System and method for making non-spherical nanoparticles and nanoparticle compositions made thereby

A technology of metal nanoparticles and compositions, applied in the system field of non-spherical nanoparticles, capable of solving problems such as non-spherical shape processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

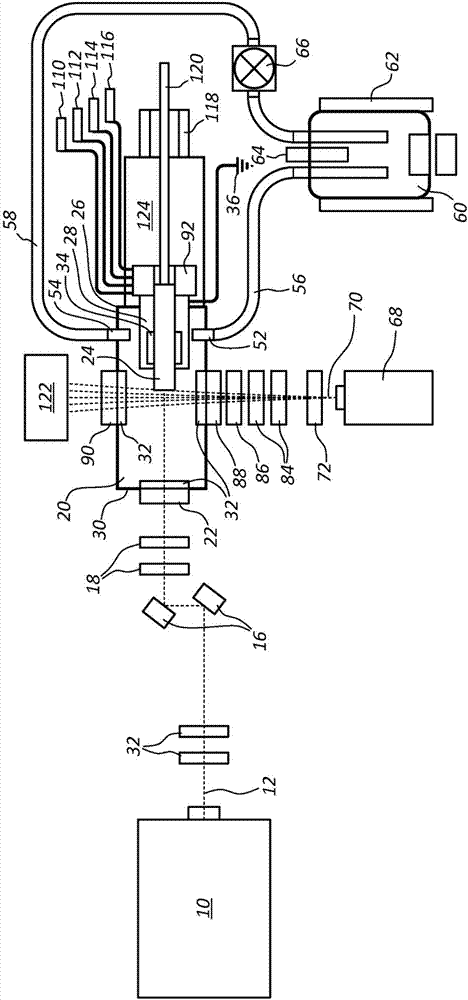

Method used

Image

Examples

Embodiment 5

[0083] Embodiment 5 (coral nanoparticles)

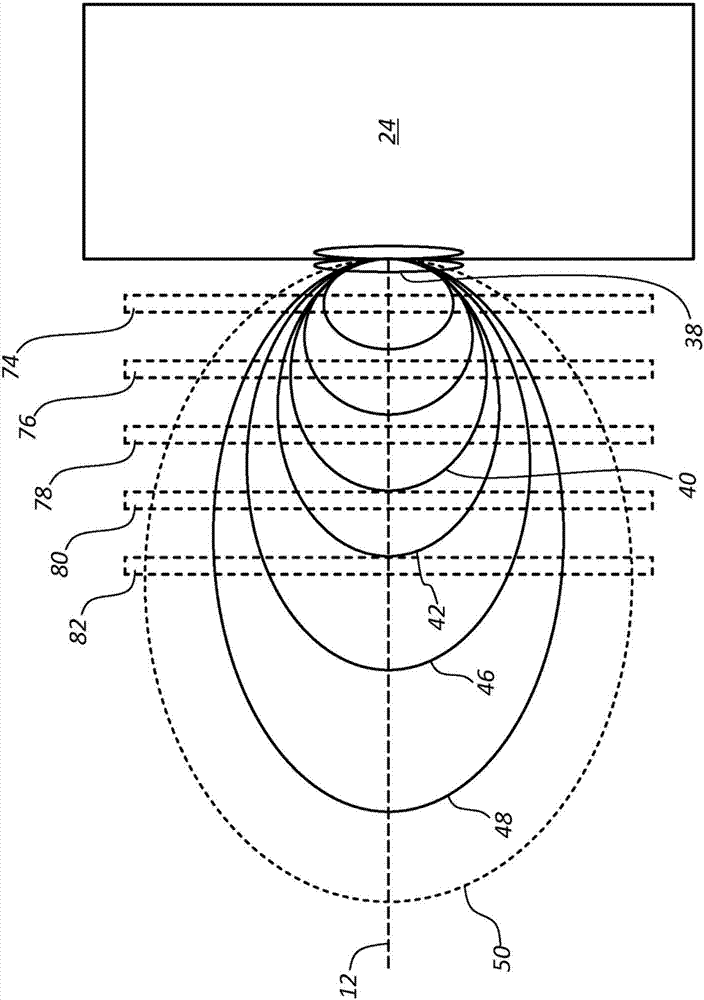

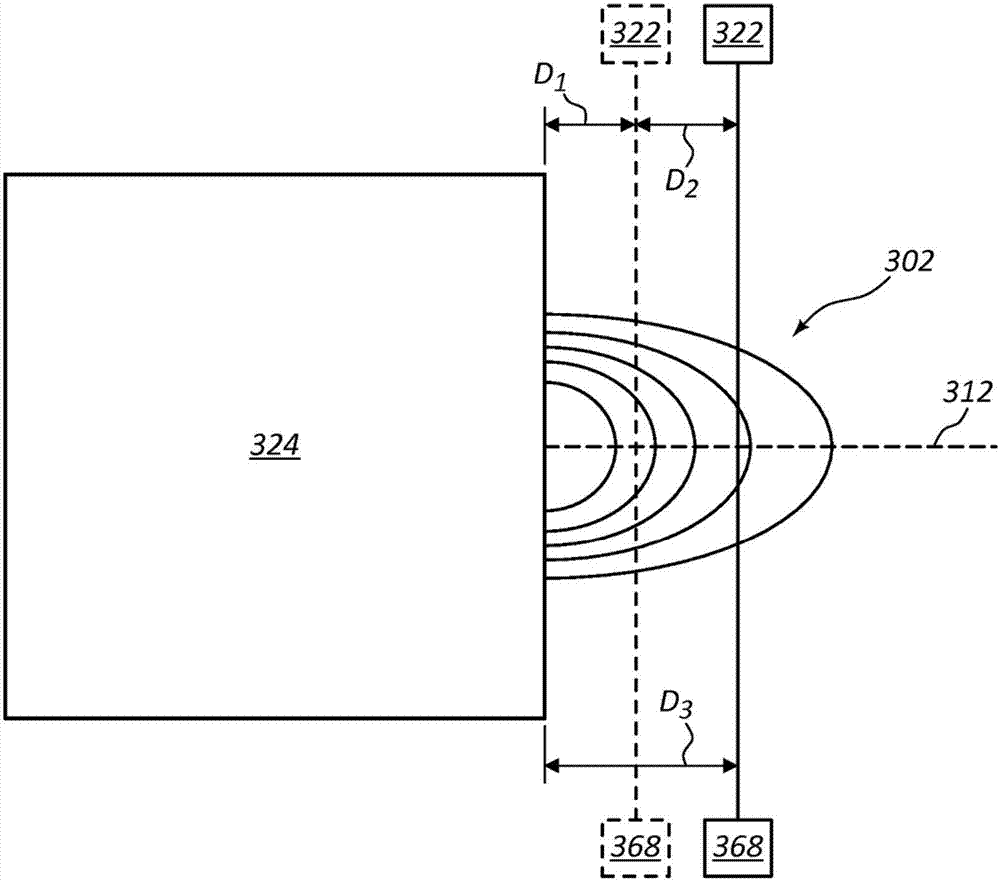

[0084] Laser ablation of the metal target surface was performed by using a 1064 nm wavelength Nd-YAG laser in 3.9 nanosecond pulses to deliver approximately 500 mJ of energy per pulse. The secondary laser is a continuous 532nm laser at 0.5W power, which enters a diffraction grating that produces three distinct electromagnetic fields in front of a gold (Au) target. The distance of the secondary laser in front of the surface of the gold (Au) target was increased from 1 mm (Example 1) to 3 mm, resulting in coral-shaped nanoparticles instead of spherical nanoparticles as in Example 1. The process produced gold (Au) nanoparticles with an average diameter between 25nm and 30nm, with 99+% of those nanoparticles being within 10% of the average diameter.

Embodiment 6

[0085] Embodiment 6 (coral nanoparticles)

[0086] A gold (Au) target was maintained in a chamber through which triple distilled deionized water flowed. Gold (Au) targets were ablated using a master laser with a wavelength of 1064 nm, 80 mJ, with a 3 mm spot size and a 9 nanosecond pulse length. The secondary laser is a continuous 532nm laser at 0.5W power, which enters a diffraction grating that produces three distinct electromagnetic fields in front of a gold (Au) target. The distance of the secondary laser in front of the surface of the gold (Au) target was increased from 1 mm (Example 1) to 3 mm, resulting in coral-shaped nanoparticles instead of spherical nanoparticles as in Example 1. The process produced coral-shaped gold (Au) nanoparticles with an average diameter between 70nm and 80nm, with 99+% of those nanoparticles being within 10% of the average diameter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com