A non-clogging micro spray nozzle

A non-clogging, nozzle technology, applied in the direction of injection devices, etc., can solve problems such as nozzle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

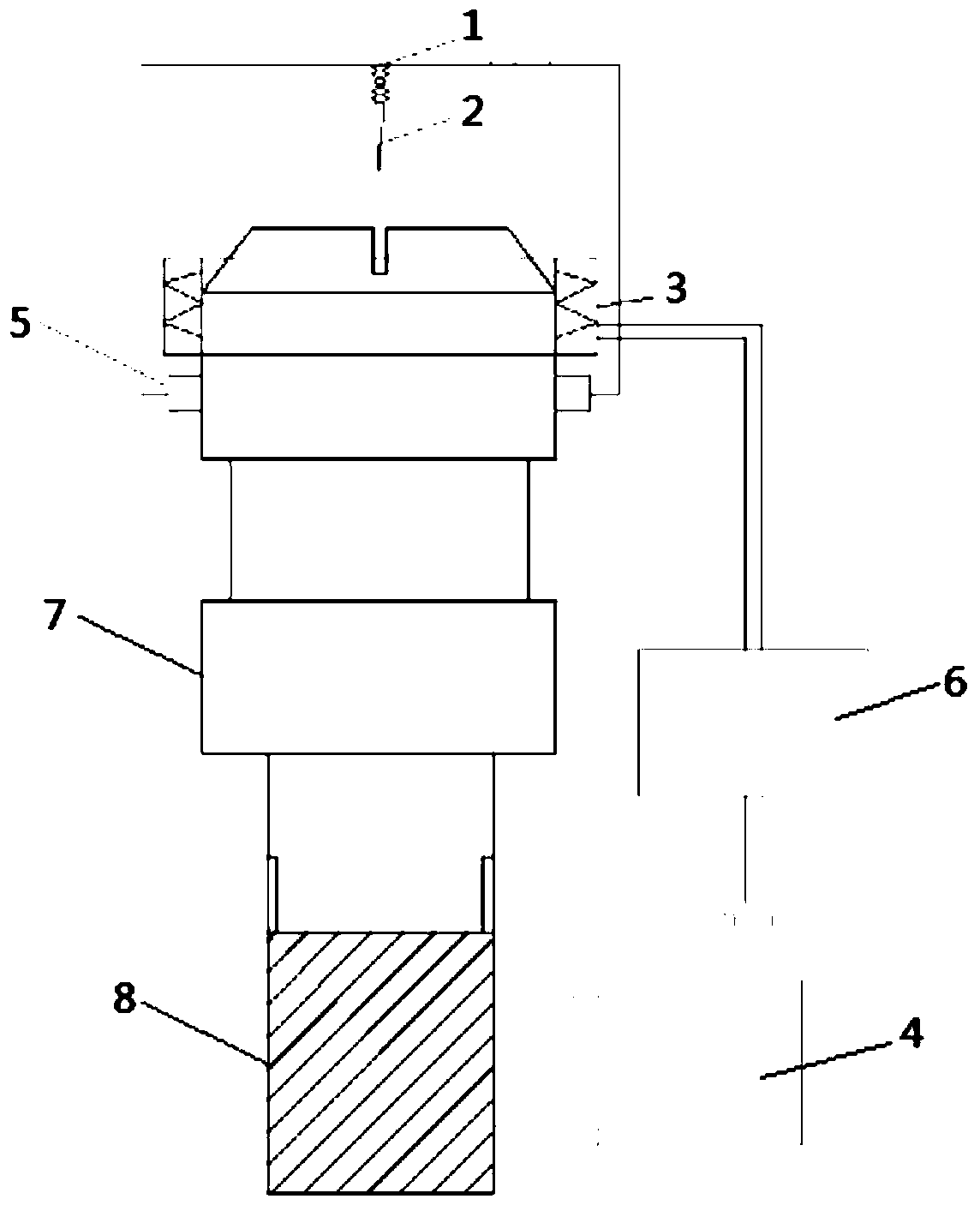

[0017] Such as figure 1 A non-clogging micro-spray nozzle shown includes a nozzle 7, a water inlet pipe 8, a sensor 4, an electromagnetic adsorption device 3 and a piercing mechanism, the nozzle 7 is composed of a nozzle and a flange connection, and the water inlet pipe 8 One end is connected to the flange, the sensor 4 is installed in the water inlet pipe 8, the sensor 4 is connected to the controller 6, the electromagnetic adsorption device 3, and the electromagnetic adsorption device 3 is arranged on the nozzle in a surrounding form. Externally, the electromagnetic adsorption device 3 is connected with the controller 6, the piercing mechanism is installed on the outside of the spray head, the piercing mechanism is magnetically connected with the electromagnetic adsorption device 3, and the sensor 4 is a pressure sensor. When blockage occurs in the nozzle of the nozzle 7, the pressure of the water will be received in the water inlet pipe 8, and the pressure sensor will recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com