the laser cutting is in no contact with the material surface, the cutting machine is suitable for processing bulky commodities and the materials are saved, moreover, the cutting machine can be applied to sheet-metal processing of relevant industries such as heavy and light industries, medical industries and the like, cutting and shaping of rotators, stators and blades, manufacturing of various chains and parts of vehicular manufacturing industry, advertisement decoration and handicraft article manufacturing industries, etc.

Owner:胡忠

Magnetic separated laser oxidizing fusion cutting machine

InactiveCN102310280AAvoid edge saggingIncrease profitLaser beam welding apparatusChemical reactionThermal deformation

The invention provides a magnetic separated laser oxidizing fusion cutting machine. The cutting machine is characterized in that oxygen or other active gases are adopted to replace inert gases to perform fusion cutting, and high-intensity magnetic fields are adopted to suck back wastes so as to replace an auxiliary air unit; under heating of high-power intensity laser beams, the speed that the temperature of a material surface rises to the boiling temperature is fast so as to avoid the fusion caused by heat conduction; the cut materials are ignited by irradiation of the laser beams so as to perform a fierce chemical reaction with the oxygen to generate a larger heat source; a part of materials is vaporized into steam and disappears, and a part of materials is sucked back by auxiliary airflows from the bottom of a cutting slot as ejecta; the cutting slot cut by lasers is thin, the cutting surface is smooth, the cutting speed is fast, the thermal deformation is small, the laser cutting is in no contact with the material surface, the cutting machine is suitable for processing large-sized products, the materials are saved, moreover, the cutting machine can be applied to sheet-metal processing of relevant industries such as heavy and light industries, medical industries and the like, cutting and shaping of rotators, stators and blades, manufacturing of various chains and parts of vehicular manufacturing industry, advertisement decoration and handicraft article manufacturing industries, etc.

Owner:胡忠

Aramid fiber ultrafiltration membrane and preparation method thereof

InactiveCN110465201AHigh tensile strengthHigh compressive strengthUltrafiltrationOrganic solventUltrafiltration

The invention discloses a preparation method of an aramid fiber ultrafiltration membrane. The preparation method includes the following steps: at least one organic solvent, at least one additive and an aramid fiber solution are provided, after the organic solvent, the additives and the aramid fiber solution are mixed and dissolved, defoaming is carried out under a vacuum condition to prepare a membrane casting solution; the membrane casting solution and braided pipes or reinforcing fibers are sprayed through a nozzle, and an ejecta is immersed in immersion liquid and gel liquid in order to solidify the ejecta into membrane filaments; and the membrane filaments are rinsed, the additives and the solvent are removed, and then the aramid fiber ultrafiltration membrane is obtained. The invention also provides the aramid fiber ultrafiltration membrane prepared by the method. The aramid fiber ultrafiltration membrane of the invention can be effectively improved in the tensile and compressivestrength of the membrane, improved in the spinnability in the process of membrane preparation and greatly improved in membrane flux.

Owner:OCHEMATE MATERIAL TECH CO LTD

Pozzolanic compositions containing fly ash and remediation agents for use in cementitious materials

It has been unexpectedly discovered that the addition of a natural or other pozzolan to non-spec fly ash significantly improves the properties of the non-spec fly ash to the extent it can be certified under ASTM C618 and AASHTO 295, as either a Class F or Class C fly ash. The natural pozzolan may be a volcanic ejecta, such as pumice or perlite. Other pozzolans may also be used for this beneficiation process. Many pozzolans are experimentally tested and may be used to beneficiate non-spec fly ash into certifiable Class F fly ash. Additionally, this disclosure provides a method of converting a Class C fly ash to a more valuable Class F fly ash. This discovery will extend diminishing Class F fly ash supplies and turn non-spec fly ash waste streams into valuable, certified fly ash pozzolan which will protect and enhance concrete, mortars and grouts.

Owner:CR MINERALS COMPANY

Auxiliary air laser oxidizing fusion cutting machine of compressor

InactiveCN102310283AAvoid edge saggingIncrease profitLaser beam welding apparatusChemical reactionThermal deformation

The invention provides an auxiliary air laser oxidizing fusion cutting machine of a compressor. The cutting machine is characterized in that oxygen or other active gases are adopted to replace inert gases to perform fusion cutting, and auxiliary airs are adopt strong airflows produced by a compressor, and the speed that the temperature of a material surface rises to the boiling temperature is fast so as to avoid the fusion caused by heat conduction under heating of high-power intensity laser beams; the cut materials are ignited by irradiation of the laser beams so as to perform a fierce chemical reaction with the oxygen to generate a larger heat source; a part of materials is vaporized into steam and disappears, and a part of materials is sucked back by auxiliary airflows from the bottom of a cutting slot as ejecta; the cutting slot cut by lasers is thin, the cutting surface is smooth, the cutting speed is fast, the thermal deformation is small, the laser cutting is in no contact with the material surface, the cutting machine is suitable for processing bulky commodities and the materials are saved, moreover, the cutting machine can be applied to sheet-metal processing of relevant industries such as heavy and light industries, medical industries and the like, cutting and shaping of rotators, stators and blades, manufacturing of various chains and parts of vehicular manufacturing industry, advertisement decoration and handicraft article manufacturing industries, etc.

Owner:胡忠

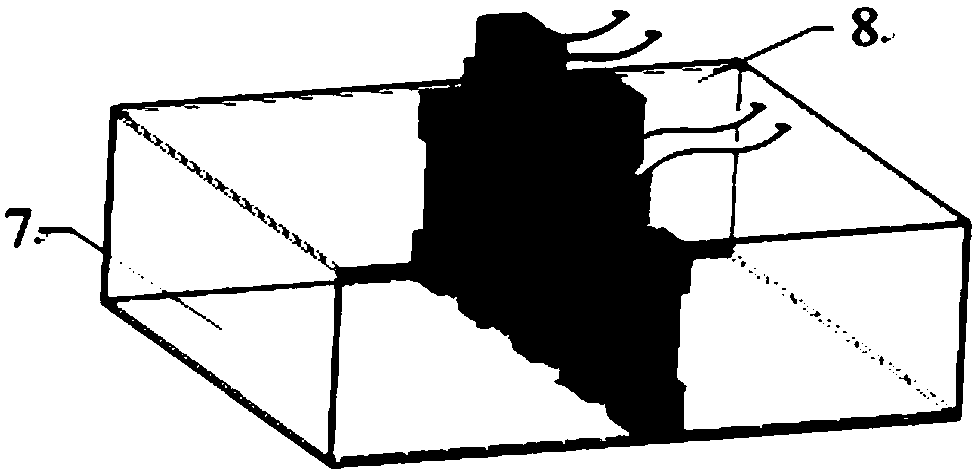

Supersonic air inlet channel plugging cap device

ActiveCN109488460AHigh strengthIncrease stiffnessGas turbine plantsRam jet enginesInlet channelEngineering

The invention relates to a supersonic air inlet channel plugging cap device. The supersonic air inlet channel plugging cap device comprises a plugging cap body (1), a damping piece (2), a supporting rod (3), a driving motor (4), an exploder (5) and a cable (6). The supersonic air inlet channel plugging cap device has the definite mounting position and the quite good fastening and damping effects,mounting and demounting operation can be conducted conveniently and quickly, disturbance to a missile in the cap opening process is small, force bearing is uniform, ejecta is not generated after blasting, the safety of an aerial carrier is facilitated, the number of structural pieces is small, and maintenance is easy.

Owner:JIANGXI HONGDU AVIATION IND GRP

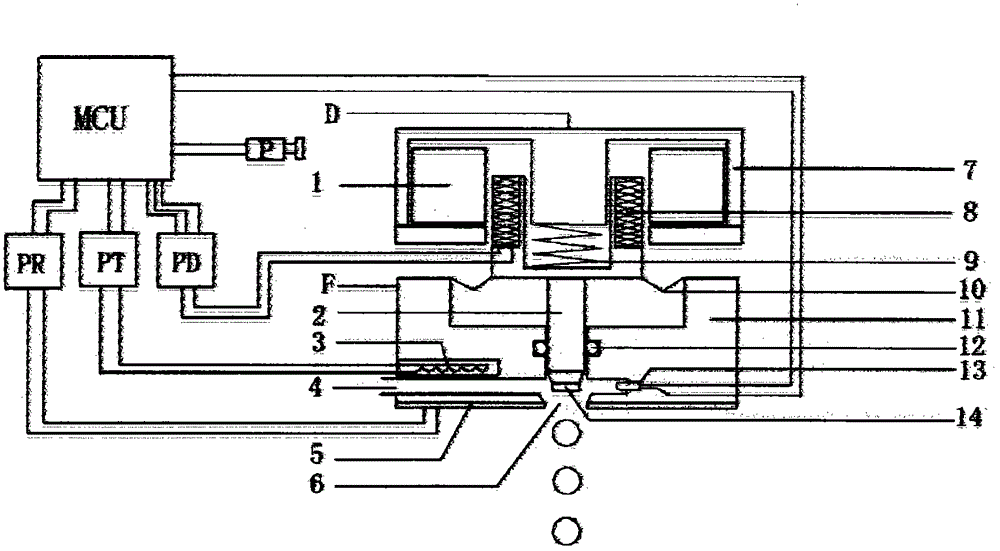

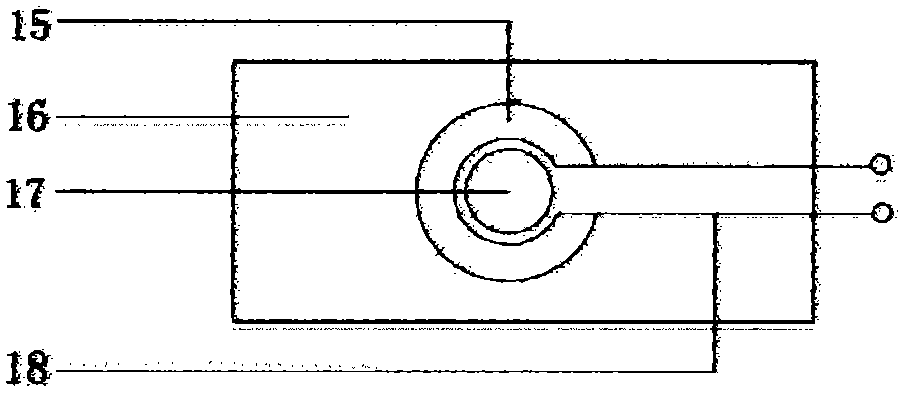

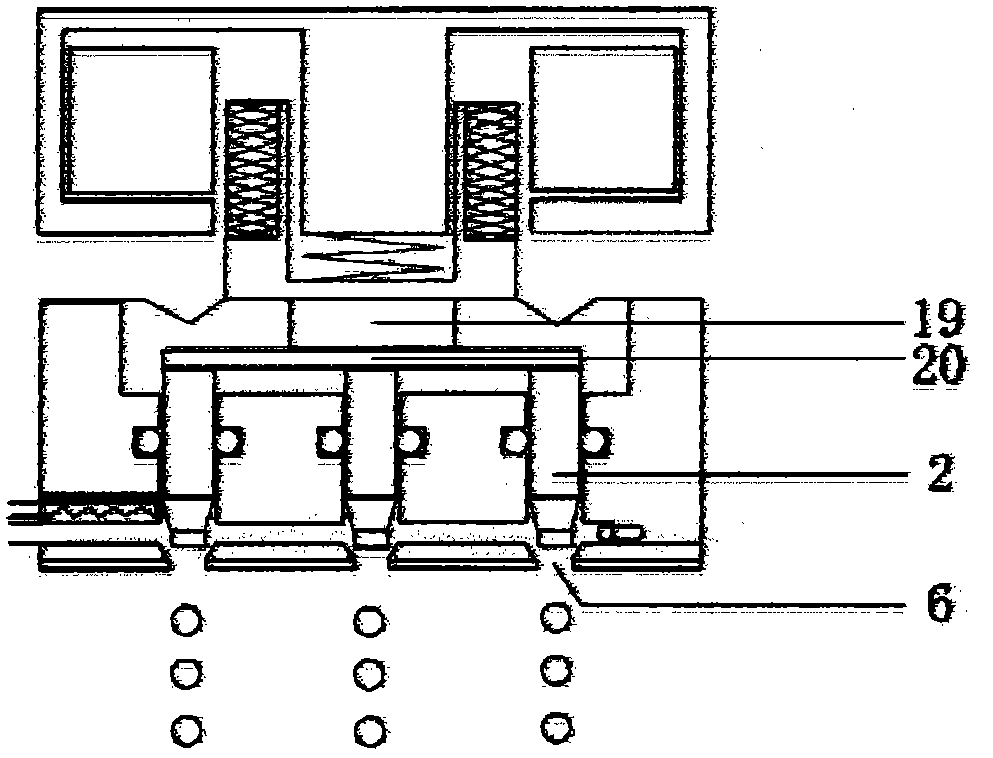

A Vacuum Drying Electronically Controlled Quantitative Micro-spraying Method and Device

ActiveCN104771920BWide concentration rangeAvoid ice blockageEvaporator accessoriesEvaporation by sprayingHeat carrierEngineering

Owner:HEBEI XINGLONG ELEVATORING EQUIP CO LTD

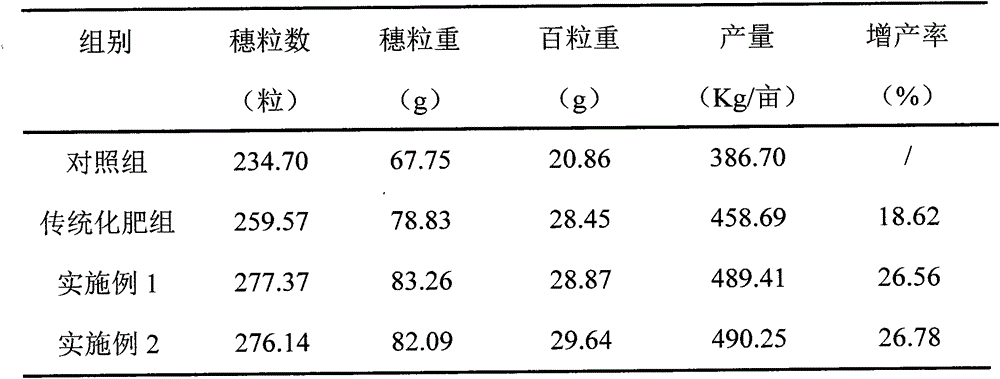

A kind of instant water-soluble fertilizer and preparation method thereof

The invention discloses an instant water-soluble fertilizer, which is mainly prepared from the following raw materials: urea, potassium dihydrogen phosphate, ammonium polyphosphate, potassium nitrate, trace elements in chelated state, anti-caking agent, surfactant, disintegrant antidote. The instant water-soluble fertilizer of the present invention can quickly dissolve, promote the rapid absorption of nutrients by plants, improve the utilization rate of nutrients, improve the quality and yield of plants, and can avoid soil pollution after application, and can meet the needs of drip irrigation and micro-spraying The preparation method of the instant water-soluble fertilizer of the present invention has easy-to-obtain raw materials, simple operation, and is easy to implement, and the obtained instant water-soluble fertilizer has stable and reliable quality, which is beneficial to the full absorption of each nutrient element by plants and greatly improves the plant yield .

Owner:孙龙专

Numerically controlled laser oxidizing fusion cutting machine with auxiliary gases

InactiveCN102310282AAvoid edge saggingIncrease profitLaser beam welding apparatusChemical reactionLaser cutting

Owner:胡忠

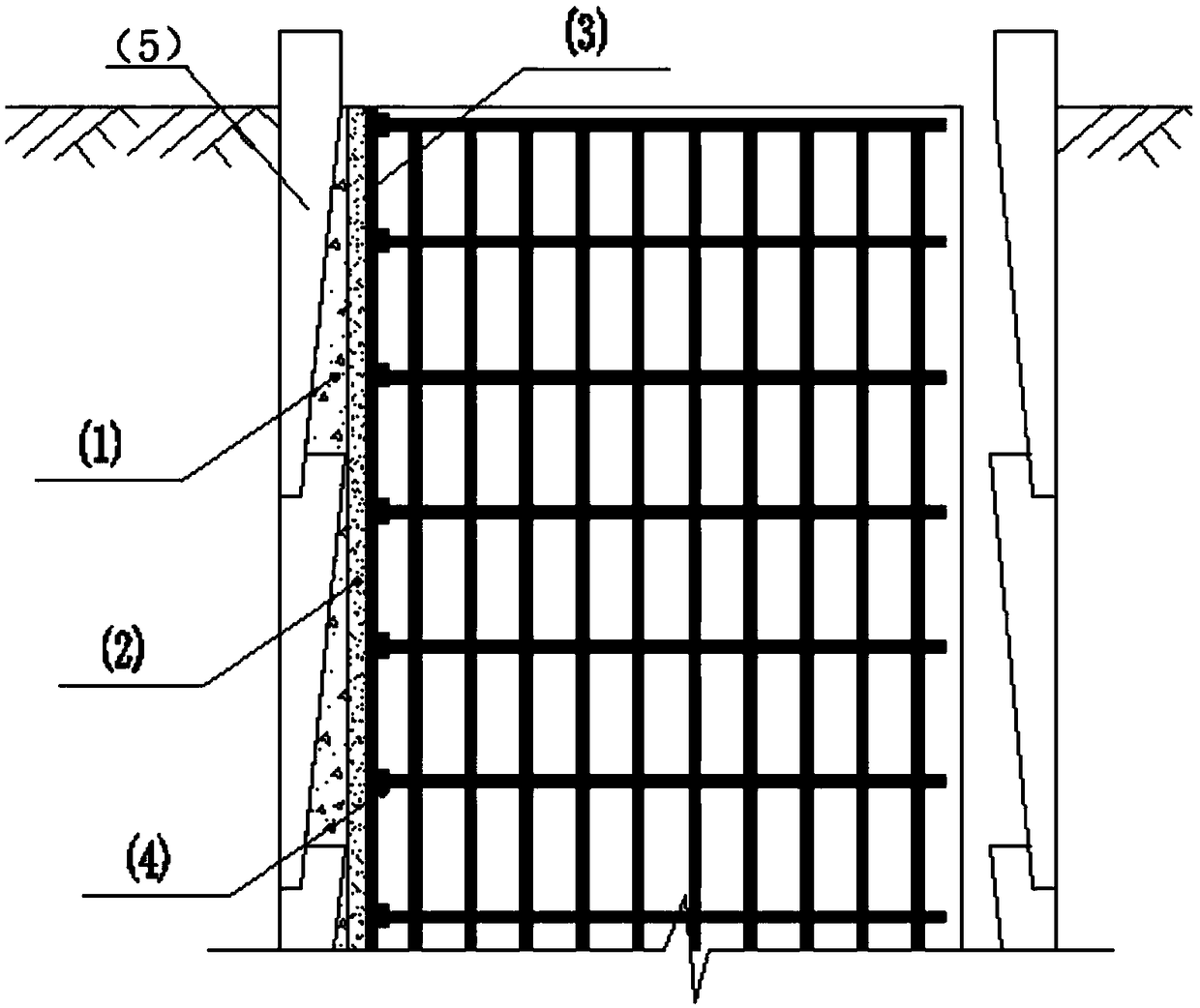

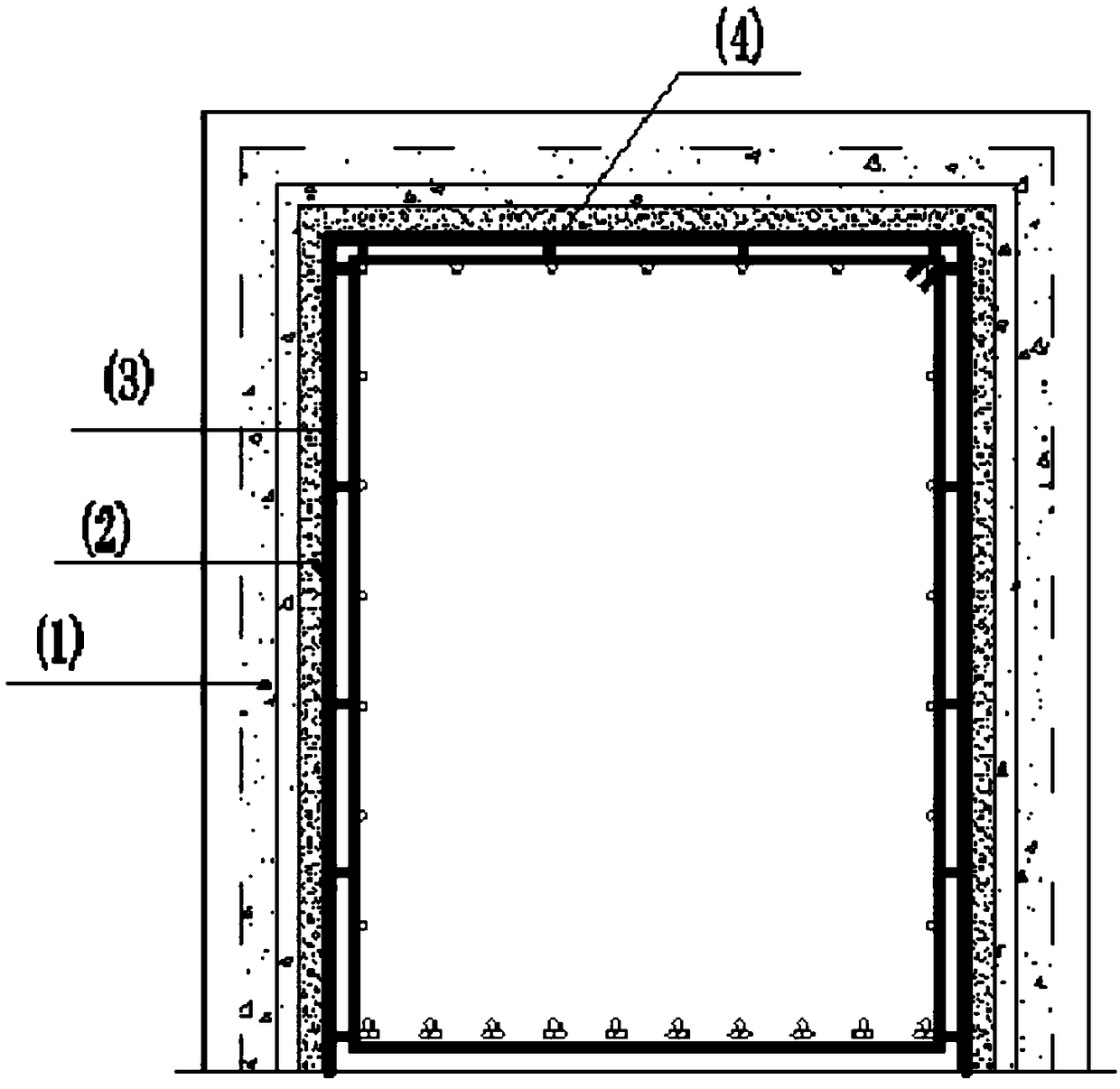

Fair-faced supporting formwork structure on exposed face of side slope road cutting manual hole digging slide-resistant pile and construction technology

The invention relates to a fair-faced supporting formwork structure on the exposed face of a side slope road cutting manual hole digging slide-resistant pile and a construction technology. The structure comprises a fine aggregate concrete back-ejecta layer, wherein the fine aggregate concrete back-ejecta layer is arranged on the inner side wall of the pile hole of a manual hole digging pile on theexposed side of a slide-resistant pile; a mortar back-ejecta layer is arranged on the surface of the fine aggregate concrete back-ejecta layer; a plastic thin film plate is paved on the inner side wall of the mortar back-ejecta layer; and a plurality of prefabricated cushion blocks bound with rebars of the slide-resistant pile are uniformly distributed on the inner side walls of the plastic thinfilm plate. The fair-faced supporting formwork structure adopts a unique multi-layer structure, is simpler in construction and realizes the purpose that the surface quality of fair-faced concrete on the exposed face of the manual hole digging slide-resistant pile is high.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

A non-clogging micro spray nozzle

The invention relates to a blocking-free micro-spraying nozzle which comprises a nozzle body, a water inlet pipe, a sensor, an electromagnetic adsorption device and a puncture mechanism. The nozzle body is formed by connecting a spray head and a flange. One end of the water inlet pipe is connected with the flange. The sensor is mounted in the water inlet pipe and connected with a controller. The electromagnetic adsorption device is arranged outside the spray head in a surrounding manner and connected with the controller. The puncture mechanism is mounted at one side of the spray head and magnetically connected with the electromagnetic adsorption device. The sensor is a pressure sensor. The blocking-free micro-spraying nozzle has the beneficial effects that product cost is low, the product maintenance amount is small, and the blocking preventing efficiency is high; and the application range is wide, the service life of the nozzle is effectively prolonged, and mounting is convenient and fast.

Owner:JAINGSU TOPSCI ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com