A Vacuum Drying Electronically Controlled Quantitative Micro-spraying Method and Device

A vacuum drying, electronically controlled technology, applied in spray evaporation, evaporator accessories, etc., can solve the problems of nozzle ice blockage, difficult matching, nozzle freezing blockage, etc., to improve drying efficiency, wide concentration range, and overcome ice blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

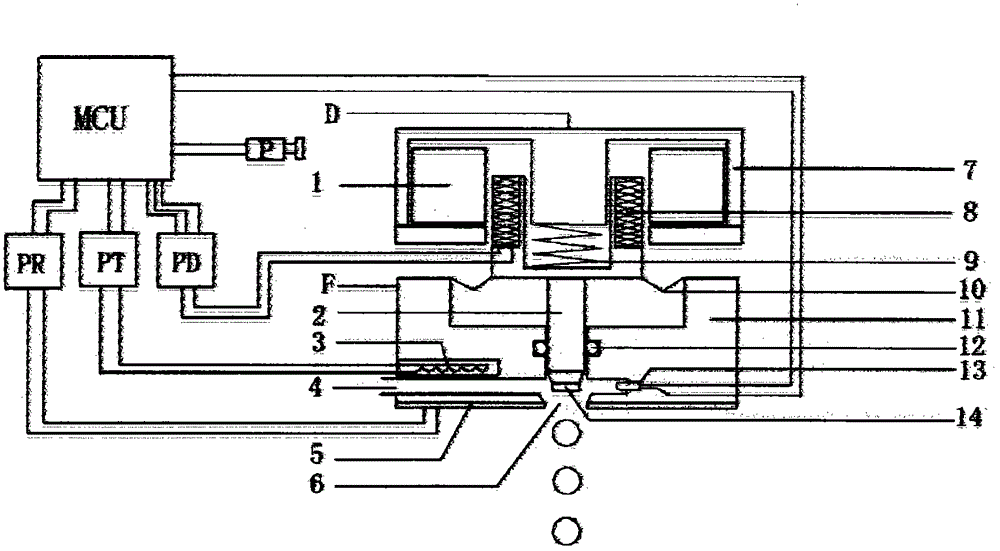

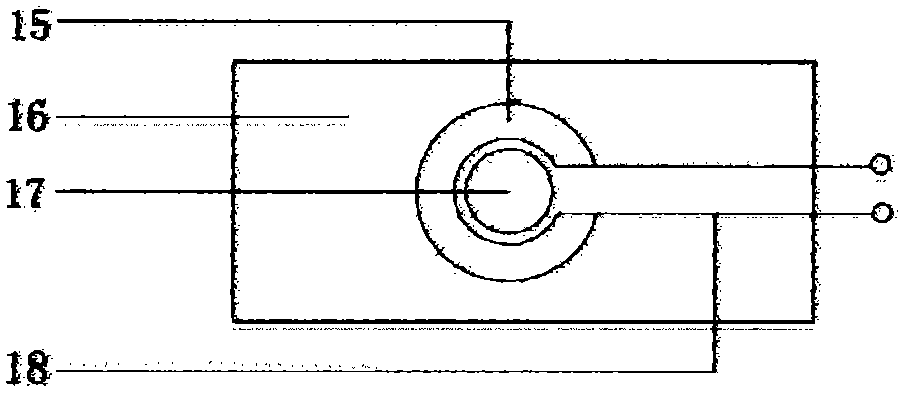

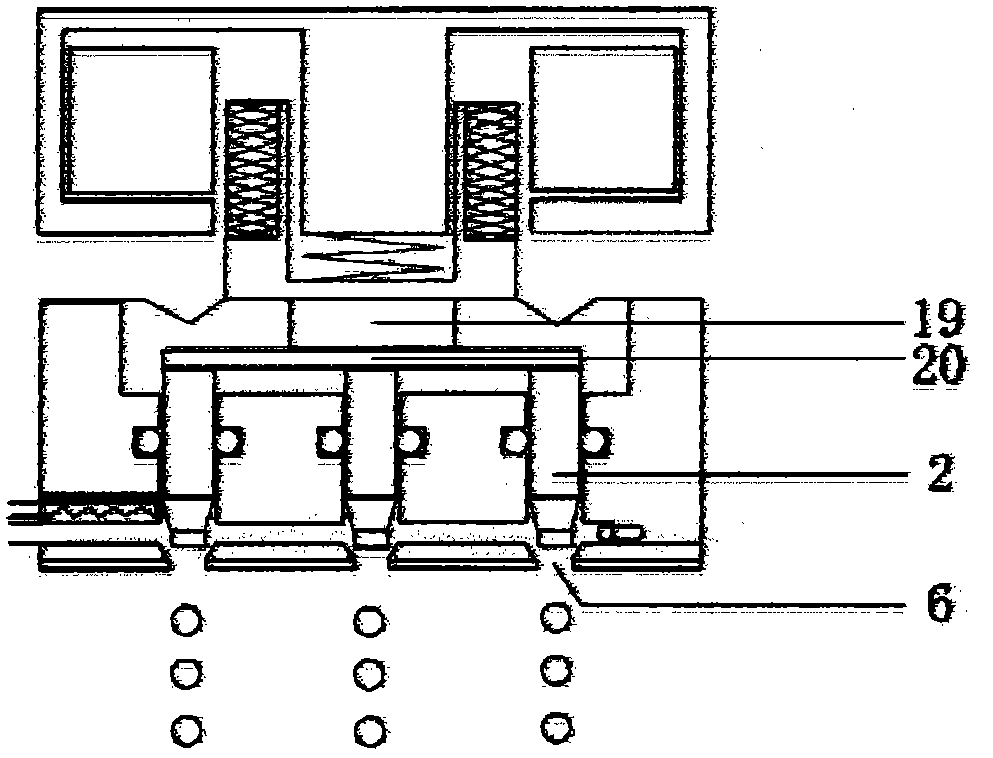

[0024] Such as figure 1 Shown is a schematic diagram of a vacuum dry explosion electronic control micro-spraying method. The voice coil motor (D), the microprocessor (MCU), the voice coil motor driver (PD), and the valve body (F) form the electronic control nozzle system. The mover (8) of the voice coil motor (D) is connected to the valve plug (2). After the mover coil is energized, it will reciprocate under the drive of the voice coil motor driver (PD) to drive the valve plug (2) to open or close the spray Hole (6); the microprocessor (MCU) generates an electric pulse signal to control the voice coil motor driver (PD), and changes the frequency and amplitude (voltage) of the electric pulse signal to change the voice coil motor mover (8) Displacement and the time it takes to complete a reciprocating movement, so as to control the degree of opening of the valve plug (2) each time and the time from opening to closing; the material liquid is input through the hose interface (4), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com