Supersonic air inlet channel plugging cap device

A technology of air inlet and supersonic speed, which is applied in jet propulsion devices, gas turbine devices, ramjet engines, etc., can solve the problems of complex structure of blocking cap devices, unfavorable protection of carrier aircraft safety, and generation of projectiles, etc., to achieve increased The effect of strength and rigidity, uniform force, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

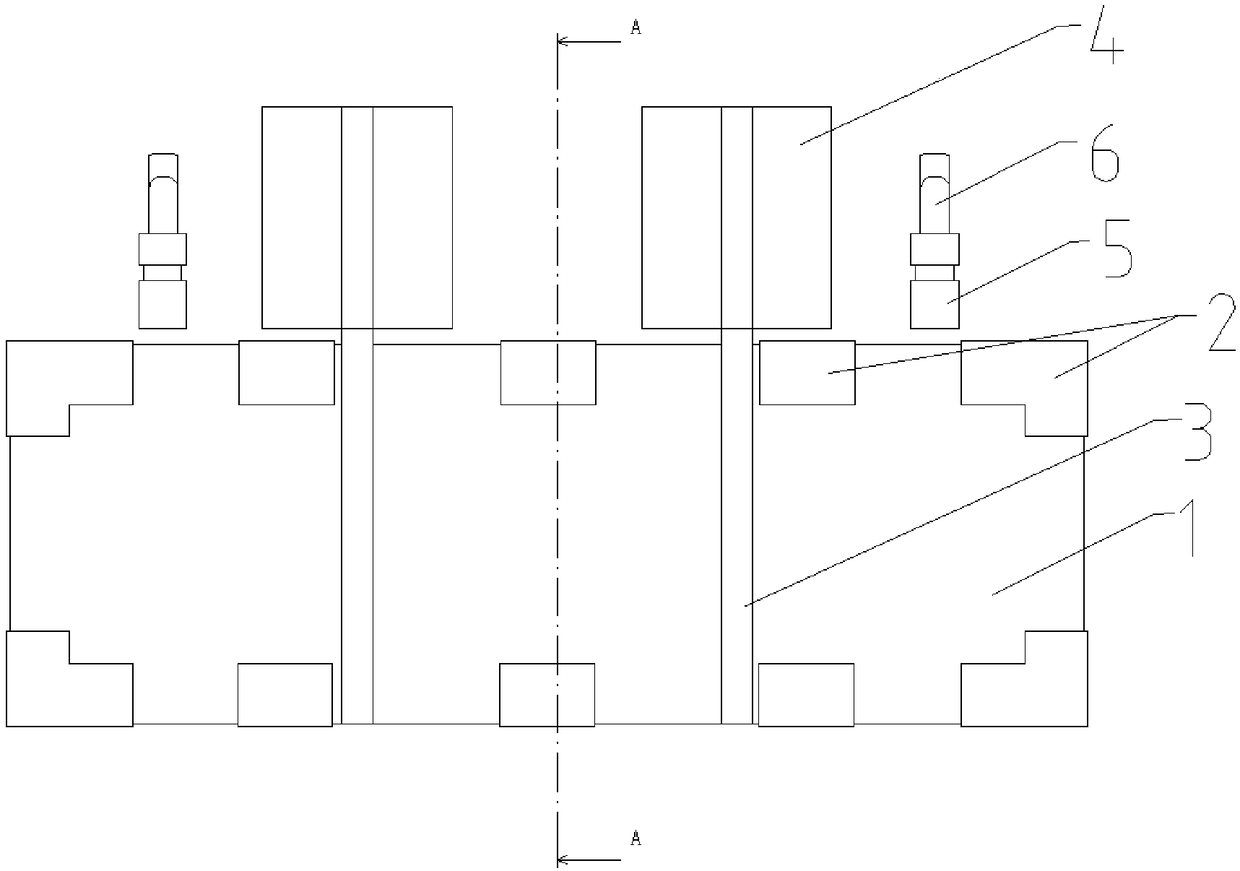

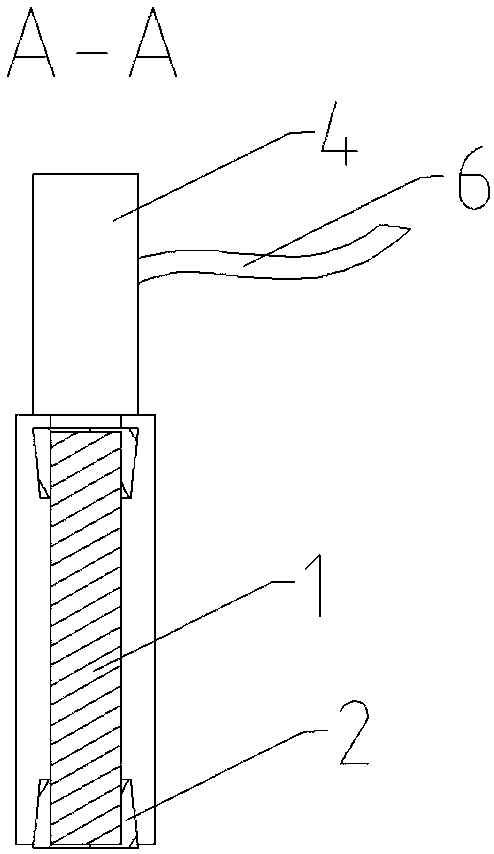

[0019] A supersonic air inlet plugging device of the present invention comprises a plugging body 1, a damping member 2, a support rod 3, a drive motor 4, a detonator 5, and a cable 6, such as figure 1 shown.

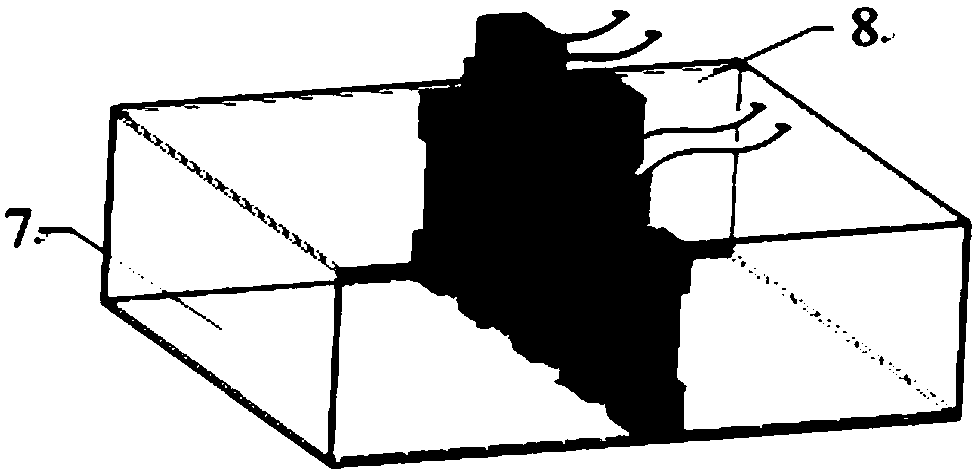

[0020] A plurality of damping parts 2 are evenly distributed and fixedly sleeved around the main body 1 of the plugging cover. After the damping parts 2 are extruded, they are closely matched with the inner wall surface 7 of the air intake duct. The main body 1 of the plugging cover is provided with a driving motor 4 and a detonator 5. The driving motor 4 and The detonator 5 is installed on the outer wall surface 8 of the air inlet, two pairs of support rods 3 are respectively arranged in the middle of the front and rear sides of the main body of the plugging cover 1, and the two drive motors 4 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com