Supercritical impact flow method for wrapping micro granule

A supercritical, impinging flow technology, applied in the field of materials engineering, which can solve problems such as difficult fluidization of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

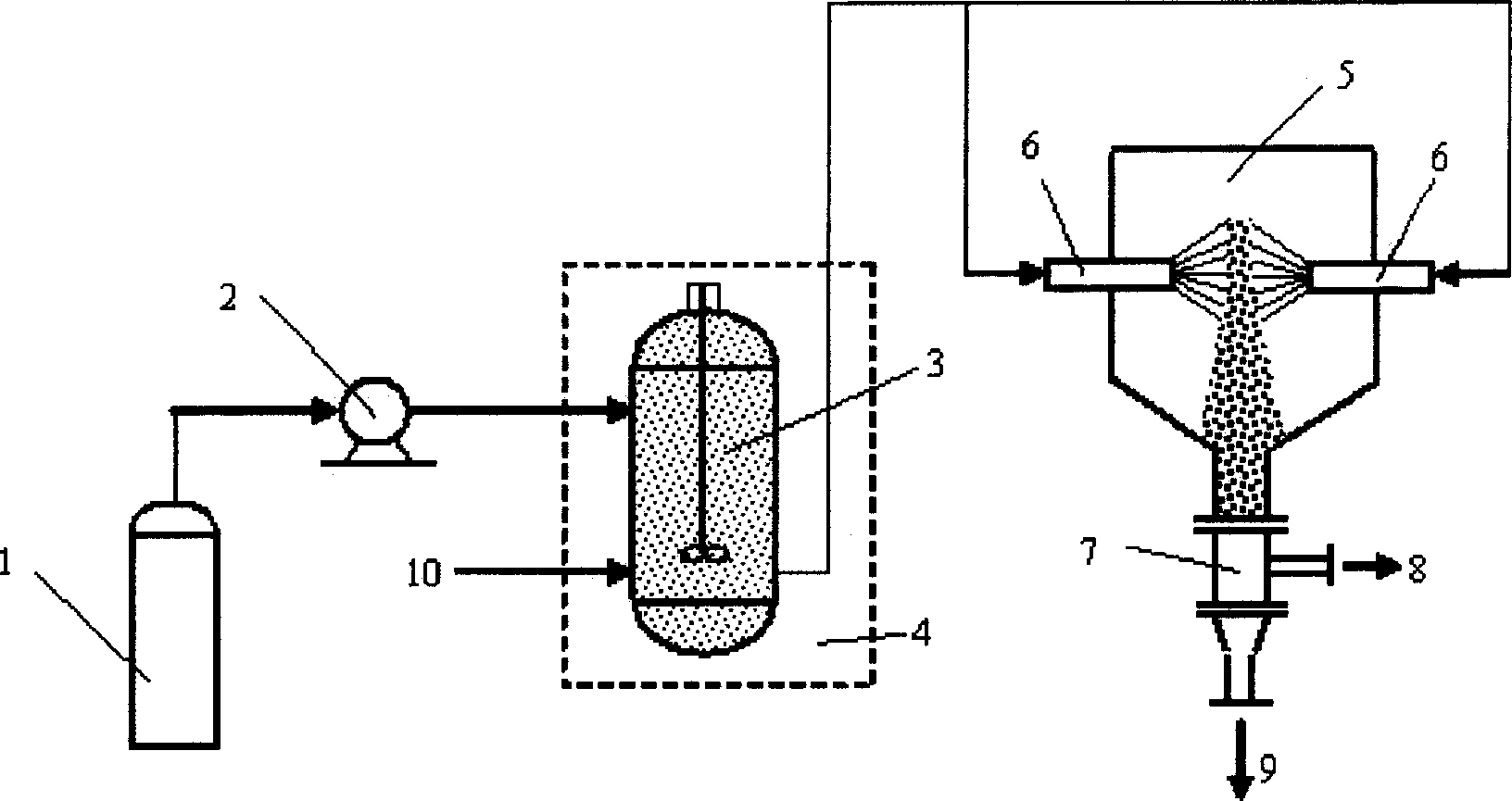

[0012] The coated wall material and coated particles are added to the dissolution mixer 3 through the feeding port 10, and the CO in the storage tank 1 2 After the pressure is boosted by the high-pressure diaphragm pump 2, it is added to the dissolution mixer 3, and the temperature of the dissolution mixer 3 is raised by the constant temperature bath 4, so that the coating wall material is dissolved in supercritical CO 2 A solution is formed in the solution, and the coated particles are uniformly dispersed in the solution to form a suspension by stirring; the suspension is sprayed into the coating device 5 through a pair of coaxial nozzles 6 to form a collision flow; dissolved in the supercritical CO 2 The coated wall material in the solution is separated out from the solution rapidly due to the great supersaturation caused by the expansion and decompression of the solution through the nozzle 6, and is deposited on the surface of the coated particles to form a uniform skin lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com