Supercritical-fluid-based 3D electrodeposition machining device and method

A technology of supercritical fluid and processing device, applied in 3D structure electroforming, additive processing, electrolysis process, etc., can solve the problem of inability to flexibly prepare 3D parts, etc., to overcome long processing time, improve electric field distribution, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

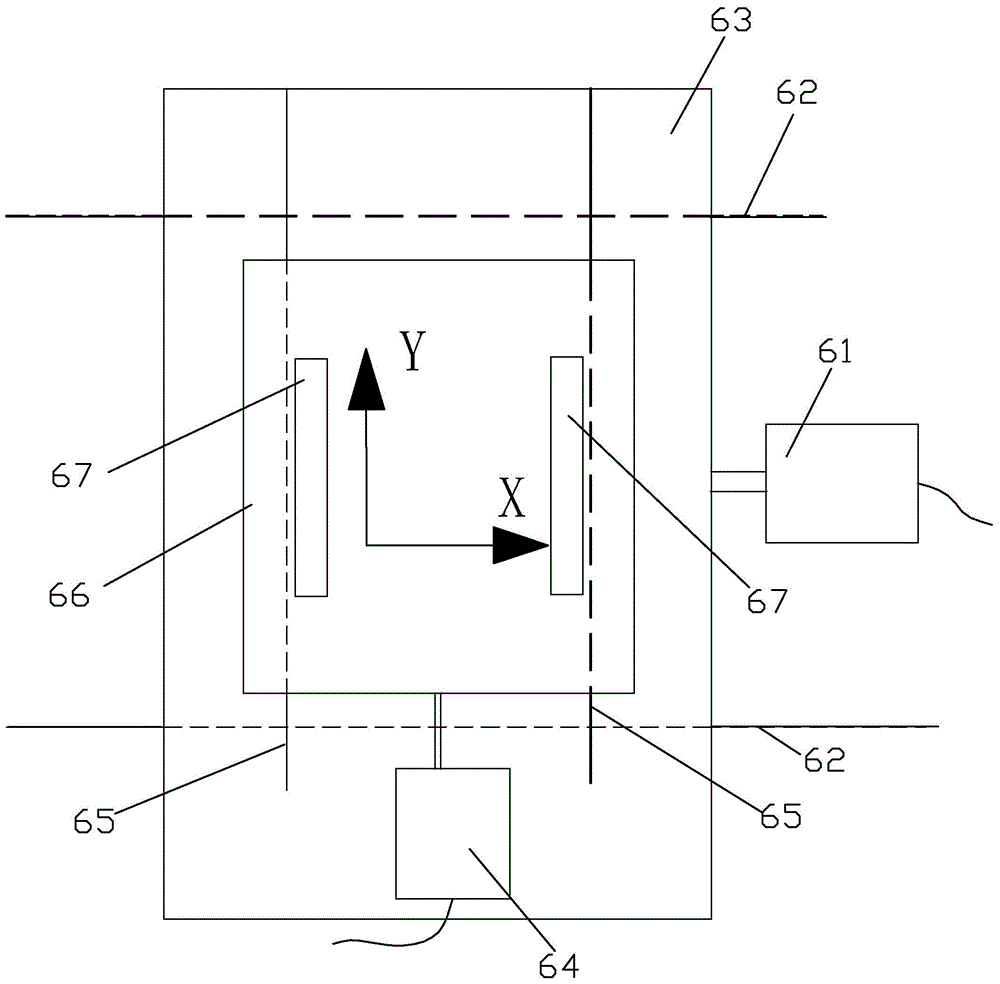

[0040] In this embodiment, when describing the direction, use figure 1 The left and right direction is the X direction, with figure 1 The back of the facing direction is the Y direction, with figure 1 The up and down direction is the Z direction.

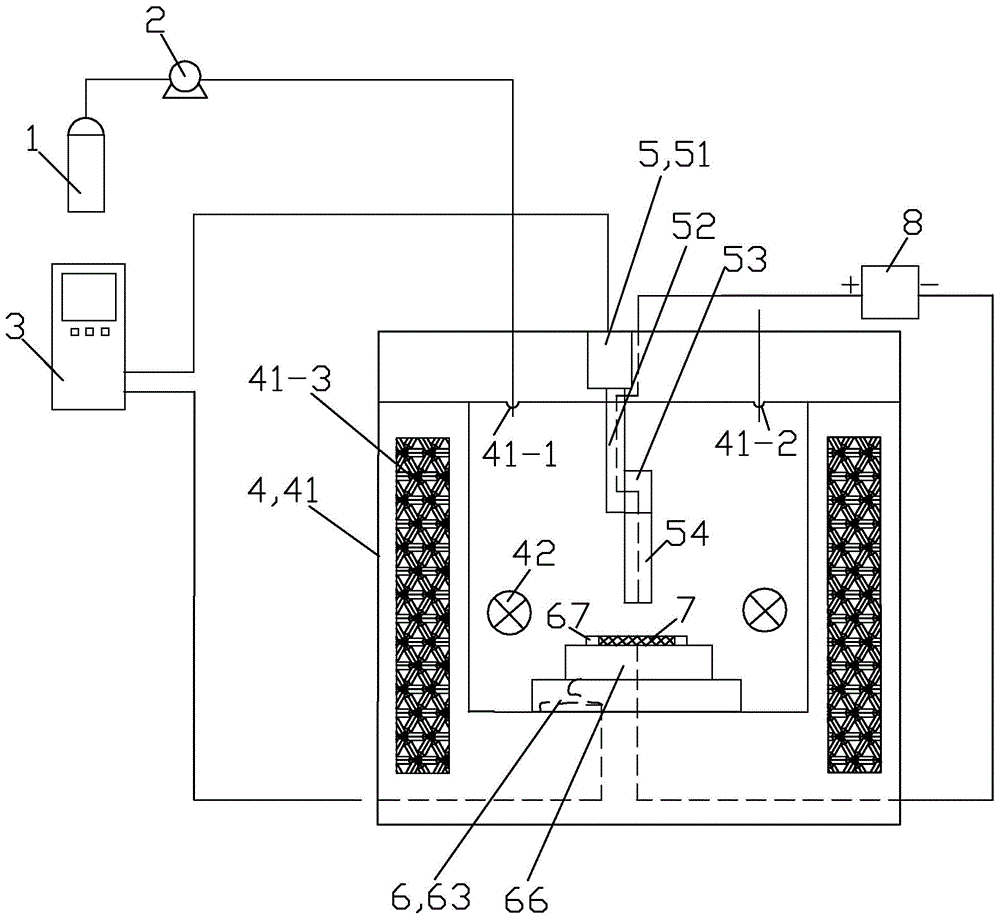

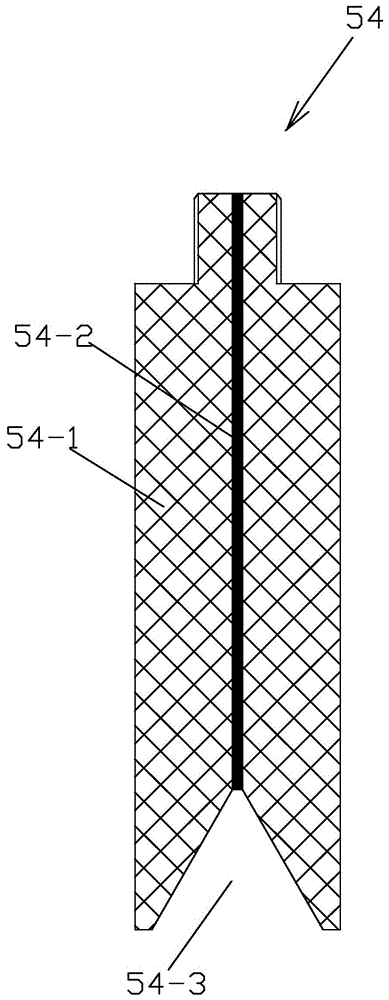

[0041] See Figure 1 to Figure 4 , the 3D electrodeposition processing device based on supercritical fluid in this embodiment is mainly composed of a carbon dioxide gas cylinder 1, a high-pressure pump 2, a numerical control controller 3, a reactor 4, a mobile anode assembly 5, a mobile cathode assembly 6, a DC power supply 8 and a cathode Substrate 7 composition.

[0042] Carbon dioxide gas cylinder 1 is used for storing CO used for preparing supercritical fluid 2 Gas; high pressure pump 2 is used to pump CO into reactor 4 when needed 2 gas.

[0043] The numerical control controller 3 is a control controller of the existing numerical control technology. When the numerical control controller 3 is used for electrodeposition pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diffusion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com