Patents

Literature

39 results about "Supercritical flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A supercritical flow is a flow whose velocity is larger than the wave velocity. The analogous condition in gas dynamics is supersonic.

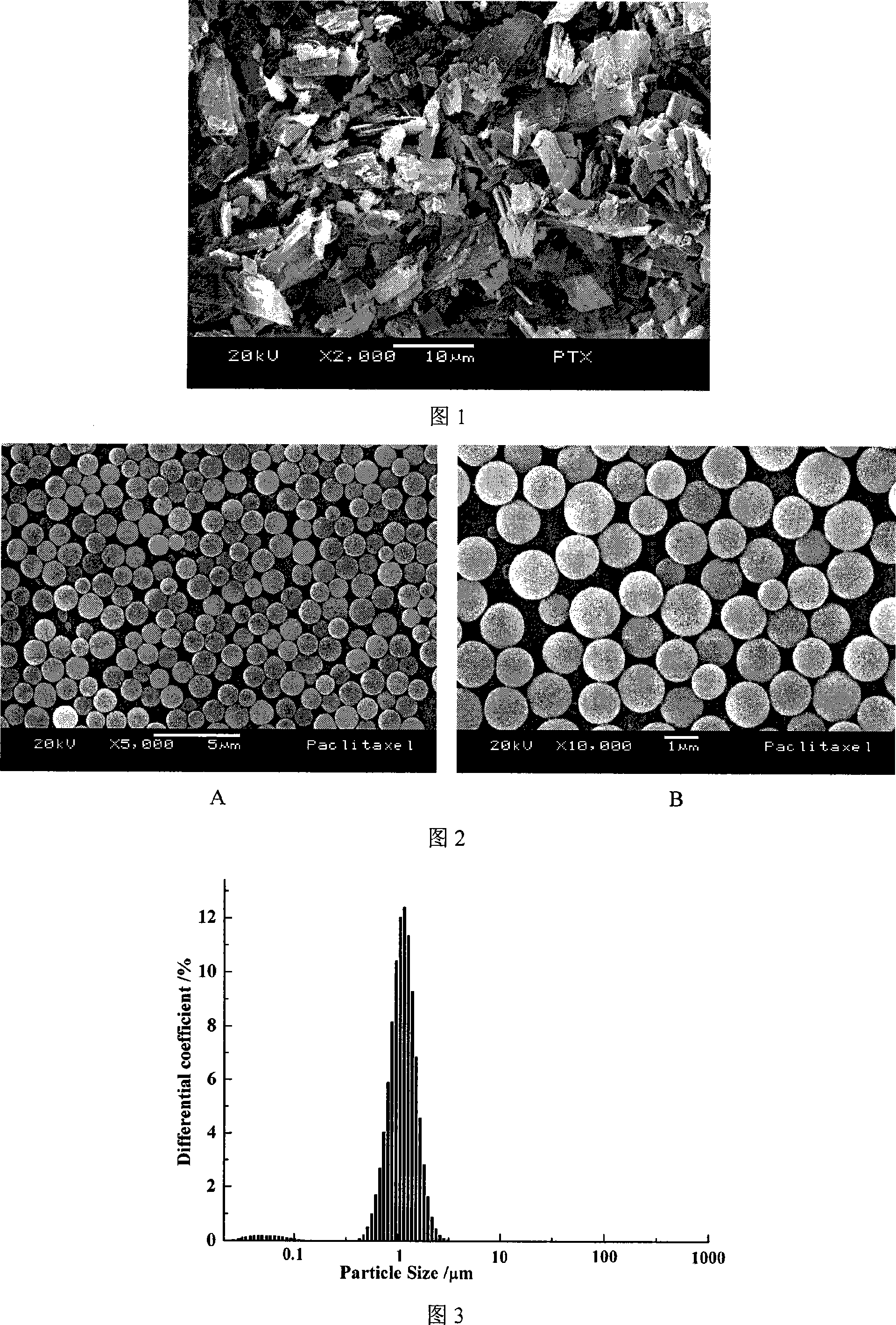

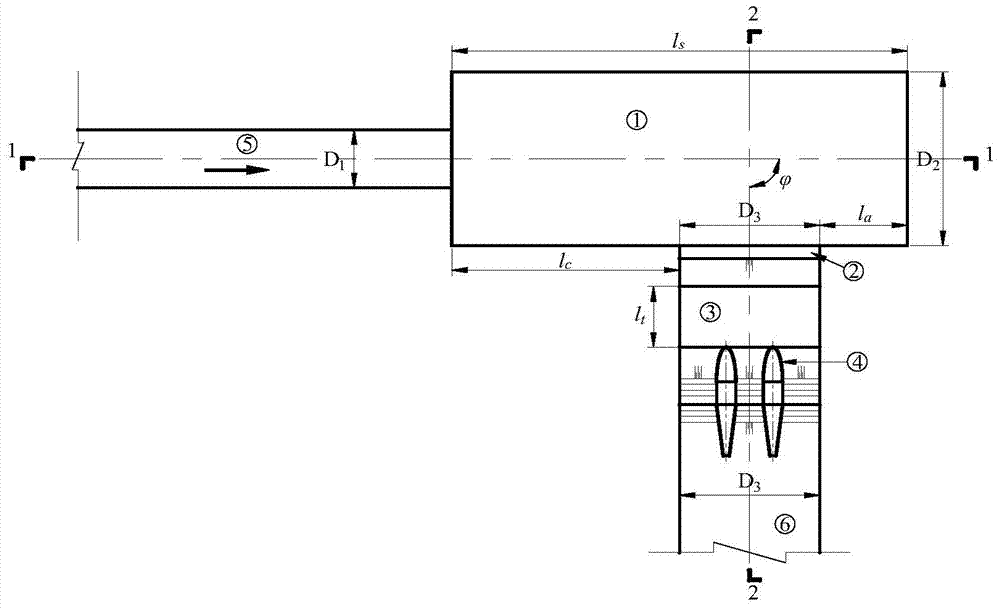

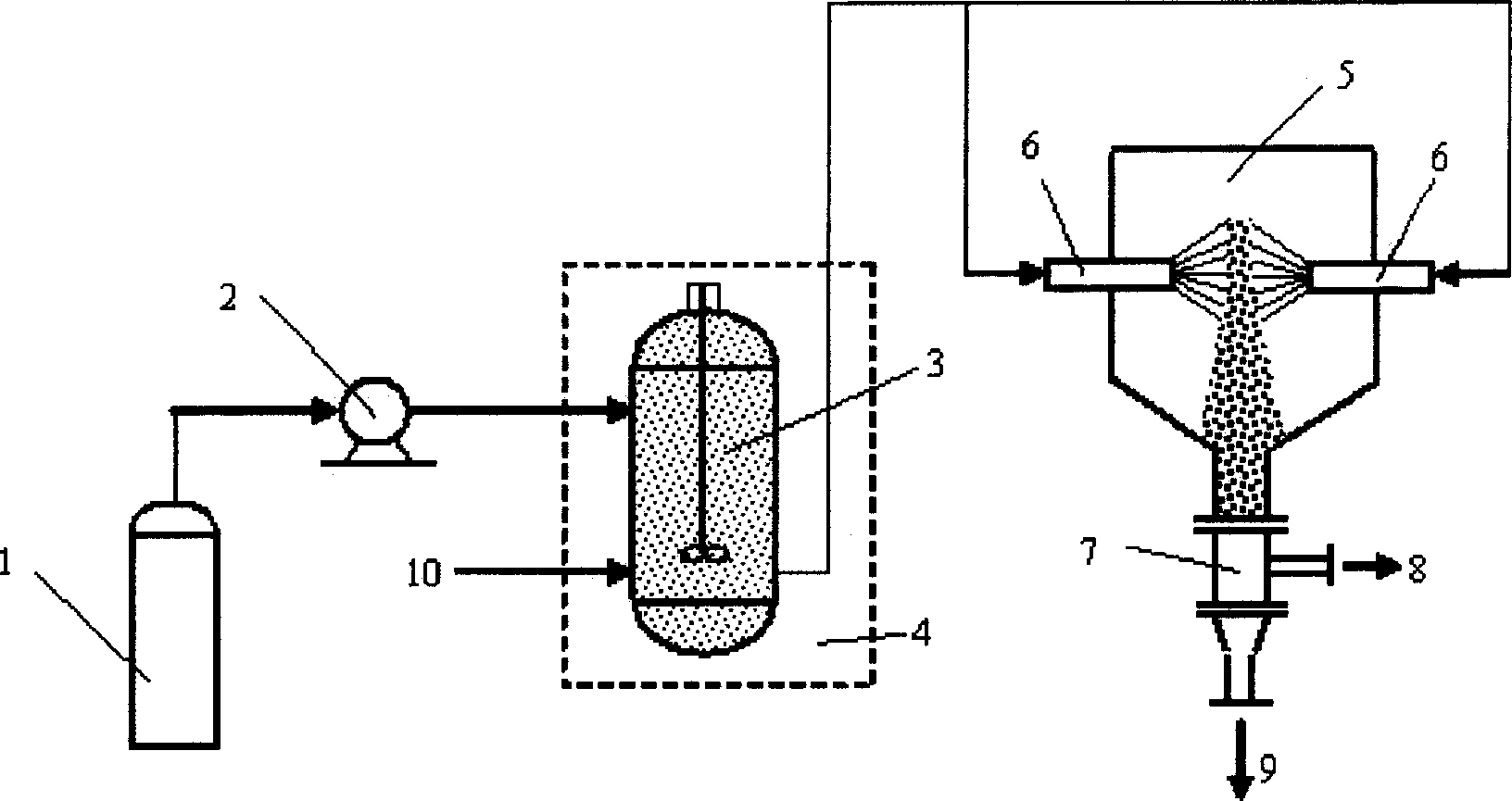

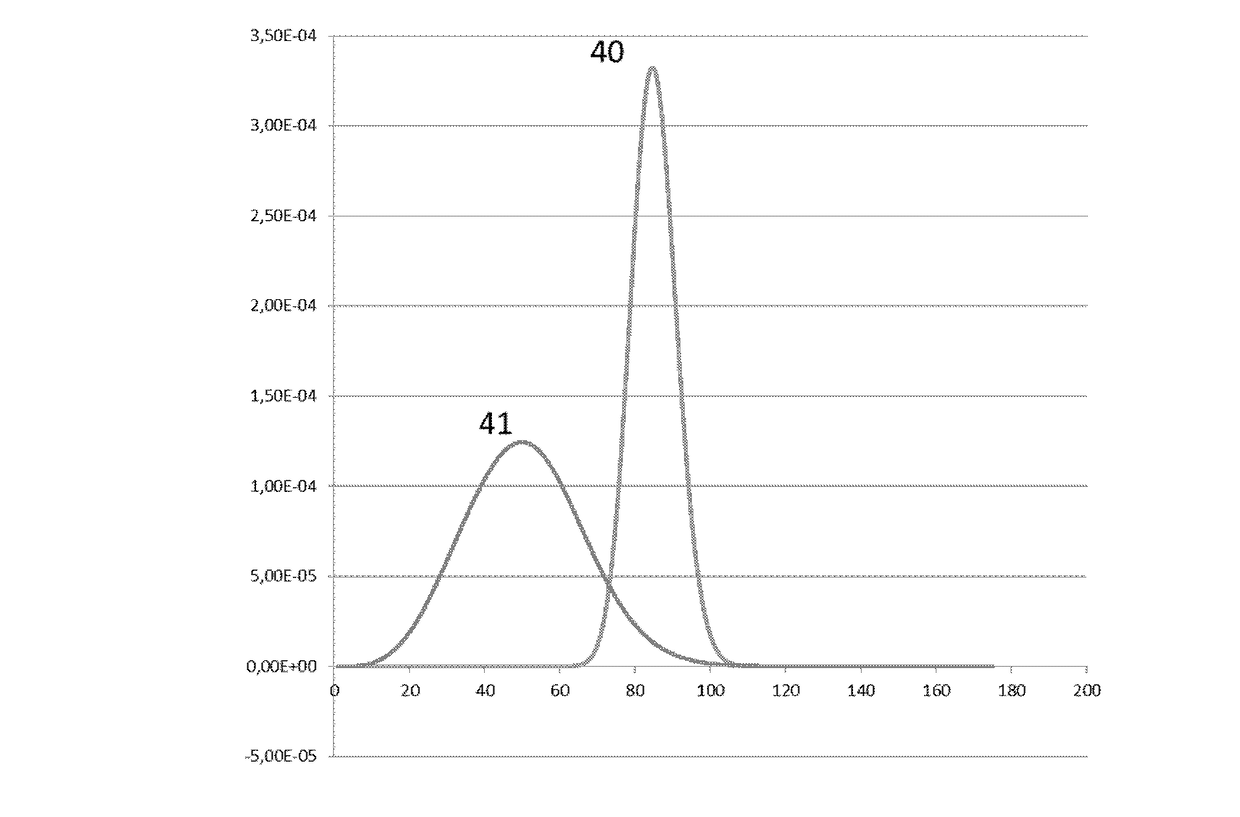

Minuteness anti-cancer medicine paclitaxel of novel technique supercritical fluid

InactiveCN101129338ANo pollution in the processReduce organic residuesOrganic active ingredientsPowder deliveryMedicineBioavailability

The paclitaxel has broad spectrum antineoplastic activity, which is used to treat oophoron cancer and breast cancer, has the significant effect, and is known as a anti-cancer drug with the wide developing prospect, but the particle diameter of paclitaxel medicine powder is bigger so that the paclitaxel medicine powder isn't absorbed by administer orally, has the lower bioavailability, and limits the clinic application of paclitaxel. The invention makes Paclitaxel fine with supercritical flow new technique. The experiment makes Paclitaxel fine with above-critical CO2 as the dissolvent and with supercritical flow forced disperse solution technique, which researches the influence of the pressure, the temperature, the concentration of the solution and the flow speed of the solution for the shape, grain diameter and the distribution of fine paclitaxel. The result indicates that the nanometer grain diameter can be changed in the finite range by changing the technology parameter, wherein the prepared surface of the nanometer grain is smooth, and has the good sphericity, and the average grain diameter is 670nm-940nm, the concentration of the solution and the flow speed is the main factor.

Owner:SICHUAN UNIV

Supercritical fluid fluidized intensified heat diffusion method and its heat diffusion working medium and applications

InactiveCN101285657AReduce thermal resistanceWide operating temperature rangeFluidised bed heat exchangersEnhanced heat transferEngineering

The invention discloses a fluidization enhanced heat transfer method and a fluidization multiphase heat transfer medium. The heat transfer process is enhanced by adding particles inside a supercritical flow body. The technique can be widely applied to an air conditioner, a heat pump, a heat pipe, the heating, the cooling of an internal-combustion engine, an electronic device and the cooling of a power device, raises the energy utilization rate of the whole system, improves the heat control of the system and increases the thermal management ability.

Owner:李建民

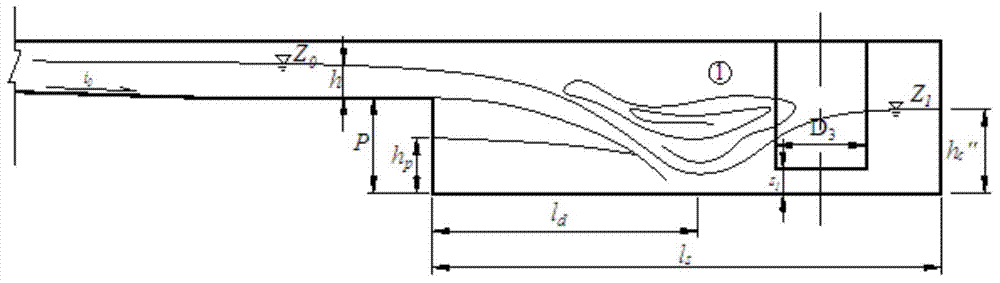

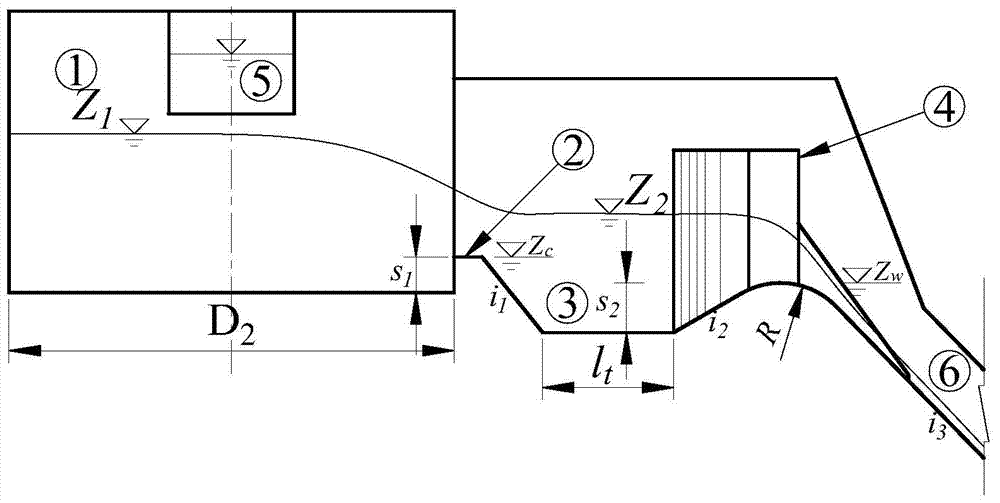

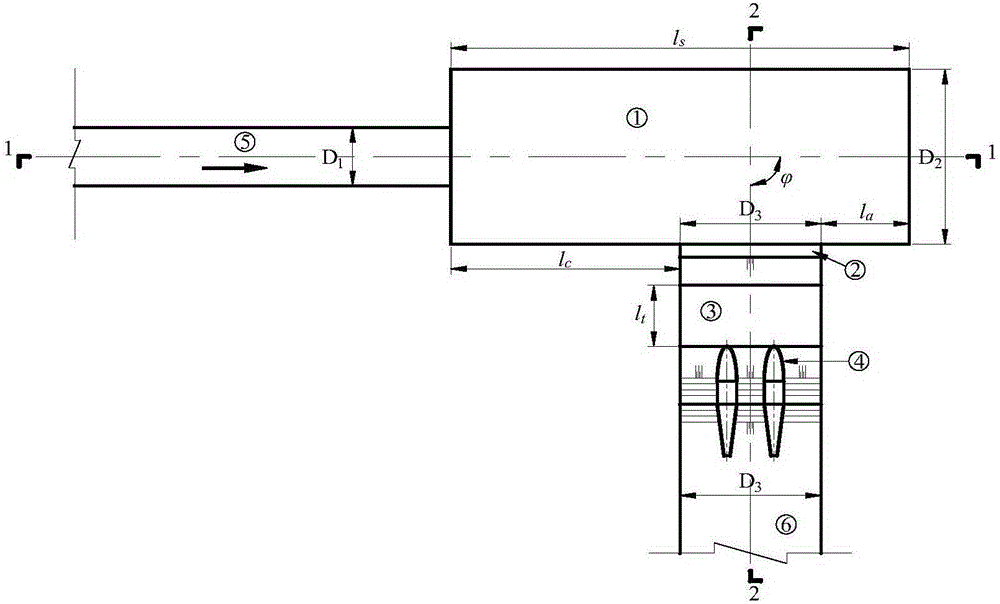

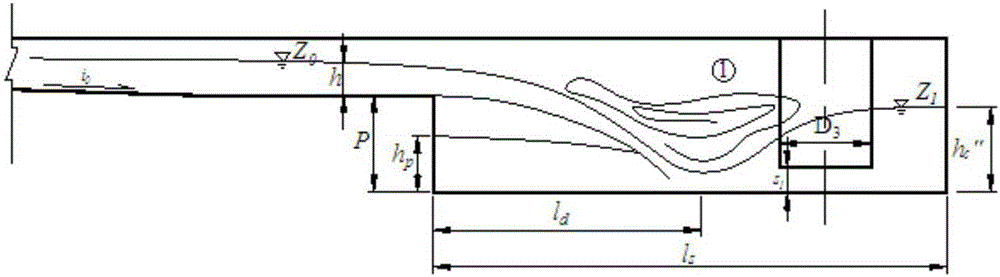

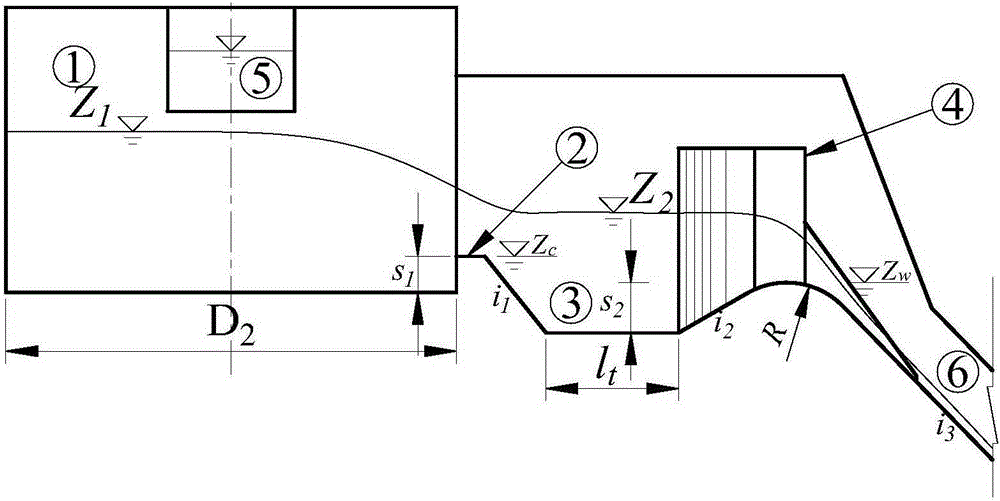

Flow state connected building suitable for supercritical flow bend

InactiveCN104499454AReduce the chance of damageAvoid Diamond WavesBarrages/weirsClimate change adaptationSupercritical flowEngineering

The invention discloses a flow state connected building suitable for a supercritical flow bend. Incoming flow from the upstream of the bend enters a stilling pool of the flow state connected building in a single-stage fall mode; a side weir is arranged on the side wall of the stilling pool and is connected with a downstream flow state regulating tank; a rectifying tail pier is arranged at an outlet of the flow state regulating tank; the axis of the rectifying tail pier is in parallel to that of a flow passage on the downstream of the bend. Design of the flow connected building adopts the main principle that firstly, the energy dissipation effect of the stilling pool is utilized to reduce a flow rate of the incoming flow, and local subcritical flow is formed in the stilling pool; then the principle that the low flow rate has high adaptability to an overflowing boundary is utilized, the side weir is adopted to change the flow direction of water flow, and by the flow state regulating tank, the flow rate of the water flow is further reduced and the flow state is further improved; finally, the rectifying tail pier is utilized to regulate the flow direction to be in parallel to the axis direction of the flow passage on the downstream of the bend. According to the flow state connected building suitable for the supercritical flow bend, the adverse flow states, such as rhombus waves, a large water surface transverse slope and a deflected side wall, formed by the water flow in the supercritical flow bend can be effectively avoided, and washout and erosion damage and the like of water flow with high sand content on the boundary of the flow passage on the downstream of the bend are reduced and avoided.

Owner:SICHUAN UNIV

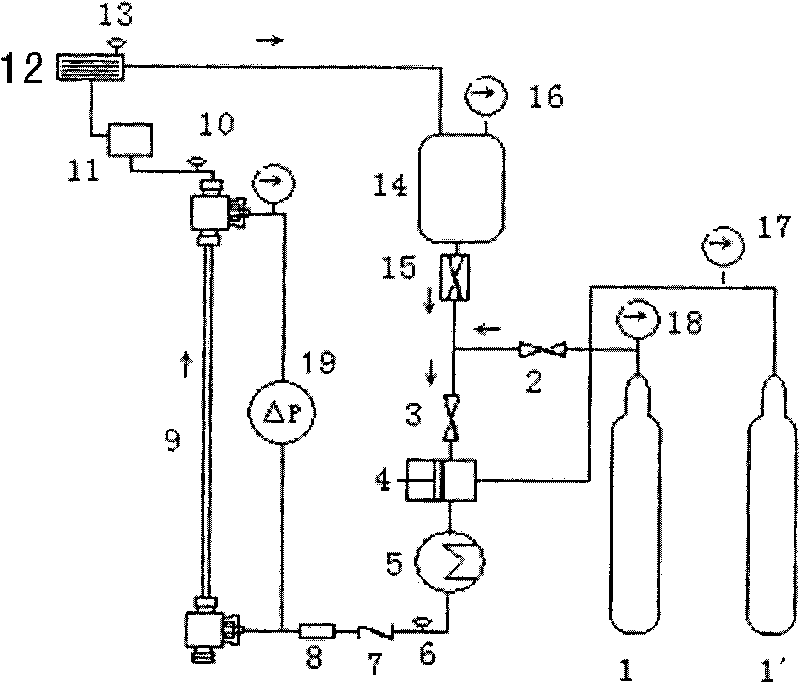

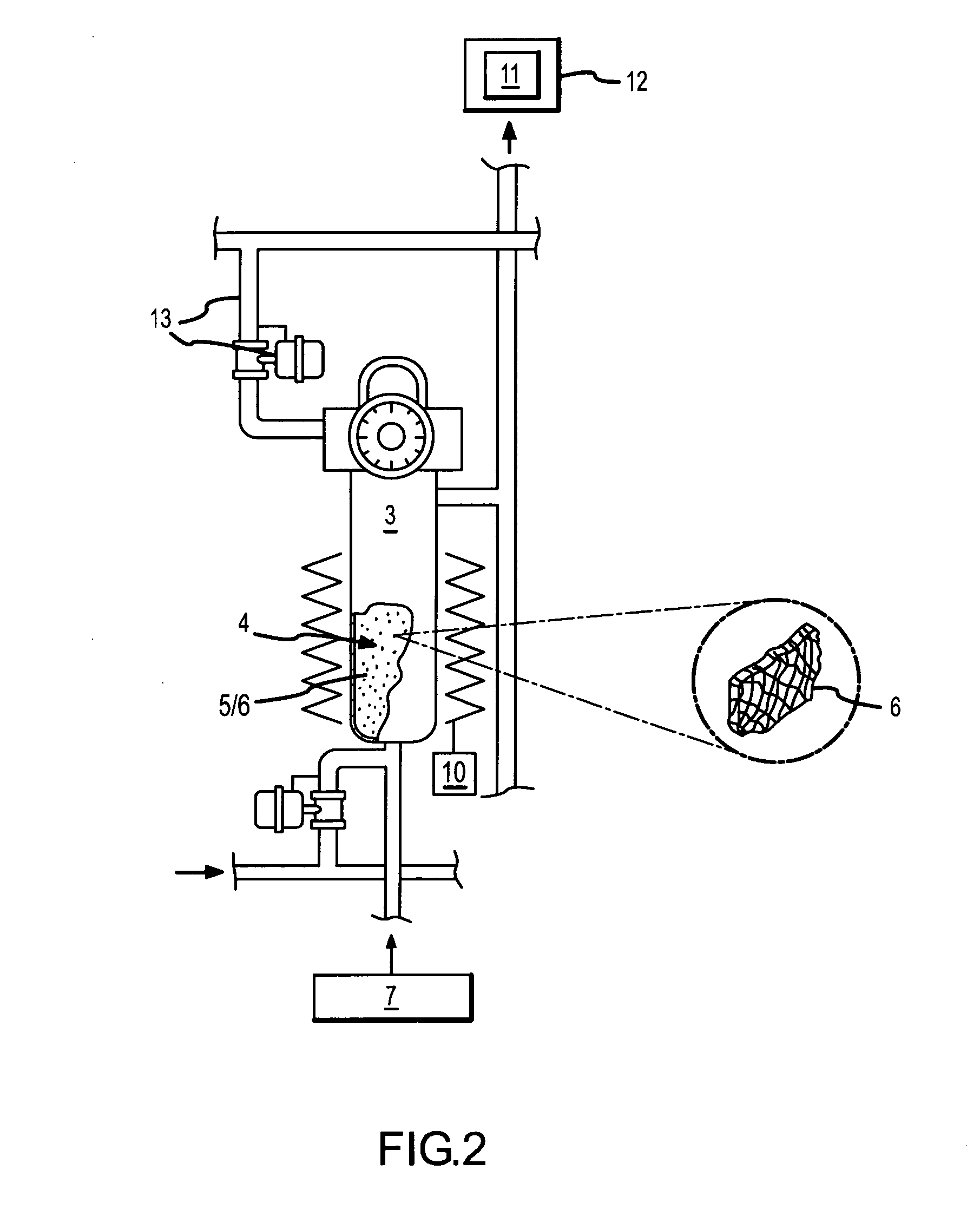

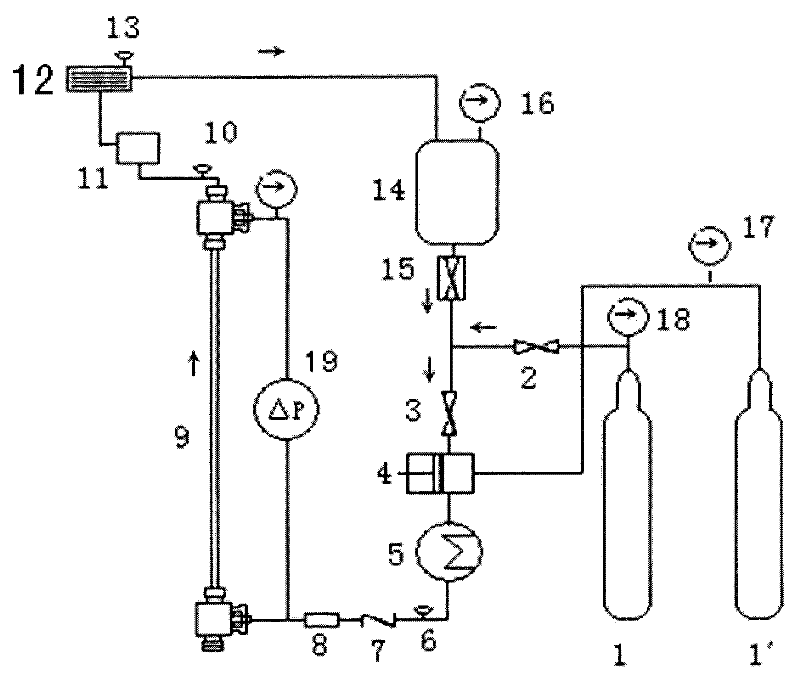

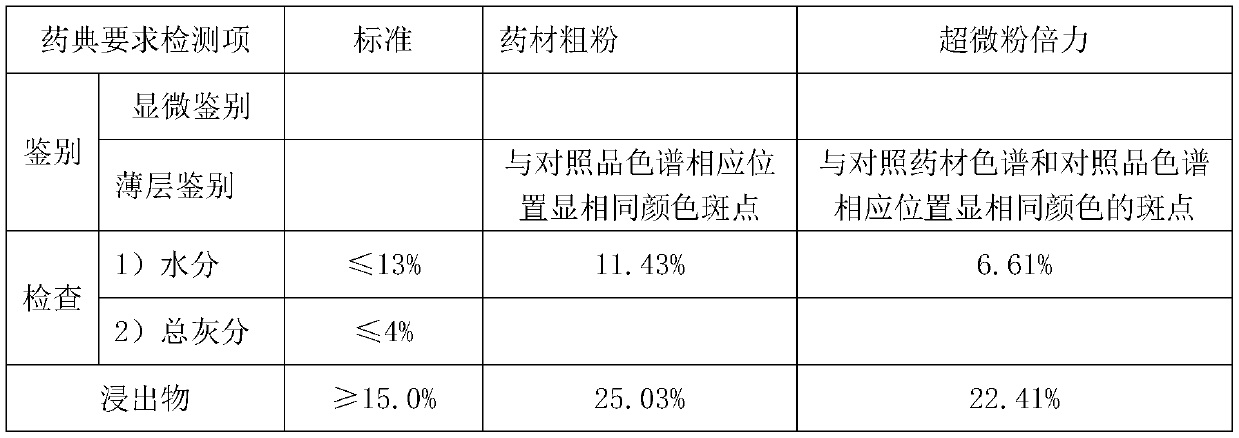

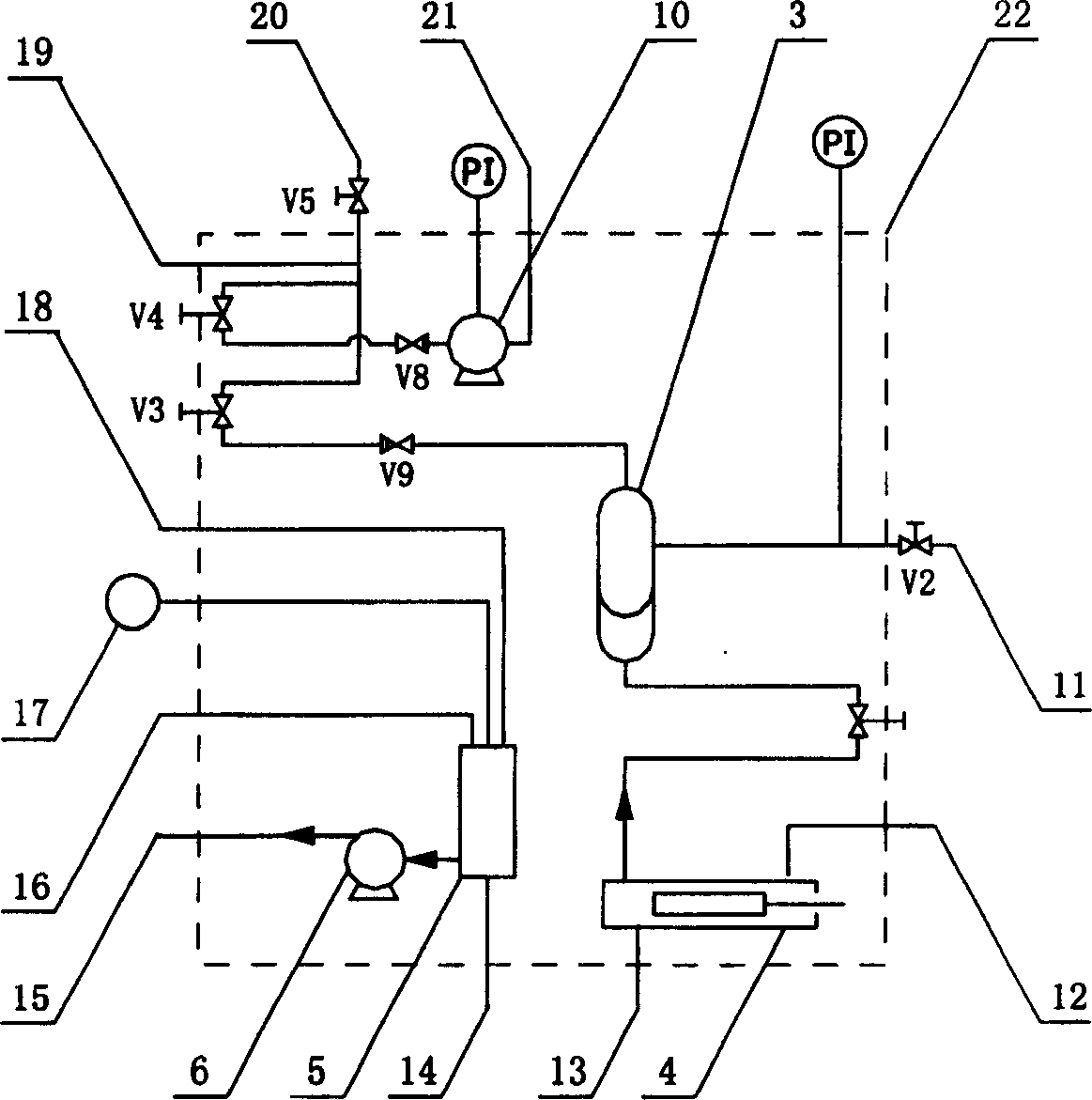

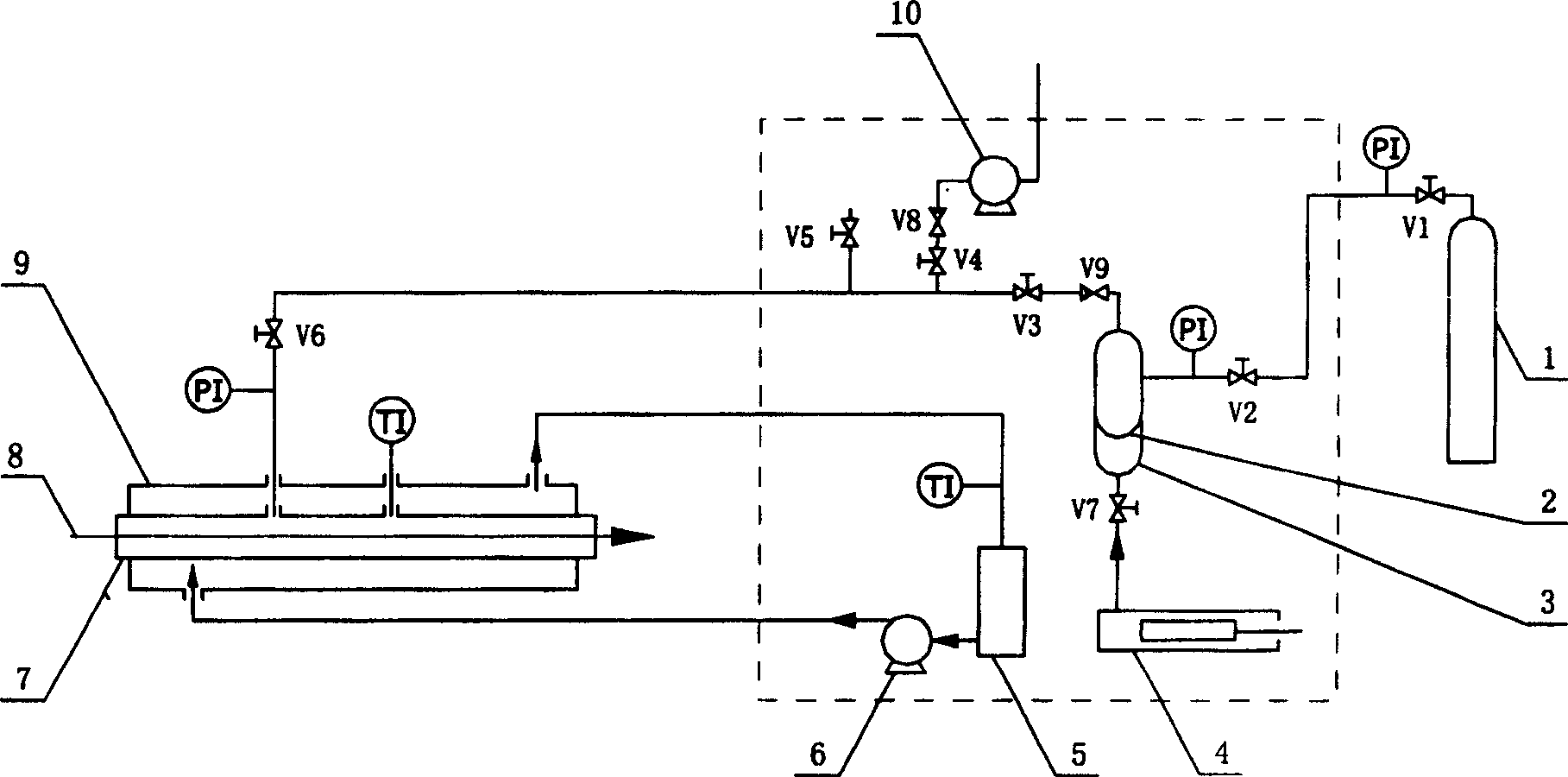

Detection device of physical property of natural gas supercritical flow state

InactiveCN101710021AHydrodynamic testingSpecific gravity using flow propertiesMeasurement deviceHigh pressure

The invention relates to a testing experimental platform, in particular relating to a detection device of the physical property of a natural gas supercritical flow state. The technical scheme is that the natural gas in a natural gas tank is further boosted by a booster pump, is heated to the temperature of simulated gas reservoir through a heating unit and a temperature controller, and enters into a flowing test section through a check valve and a flowmeter to form supercritical flow; a backpressure control system controls gas reservoir pressure value needing to be stimulated; a cooling system and the temperature controller cool the gas flowing out from the testing section; and a buffer tank can depressurize the effluent gas to achieve the temperature and pressure condition of the booster pump. The detection device of the invention has the beneficial effects that the density and the viscosity of the five-element parameters of the natural gas can be detected under the high temperature and high pressure supercritical condition. The device can realize wellhole gas flow stimulation and physical property parameter testing under the supercritical conditions, and flowing stimulation of the natural gas under the undercritical conditions.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Supercritical heat waves heat-transfer element and its working medium loading sealing method

InactiveCN101285659ASolve the use problemEfficient use ofIndirect heat exchangersThermal energyHeat wave

The invention provides a supercritical heat wave heat transfer element, comprising at least one cavity body capable of being sealed and at least one working medium, wherein, the working medium is bulked into the cavity body capable of being sealed, the cavity body capable of being sealed is sealed, the sum of the liquid volume of the bulked working medium is less than the total cavity volume; at least one part of the cavity body is a heat absorbing end, at least the other part of the cavity body is a heat discharging end; the heat transfer element absorbs the heat quantity from the heat absorbing end. When the working medium in the cavity body is in a subcritical and / or supercritical state, the supercritical flow body inside the cavity body transfers the heat quantity to the radiating end from the heating absorbing end mainly in a way of heat wave in order to realize the heat energy transfer because the supercritical working medium has low thermal diffusivity and high thermal expansivity near a critical point and / or an imitated critical point.

Owner:李建民

Supercritical impact flow method for wrapping micro granule

InactiveCN1879957AIncrease resistanceReduce resistanceMicroballoon preparationMicrocapsule preparationParticle packingPaper production

The invention relates to a ultra-critical impact flow particle packing method, which is characterized in that: adding the wall material into the mixer to be dissolved into solution; mixing and dispersing the particle uniformly, to form suspension; using a couple of coaxial nozzles to output the wall material to be deposited on the surface of packed particle to form the coat, and separated by the separator to obtain the micro capsule product. The invention can combine the advantages of present packing fluid bed packing method and impact flow method, to be used in food industry, paper production, etc.

Owner:DALIAN UNIV OF TECH

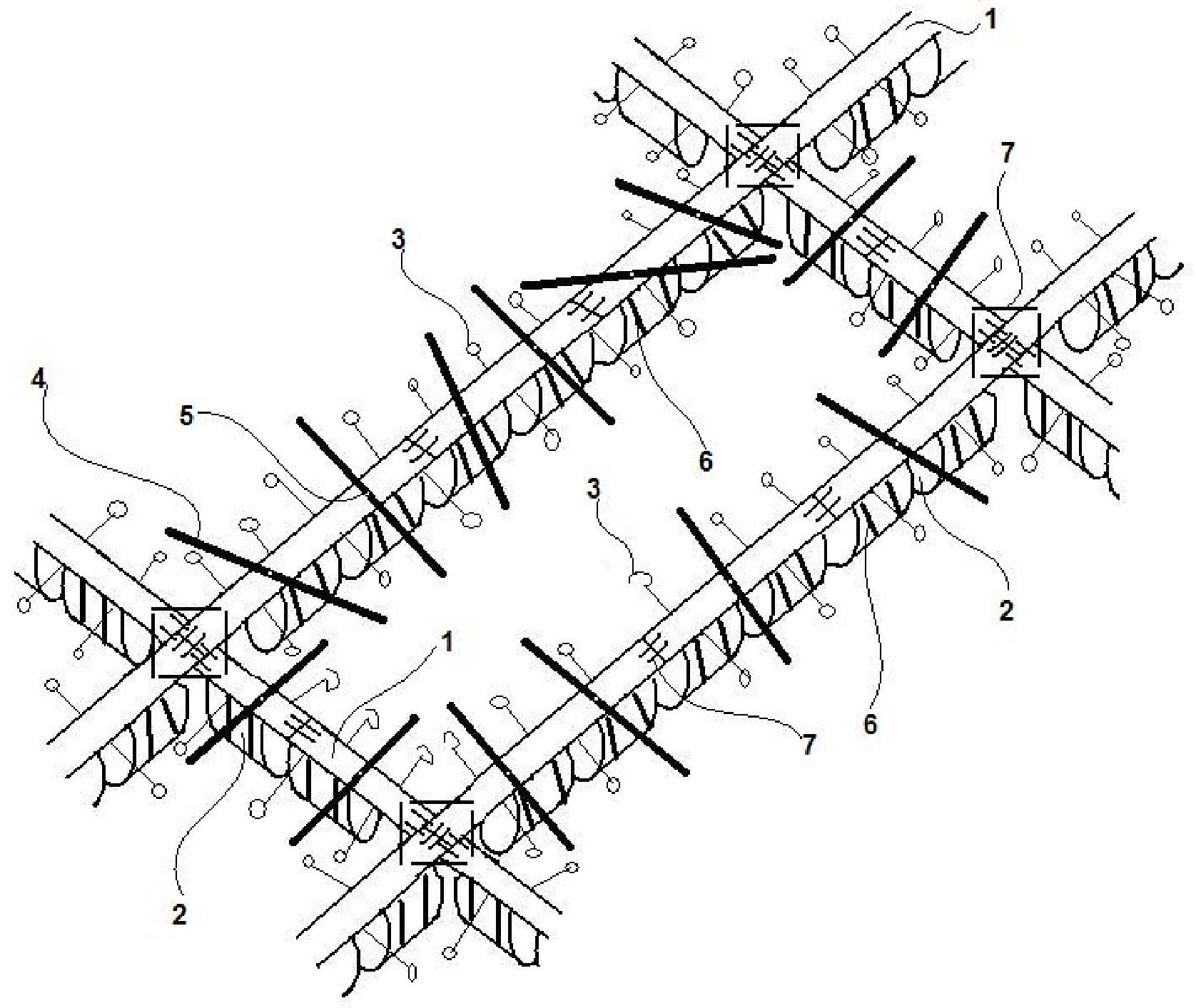

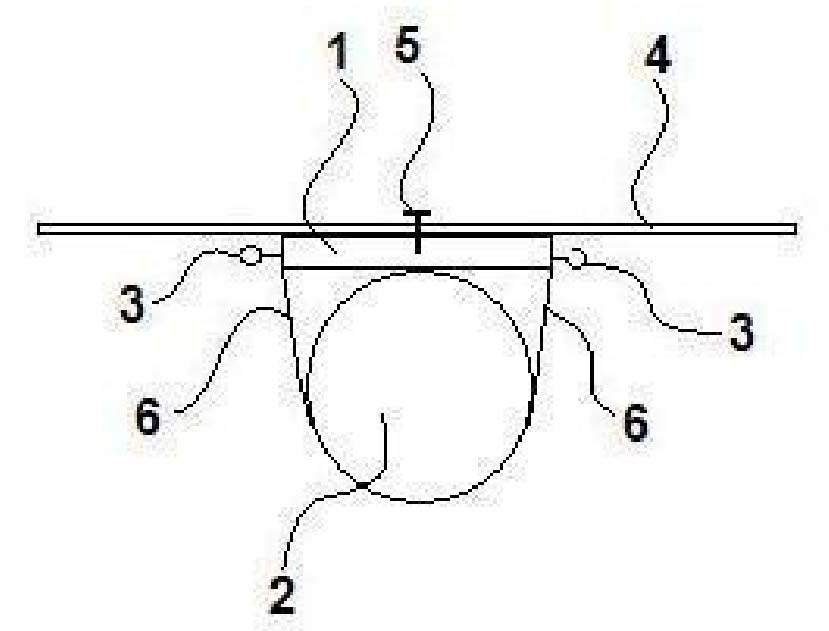

Aquaculture raft

InactiveCN102630608AReduce shockContain spillsClimate change adaptationPisciculture and aquariaAntibody hypervariable regionAquaculture

The invention relates to an aquaculture raft. The aquaculture raft is a firm cultivation raft capable of floating under the water surface, which is built by materials, such as a fixing material layer (1), a floating material layer (2), a suspending device (3), a hanging arm (4), a fixing device (5), a rope (6), a connector (7) and the like. The aquaculture raft is used for culturing various aquatic products, and cultivates for a period of time through a method of applying fertilizer or feed to the cultured aquatic products so that the content of specific elements of the aquatic products is remarkably improved and an aquatic product culture effect of reinforcing the nutrition of the specific elements is reached. When the aquaculture raft disclosed by the invention is applied to aquaculture, a large amount of the fertilizer and the feed can be saved, and the aquaculture raft can be applied to cultivating aquatic products in rivers, lakes and seas, such as sea tangles, agars, fishes, shrimps, crabs, shellfishes, abalones, sea cucumbers and the like, is especially suitable for the aquaculture with reinforced biological nutrition and is also suitable for deepwater hypervariable regions with lack water nutritions, deep water, supercritical flow, large wind and large waves.

Owner:苏州安德鲁生物技术咨询有限公司

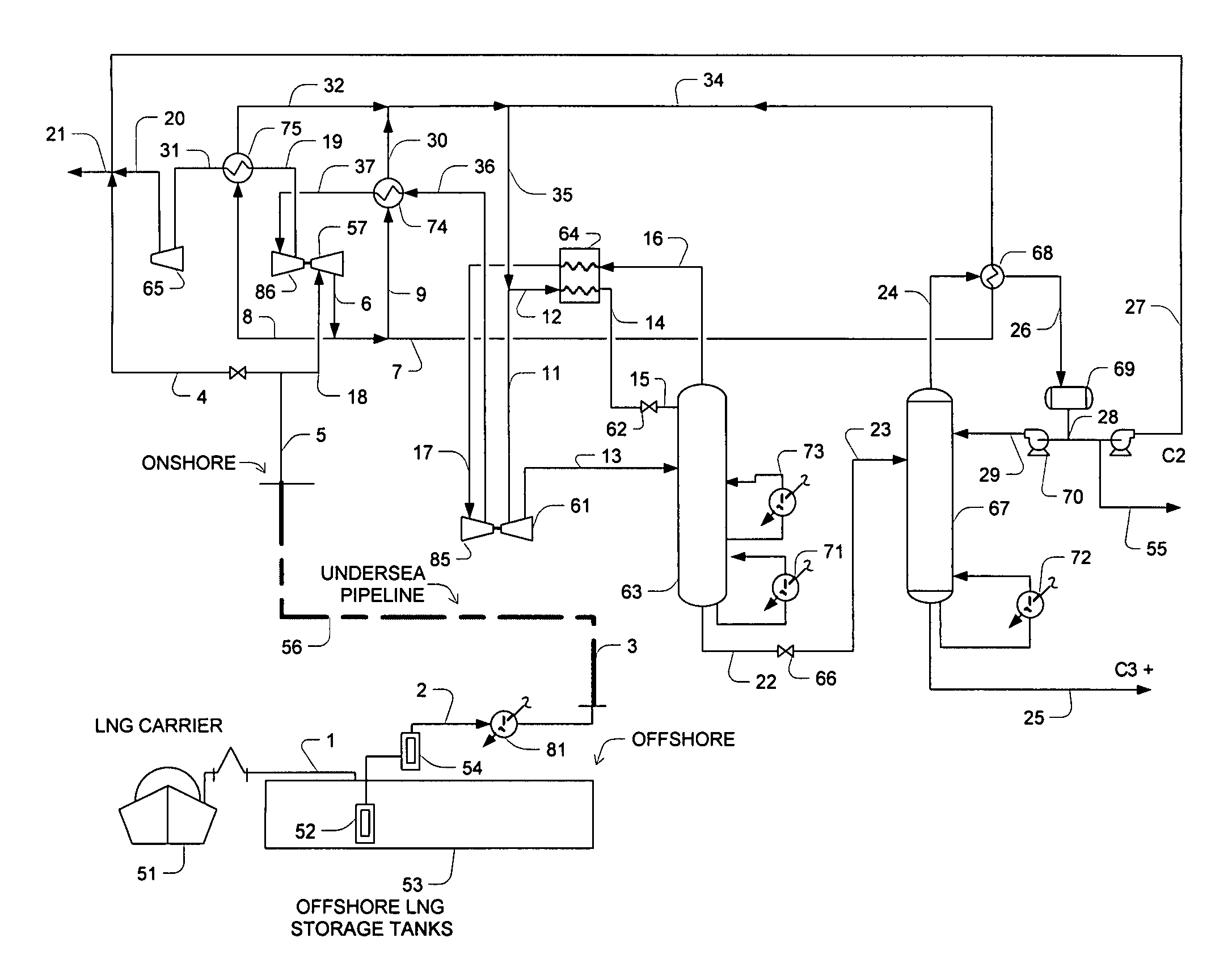

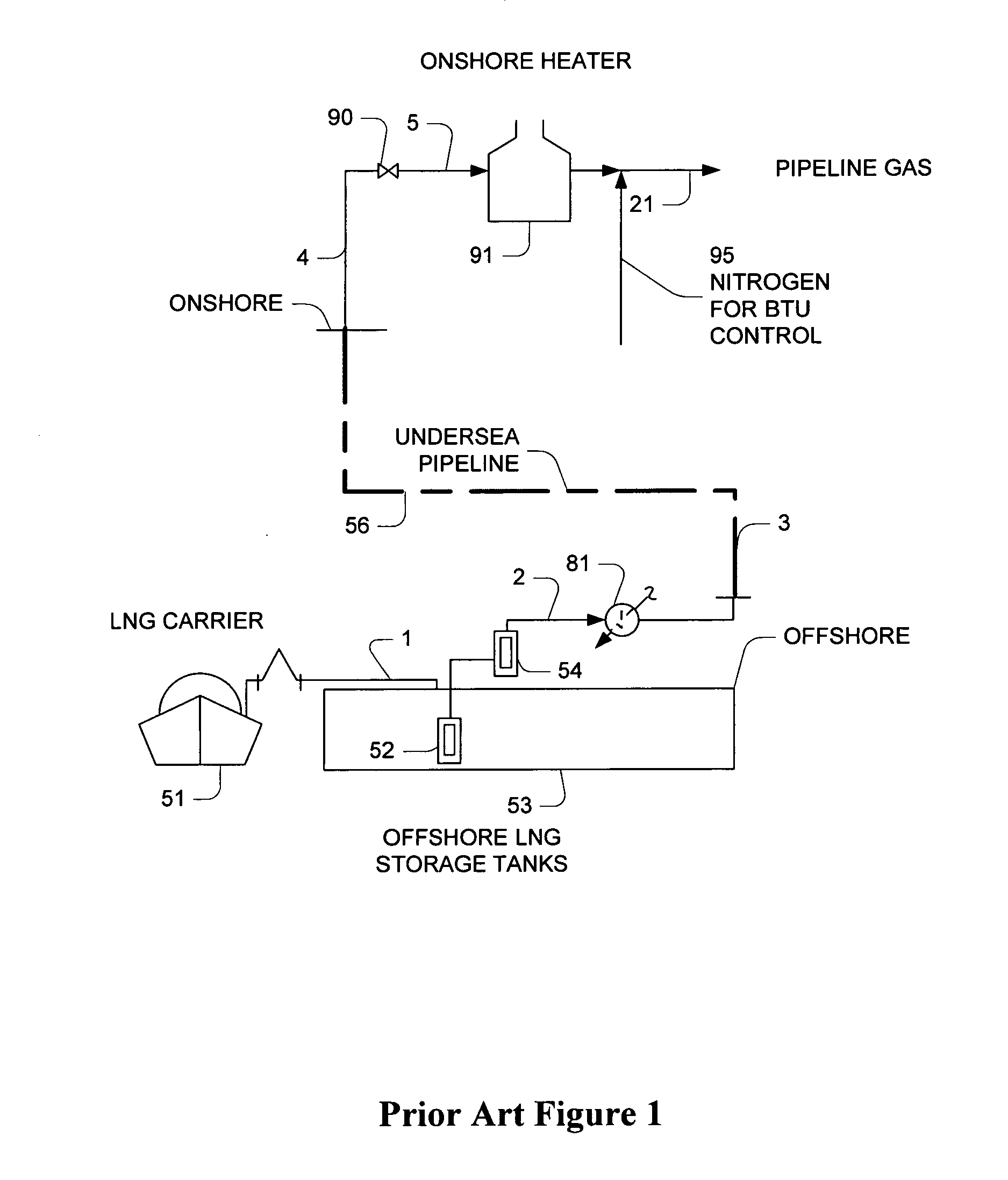

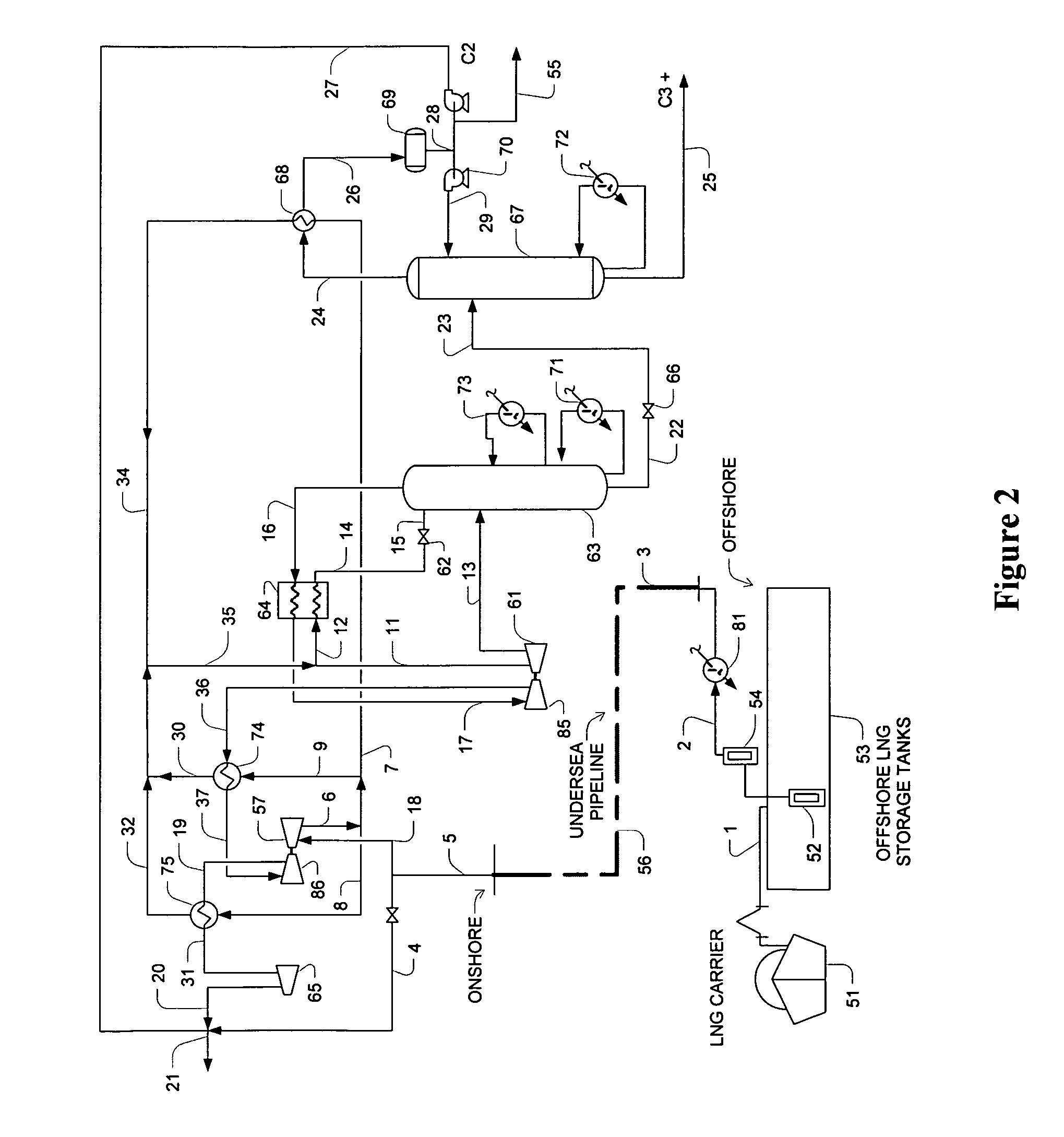

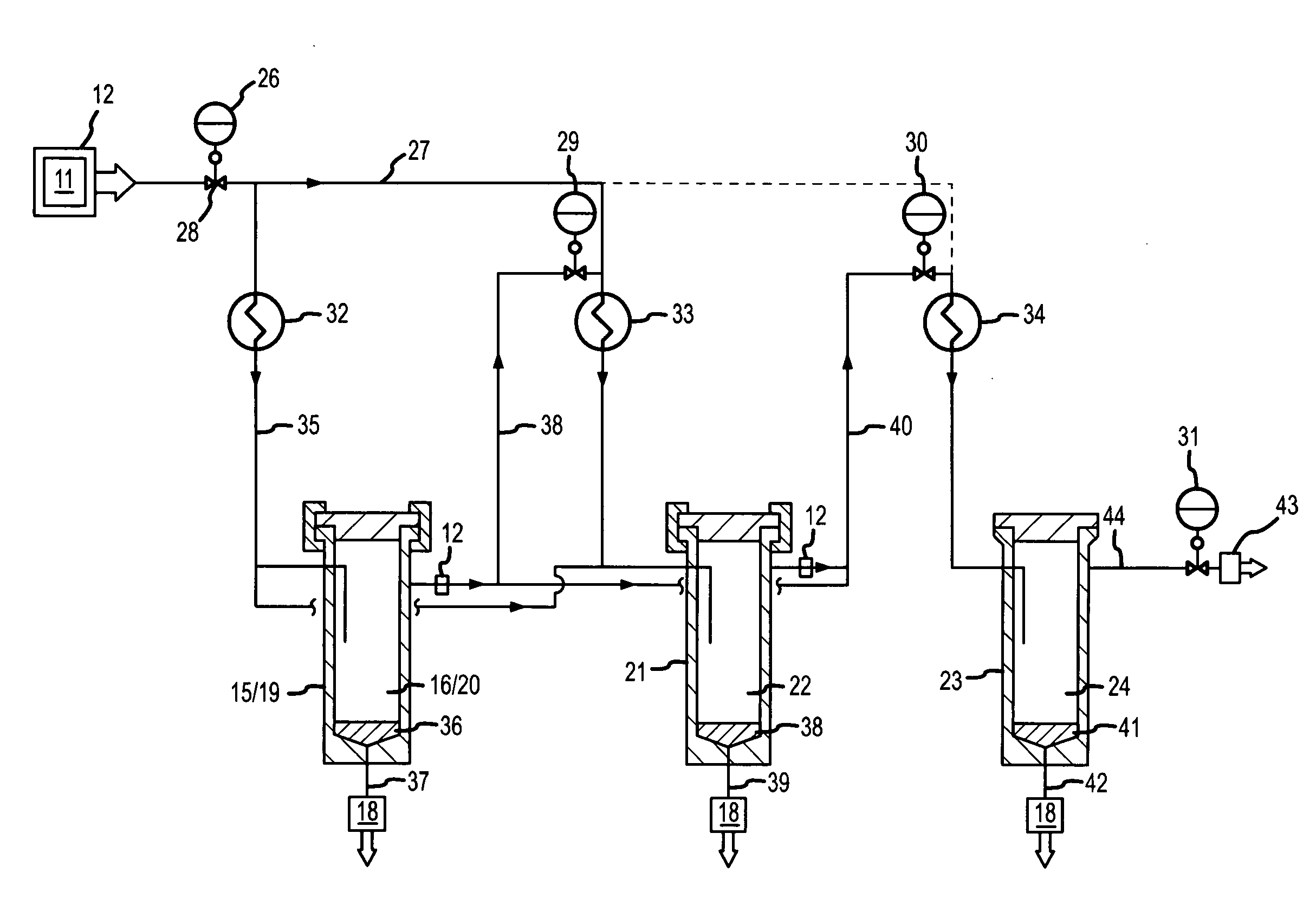

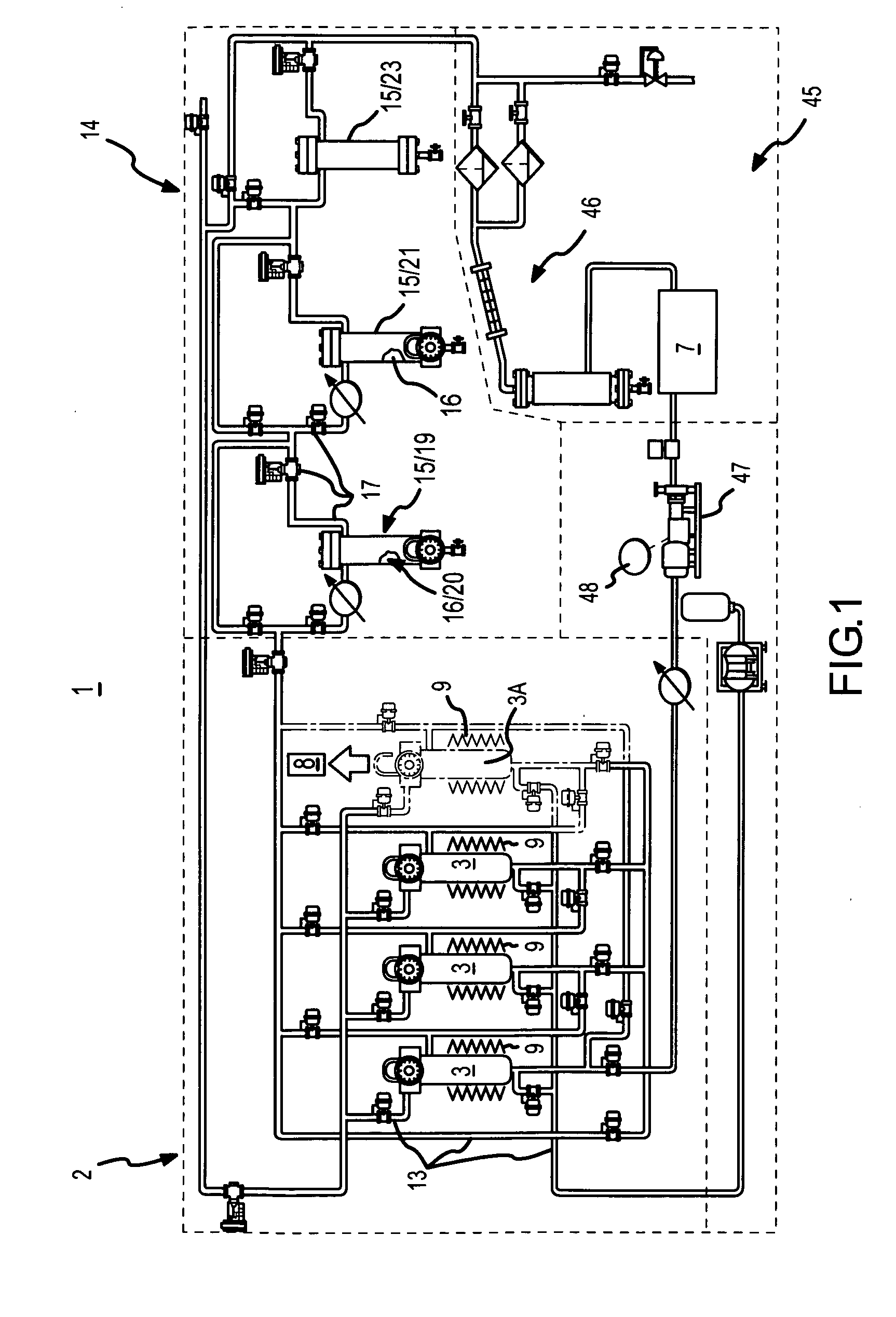

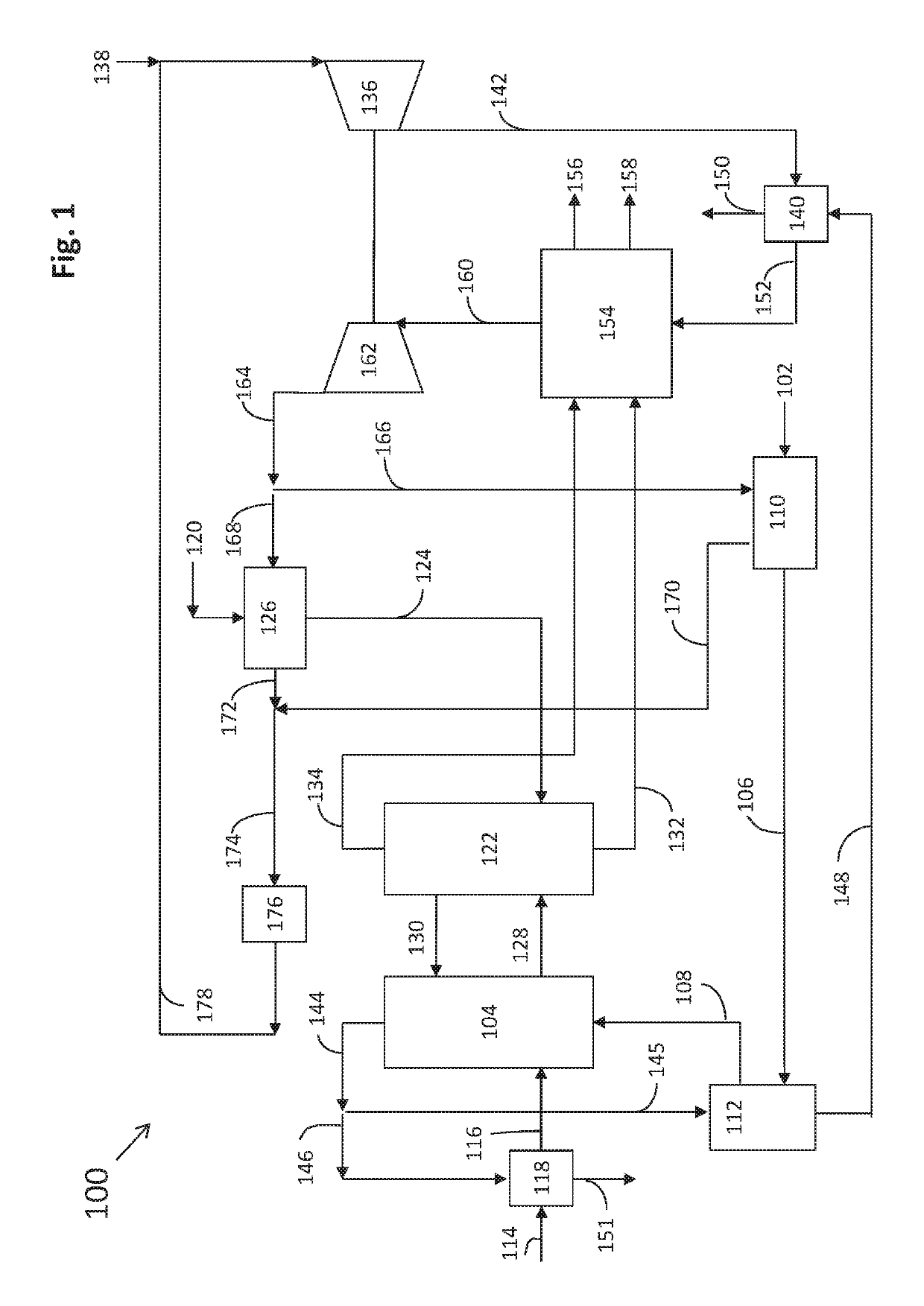

Configurations and methods for offshore LNG regasification and heating value conditioning

Contemplated plant configurations and methods employ a vaporized and supercritical LNG stream at an intermediate temperature that is expanded, wherein refrigeration content of the expanded LNG is used to chill one or more recompressor feed streams and to condense a demethanizer reflux. One portion of the so warmed and expanded LNG is condensed and fed to the demethanizer as reflux, while the other portion is expanded and fed to the demethanizer as feed stream. Most preferably, the demethanizer overhead is combined with a portion of the vaporized and supercritical LNG stream to form a pipeline product.

Owner:FLUOR TECH CORP

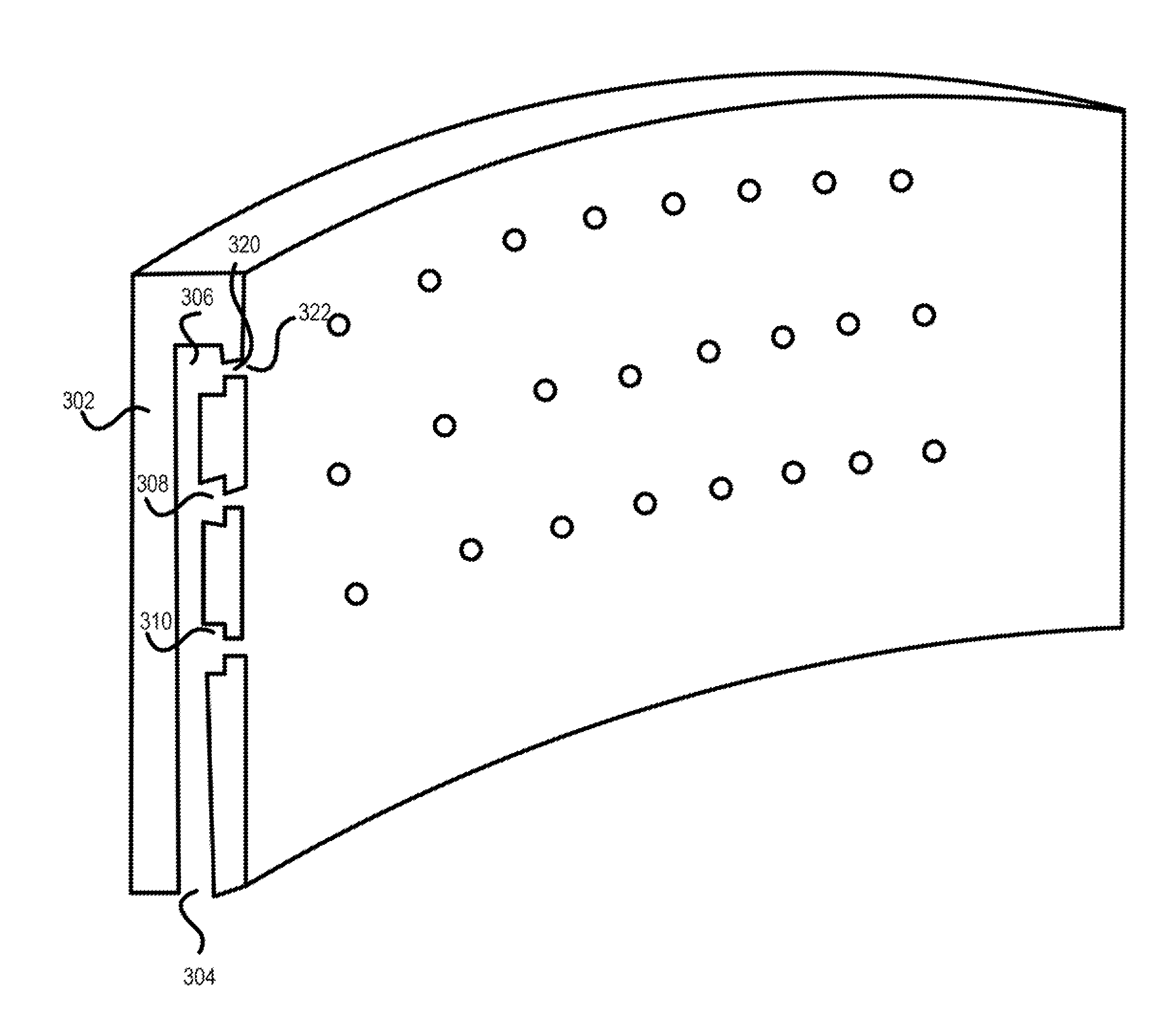

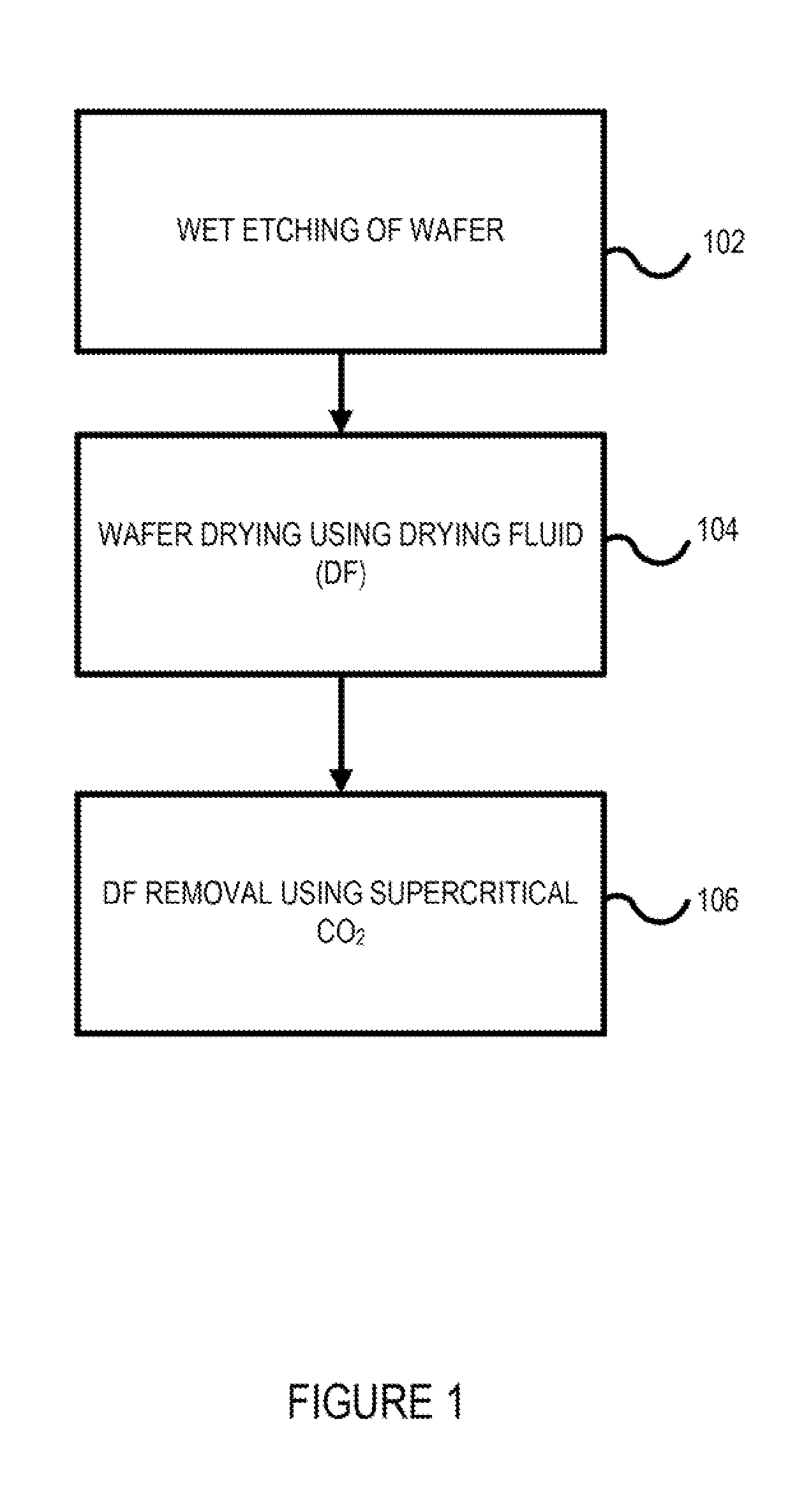

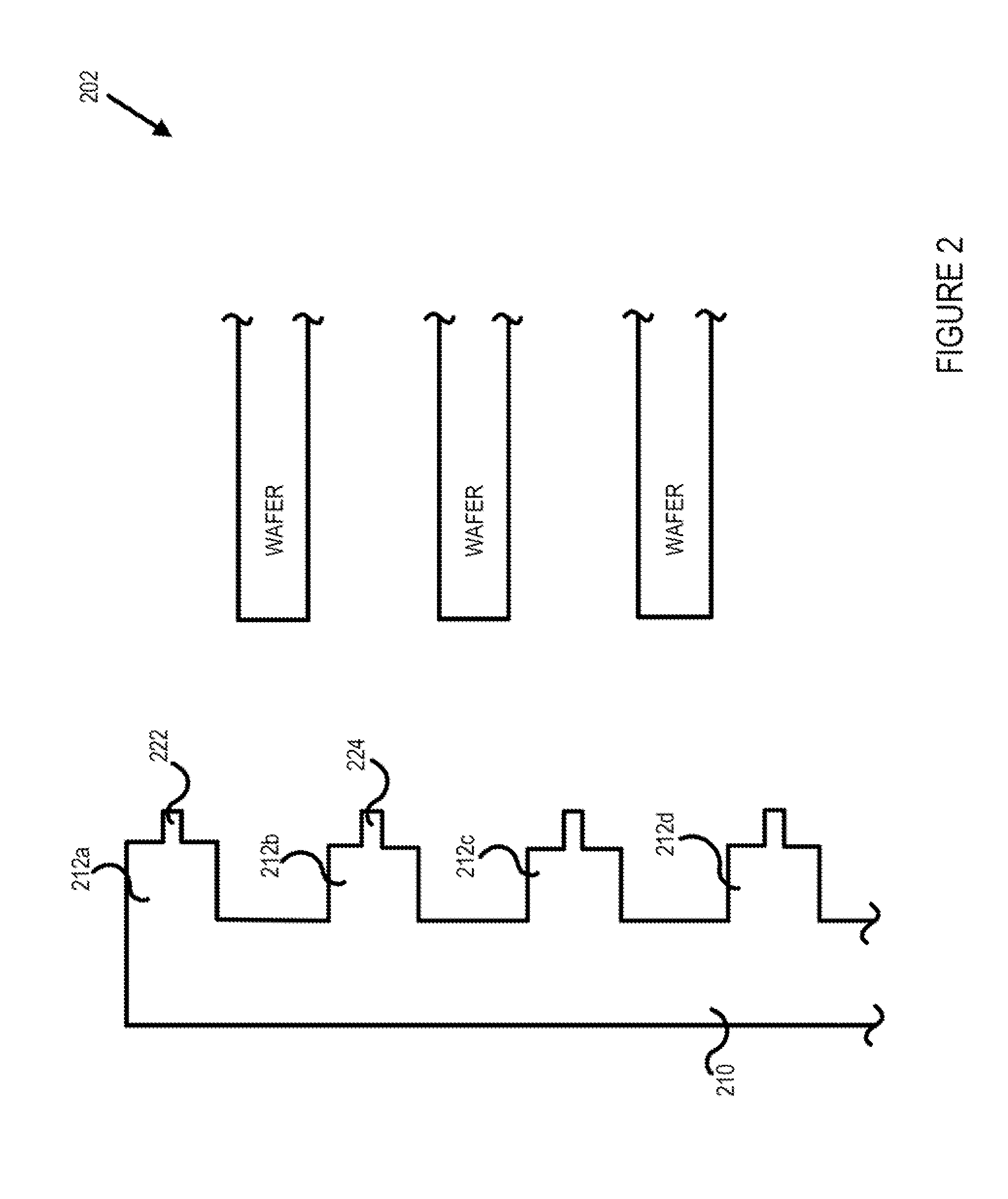

Methods and apparatus for displacing fluids from substrates using supercritical co2

ActiveUS20120111379A1Semiconductor/solid-state device manufacturingElectrostatic cleaningEngineeringSupercritical carbon dioxide

A processing chamber for post-wet-etch removing of drying fluid (DF) is disclosed. The chamber includes a chamber wall surrounding a processing volume and a plurality of nozzles disposed annularly about the processing volume and arranged into a set of nozzle rows that includes at least one nozzle row. The chamber also includes a plenum and a set of manifolds coupled to the plurality of nozzles to deliver the supercritical CO2 to the plurality of nozzles. Each nozzle has a nozzle outlet directed toward an interior portion of the processing volume and the nozzles are configured to flow the supercritical CO2 toward the substrates in a manner that minimizes recirculation loops and vortices.

Owner:LAM RES CORP

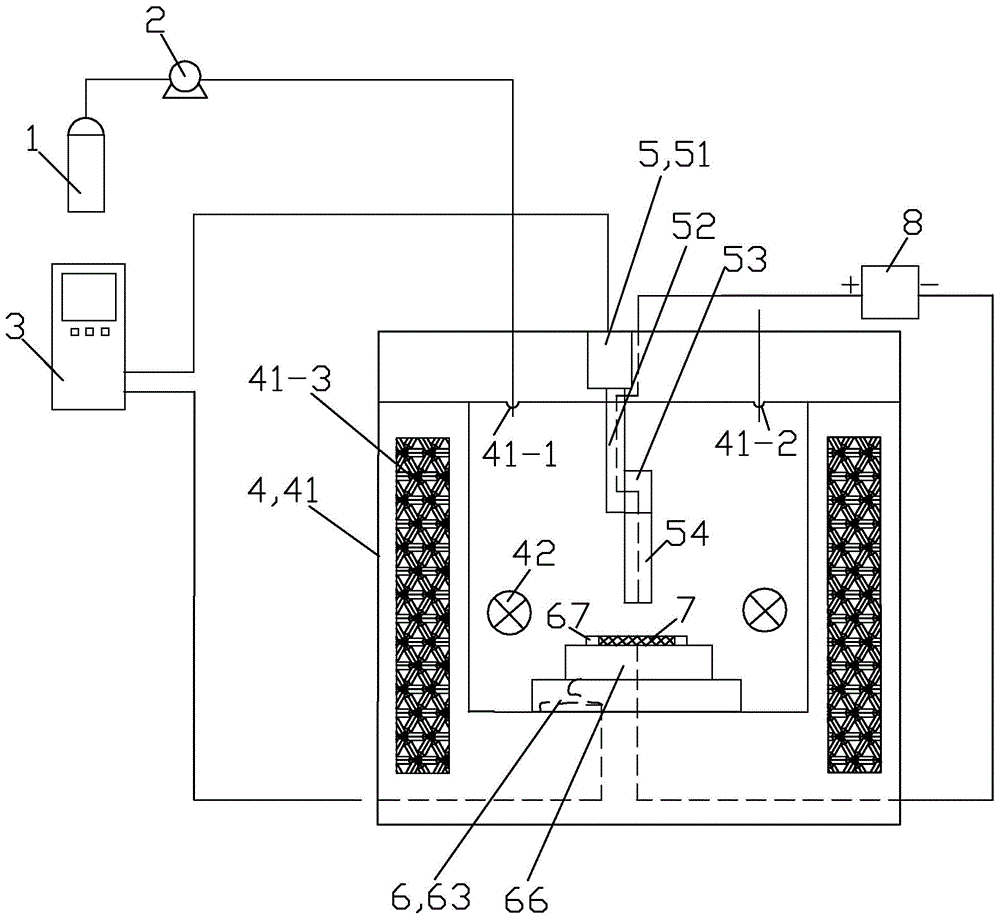

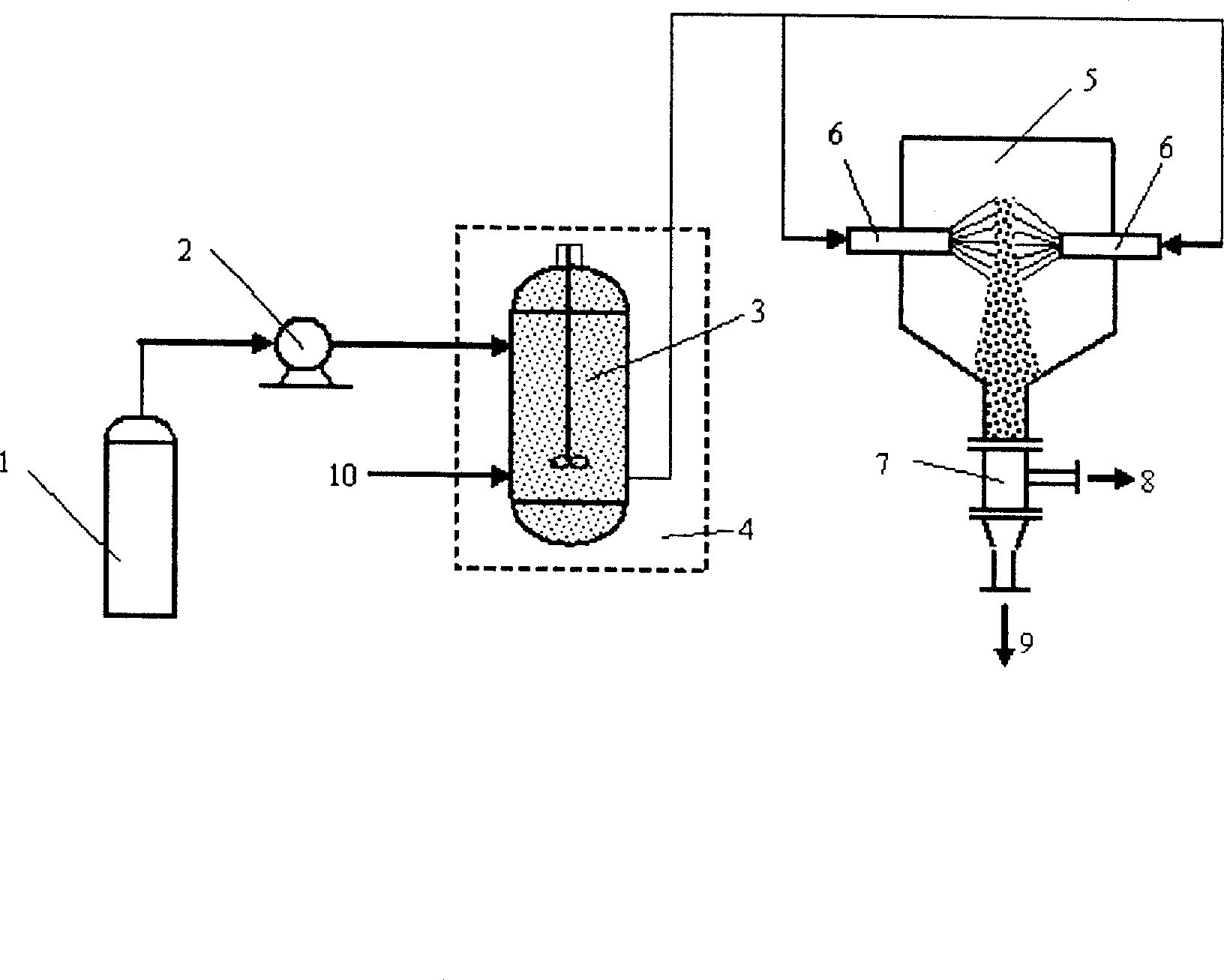

Supercritical-fluid-based 3D electrodeposition machining device and method

ActiveCN104480505AGood miscibilityImprove electric field distributionCellsAdditive manufacturing apparatusMachine partsChemical plating

The invention provides a supercritical-fluid-based 3D electrodeposition machining device and method. The device comprises a carbon dioxide gas bottle, a high-pressure pump, a digital controller, a reactor, a moving anode assembly, a moving cathode assembly, a direct-current power supply and a cathode matrix serving as a machined part, wherein the reactor is internally provided with a mechanical stirrer; the moving anode assembly comprises a Z-directional linear motor, a driving lead screw, an anode connecting rod and a moving anode; the moving cathode assembly comprises an X-directional linear motor, a Y-directional linear motor, a guide rail, a moving block and a fixture; and when the supercritical-fluid-based 3D electrodeposition machining device is used, the moving anode and the cathode matrix are respectively and electrically connected with the anode and cathode of the direct-current power supply. The machining method mainly comprises the steps of carrying out chemical plating treatment on the cathode matrix in advance; mounting the cathode matrix; preparing a supercritical fluid; carrying out electrodeposition machining and after-treatment and the like. By using the supercritical-fluid-based 3D electrodeposition machining device and method, the electrodeposition speed can be effectively increased, the deposition quality can be improved, a complex and precise metal part can be prepared through electrodeposition in a three-dimensional space, and the application field of an electrodeposition technology is widened.

Owner:JIANGSU UNIV OF TECH

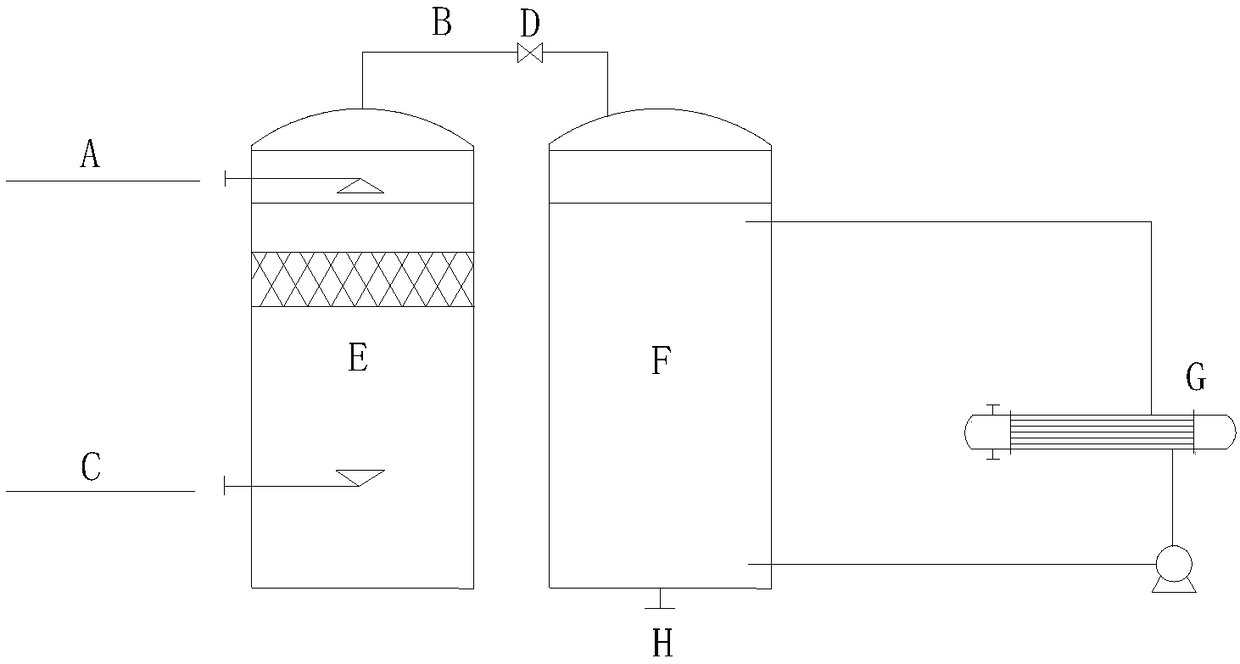

Pressure regulated supercritical fluid fractionation of oil seed extraction materials

InactiveUS20090011112A1Fatty-oils/fats refiningFatty-oils/fats productionFractionationSupercritical flow

Generally, a method of pressure regulated supercritical fluid fractionation of oil seed extraction materials which can be utilized to refine oil seed extraction material established in an amount of supercritical fluid. Specifically, a method of pressure regulated supercritical fluid fractionation of corn germ extraction material to produce a refined corn oil extraction material.

Owner:MOR SUPERCRITICAL

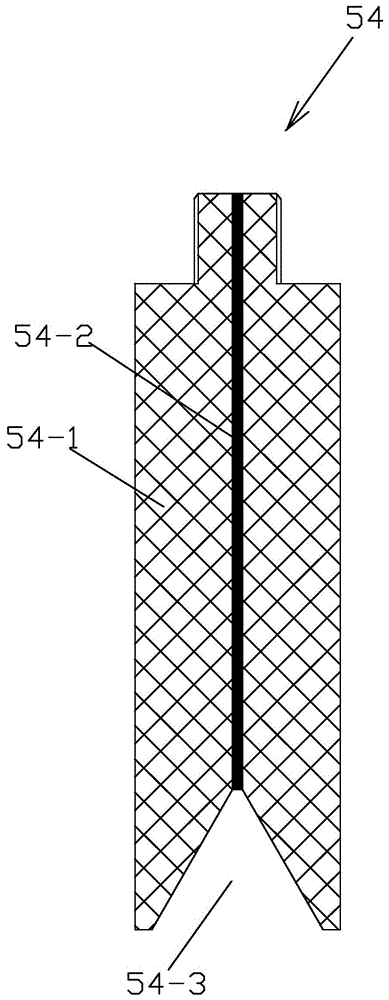

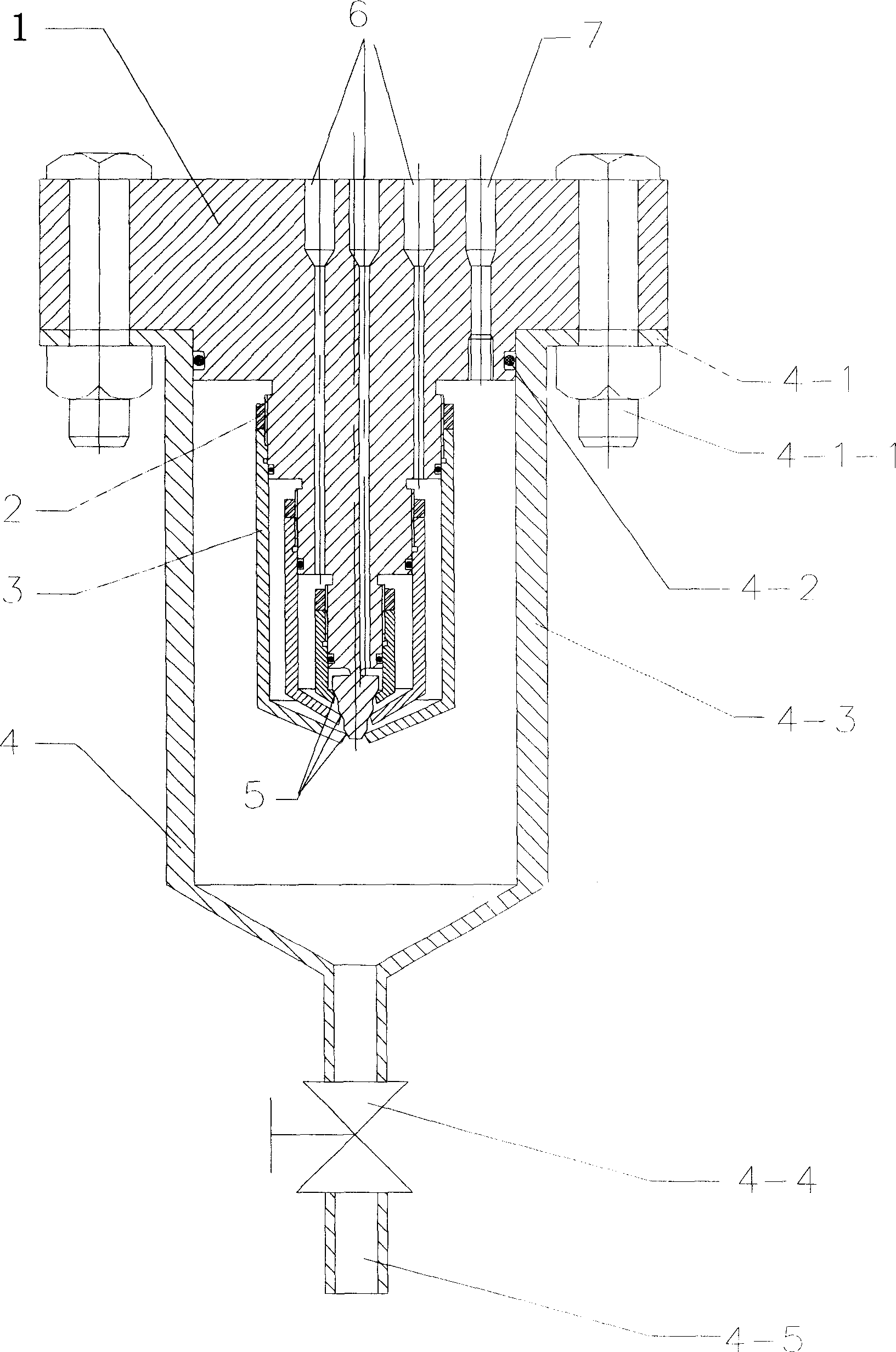

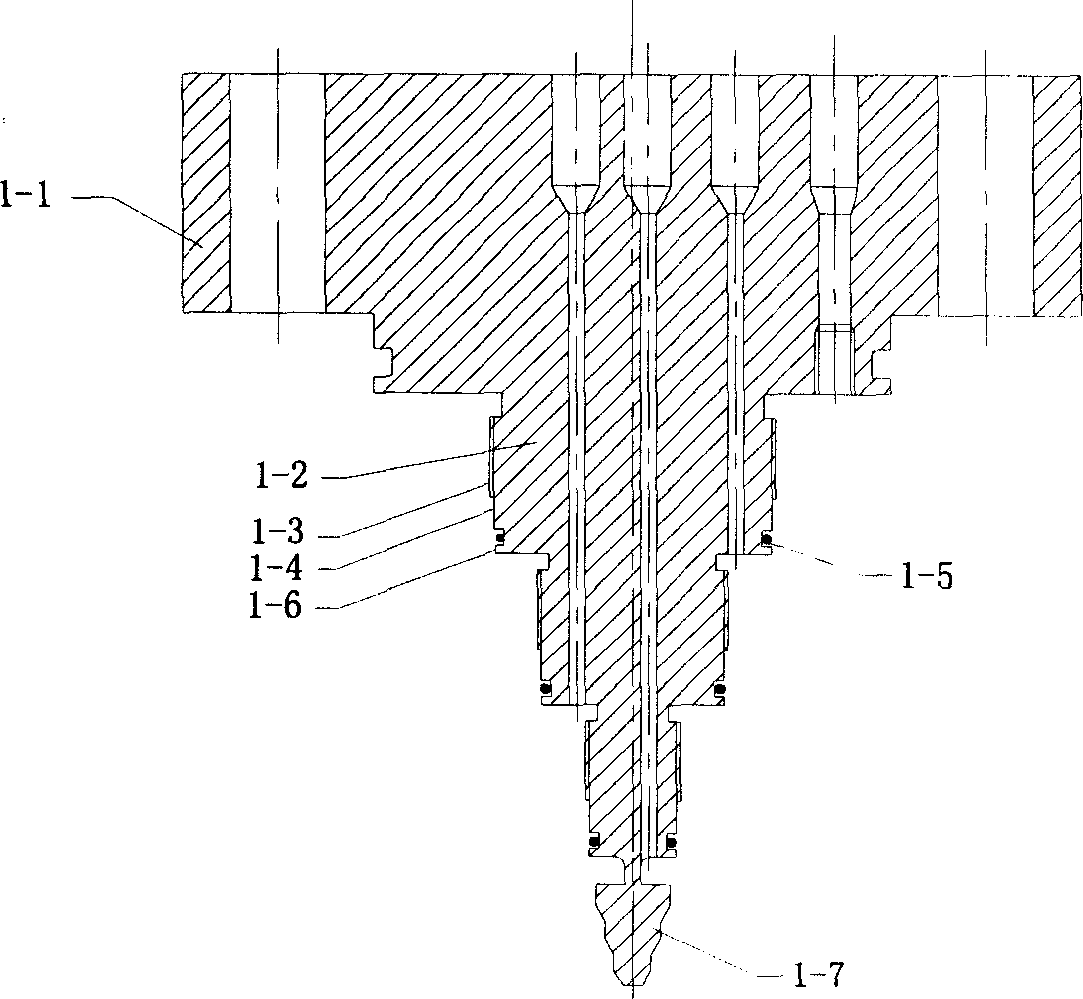

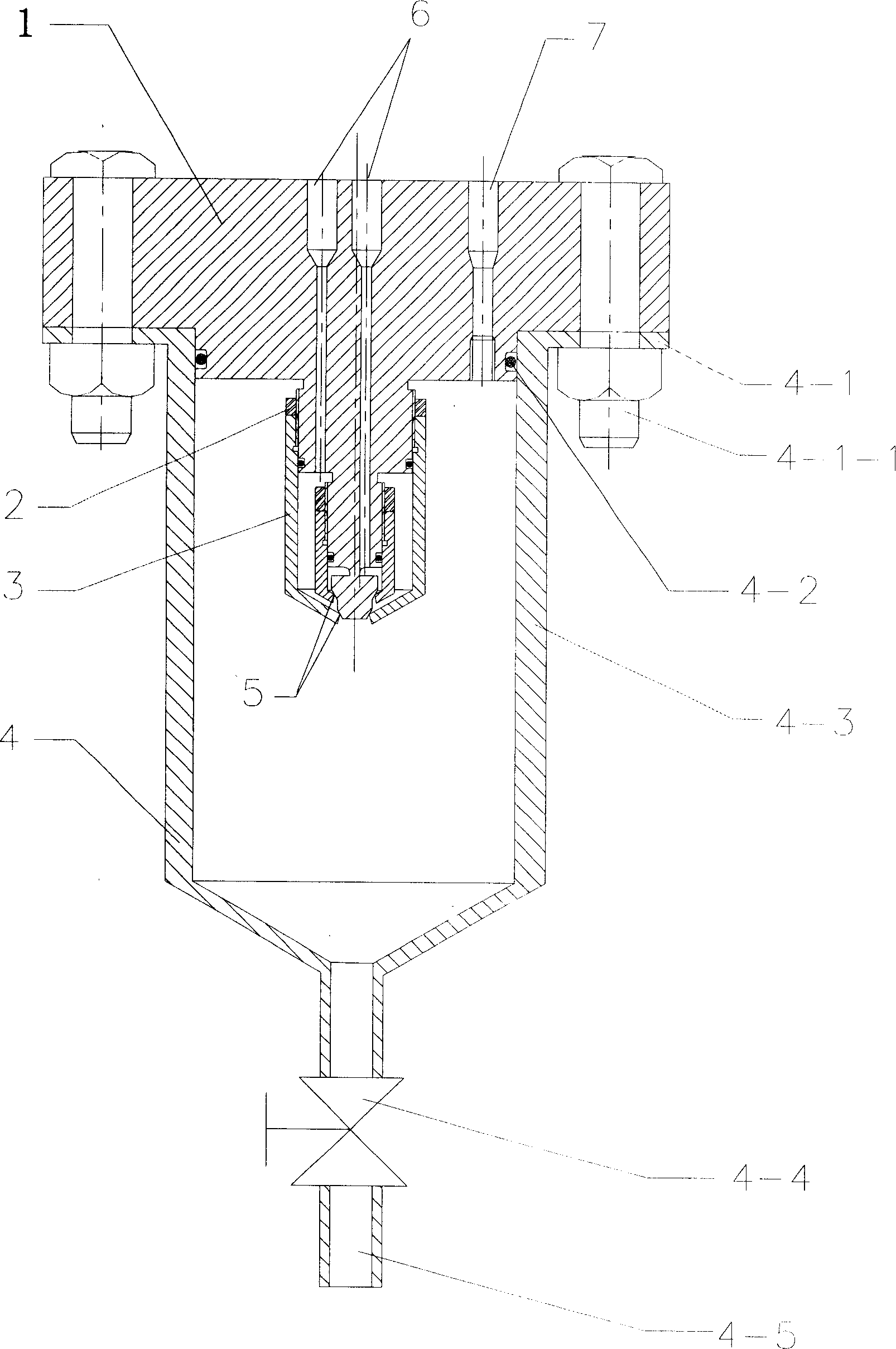

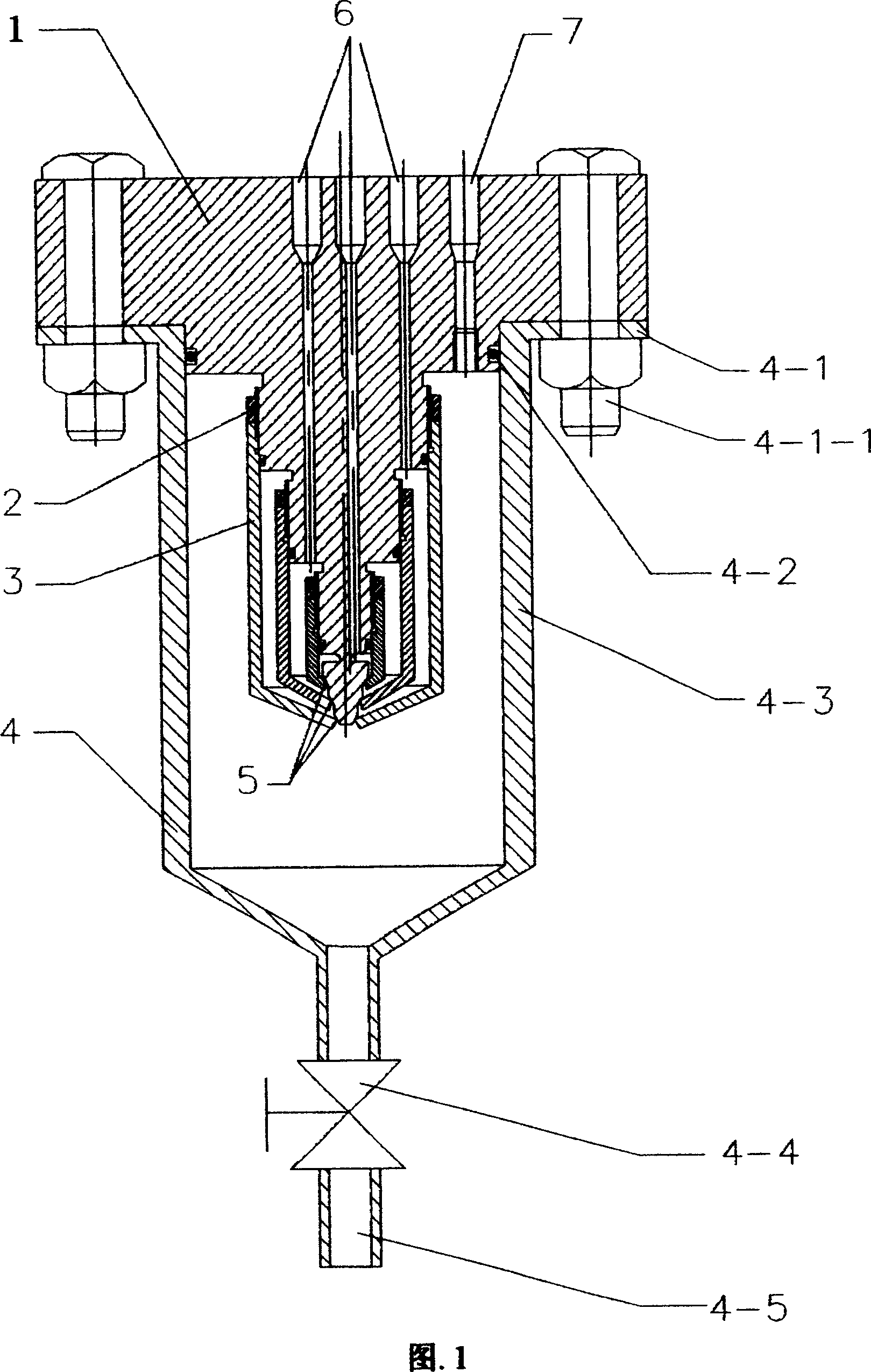

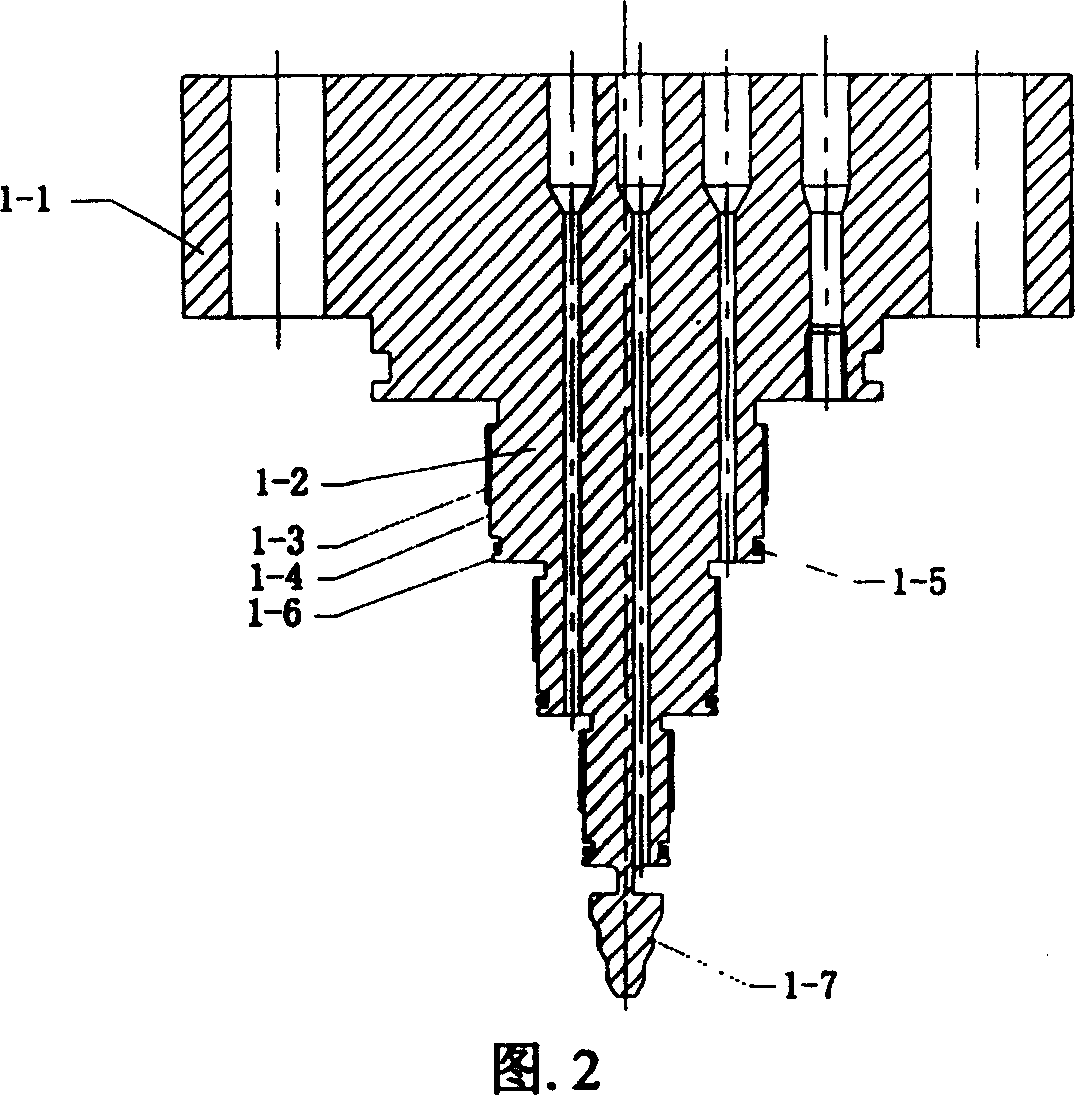

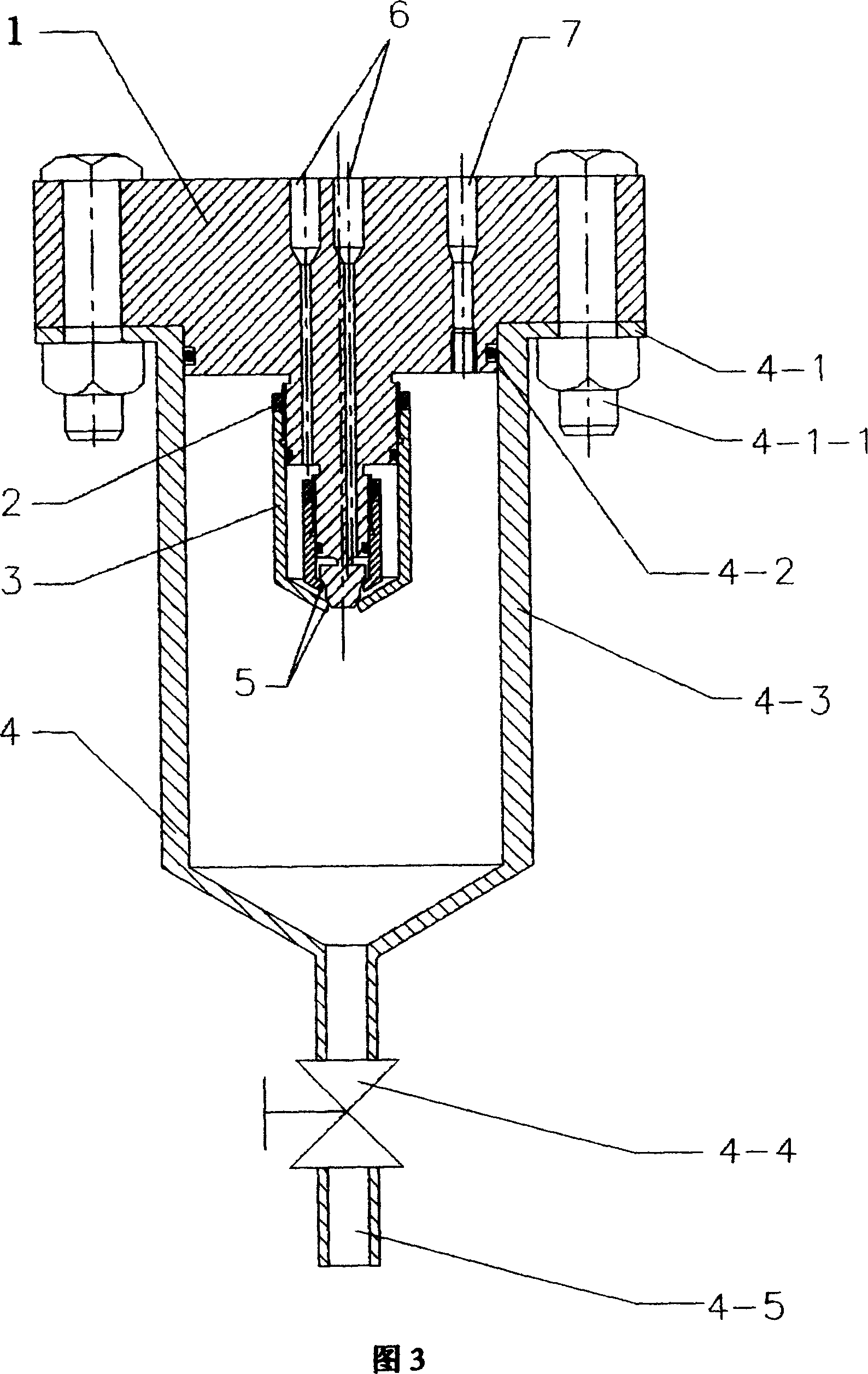

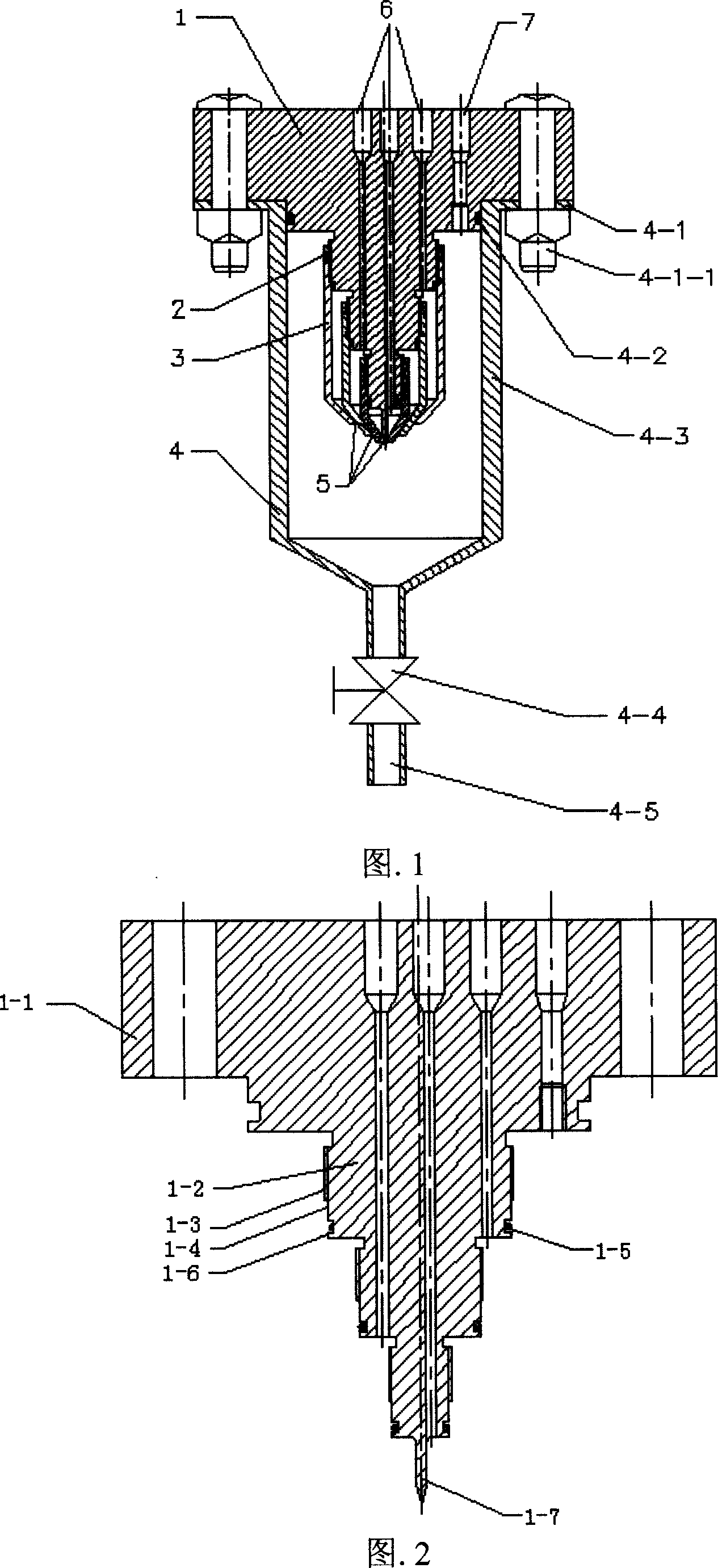

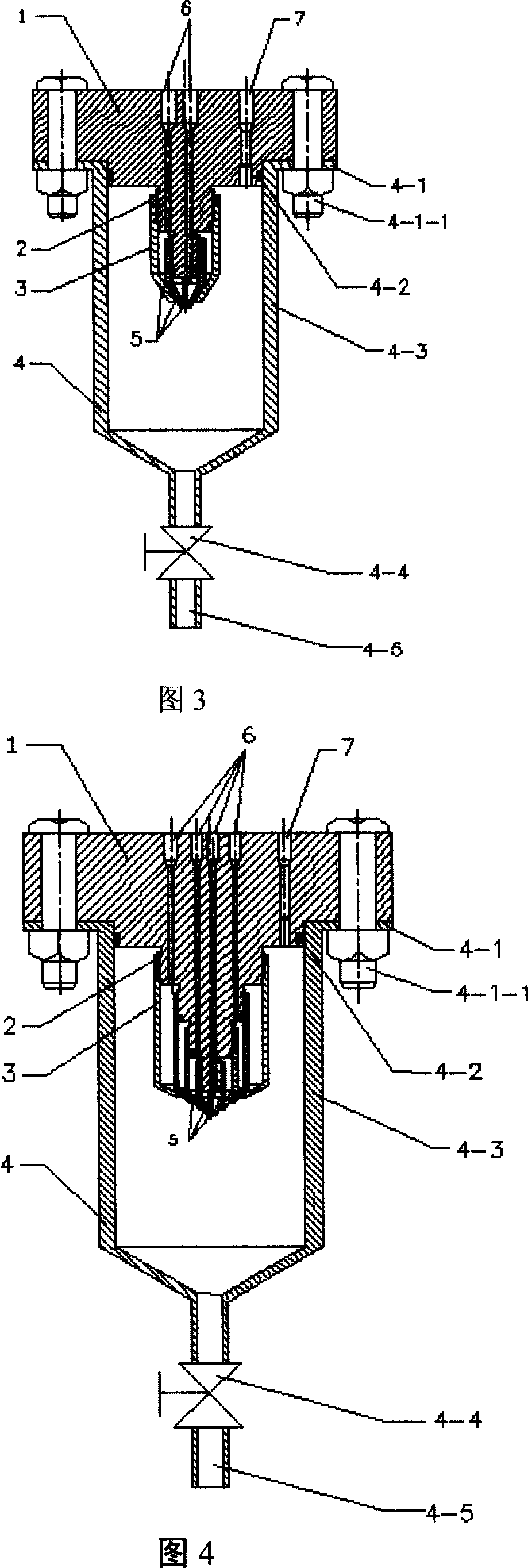

Nozzle for micro and nano material preparation by interior mixing supercritical fluid

InactiveCN1827227ANot easy to changeReasonable structureLiquid spraying apparatusMaterials preparationEngineering

The invention belongs to the nanometer micro material preparing device, which especially relates to an internal mixed hypercritical fluid nanometer micro material preparing nozzle. The invention is formed by a nozzle main body and a taper end sheath and a collector which are mounted on the main body; wherein, the tail of said main body is a nozzle core; the main body and the taper end sheath are positioned by positioning surface, locked by screw connection and adjusting locking element, and sealed by sealing ring; the taper end sheath and the nozzle core form the annular slit as the nozzle; the nozzle via the feeding channel of main body is connected to the material feeding channel; the collector is outside the main body and the taper end sheath to be fixed on the main body; the collector has a valve. The invention has reasonable structure which can mix several materials synchronously to be sprayed, to realize internal mixed hypercritical fluid nanometer micro particle preparation. The annular slit of nozzle can be adjusted easily to avoid jam and prepare smaller particle. The invention can reduce the cost and improve the efficiency.

Owner:SHANDONG UNIV

Method for preparation of fermentation cordyceps active site and the application thereof in the aspect of respiratory disease

The invention relates to a method for preparing active part of fermented Cordyceps sinensis bacteria powder and its application for treating respiratory disease. Said active part is fat soluble active part of fermented Cordyceps sinensis bacteria powder, and can be called Cordyceps sinensis oil or fermented Cordyceps sinensis bacteria powder oil, which comprises nonpolar component such as unsaturated fatty acid, saturated fatty acid, ester, alkane and polar component with macromolecular weight. The method comprises three kinds of processes: CO2 supercritical flow extraction and separation; extraction with fat soluble organic dissolvent such as ether and ligroine; water steam evaporation. The active part can prevent and treat chronic obstructive pulmonary disease such as asthma, chronic bronchitis and pneumonectasis, allergic rhinitis and cough. It can be produced into medicine, health-care foodstuff and foodstuff addictive. The active part of fermented Cordyceps sinensis bacteria powder greatly increases the effect for treating respiratory disease, and is characterized by defined treating effect, small intake dose, easy to controllable effective component content and easier absorption.

Owner:王勤科

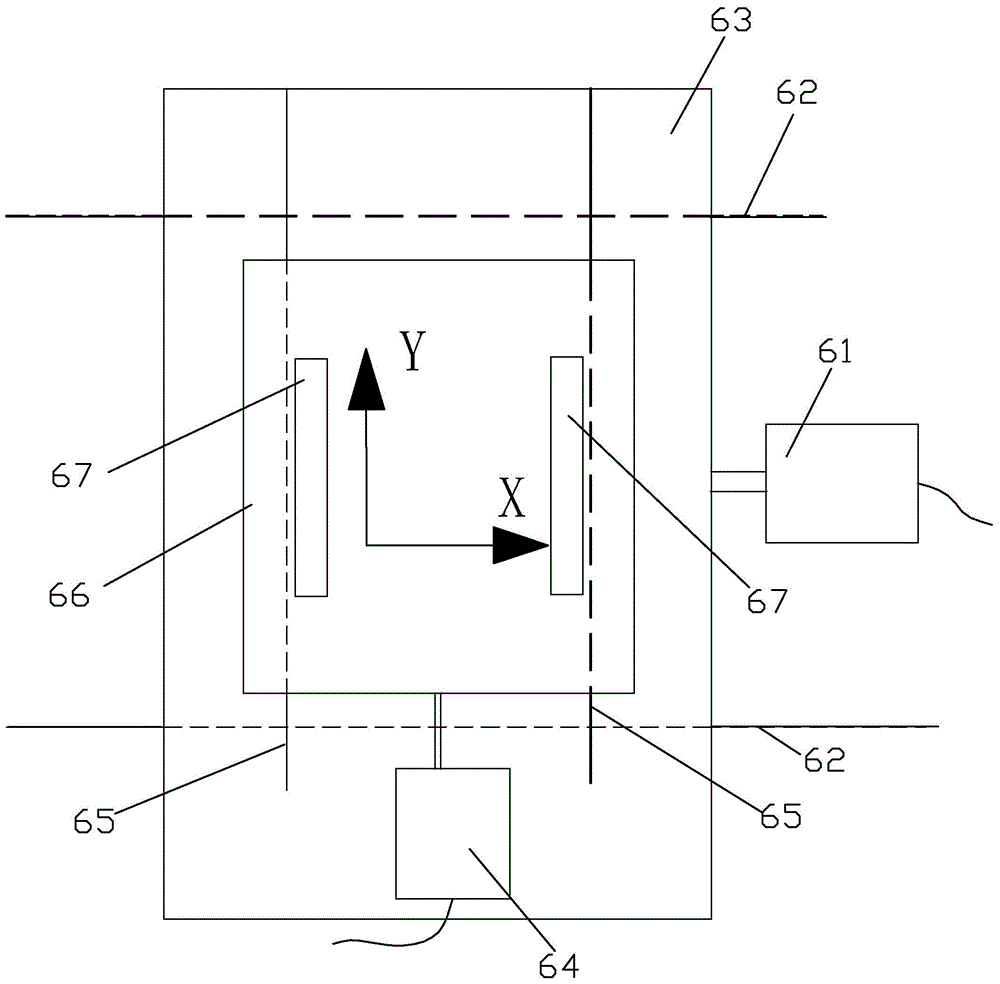

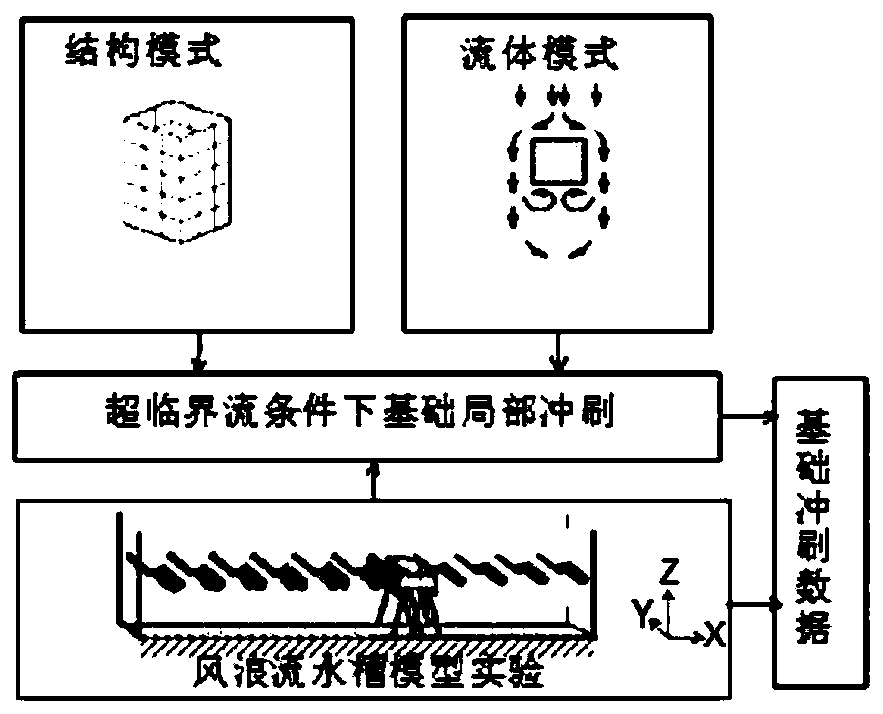

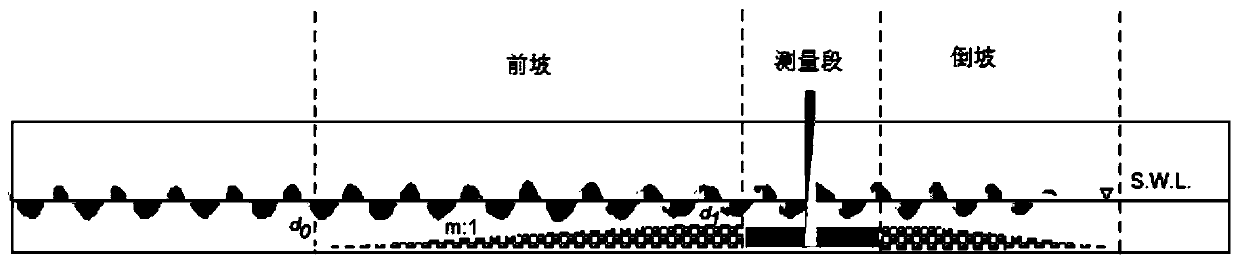

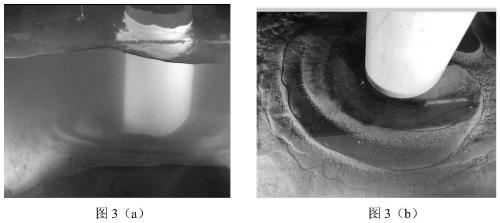

Water tank test method for local scouring of foundation under supercritical flow condition

InactiveCN111289219AAccurately measure depthPrecisely Measure MorphologyHydrodynamic testingShock waveWind wave

Owner:李熙

Nozzle for micro and nano material preparation by interior mixing supercritical fluid

InactiveCN100352558CNot easy to changeReasonable structureLiquid spraying apparatusMaterials preparationEngineering

The invention belongs to the nanometer micro material preparing device, which especially relates to an internal mixed hypercritical fluid nanometer micro material preparing nozzle. The invention is formed by a nozzle main body and a taper end sheath and a collector which are mounted on the main body; wherein, the tail of said main body is a nozzle core; the main body and the taper end sheath are positioned by positioning surface, locked by screw connection and adjusting locking element, and sealed by sealing ring; the taper end sheath and the nozzle core form the annular slit as the nozzle; the nozzle via the feeding channel of main body is connected to the material feeding channel; the collector is outside the main body and the taper end sheath to be fixed on the main body; the collector has a valve. The invention has reasonable structure which can mix several materials synchronously to be sprayed, to realize internal mixed hypercritical fluid nanometer micro particle preparation. The annular slit of nozzle can be adjusted easily to avoid jam and prepare smaller particle. The invention can reduce the cost and improve the efficiency.

Owner:SHANDONG UNIV

Nozzle for micro and nano material preparation by exterior mixing supercritical fluid

InactiveCN100352559CNot easy to changeReasonable structureLiquid spraying apparatusMaterials preparationEngineering

The invention belongs to the nanometer micro material preparing device, which especially relates to an external mixed hypercritical fluid nanometer micro material preparing nozzle. The invention is formed by a nozzle main body and a taper end sheath and a collector which are mounted on the main body; wherein, the tail of said main body is a nozzle core; the main body and the taper end sheath are positioned by positioning surface, locked by screw connection and adjusting locking element, and sealed by sealing ring; the taper end sheath and the nozzle core form the annular slit as the nozzle; the nozzle via the feeding channel of main body is connected to the material feeding channel; the collector is outside the main body and the taper end sheath to be fixed on the main body; the collector has a valve. The invention has reasonable structure which can mix several materials synchronously to be sprayed, to realize external mixed hypercritical fluid nanometer micro particle preparation. The annular slit of nozzle can be adjusted easily to avoid jam and prepare smaller particle. The invention can reduce the cost and improve the efficiency.

Owner:SHANDONG UNIV

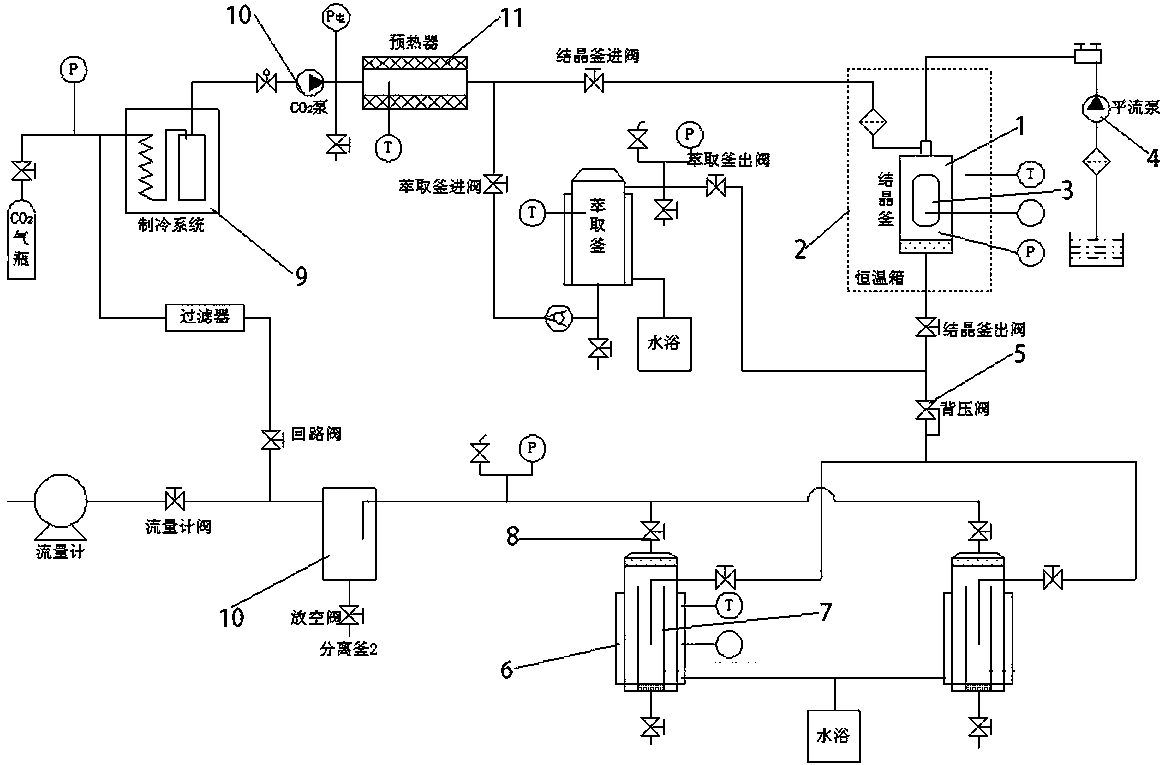

Supercritical fluid recrystallization device

PendingCN108310797AHigh saturation rateSolution crystallizationCrystallization plant arrangementsSupercritical flowChemistry

The invention provides a supercritical fluid recrystallization device. The supercritical fluid recrystallization device comprises a crystallization kettle body and a constant-temperature tank, whereinan observation window is formed in the crystallization kettle body; a solution is injected to the upper end of the crystallization kettle body through a constant flux pump; the crystallization kettlebody is arranged in the constant-temperature tank. The supercritical fluid recrystallization device provided by the invention has the beneficial effects that under a supercritical situation, generation of supersaturation can be caused by reducing the pressure, a high saturation rate can be achieved, and a solid solute can be crystallized out from a supercritical solution; a solute in the solutionis separated out and collected by utilizing CO2 in a supercritical state, so that nano-grade crystalline particles can be obtained.

Owner:NANTONG HUAAN SUPER CRITICAL EXTRACTION

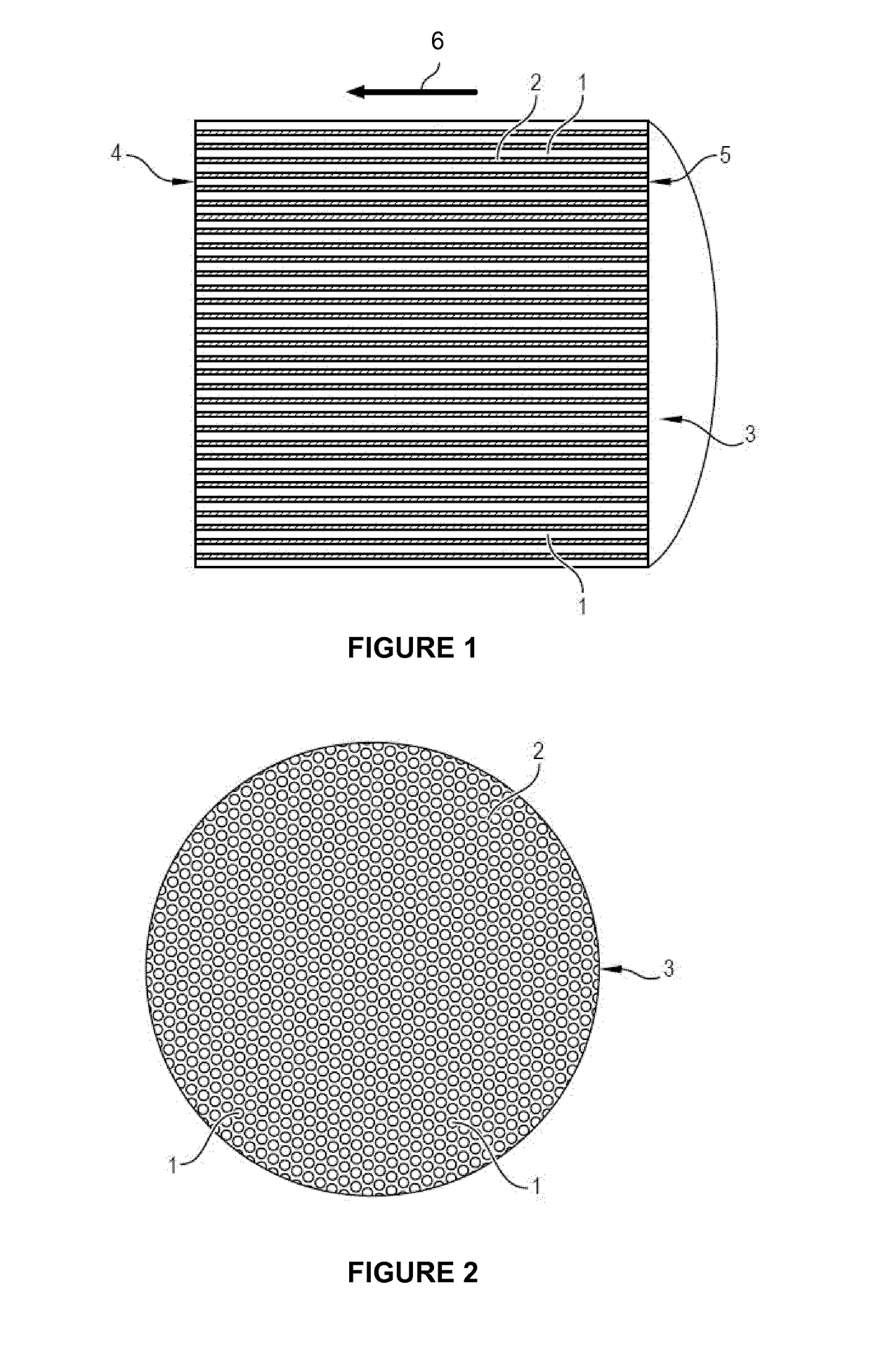

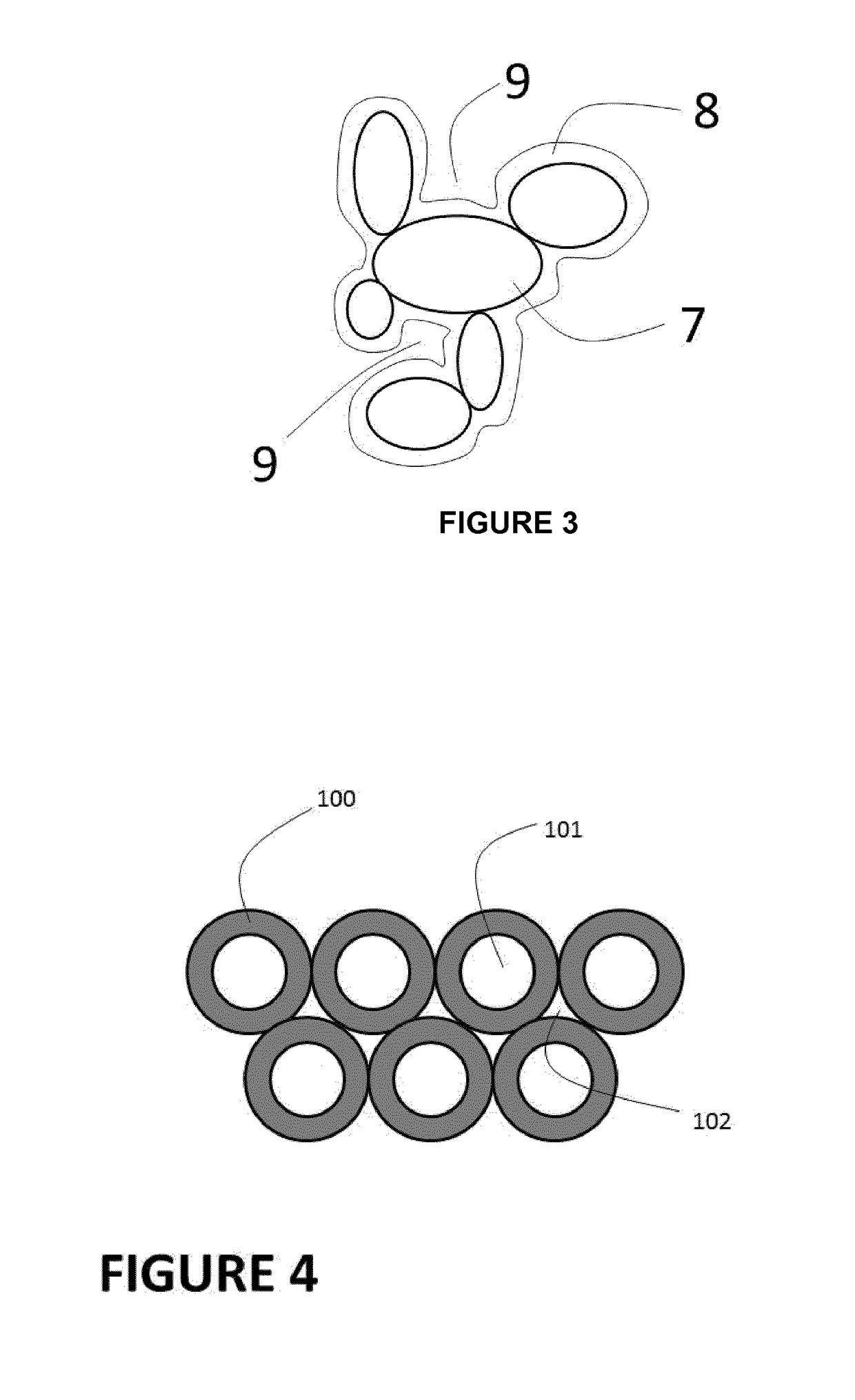

Organic gel or liquid chromatography method

ActiveUS20180229151A1Chromatographic cation exchangersCation exchanger materialsOrganic fluidCapillary action

The invention relates to a chromatography method in which a gaseous, liquid or supercritical mobile phase containing species to be separated is circulated through a packing, said packing comprising: —a plurality of capillary ducts extending in the packing between an upstream face through which the mobile phase enters the packing and a downstream face through which the mobile phase leaves the packing, and —a continuous medium permeable to molecular diffusion extending between said ducts, comprising a porous organic gel or an organic liquid and including at least one network of connected pores, the size of which is greater than two times the molecular diameter of at least one species to be separated and opening to the ducts, so as to give said at least one species a diffusive path between said ducts. The invention also relates to a packing for the implementation of such a method and a method for manufacturing such a packing.

Owner:PARMENTIER FRANCOIS

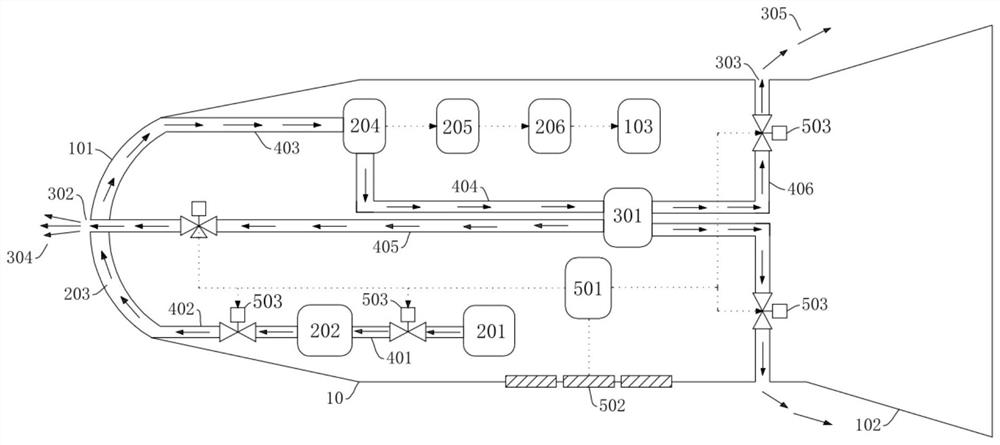

Hypersonic aircraft with heat energy utilization system and flow control method thereof

ActiveCN113247245ARealize comprehensive utilizationZero energy consumptionSteam engine plantsAir-flow influencersShock waveHeat management

The invention discloses a hypersonic aircraft with a heat energy utilization system and a flow control method, and relates to the field of heat management and flow control of hypersonic aircrafts. A supercritical CO2 heat exchange micro-channel is arranged at the head position of the hypersonic flight vehicle for heat exchange, supercritical CO2 flows through the supercritical CO2 heat exchange micro-channel to absorb a large amount of heat so as to achieve heat reduction of the head of the flight vehicle, and then high-temperature and high-pressure supercritical CO2 impacts a turbine to do work; the internal energy of hypersonic gas carried by the supercritical CO2 is converted into electric energy through a generator, and the electric energy is stored in a storage battery and can be used for supplying power to all systems of the aircraft; then high-pressure CO2 gas subjected to the heat energy utilization process is fully utilized, high-pressure jet flow is jetted at the front edges of the head and the empennage of the aircraft to control head shock waves and empennage shock waves, and therefore heat flow and resistance of the head and the empennage of the aircraft are reduced, and heat reduction and resistance reduction of the hypersonic aircraft are achieved.

Owner:NAT UNIV OF DEFENSE TECH

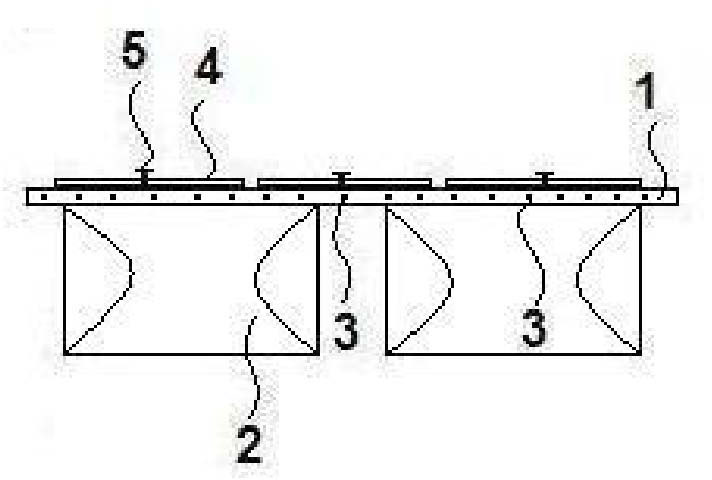

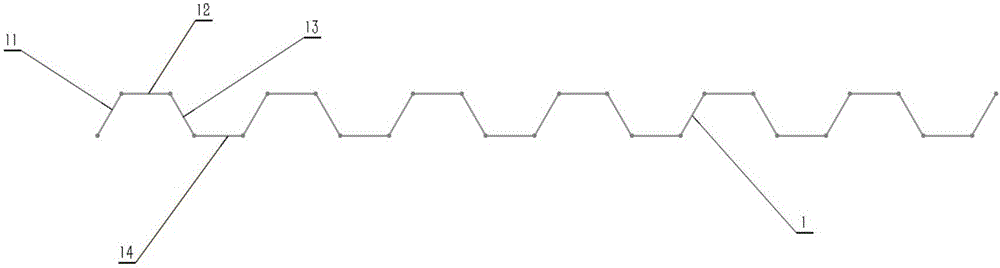

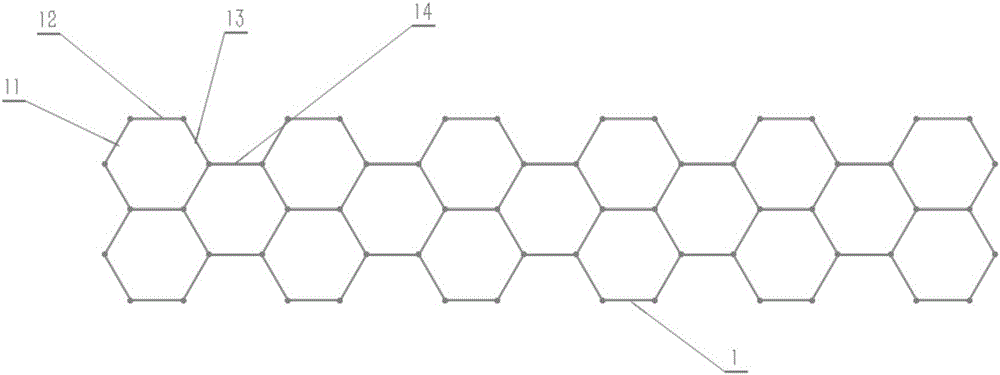

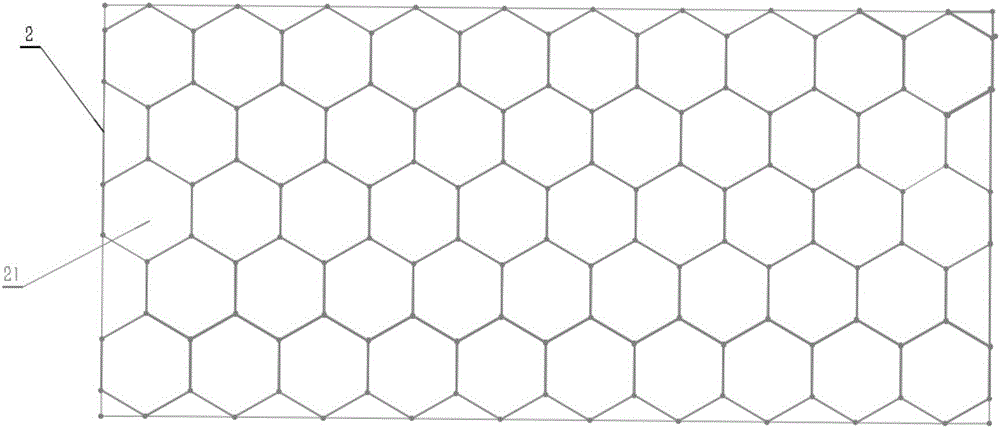

Distributing plate for carbon fiber spinning and distributing assembly thereof

ActiveCN106480522AUniform flow rateAvoid rapid turbulenceArtificial thread manufacturing machinesWet spinning methodsCarbon fibersHoneycomb

The invention discloses a distributing plate for carbon fiber spinning and a distributing assembly thereof and belongs to the technical field of carbon fiber spinning and processing. The distributing plate consists of a plate frame and a plurality of plate strips, wherein the plate strips are provided with bent surfaces, connecting surfaces I and connecting surfaces II, the plate stirps are fixedly connected to form a plate strip body through the connecting surfaces I and the connecting surfaces II of the adjacent plate strips, and the edge of the plate strip body is fixedly connected with the inside of the plate frame. Distributing holes are formed in the bent surfaces, the connecting surfaces I and the connecting surfaces II of the adjacent plate strips. In addition, the invention further provides a distributing assembly of the distributing plate. The plate surface of the distributing plate is honeycomb, the flowing speed of a solution entering a spinning box can be effectively homogenized, accordingly the phenomena of supercritical flow and turbulent flow occurred when the solution enters the spinning box surging channel are avoided, and the production efficiency of spinning production is remarkably improved.

Owner:HARBIN TIANSHUN CHEM TECH DEV CO LTD

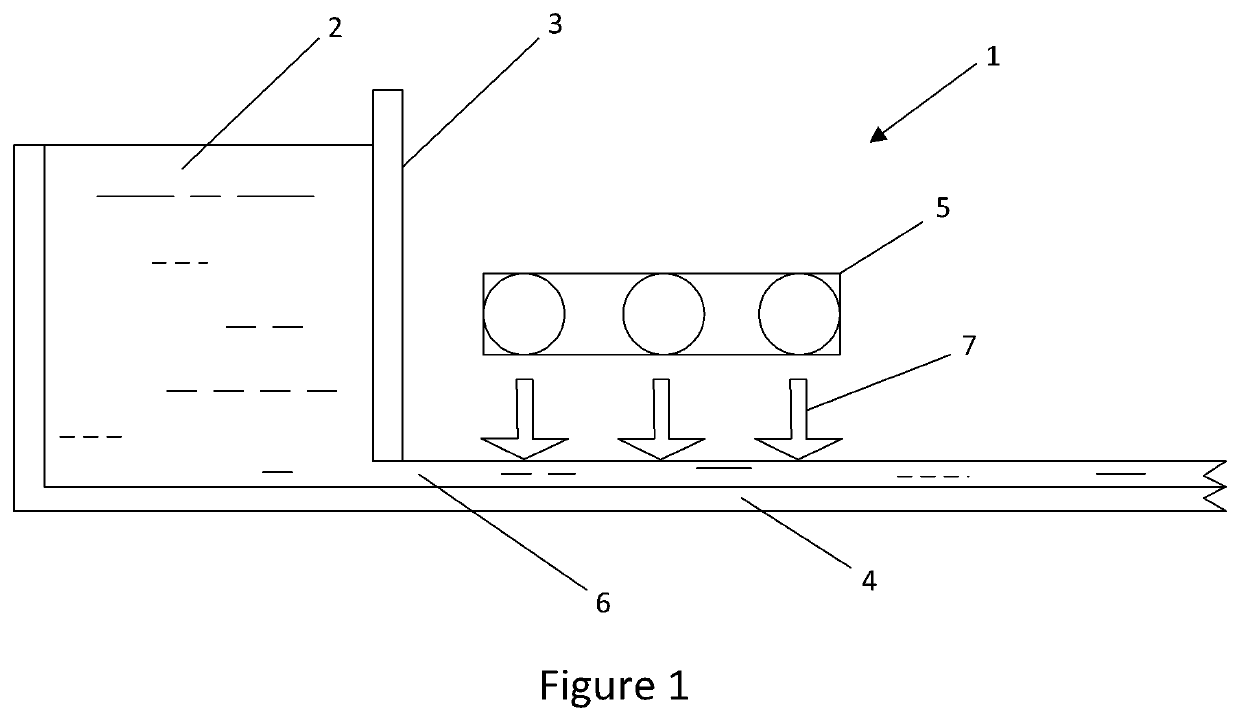

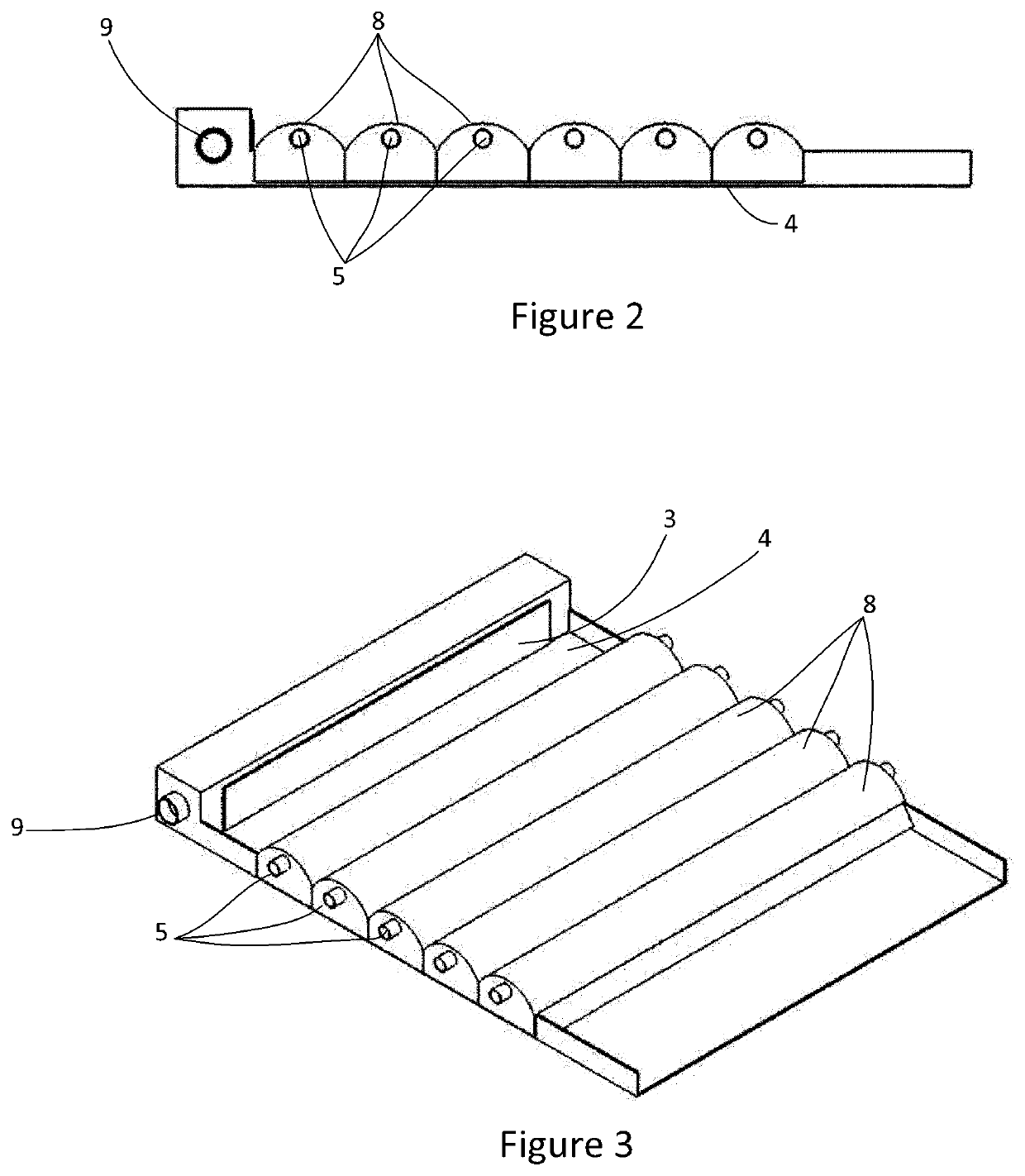

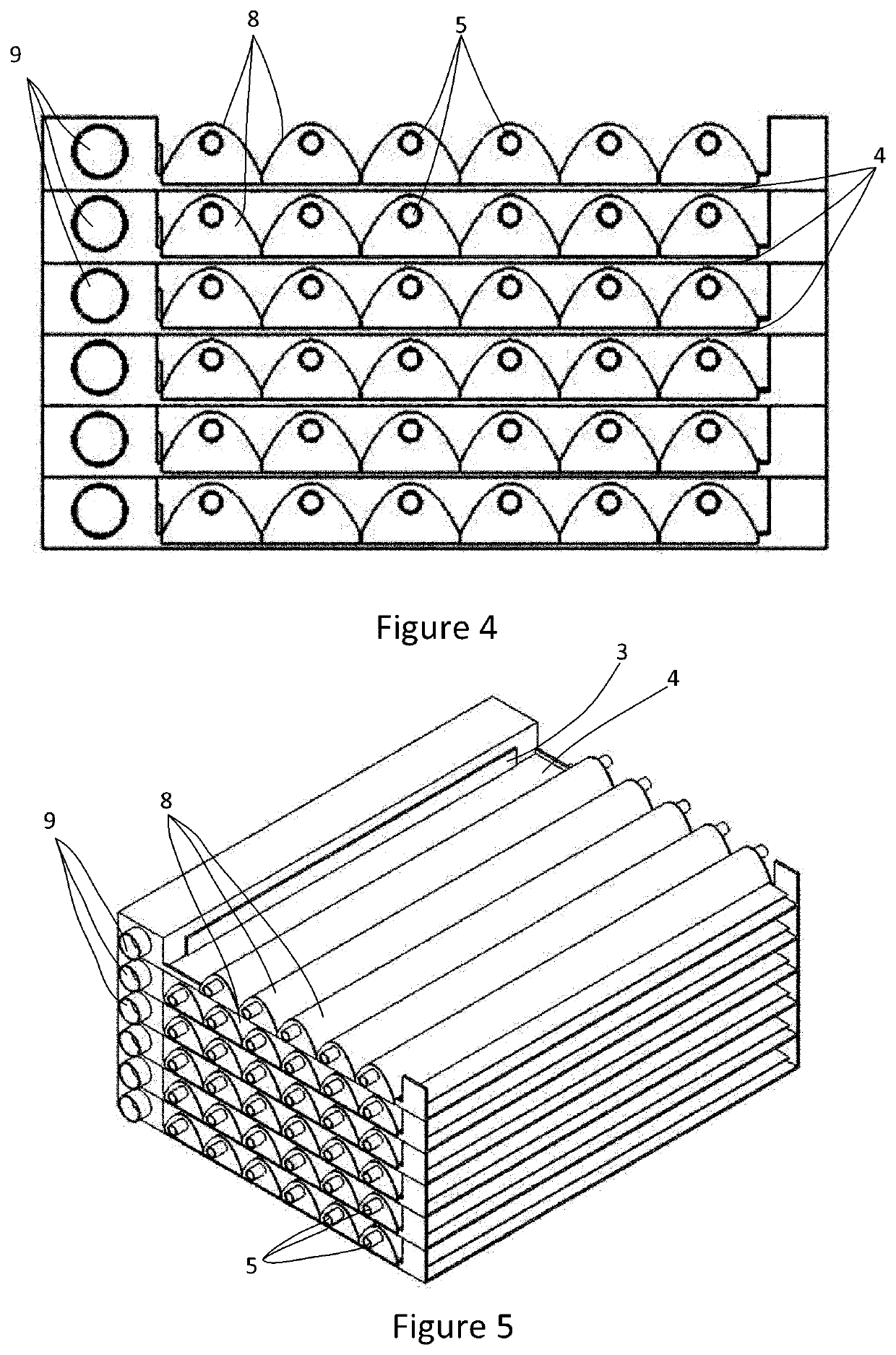

Liquid treatment method and apparatus

ActiveUS20210163315A1Water treatment parameter controlWater/sewage treatment by irradiationEngineeringMechanical engineering

A method and apparatus for treating a liquid using ultraviolet radiation. A thin flow of liquid in a supercritical flow is irradiated by at least one radiation source external to the thin flow. The flow may desirably have a Froude number greater than 3 and a velocity greater than 0.8 m / s. The apparatus for treating a liquid including may have a reservoir supplying liquid though a slot into an open channel to generate a thin flow of liquid having a supercritical flow along the channel with at least one radiation source external to the thin flow to irradiate the thin flow.

Owner:NOVOLABS LTD

Detection device of physical property of natural gas supercritical flow state

InactiveCN101710021BHydrodynamic testingSpecific gravity using flow propertiesMeasurement deviceHigh pressure

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Suitable for fluid connection buildings with rapid bends

InactiveCN104499454BReduce the chance of damageSmooth transitionBarrages/weirsClimate change adaptationSingle stageJet flow

The invention discloses a flow state connected building suitable for a supercritical flow bend. Incoming flow from the upstream of the bend enters a stilling pool of the flow state connected building in a single-stage fall mode; a side weir is arranged on the side wall of the stilling pool and is connected with a downstream flow state regulating tank; a rectifying tail pier is arranged at an outlet of the flow state regulating tank; the axis of the rectifying tail pier is in parallel to that of a flow passage on the downstream of the bend. Design of the flow connected building adopts the main principle that firstly, the energy dissipation effect of the stilling pool is utilized to reduce a flow rate of the incoming flow, and local subcritical flow is formed in the stilling pool; then the principle that the low flow rate has high adaptability to an overflowing boundary is utilized, the side weir is adopted to change the flow direction of water flow, and by the flow state regulating tank, the flow rate of the water flow is further reduced and the flow state is further improved; finally, the rectifying tail pier is utilized to regulate the flow direction to be in parallel to the axis direction of the flow passage on the downstream of the bend. According to the flow state connected building suitable for the supercritical flow bend, the adverse flow states, such as rhombus waves, a large water surface transverse slope and a deflected side wall, formed by the water flow in the supercritical flow bend can be effectively avoided, and washout and erosion damage and the like of water flow with high sand content on the boundary of the flow passage on the downstream of the bend are reduced and avoided.

Owner:SICHUAN UNIV

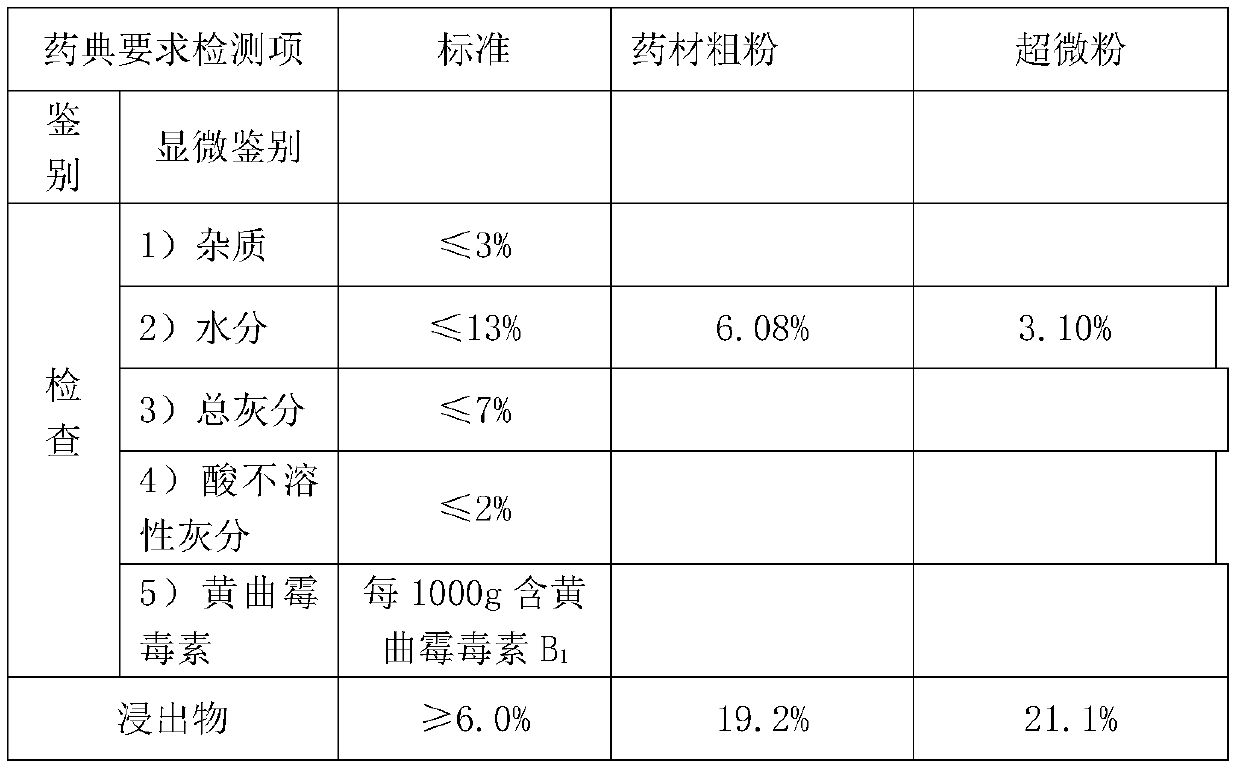

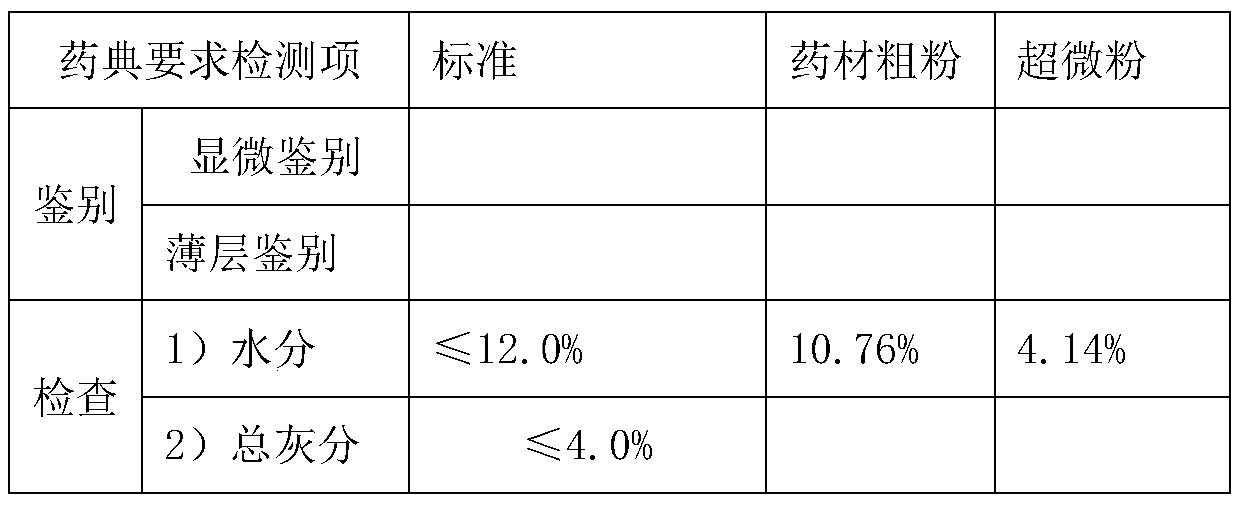

Preparation technology of capsules having multiple treatment effects

InactiveCN110327426AIncreased ultrafine powder contentImprove efficacyAnthropod material medical ingredientsAntipyreticDrugSupercritical flow

The invention belongs to the technical field of capsules, and particularly relates to a preparation technology of capsules having multiple treatment effects. The capsules having multiple treatment effects are characterized by comprising stiff silkworm, giant typhonium rhizomes, prepared rhizoma arisaematis, radix angelicae, rhizoma gastrodiae, divaricate saposhnikovia roots, rhizoma et radix notopterygii and pseudo-ginseng. The preparation technology comprises the following steps of preferably selecting medicinal materials of the stiff silkworms, the giant typhonium rhizomes, the rhizoma arisaematis, the radix angelicae, the rhizoma gastrodiae, the divaricate saposhnikovia roots, the rhizoma et radix notopterygii and the pseudo-ginseng which are high in medicine property reserving degree,performing cleaning, performing drying in the shade for standby application, sequentially cutting the medicinal materials, crushing the cut medicinal materials, adding medicinal powder to a centrifuge, performing high-speed rotation, performing supercritical flow extraction on the medicinal materials to obtain essence substances by using carbon dioxide as a medium, and concentrating the essence substances of the medicinal materials. The medicine effects of the capsules having multiple treatment effects produced by the technology are remarkably improved, after the content of submicron powder isincreased, the granule gap of traditional Chinese medicine substances of the capsules is obviously reduced, the granule fluidity is reinforced, capsule shells having a same volume can accommodate more mass of medicine powder, and the medicine taking quantity of a patient can be reduced.

Owner:HEBEI AOXING GROUP PHARMA

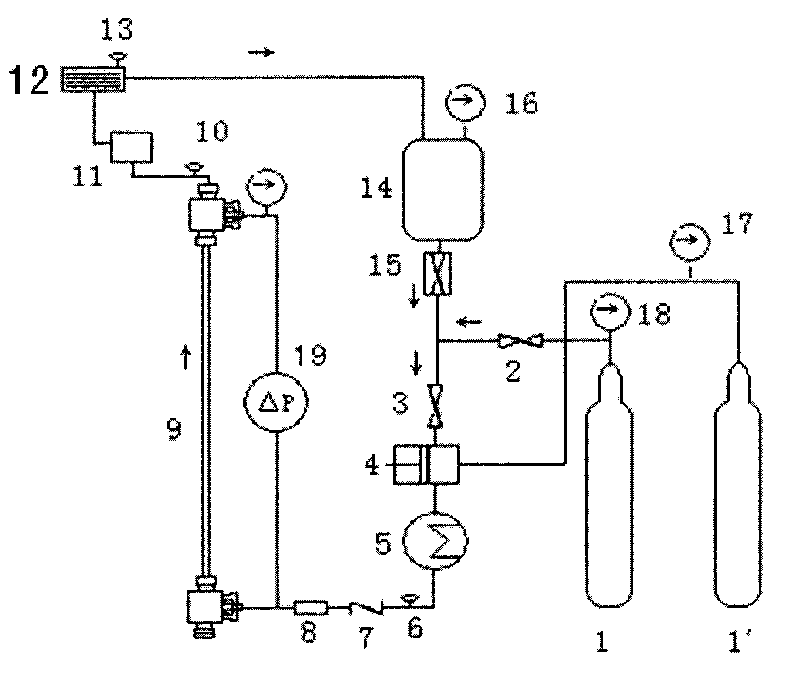

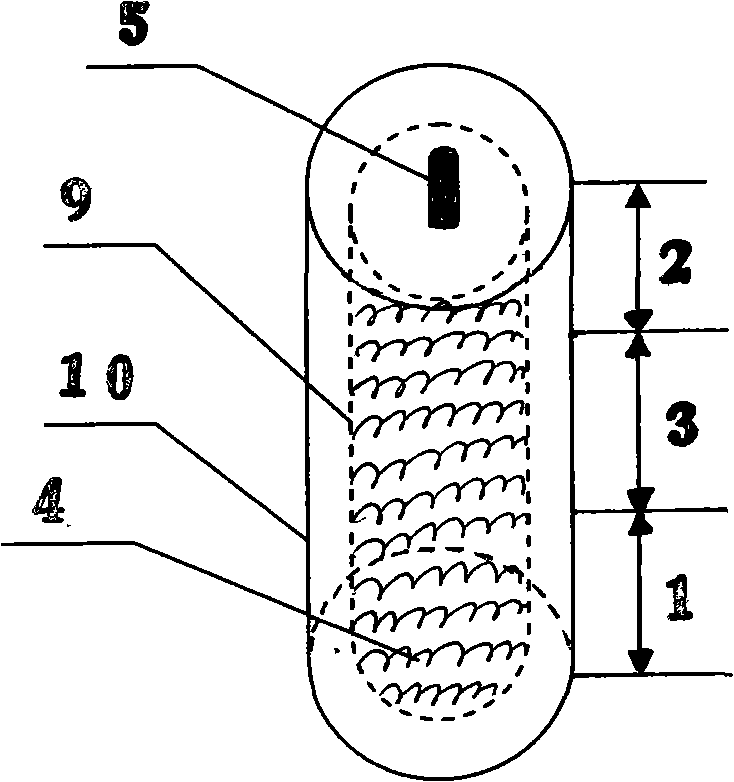

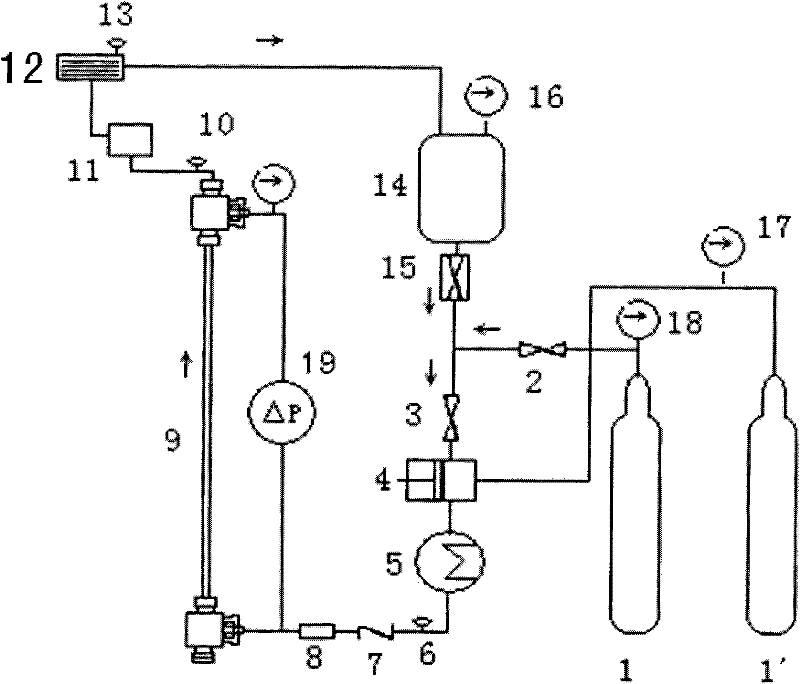

Approximate outer fluid generator for pulsed laser Q modulation

It is an impulse laser Q adjusting approximate fluid generator belonging to laser technique field. This invention establishes pressure part of high-pressure pump connection accumulator connected with steel bottle with optics fluid and with laser Q adjusting optics pool; the vacuum pump connects the laser Q adjusting optics pool; the recycle temperature constant pump connects the optics pool and the temperature constant trough connects the optics pool through temperature constant trough.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for purifying deoxyribose

InactiveCN108440610ALow priceHigh puritySugar derivativesSugar derivatives preparationHigh pressureDeoxyribose

The invention discloses a technology for purifying deoxyribose through supercritical fluid crystallization. The technology comprises the steps as follows: (1) spraying a neutralized 90 DEG C deoxyribose liquor containing impurities from the top of an extraction tower through a raw material pump, meanwhile, introducing a supercritical fluid into the bottom of the extraction tower, and controlling the temperature of the supercritical fluid at 33-36 DEG C, the pressure at 9-11 Mpa and the flow at 15-20 m<3> / min; (2) reducing the pressure of the high-pressure supercritical fluid containing dissolved deoxyribose to the pressure lower than supercritical flow critical pressure through a throttle valve to allow the supercritical fluid to enter a separation kettle; (3) after extracting the deoxyribose, performing dehydration and drying processes sequentially on a product. The technology is simple, the equipment structure is compact, meanwhile, crystals form a crystal layer on a heat transfer surface instead of suspending in a liquid in the technological process, so that blockage of equipment and pipelines is avoided, and production faults are reduced. The product produced with the technology has high purity, bright and white appearance, good bioactivity and uniform grain size.

Owner:NANTONG DISONG TEXTILE CO LTD

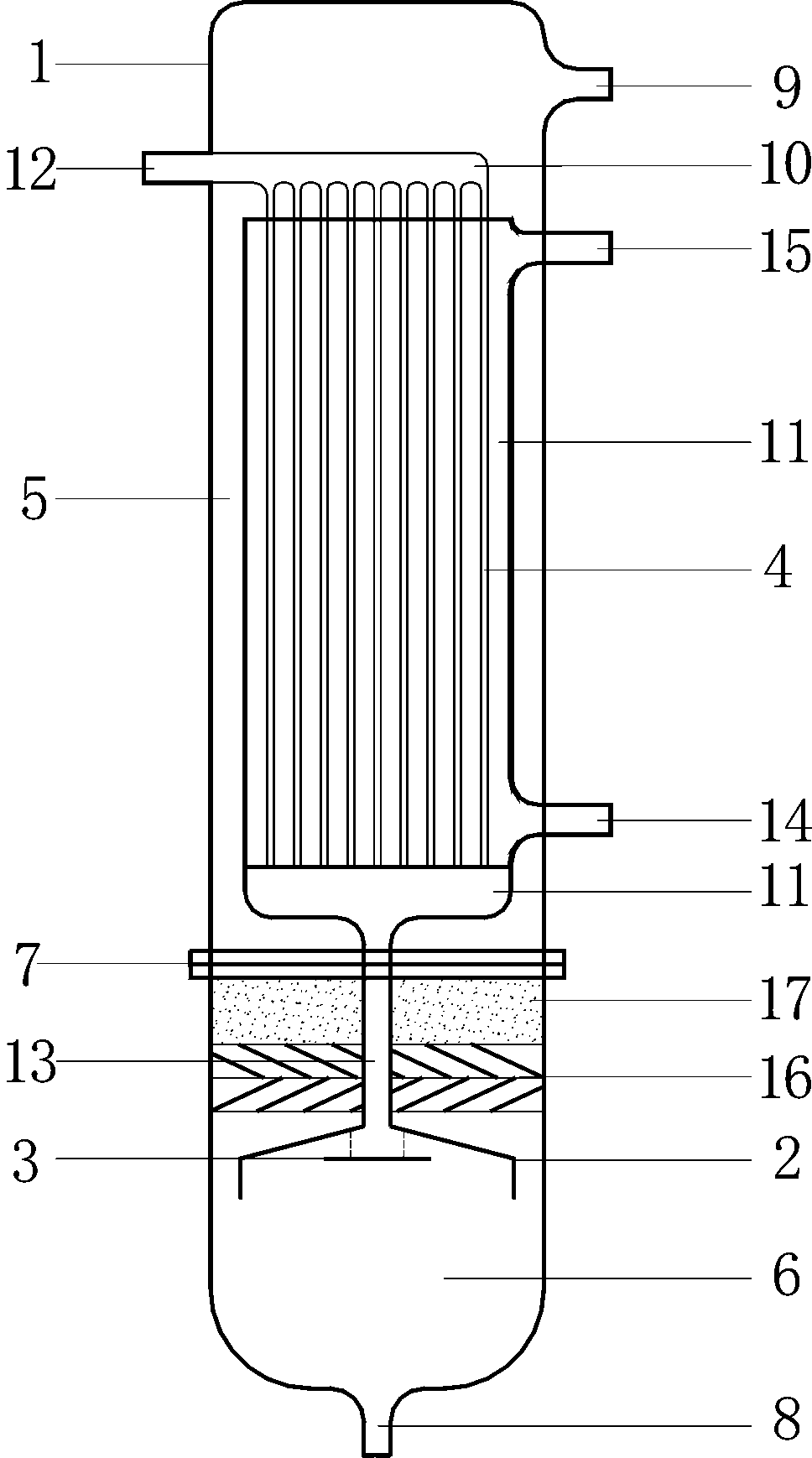

Internally-heating clean supercritical mixed fluid separating kettle

PendingCN110075657ASeparation Maximum EfficiencyEasy to separateCombination devicesEngineeringRecuperator

The invention discloses an internally-heating clean supercritical mixed fluid separating kettle. The internally-heating clean supercritical mixed fluid separating kettle comprises a kettle body, a flow baffle, a flow collecting hood and a mixed fluid heating heat exchanger, wherein the kettle body comprises an upper gas flow chamber and a lower separating chamber; a mixed fluid passage and a heatmedium passage are formed in the mixed fluid heating heat exchanger; a heat medium in the heat medium passage heats a mixed fluid in the mixed fluid passage; the mixed fluid heating heat exchanger ispositioned inside the upper gas flow chamber in the kettle body; a mixed fluid educing pipe is communicated with the flow collecting hood in the lower separating chamber; the flow baffle is arranged inside the flow collecting hood; separated supercritical gas enters the upper gas flow chamber from the lower separation chamber and is discharged from a supercritical gas discharging port of the uppergas flow chamber; a separated deposit is deposited in the lower separating chamber. The internally-heating clean supercritical mixed fluid separating kettle adopts a supercritical fluid phase separation-type working mode, can separate a supercritical fluid from an extract or a pigment at the maximum efficiency, and is relatively thorough in separation; the internally-heating clean supercritical mixed fluid separating kettle is a separation kettle applied to supercritical extraction and supercritical flow dyeing.

Owner:广东碳染科技有限公司

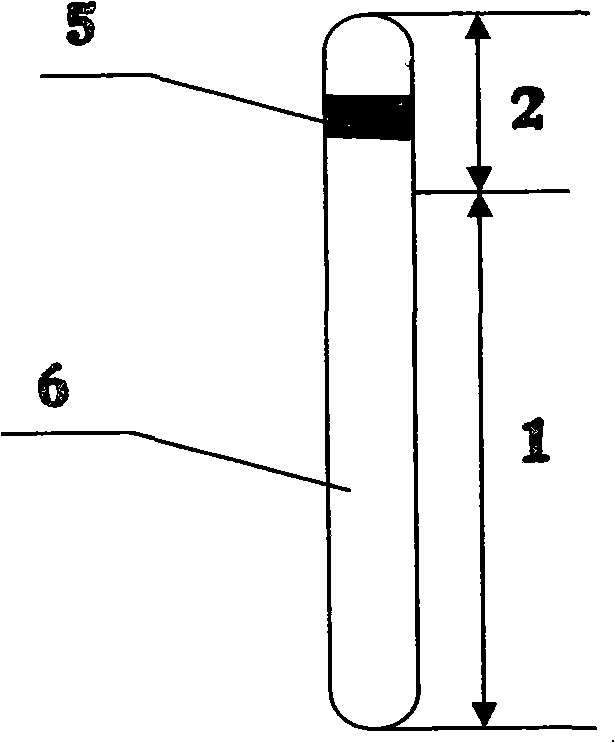

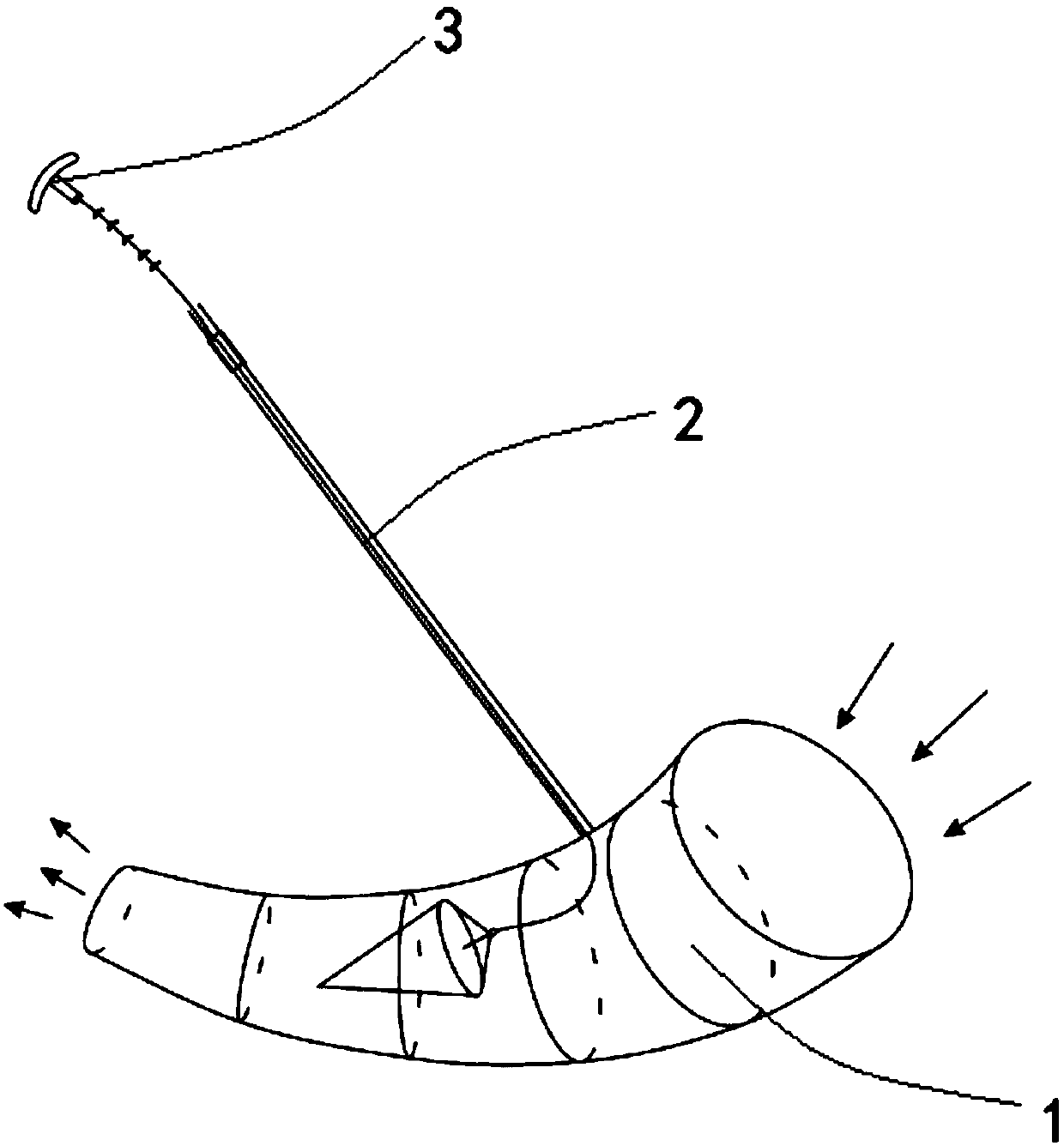

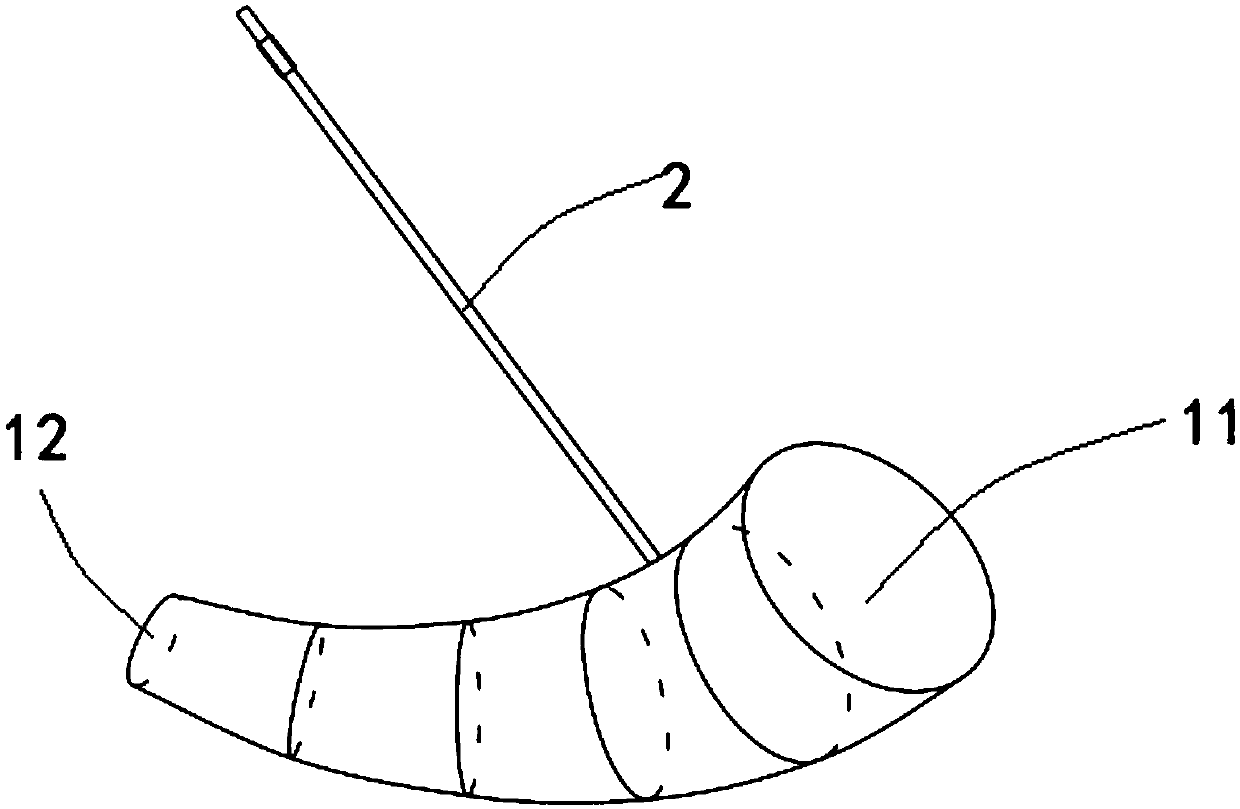

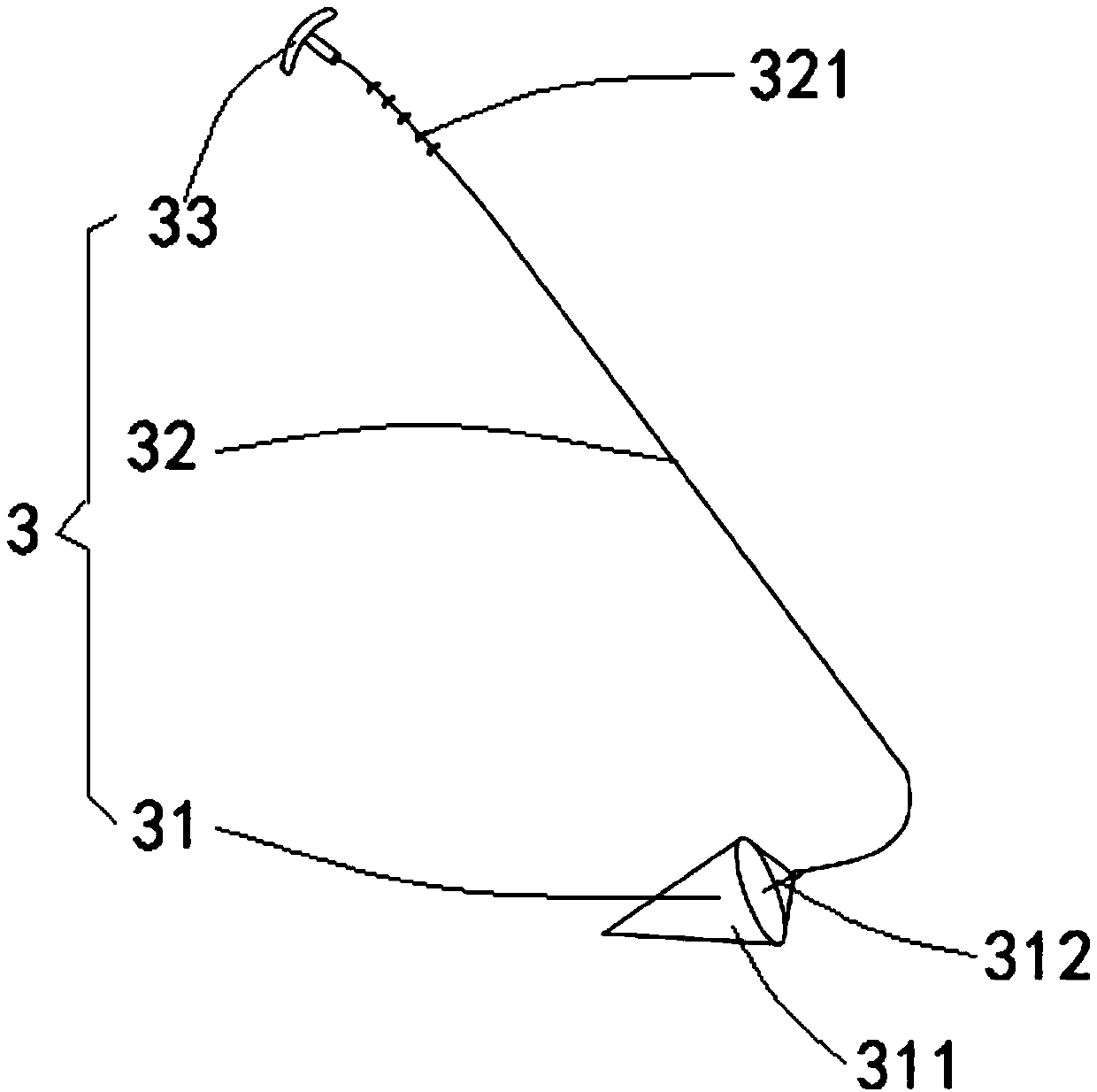

Supercritical flow water taking device

PendingCN107727454AEasy dischargeAlleviate water flow resistanceWithdrawing sample devicesStraight tubeWater flow

The invention relates to a supercritical flow water taking device. The supercritical flow water taking device comprises a water taking device, a hollow rod connected with the outer side of the water taking device, and a moveable device. The water taking device is a hollow bull horn shape of which two ends are opened. Two ends of the water taking device are provided with a first opening and a second opening, and the inner diameter of the first opening is greater than the inner diameter of the second opening. The hollow rod is a hollow straight tube. The bottom end of the hollow rod is connectedwith the outside wall of the water taking device, and the hollow rod is communicated with the interior of the water taking device. The moveable device comprises a cone rubber stopper, a cable connected with one end of the cone rubber stopper, and a handle connected with the other end of the cone rubber stopper. The cone rubber stopper comprises a bi-directional cone and a fixed part installed atone end of the bi-directional cone. The radius of the bottom surface of the bi-directional cone is greater than the inner diameter of the second opening of the water taking device. The supercritical flow water taking device is capable of greatly relieving the water flow resistance, so the internal air is easily discharged from the tail part under the supercritical flow environment, and the water taking process is convenient.

Owner:YANGTZE UNIVERSITY

Supercritical impact flow method for wrapping micro granule

InactiveCN100351010CIncrease resistanceReduce resistanceMicroballoon preparationMicrocapsule preparationParticle packingPaper production

The invention relates to a ultra-critical impact flow particle packing method, which is characterized in that: adding the wall material into the mixer to be dissolved into solution; mixing and dispersing the particle uniformly, to form suspension; using a couple of coaxial nozzles to output the wall material to be deposited on the surface of packed particle to form the coat, and separated by the separator to obtain the micro capsule product. The invention can combine the advantages of present packing fluid bed packing method and impact flow method, to be used in food industry, paper production, etc.

Owner:DALIAN UNIV OF TECH

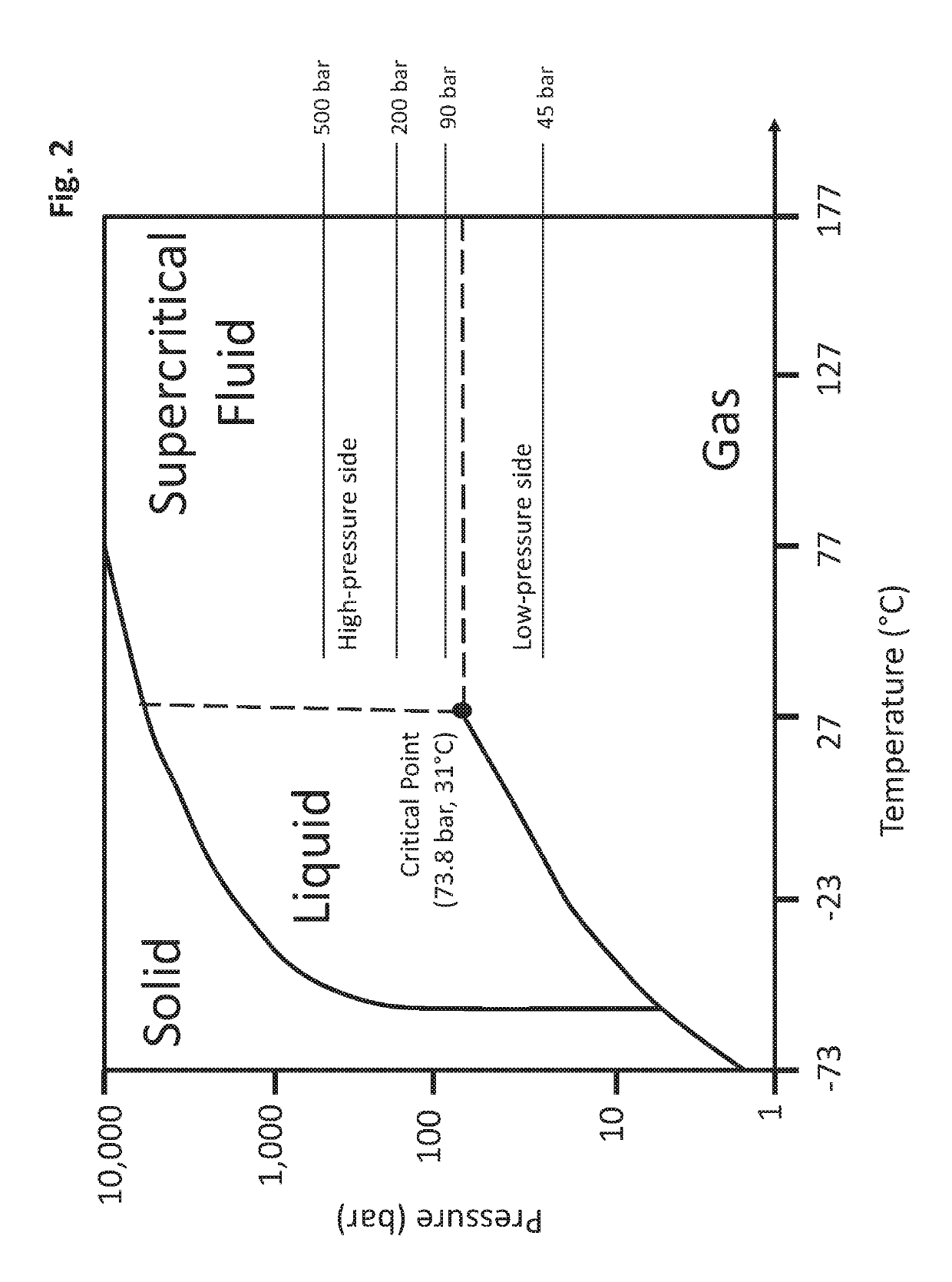

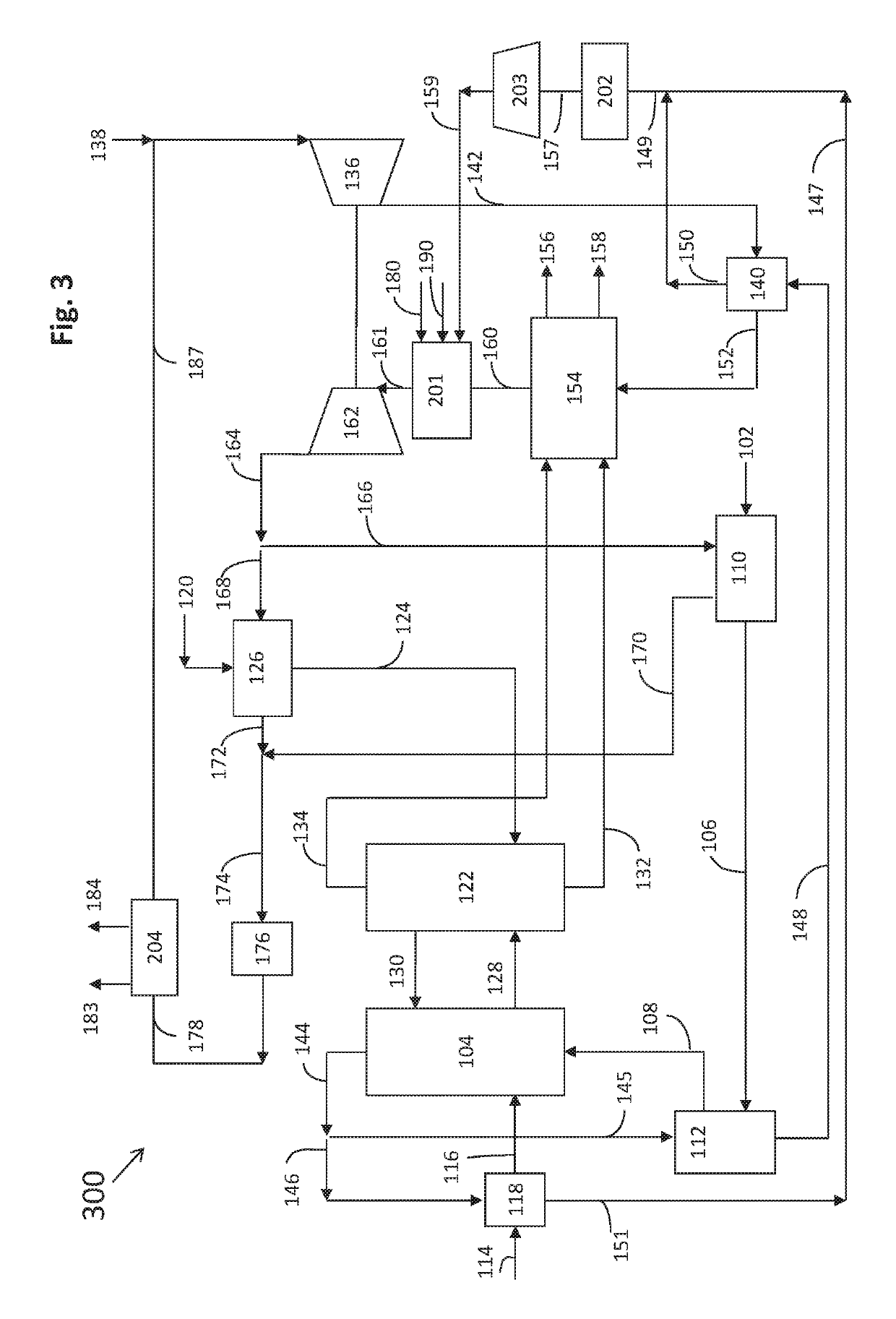

Supercritical CO2 cycle coupled to chemical looping arrangement

Systems and methods for coupling a chemical looping arrangement and a supercritical CO2 cycle are provided. The system includes a fuel reactor, an air reactor, a compressor, first and second heat exchangers, and a turbine. The fuel reactor is configured to heat fuel and oxygen carriers resulting in reformed or combusted fuel and reduced oxygen carriers. The air reactor is configured to re-oxidize the reduced oxygen carriers via an air stream. The air stream, fuel, and oxygen carriers are heated via a series of preheaters prior to their entry into the air and fuel reactors. The compressor is configured to increase the pressure of a CO2 stream to create a supercritical CO2 stream. The first and second heat exchangers are configured to heat the supercritical CO2 stream, and the turbine is configured to expand the heated supercritical CO2 stream to generate power.

Owner:SAUDI ARABIAN OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com