Novel energetic base material prepared from porous material and preparation method thereof

A technology of porous materials and substrates, which is applied in the field of new energetic substrates and their preparation, can solve the problems of damaged stamping afterburning chambers, improved reliability, and complex structures, so as to reduce speed loss, improve ballistic performance, and be economical. value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] Step 1, preparation of energetic medicament:

[0019] The preparation steps of SY are: add perchloric acid (the ratio is ethylenediamine: triethylenediamine: perchloric acid=5: 9.4:48), the reaction temperature is controlled at 62°C to 72°C, the stirring speed is adjusted to 400r / min±5r / min, after the reaction is complete, it is fully cooled and discharged.

[0020] NHN preparation steps are: feed ratio (mass ratio) is Ni(Ac) 2 4H 2 O:NaN 3 :N 2 h 4 ·H 2 O=1.76:1:0.8, when the temperature of the bottom liquid is 50°C, add sodium nitride and hydrazine hydrate in the way of double-pipe feeding, control the feeding time of sodium nitride to 30min±5min, and the feeding time of hydrazine hydrate to 45min±5min , Stir at constant temperature for 10 minutes after the feeding is completed, then water-cool to below 35°C and discharge.

[0021] Step 2, adding talcum powder and thermosetting phenolic resin to obtain a mixed agent: the particle diameter of the talcum powder i...

Embodiment 1

[0027]Embodiment 1: Porous copper (the specification is 40PPI, size is (20.1 ± 0.1) × (20.1 ± 0.1) × (10.0 ± 0.1) mm) is sealed with sealant on five sides, and the doping ratio is talcum powder: Phenolic resin: SY=15:20:65, weigh 1.5g of talcum powder, 2.0g of phenolic resin and 6.5g of SY in a dry state and mix thoroughly, weigh an appropriate amount of mixed agent and place it in a special charging mold, use frequency modulation vibration The charging method is used to fill the mixed medicament, the vibration frequency (voltage is 110V), the number of vibrations (2 times) and the time of each vibration (1min), the base material that has been charged is placed in a pressurized mold and a pressure of 8 MPa is applied. Place it at 120°C for heating for 25 minutes, and obtain an energetic substrate after complete cooling. The size of the obtained energetic substrate is (20.1±0.1)×(20.1±0.1)×(5.4±0.2) mm.

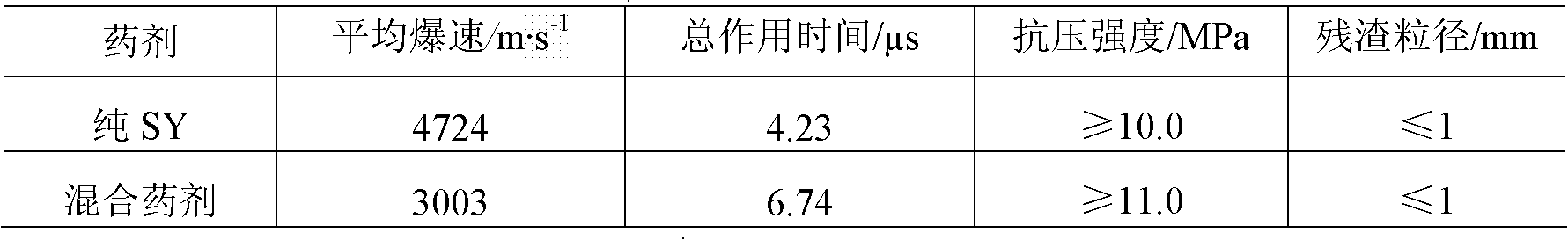

[0028] The measured performance parameters are shown in Table 1 below: ...

Embodiment 2

[0032] Embodiment 2: Porous copper (the specification is 60PPI, size is (20.1 ± 0.1) × (20.1 ± 0.1) × (10.0 ± 0.1) mm) is sealed with sealant on five sides, and the doping ratio is talcum powder: Phenolic resin: SY=21:20:59, weigh 2.1g of talcum powder, 2.0g of phenolic resin and 5.9g of SY in a dry state and mix thoroughly, weigh an appropriate amount of mixed agent and place it in a special charging mold, and use frequency modulation vibration The filling method is used to fill the mixed agent. The vibration frequency (voltage is 110V and 220V), the number of vibrations (2 times) and the time of each vibration (1min) are fixed. 12MPa pressure, and further heat treatment (heating temperature is controlled at 120°C, heating time is controlled at 20min), and the energetic substrate is obtained after complete cooling. The size of the obtained energetic substrate is (20.1±0.1)×(20.1±0.1)×(6.0±0.2) mm.

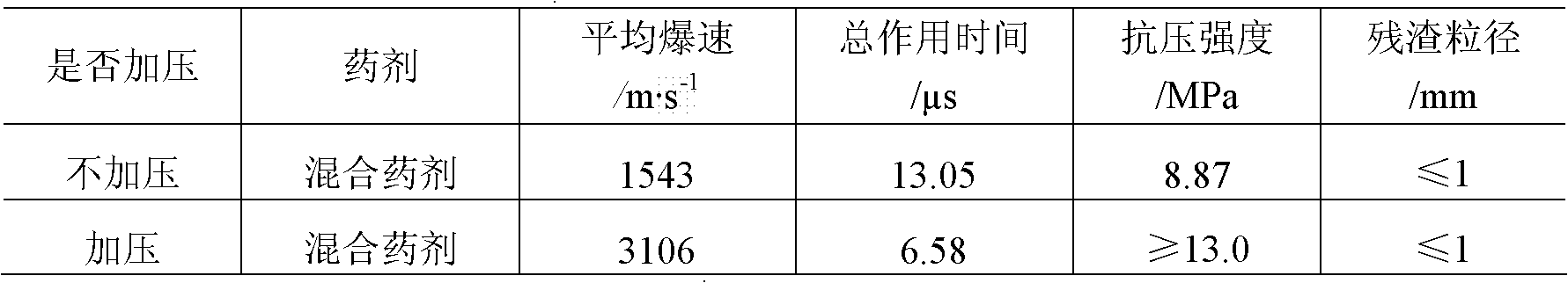

[0033] The measured performance parameters are shown in Table 2 below:

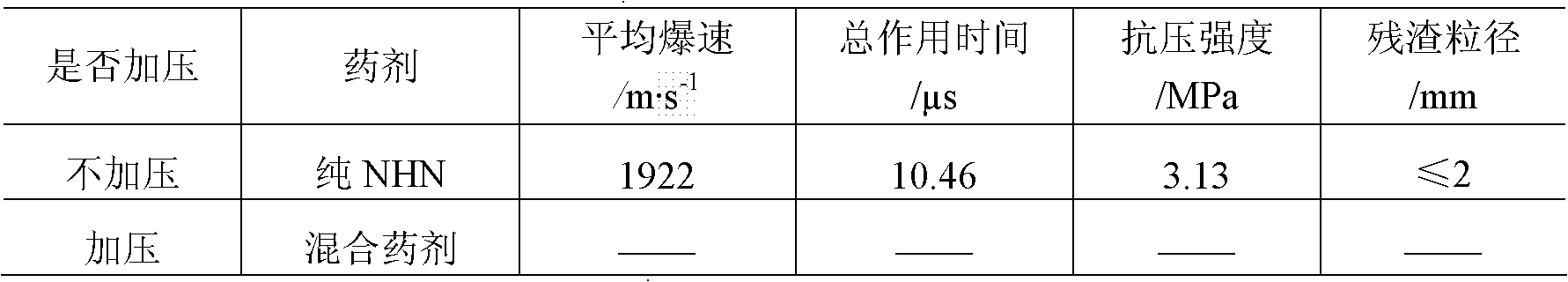

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Performance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com