Patents

Literature

162results about How to "Improve deposition quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of forming an electronic structure using reforming gas, system for performing the method, and structure formed using the method

ActiveUS20200395209A1Improve deposition qualityQuality improvementElectric discharge tubesSolid-state devicesPhysicsChemistry

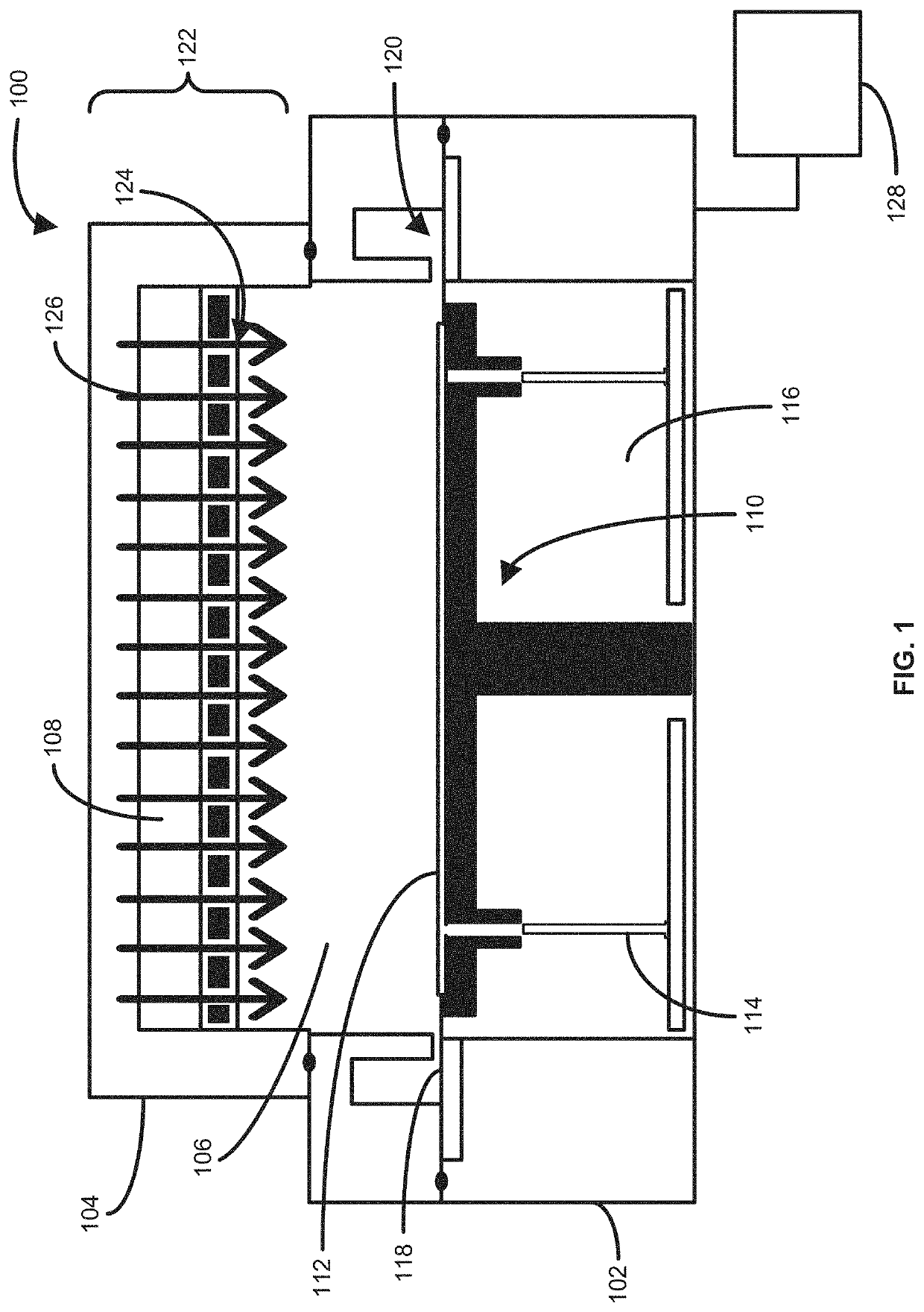

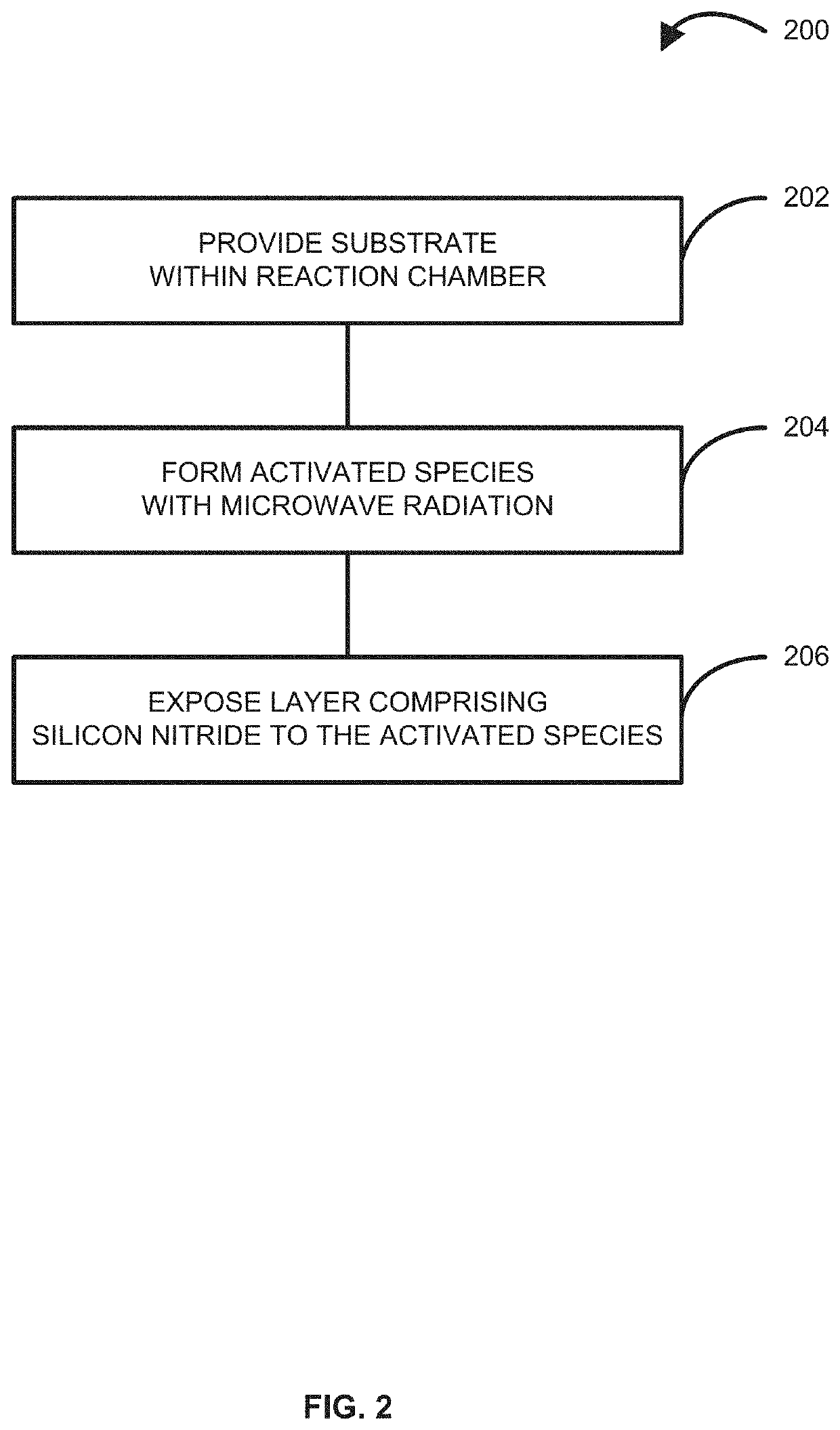

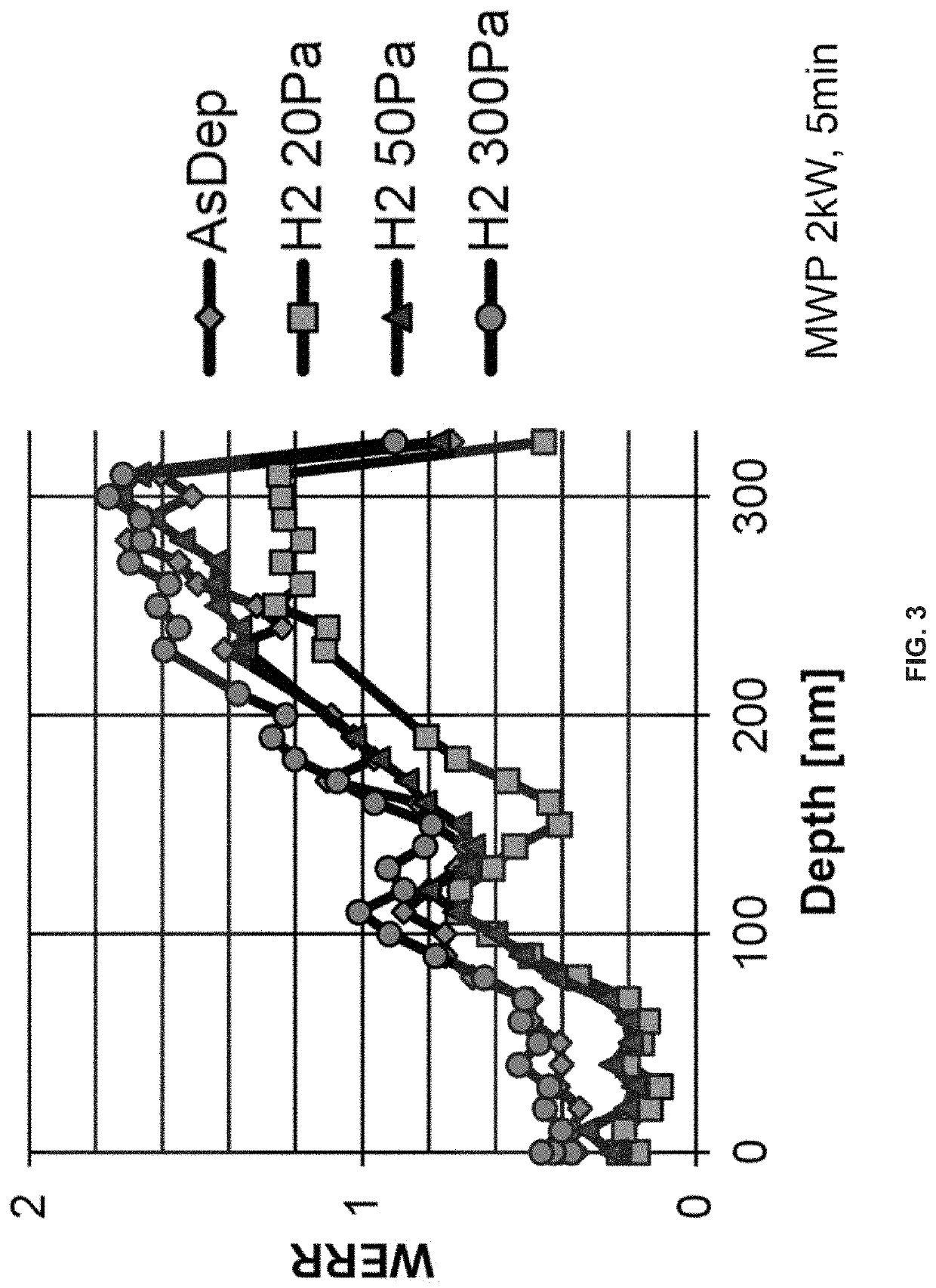

Methods of and systems for reforming films comprising silicon nitride are disclosed. Exemplary methods include providing a substrate within a reaction chamber, forming activated species by irradiating a reforming gas with microwave radiation, and exposing substrate to the activated species. A pressure within the reaction chamber during the step of forming activated species can be less than 50. Pa.

Owner:ASM IP HLDG BV

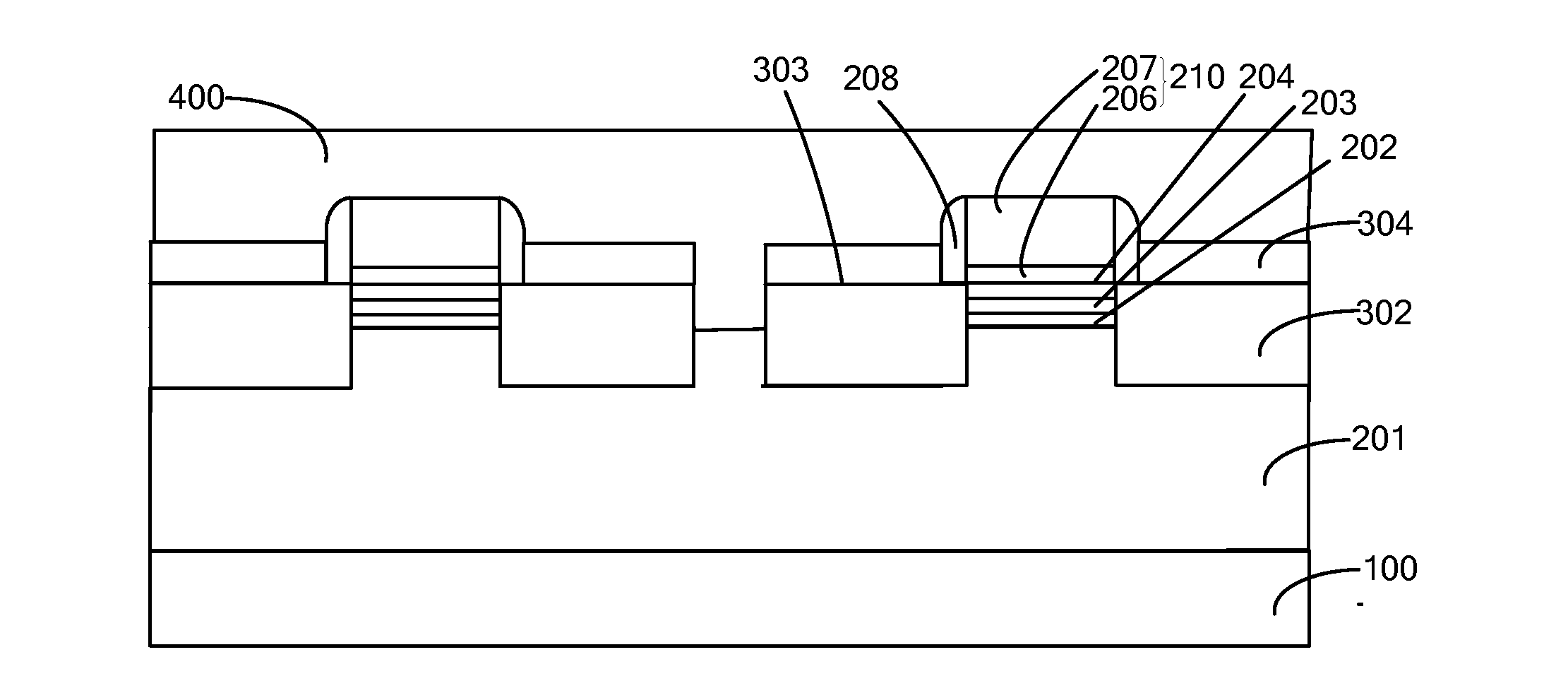

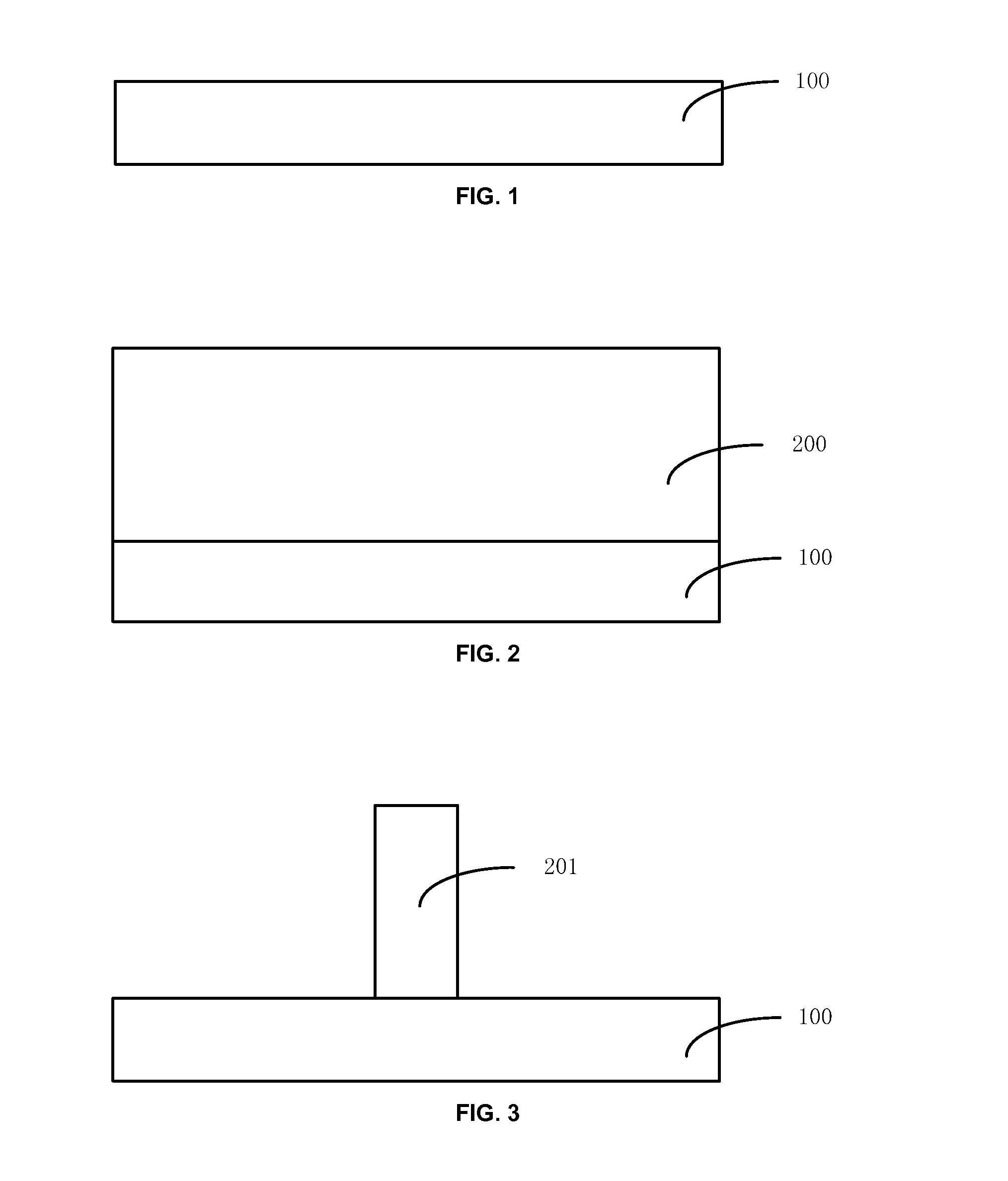

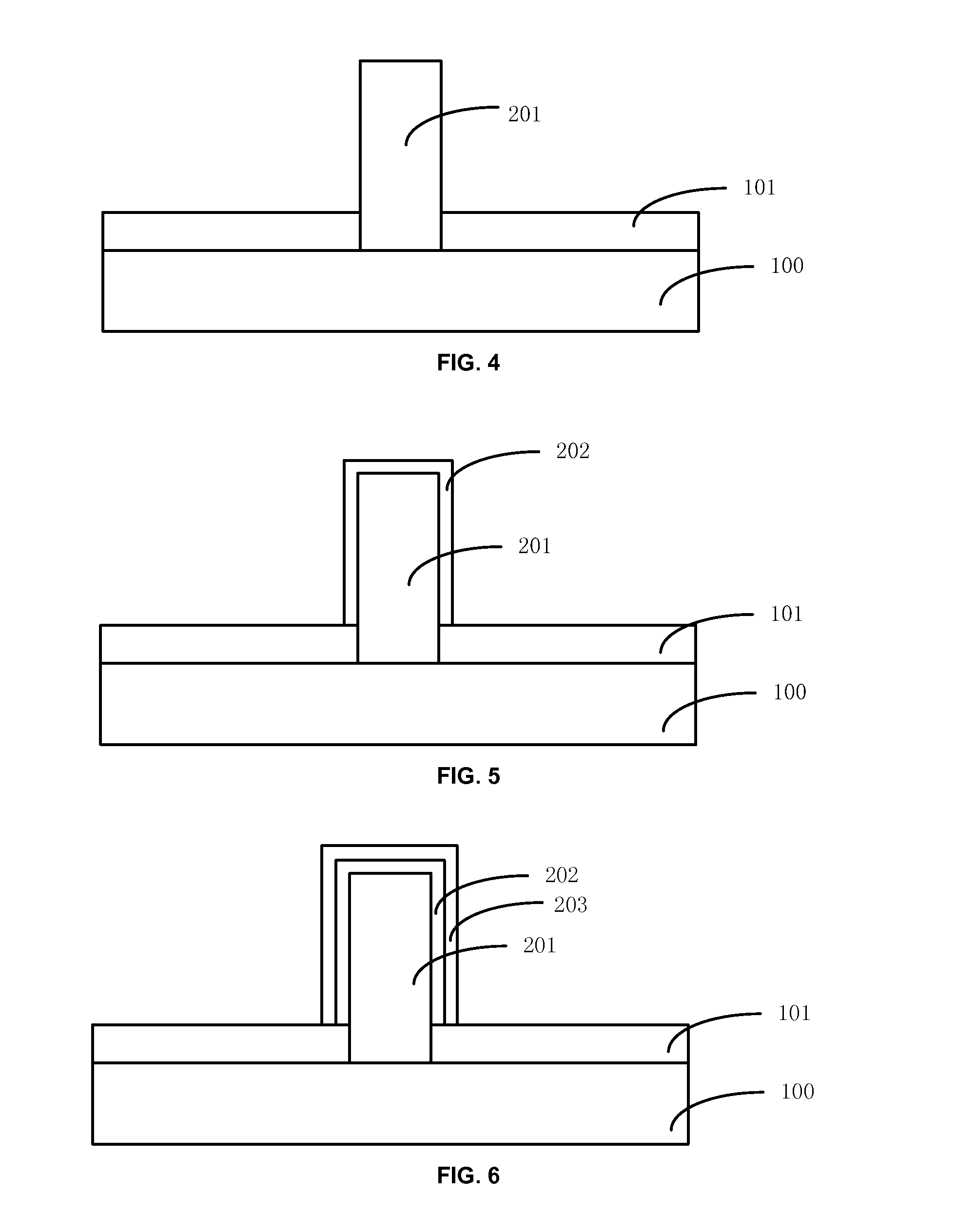

Three-dimensional quantum well transistor and fabrication method

ActiveUS20140203243A1Reduce resistanceImprove thermal stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesQuantum wellEpitaxial material

Three dimensional quantum well transistors and fabrication methods are provided. A quantum well layer, a barrier layer, and a gate structure can be sequentially formed on an insulating surface of a fin part. The gate structure can be formed over the barrier layer and across the fin part. The QW layer and the barrier layer can form a hetero-junction of the transistor. A recess can be formed in the fin part on both sides of the gate structure to suspend a sidewall spacer. A source and a drain can be formed by growing an epitaxial material in the recess and the sidewall spacer formed on both sidewalls of the gate electrode can be positioned on surface of the source and the drain.

Owner:SEMICON MFG INT (SHANGHAI) CORP

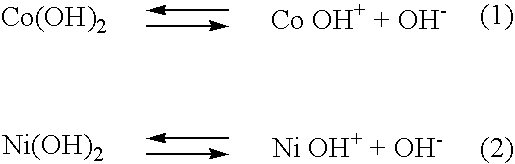

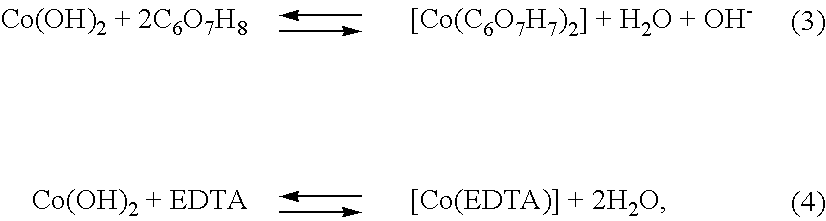

Solution composition and method for electroless deposition of coatings free of alkali metals

InactiveUS6911067B2Low costImprove anti-corrosion performanceAnti-corrosive paintsLiquid/solution decomposition chemical coatingElectroless depositionMaterials science

An electroless deposition solution of the invention for forming an alkali-metal-free coating on a substrate comprises a first-metal ion source for producing first-metal ions, a pH adjuster in the form of a hydroxide for adjusting the pH of the solution, a reducing agent, which reduces the first-metal ions into the first metal on the substrate, a complexing agent for keeping the first-metal ions in the solution, and a source of ions of a second element for generation of second-metal ions that improve the corrosion resistance of the aforementioned coating. The method of the invention consists of the following steps: preparing hydroxides of a metal such as Ni and Co by means of a complexing reaction, in which solutions of hydroxides of Ni and Co are obtained by displacing hydroxyl ions OH− beyond the external boundary of ligands of mono- or polydental complexants; preparing a complex composition based on a tungsten oxide WO3 or a phosphorous tungstic acid, such as H3[P(W3O10)4], as well as on the use of tungsten compounds for improving anti-corrosive properties of the deposited films; mixing the aforementioned solutions of salts of Co, Ni, or W and maintaining under a temperatures within the range of 20° C. to 100° C.; and carrying out deposition from the obtained mixed solution.

Owner:LAM RES CORP

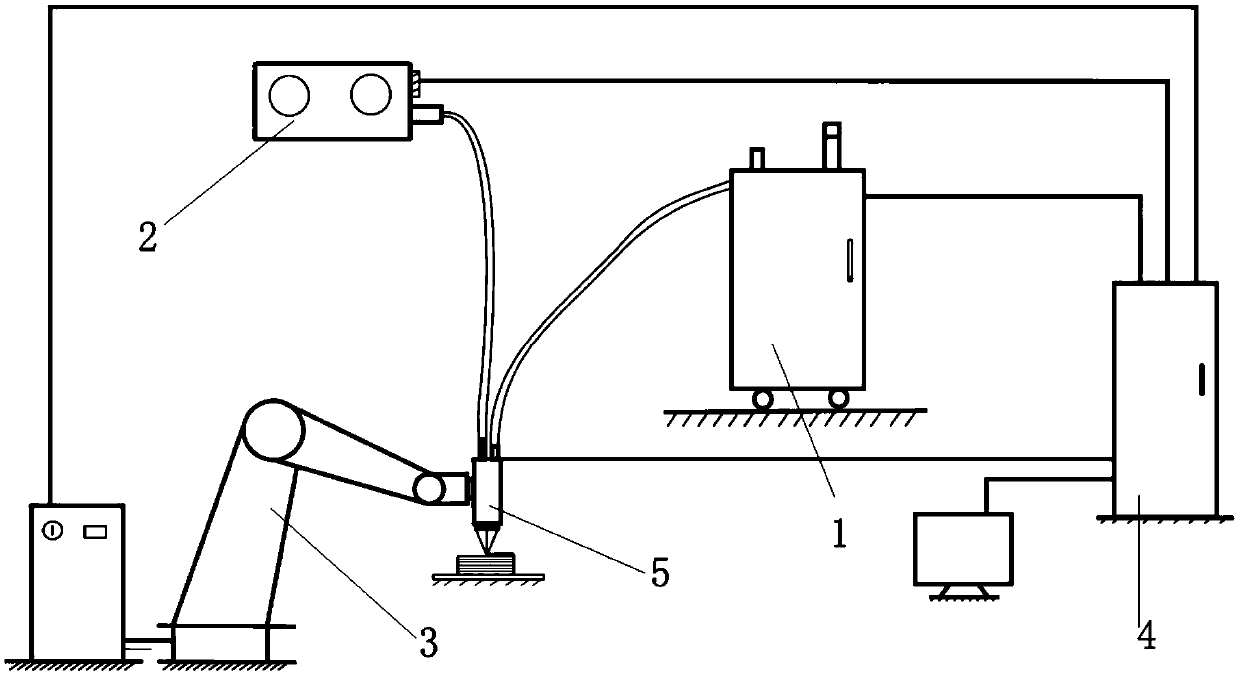

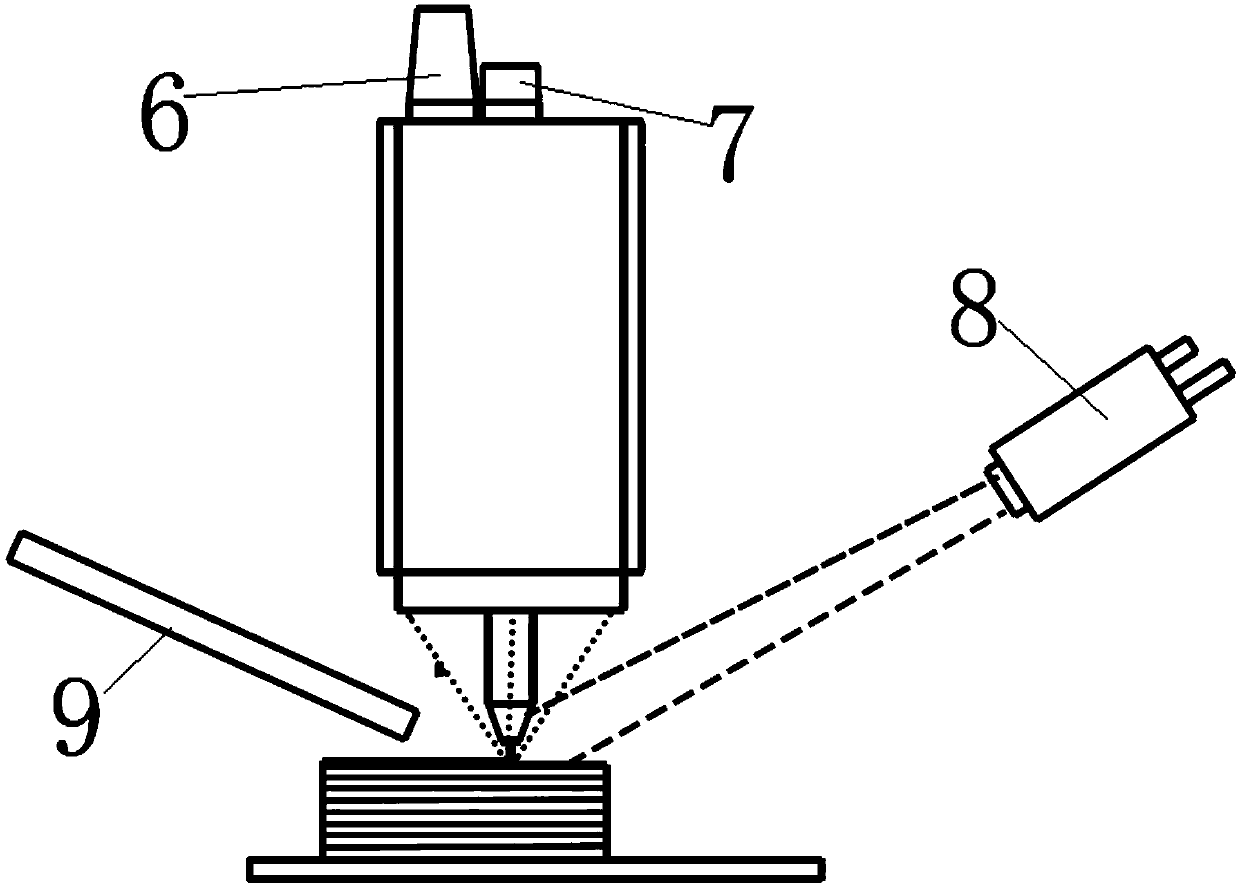

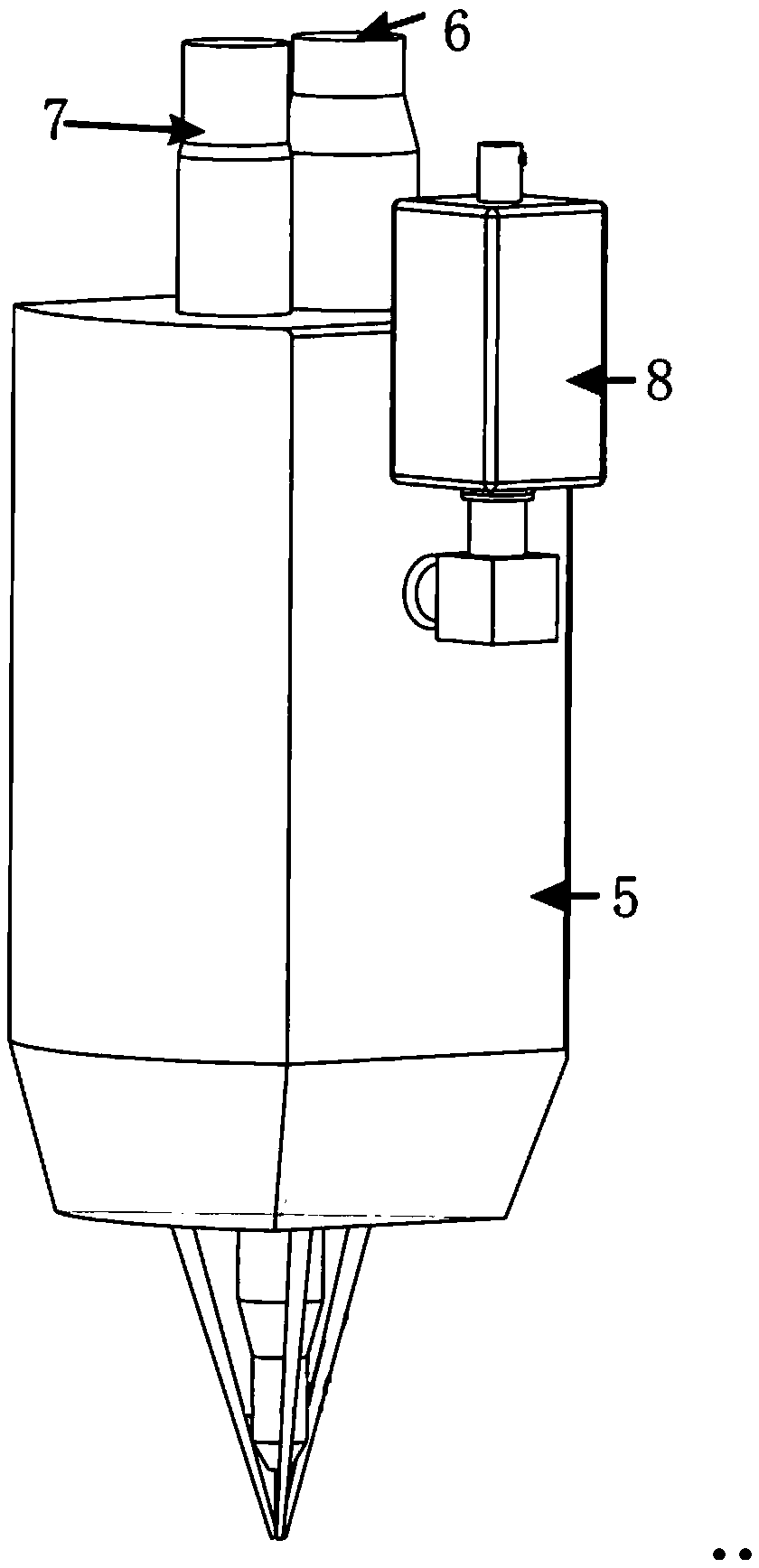

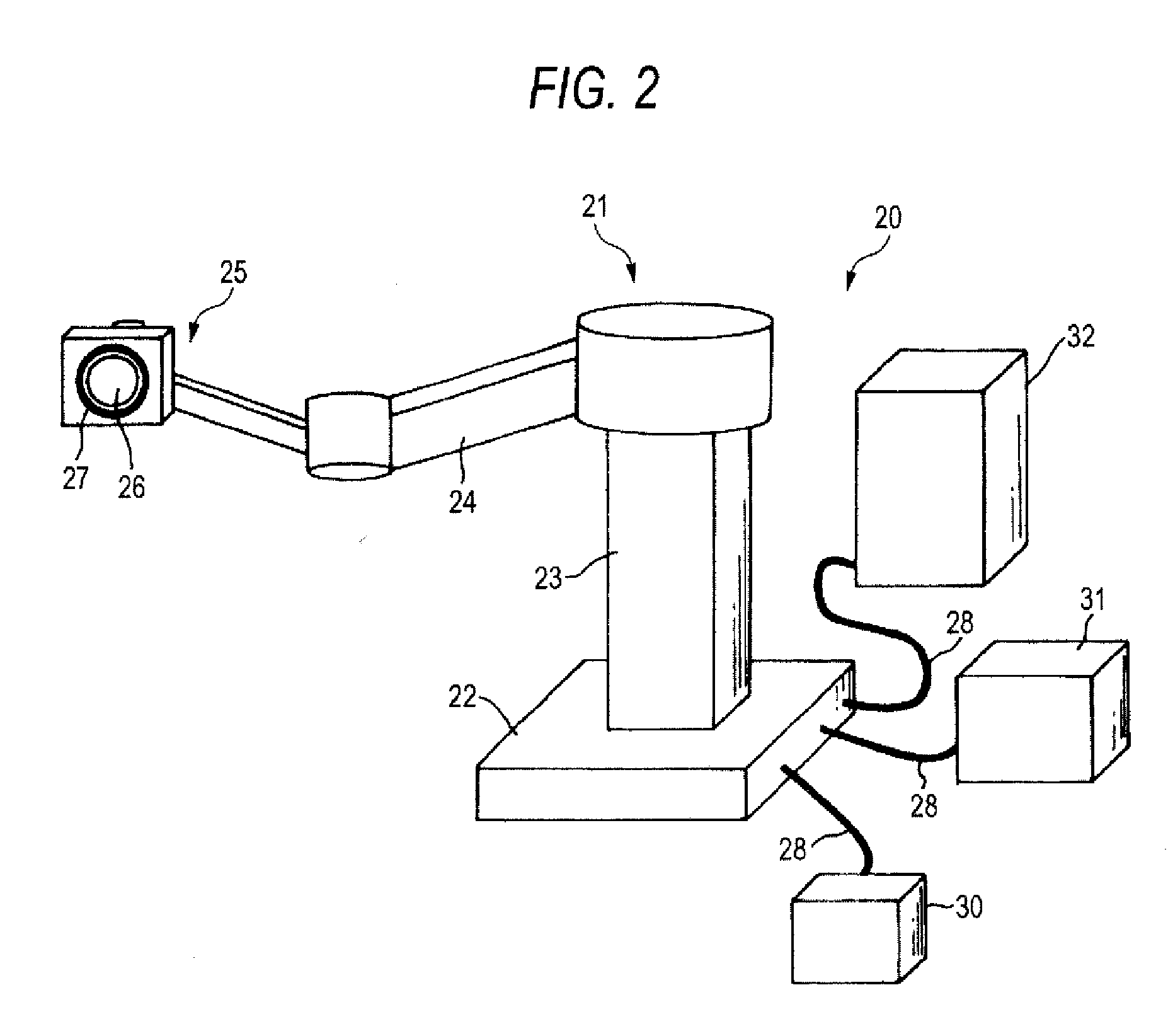

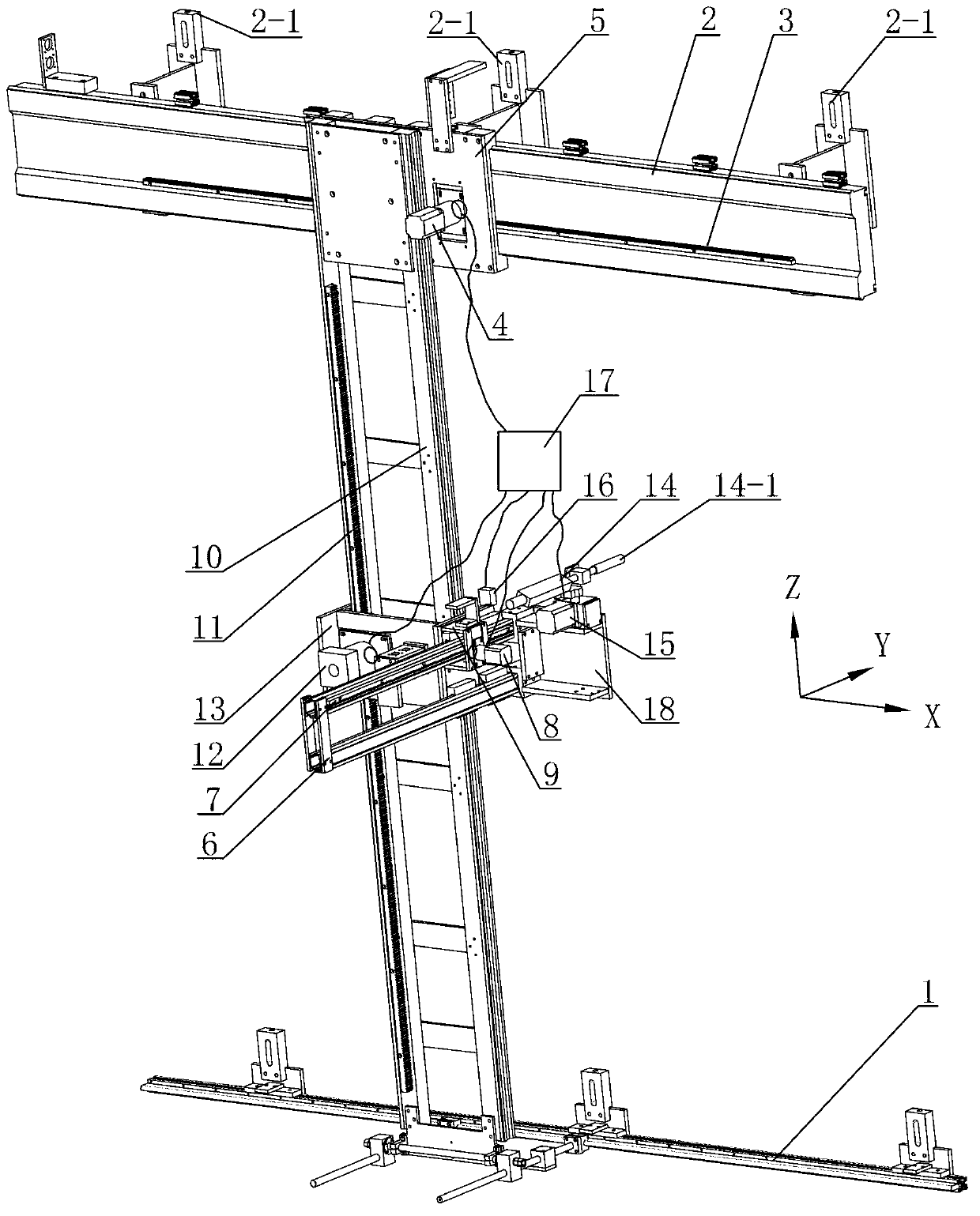

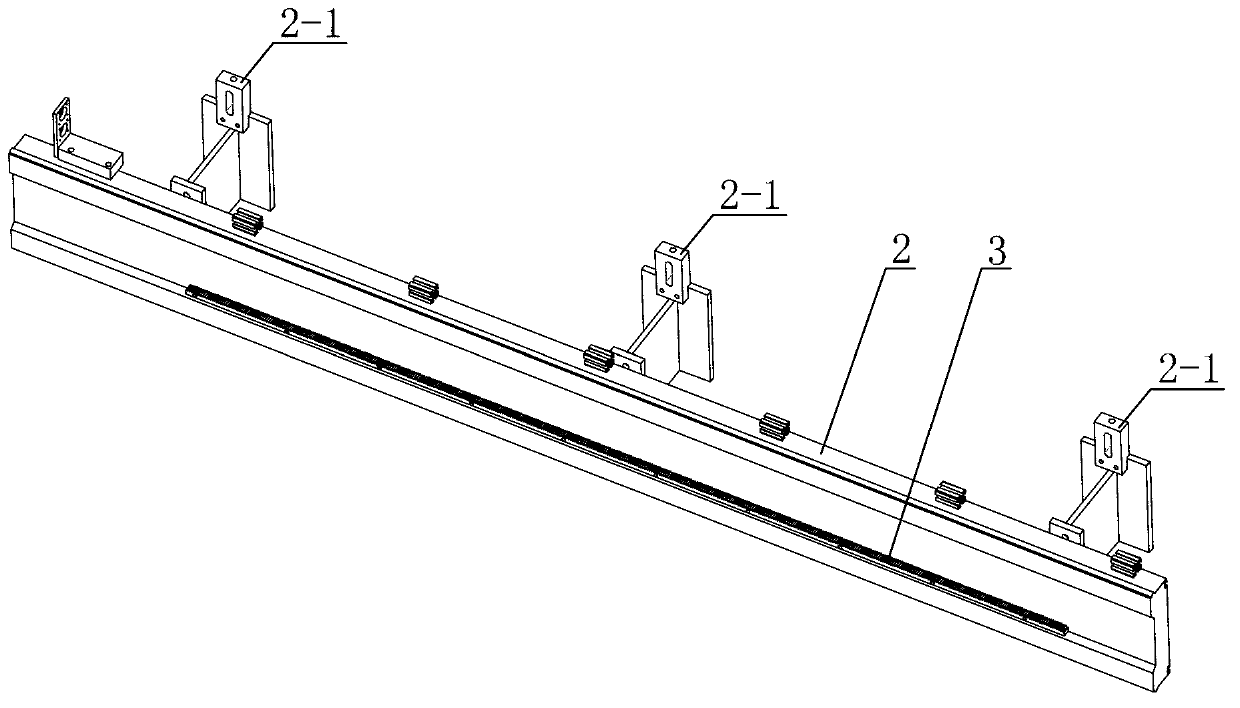

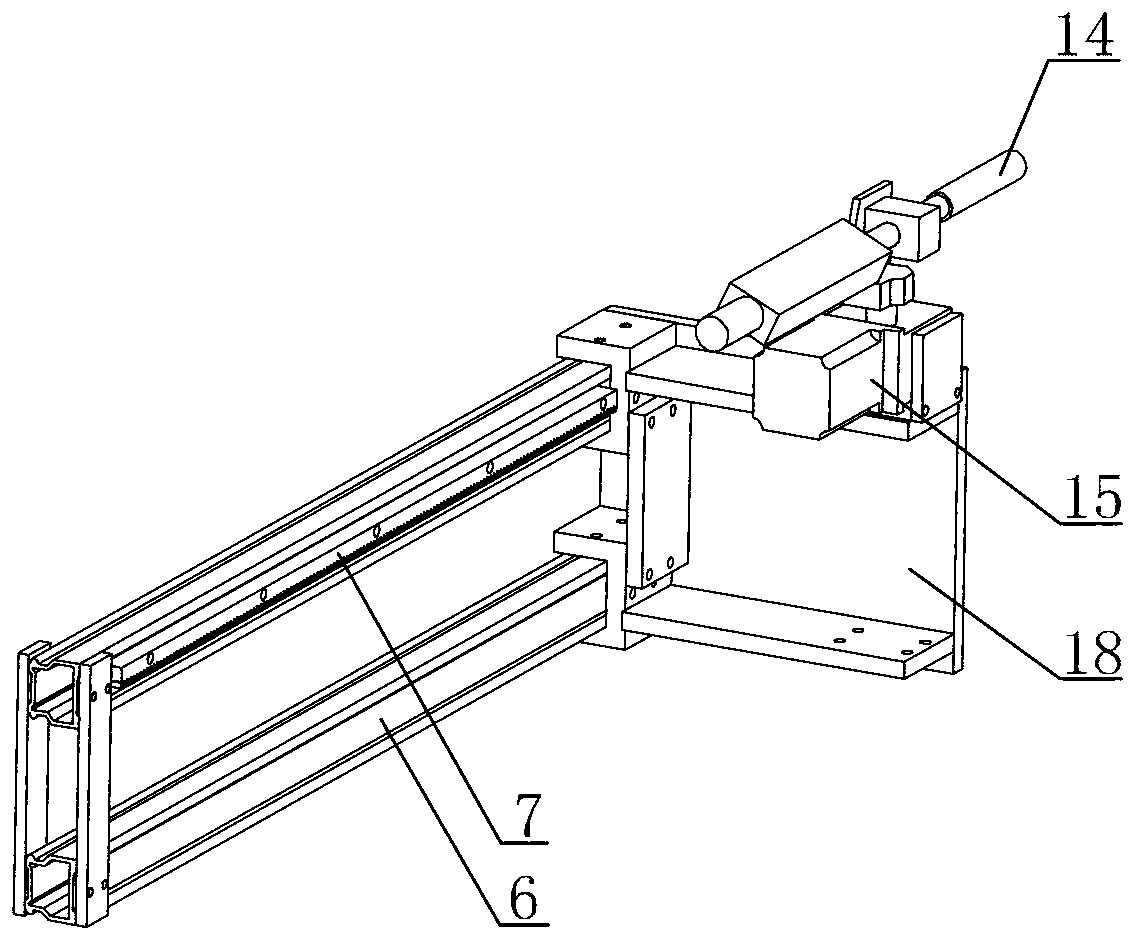

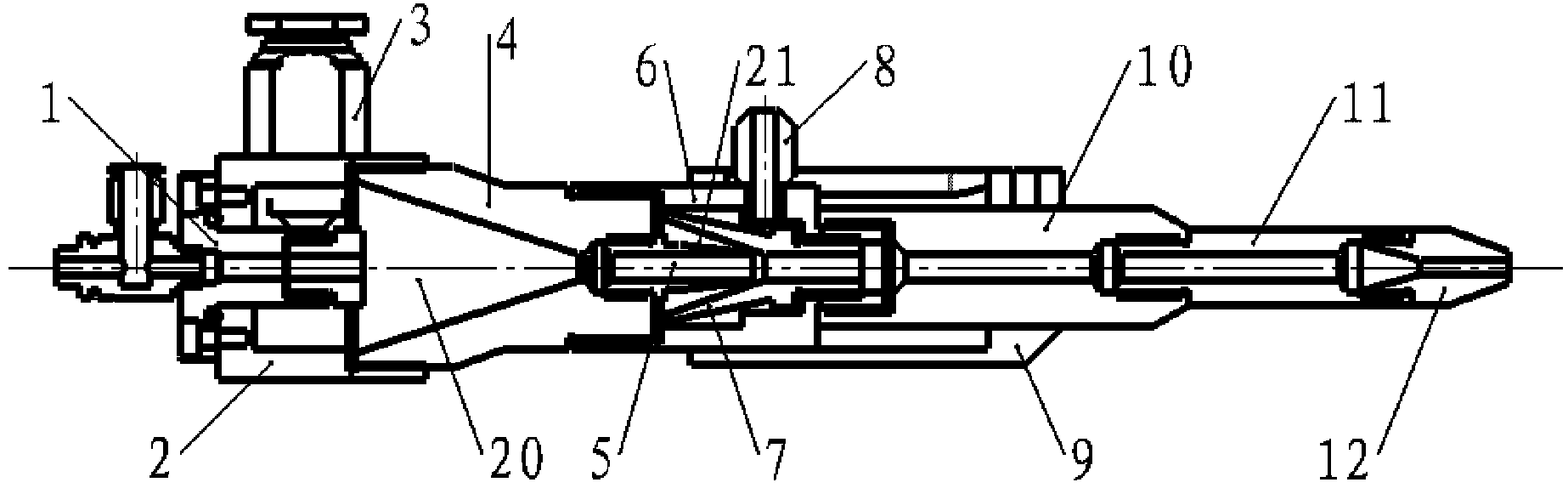

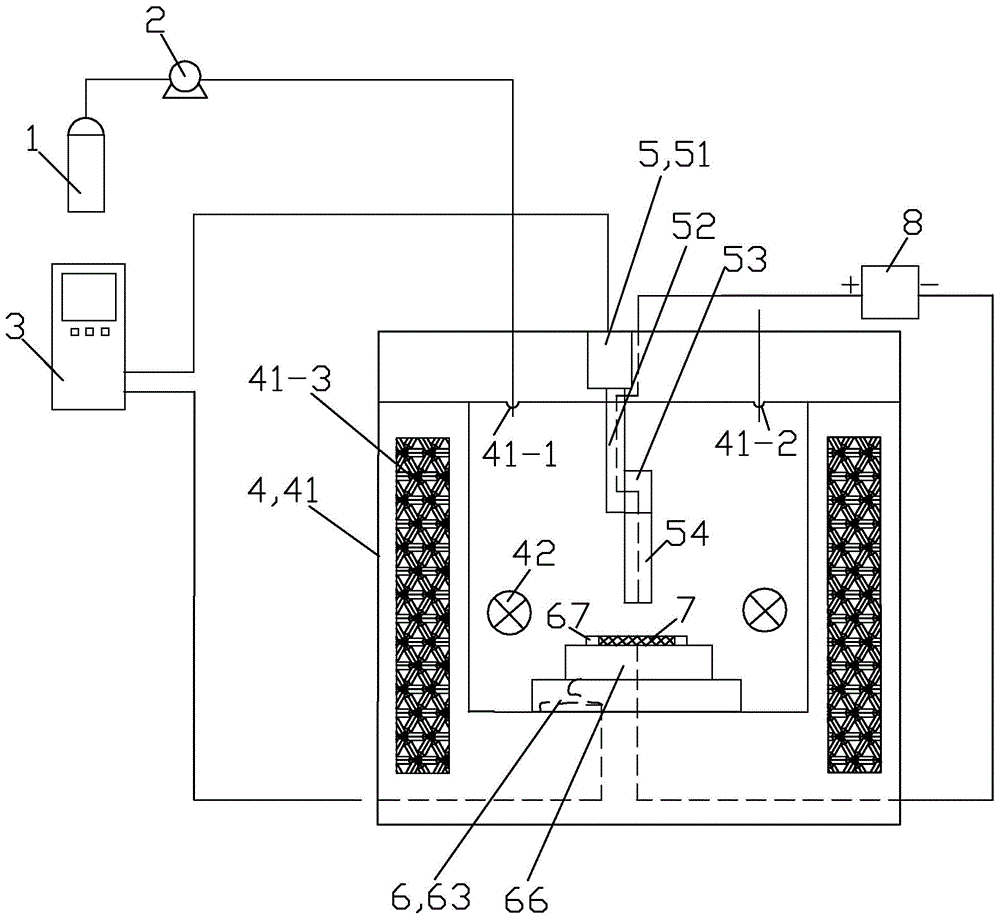

Laser-based inside-laser coaxial wire-feeding additive manufacturing system and forming method

InactiveCN109530918AReduce unevennessImprove deposition qualityAdditive manufacturing apparatusLaser beam welding apparatusMelting tankFeature structure

The invention discloses a laser-based inside-laser coaxial wire-feeding additive manufacturing system and a forming method. The laser-based inside-laser coaxial wire-feeding additive manufacturing system is formed by a laser, a wire feeder mechanism, a movement actuating mechanism, a molten pool shape monitoring feedback module and a system control module. After a part model is cut into slices, aninitial path is planned, input parameters and technological parameters in a technology database are compared, the molten pool temperature corresponding to technological parameters and input technology parameters under different feature structures is optimized, printing parameters and a robot code under an optimal path are generated, a high-speed infrared camera acquires molten pool shape parameters during the printing process and transmits to the system control module, the system control module compares the acquired molten pool shape data and the technology data of the technology database module, meanwhile, the molten pool temperature change is monitored, and the molten pool temperature is corrected through feedback-adjusting laser power and is monitored and feedback-adjusted in real time, so that the molten pool shape is uniform and consistent and the printing process is stably controlled during the printing process.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

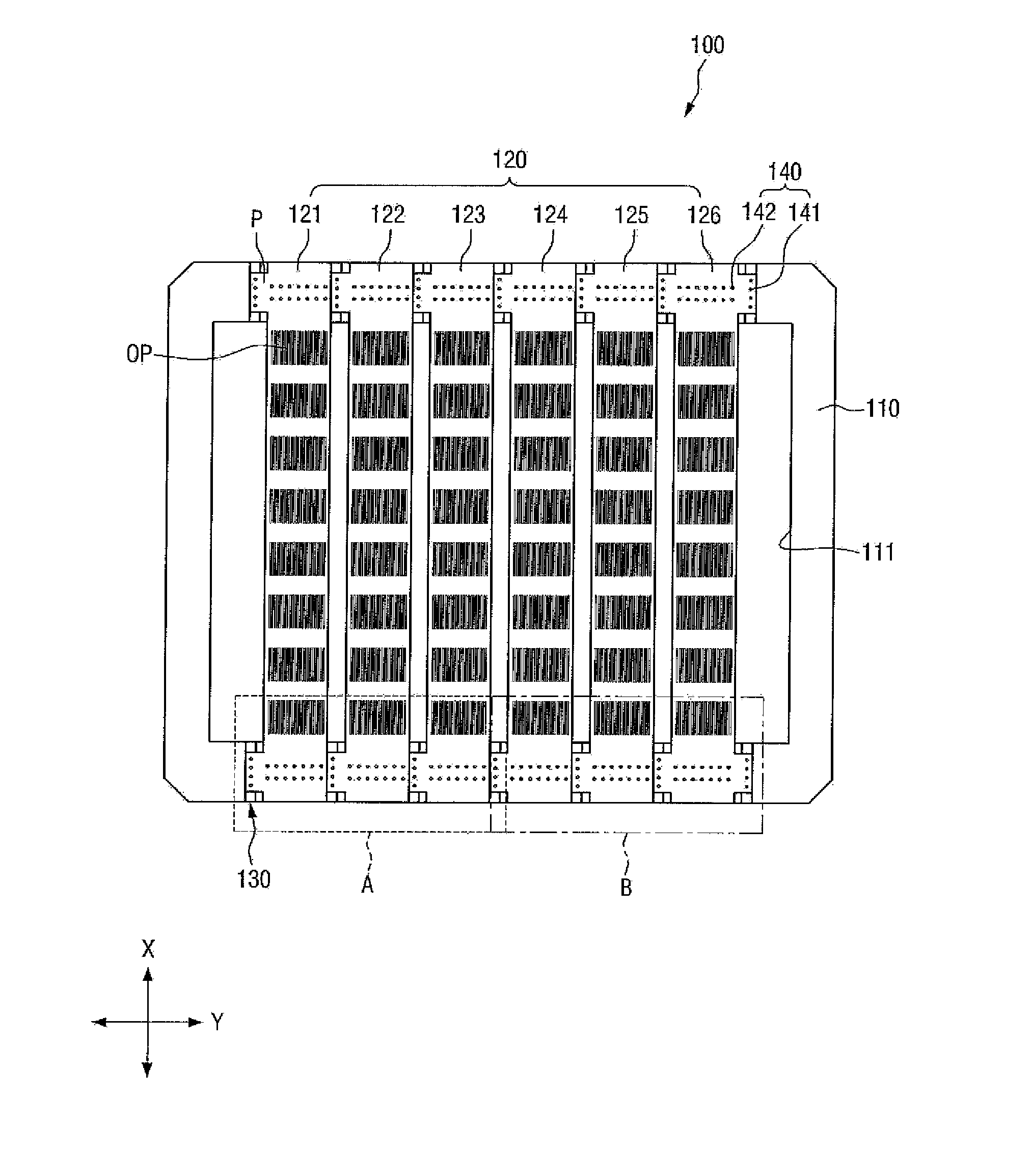

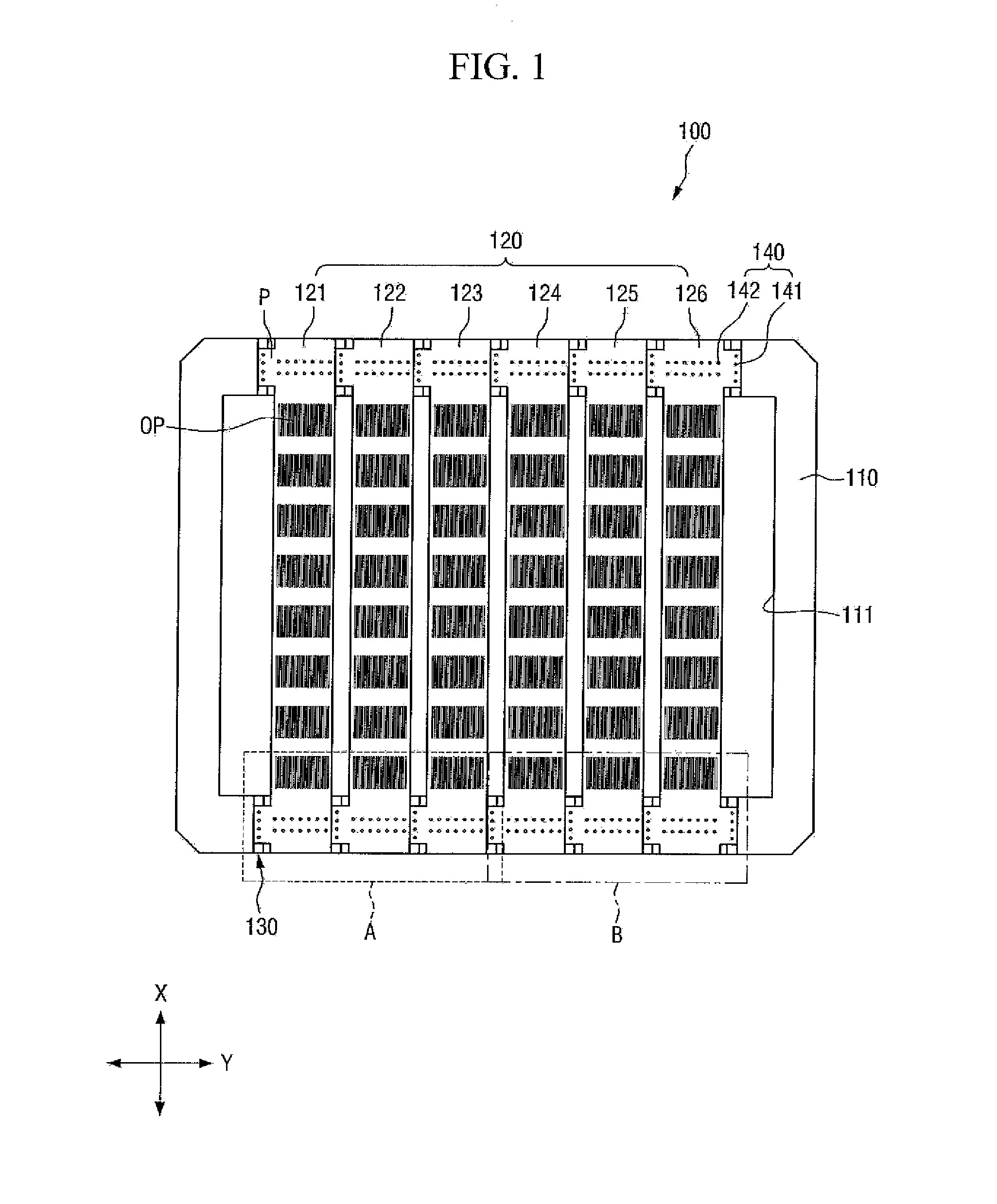

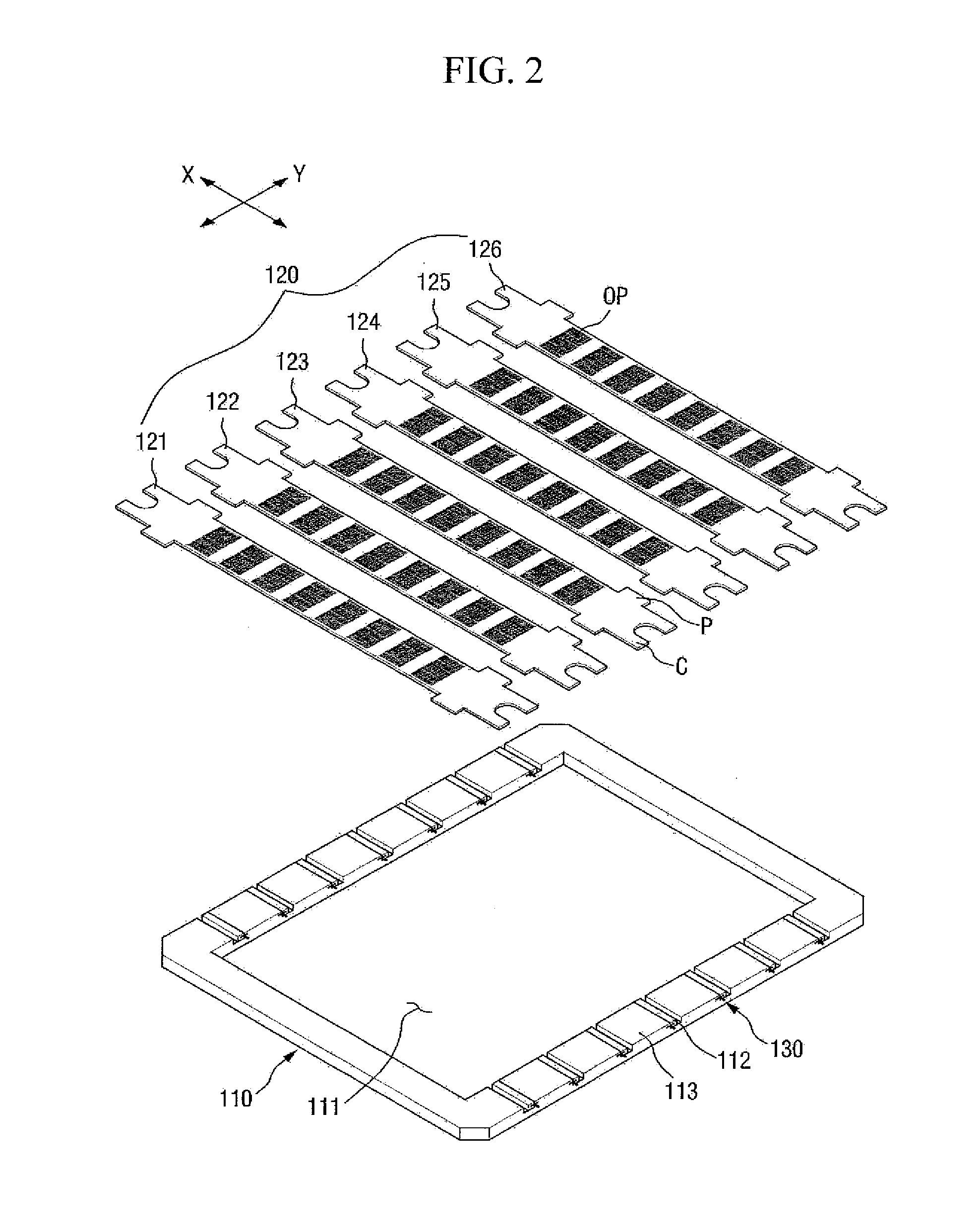

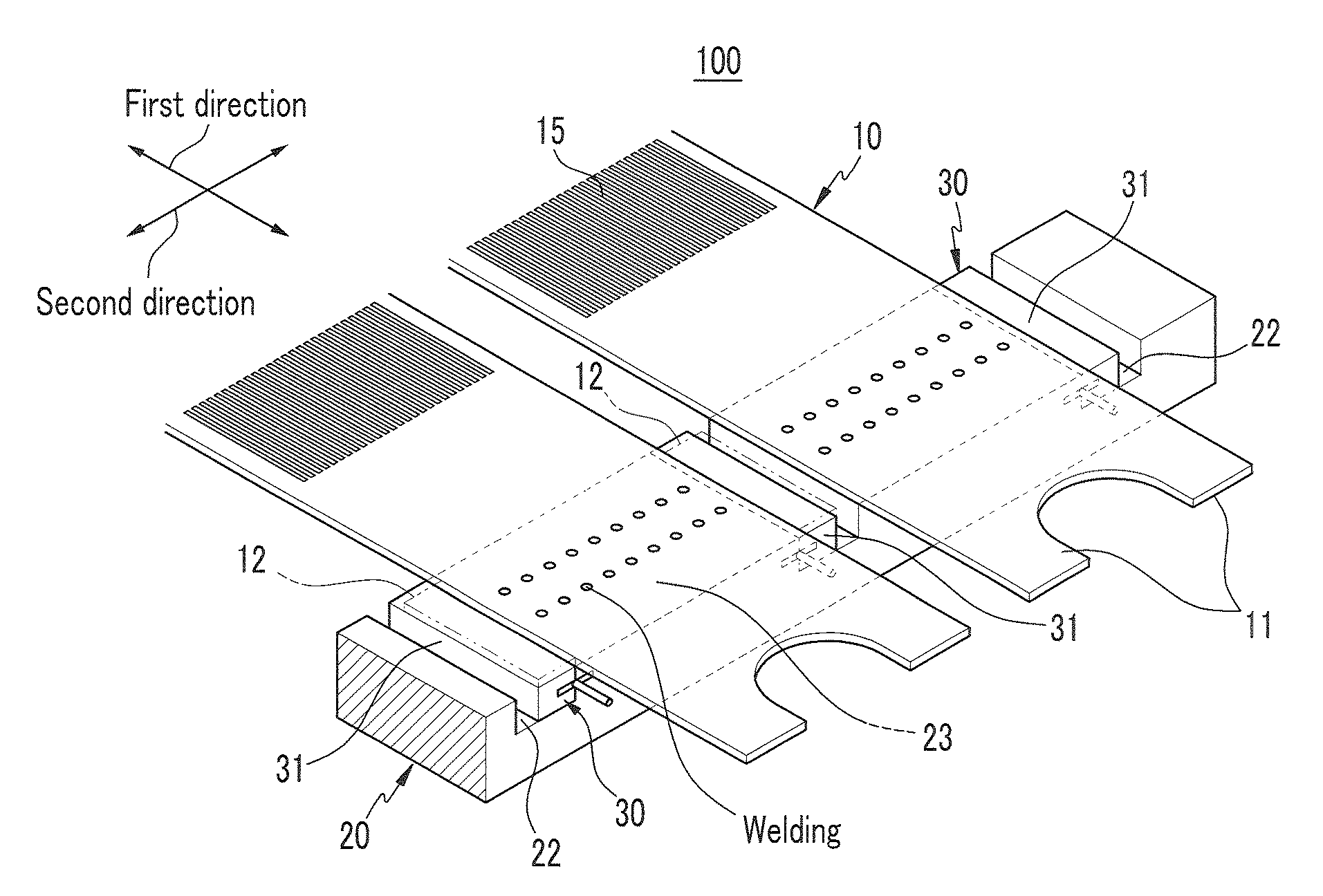

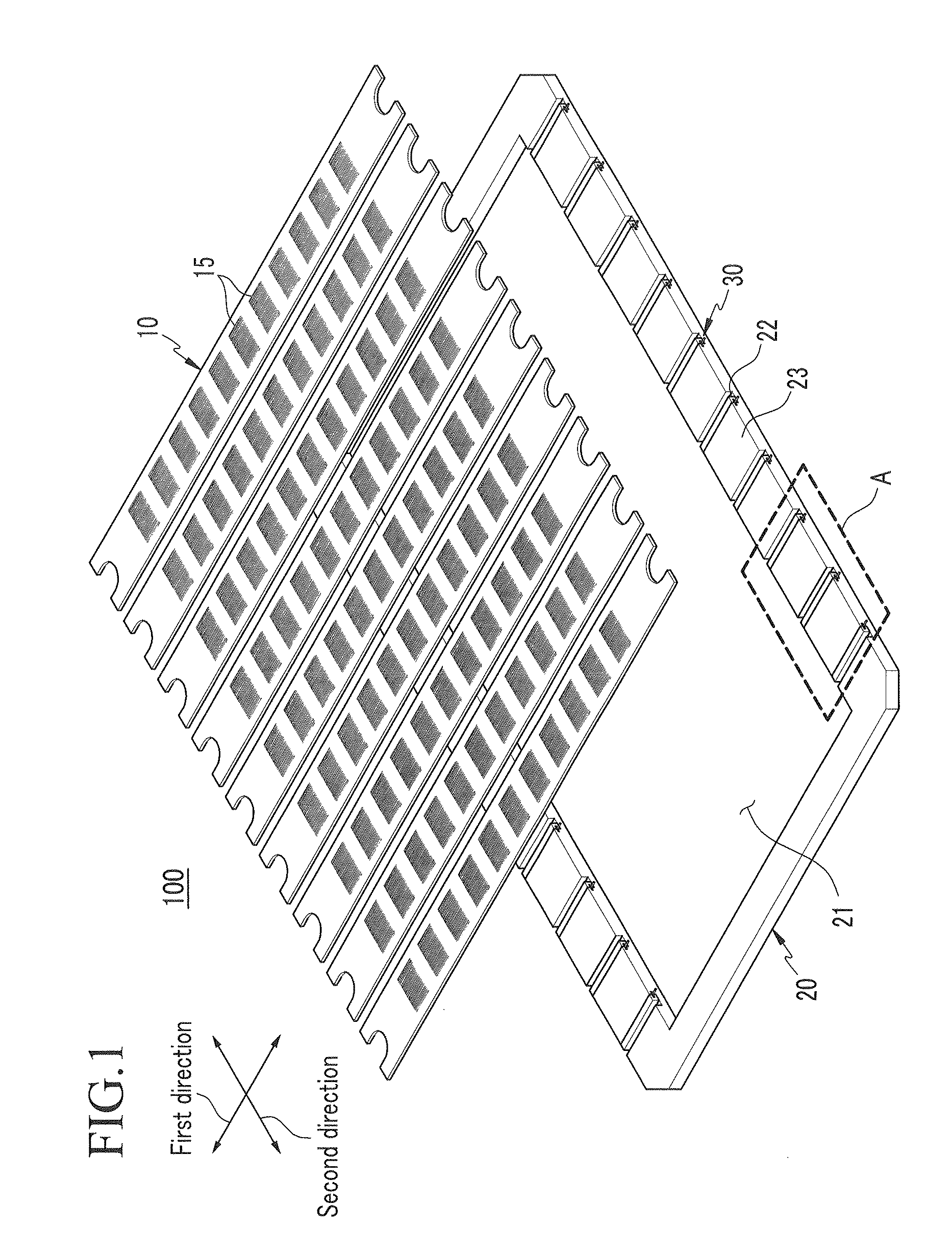

Mask assembly and method for fabricating the same

ActiveUS20140331926A1Effectively remove waveImprove deposition qualityLiquid surface applicatorsWelding/cutting auxillary devicesEngineeringMechanical engineering

A mask assembly includes a mask frame having frame openings formed thereon, and a plurality of unit masks fixed to the mask frame. The respective unit masks extend in a first direction, and at least one of the plurality of unit masks includes at least one of a one sided projection projecting to one side thereof and another sided projection projecting to another side thereof, at both end portions of the unit mask, in a second direction that crosses the first direction.

Owner:SAMSUNG DISPLAY CO LTD

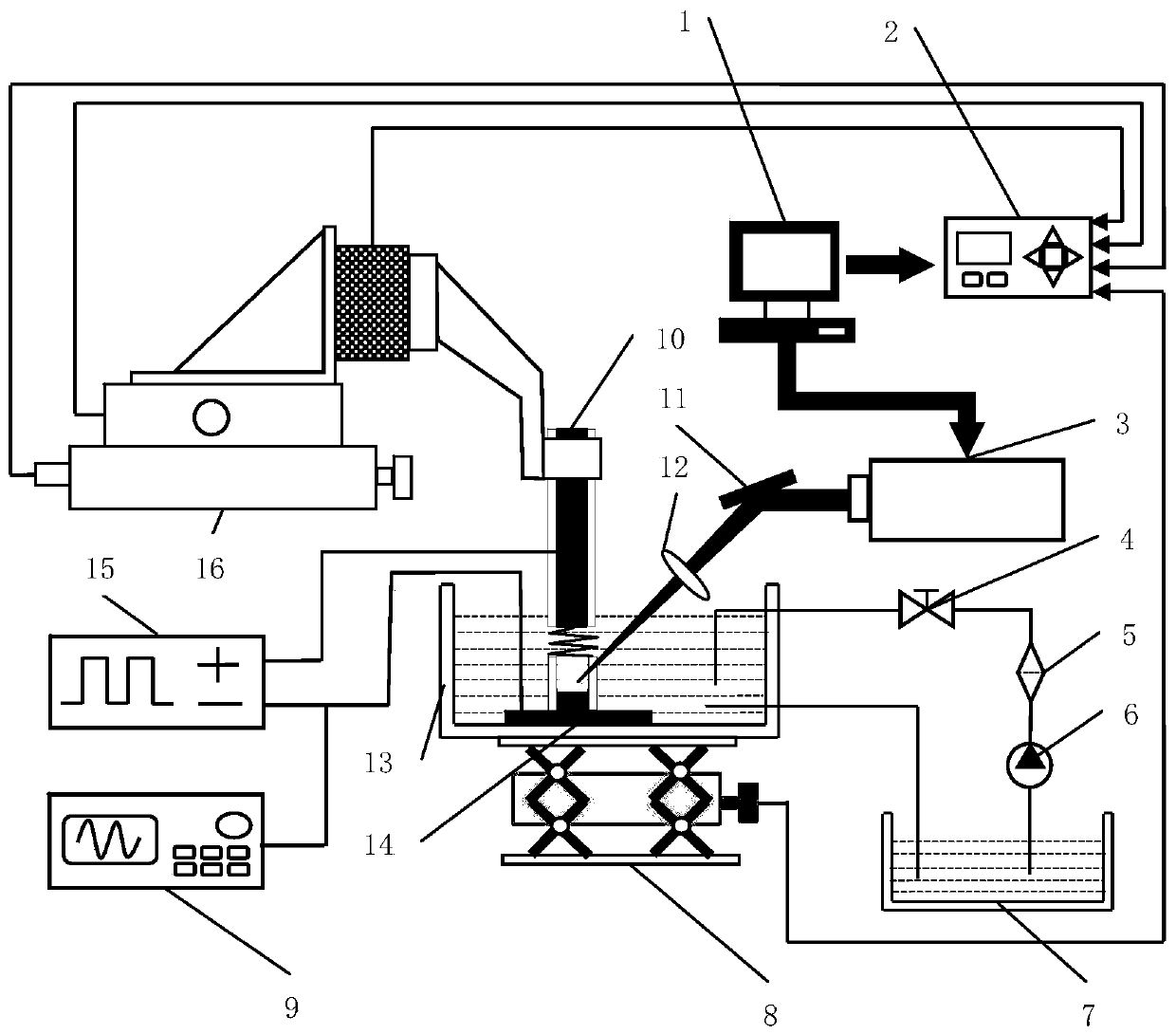

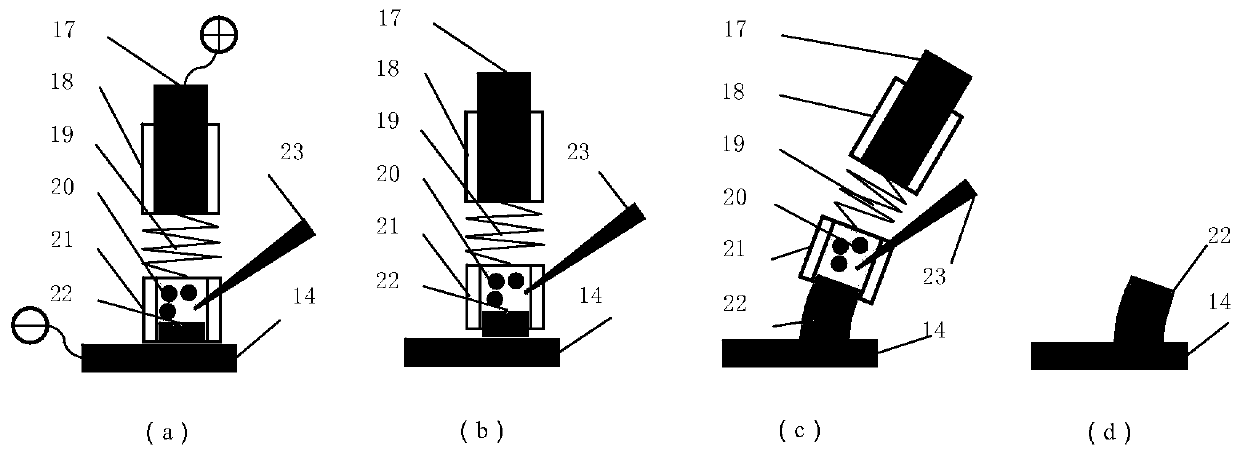

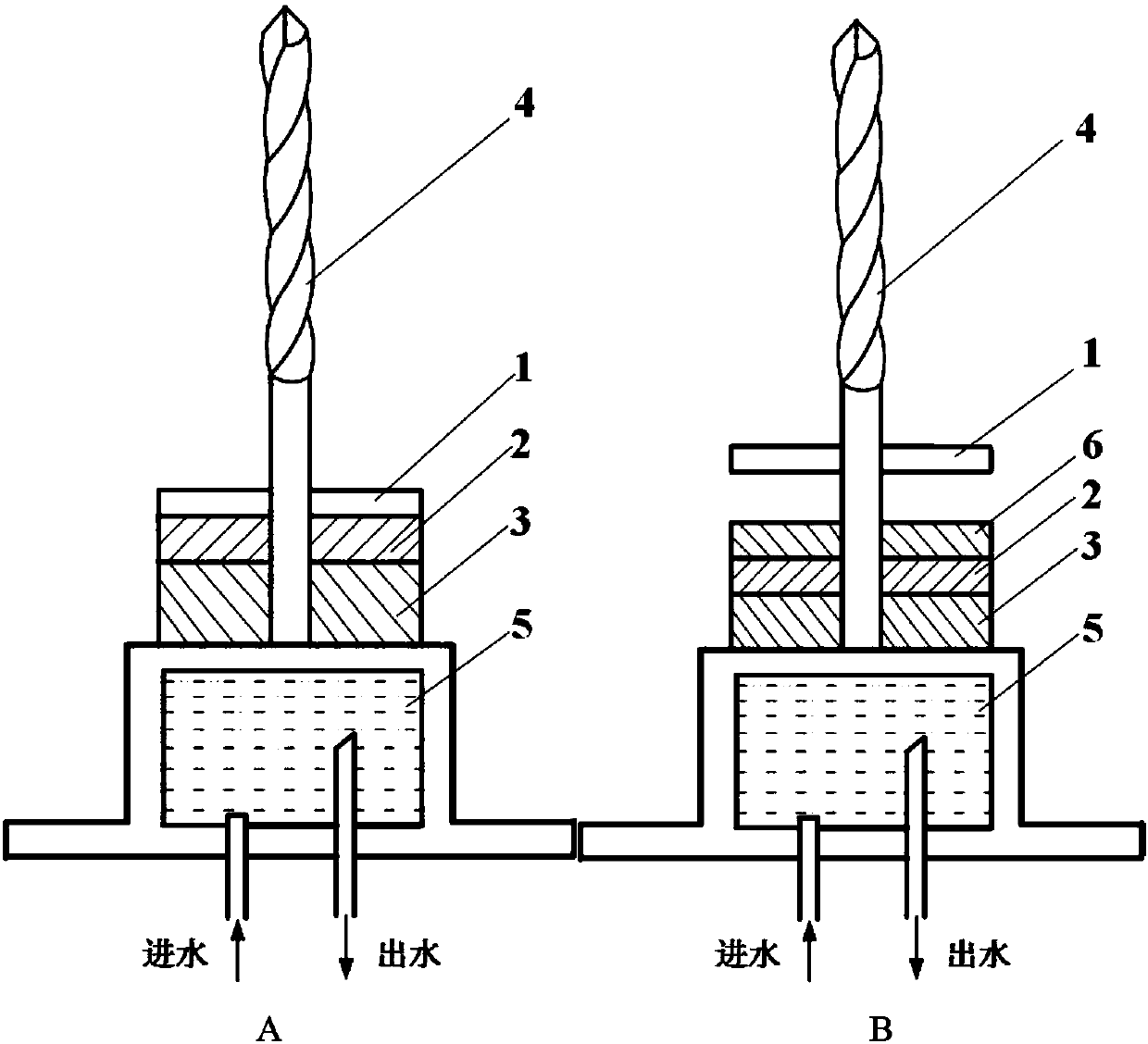

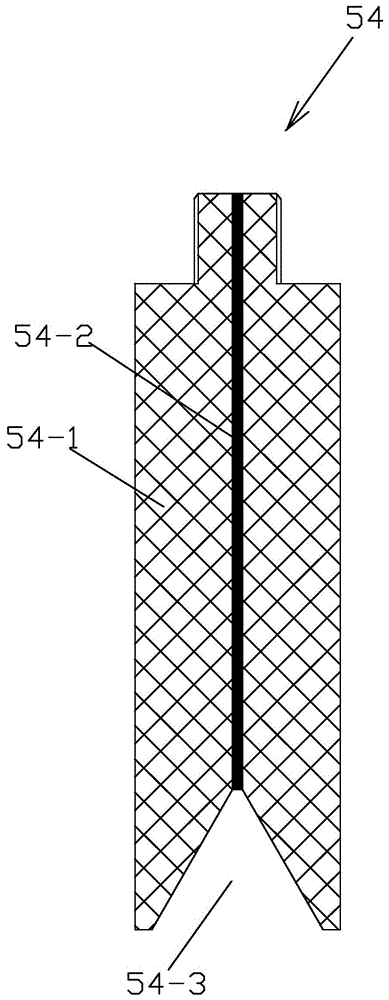

Laser-assisted flexible follow-up tool electrode fine electrodeposition device and method

ActiveCN109735883AImprove localizationSolve the accuracy problemCellsElectrodesElectricityEngineering

The invention discloses a laser-assisted flexible follow-up tool electrode fine electrodeposition device and method, and relates to the technical field of localized fine electrodeposition. According to the device and method, a flexible follow-up tool electrode is used for limiting an electric-field dispersion region and an electrodeposition reaction region, so that the fixed-area performance of electrodeposition and the dimensional accuracy of a component are improved; and a component with a complex shape can be deposited by controlling a movement path of the flexible follow-up tool electrode.Due to the fact that a laser has a high power density, laser irradiation is introduced to change the electrode state of an irradiation area, the ion diffusion speed and electron transfer speed are accelerated, the deposition rate is increased, the defects such as hemp holes and cracks in the deposition body are reduced, and the deposition quality is improved. The manufacturing of fine parts is realized through the combined action of two kinds of energy of electrochemistry and lasers. The method is mainly used for manufacturing the fine parts and can effectively improve the precision of electrochemical deposition and the forming precision of the parts.

Owner:JIANGSU UNIV

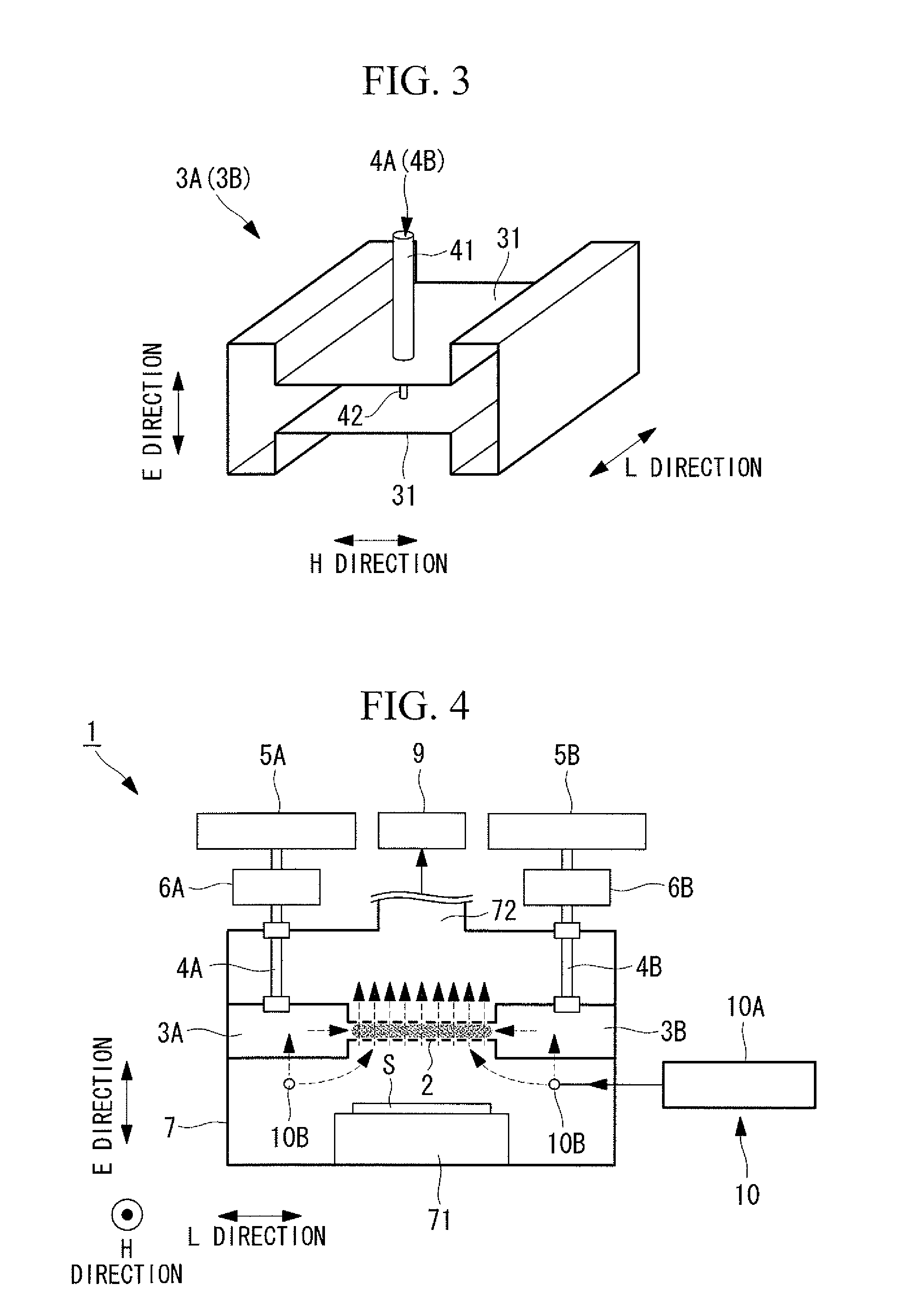

Magnetron sputtering device and magnetron sputtering method

ActiveCN105543792AReasonable device configurationVersatileVacuum evaporation coatingSputtering coatingPhysicsThin membrane

The invention discloses a magnetron sputtering device and a magnetron sputtering method. The magnetron sputtering device comprises a substrate table for placing a substrate, a target opposite to the substrate table and used for sputtering the substrate, and a reaction cavity for accommodating the substrate table and the target. The magnetron sputtering device further comprises an angle adjusting device corresponding to the target and used for adjusting an angle of the corresponding target to the substrate table. The magnetron sputtering method comprises the following steps: (1) the reaction cavity and the substrate are cleaned; and the target is mounted; (2) the angle of the target corresponding to the substrate and the distance between the target and the substrate are adjusted; (3) the reaction cavity is vacuumized; (4) the presputtering is performed; and meanwhile, the rotating and swinging functions of the substrate table are started; and (5) the magnetron sputtering is performed. The device can be applied to deposition of large-area films with high uniformity and excellent repeatability, and can realize continuous magnetron sputtering of multiple layers of films; and the method can save the film plating time and improve the film plating efficiency.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

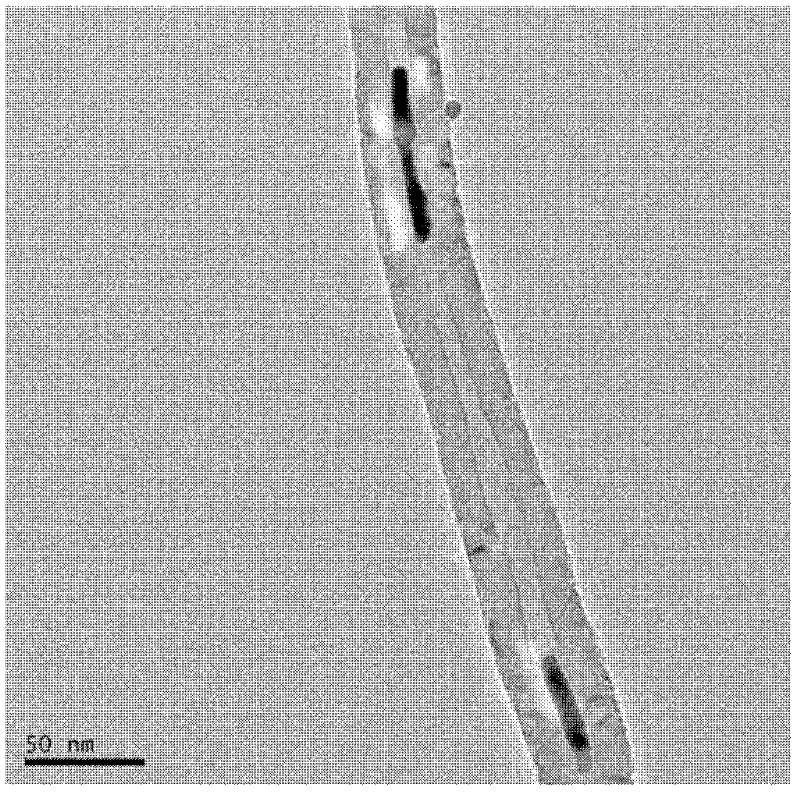

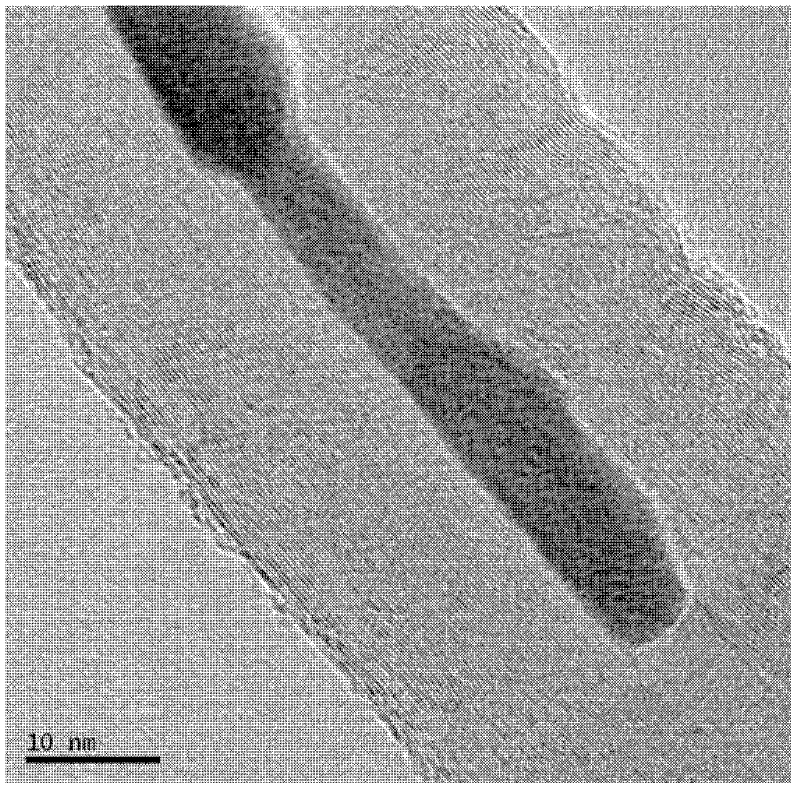

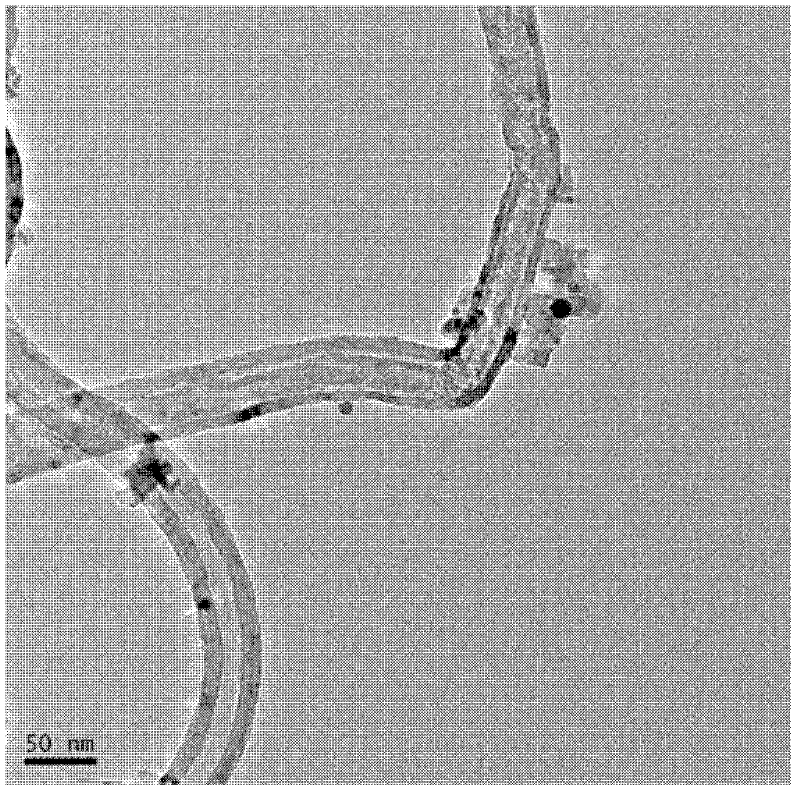

Preparation method of carbon nano tube

InactiveCN102330069ASimple preparation processFast deposition rateNanotechnologyChemical vapor deposition coatingCarbon nanotubeMagnesium

The invention relates to a preparation method of a carbon nano tube. A direct current plasma injection chemical vapour deposition system is adopted for preparing the carbon nano tube. The preparation method comprises the following steps: by taking a mixed solution of nickel nitrite and magnesium nitrite as a catalyst precursor, dropping the mixed solution on a substrate such as molybdenum, zirconium or the like; airing and then placing the substrates on a deposition platform in a cavity of direct current plasma injection chemical vapour deposition equipment; discharging a direct-current arc so that argon and hydrogen form high temperature plasma; decomposing and reducing the catalyst solution by the high temperature plasma, so as to generate a Ni / MgO catalyst; and after hydrocarbon gas isintroduced, cracking the hydrocarbon gas by using the high temperature plasma, and then injecting the cracked hydrocarbon gas on the substrate so that the carbon nano tube is formed in the presence of the catalyst. The preparation method provided by the invention has the advantages that: the catalyst is obtained while the carbon nano tube directly grows, preparation process is simple, deposition speed is fast, and deposition quality is good; and meanwhile, the bamboo-joint-like carbon nano tube is generated, and the prepared carbon nano tube has larger diameter, good crystallinity, no windingand good dispersibility.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

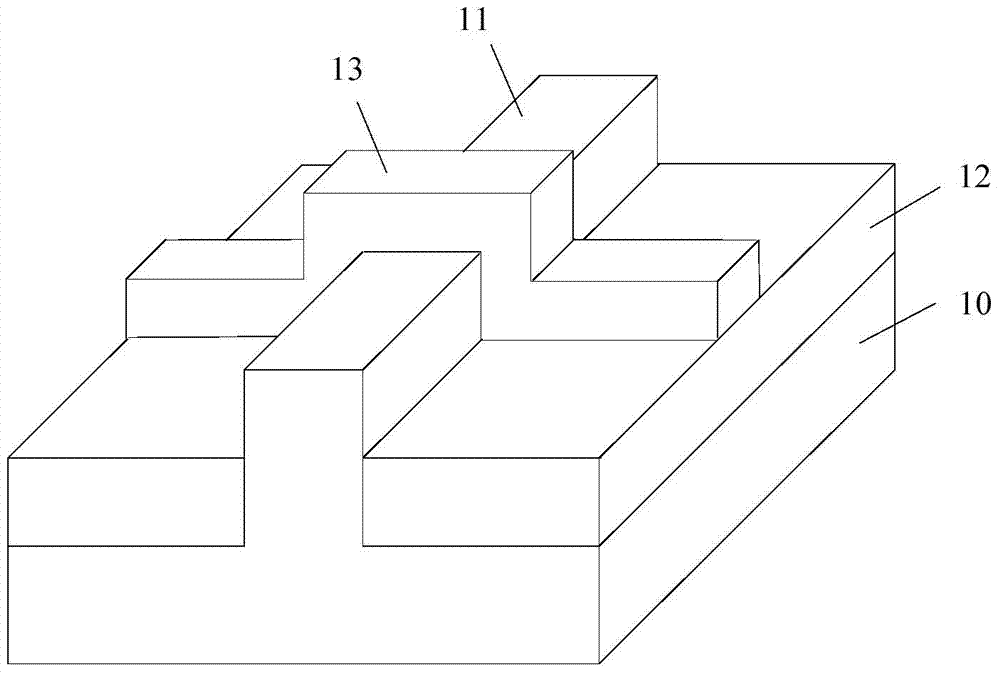

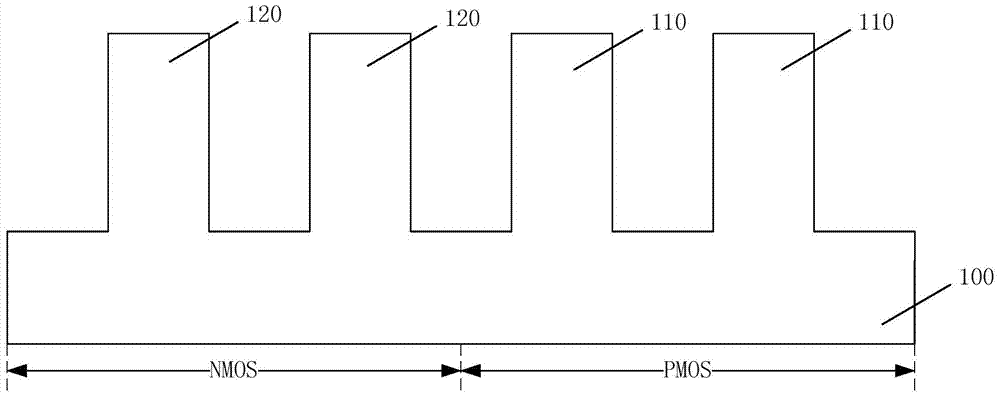

Fin-type field effect transistor forming method

InactiveCN104733311AAffect performanceImprove deposition qualitySemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorGas phase

The invention discloses a fin-type field effect transistor forming method. The forming method comprises steps: a semiconductor substrate is provided, wherein the semiconductor substrate is provided with an NMOS region and a PMOS region, a first fin part is formed on the PMOS region, and a second fin part is formed on the NMOS region; a first dielectric layer is formed on the semiconductor substrate; a gate structure crossing the first fin part and the second fin part is formed on the surface of the first dielectric layer; a mobile chemical vapor deposition process is adopted to form a second dielectric layer on the first dielectric layer; a part of the second dielectric layer at the top part of the first fin part at two sides of the gate structure is removed to enable the top surface of the first fin part to be exposed; a first semiconductor layer is formed on the surface of the first fin part; an oxide layer is formed on the surface of the second semiconductor layer; a part of the second dielectric layer at the top part of the second fin part at two sides of the gate structure is removed to enable the top surface of the second fin part to be exposed; and a second semiconductor layer is formed on the surface of the second fin part.

Owner:SEMICON MFG INT (SHANGHAI) CORP

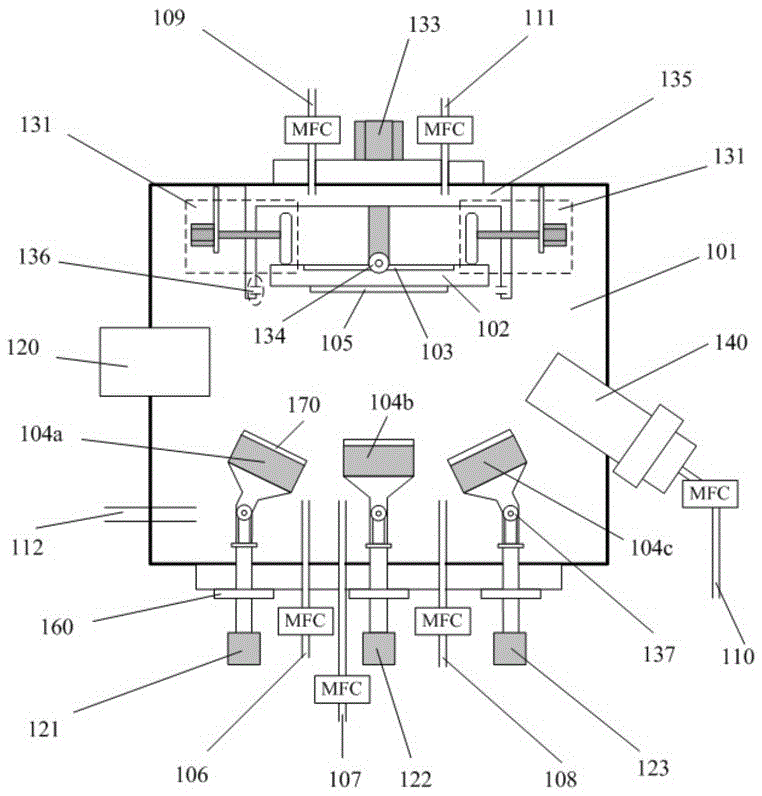

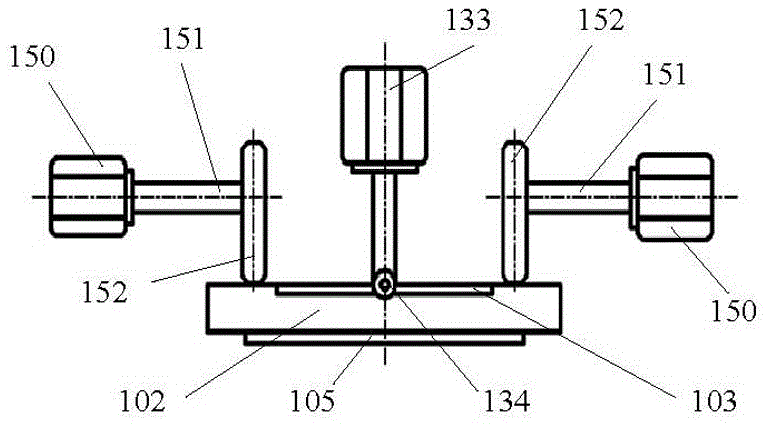

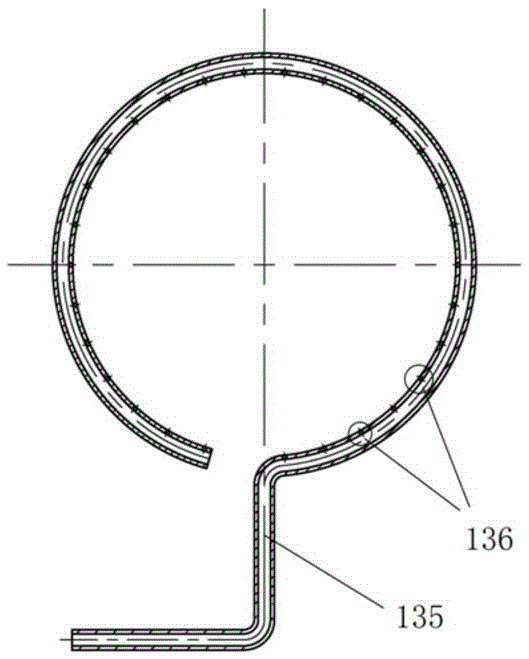

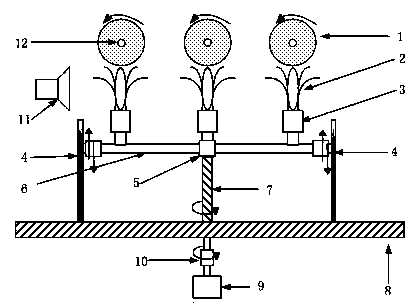

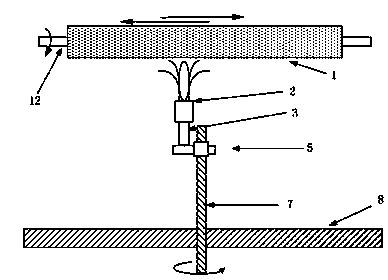

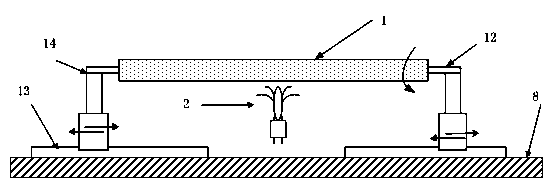

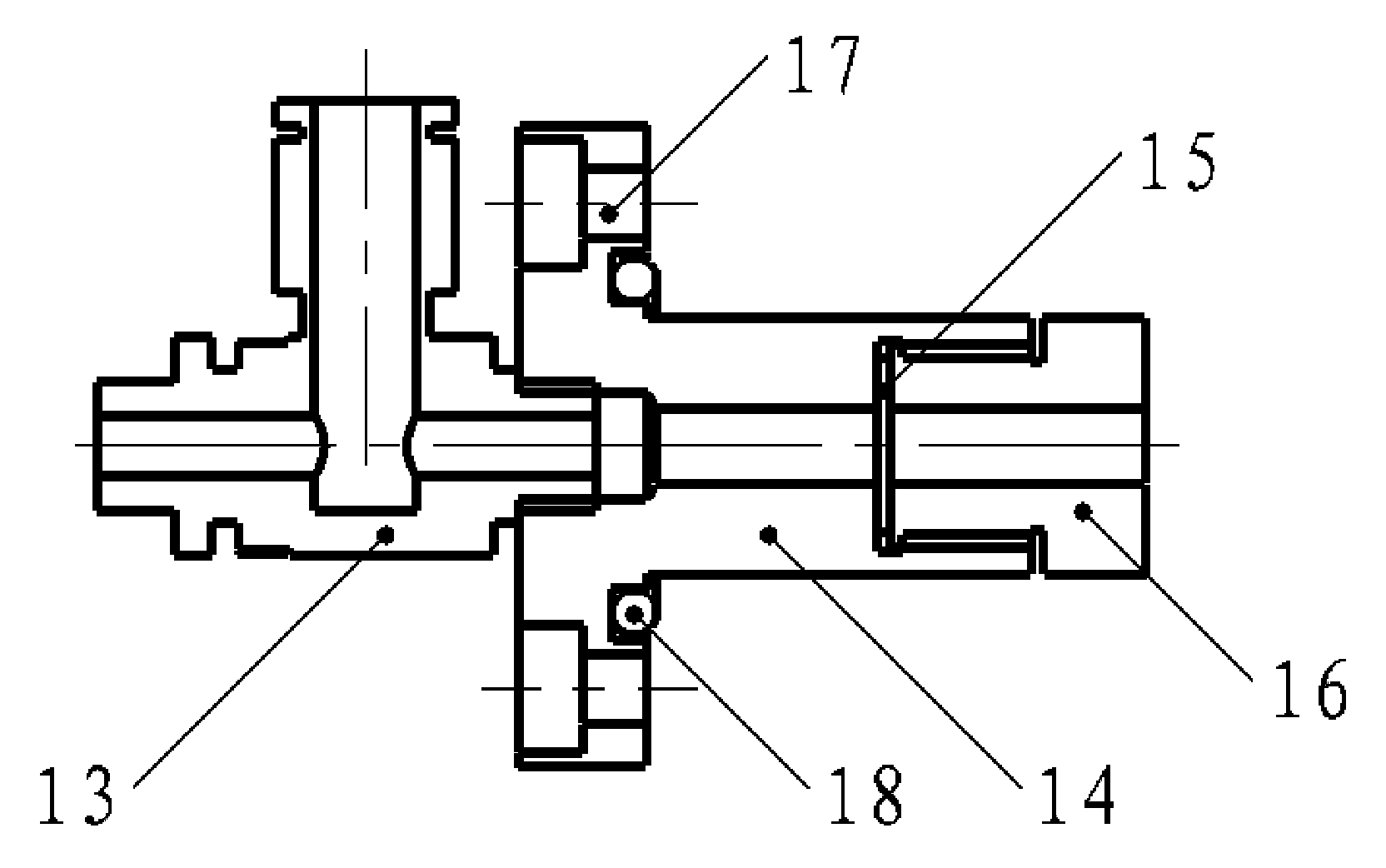

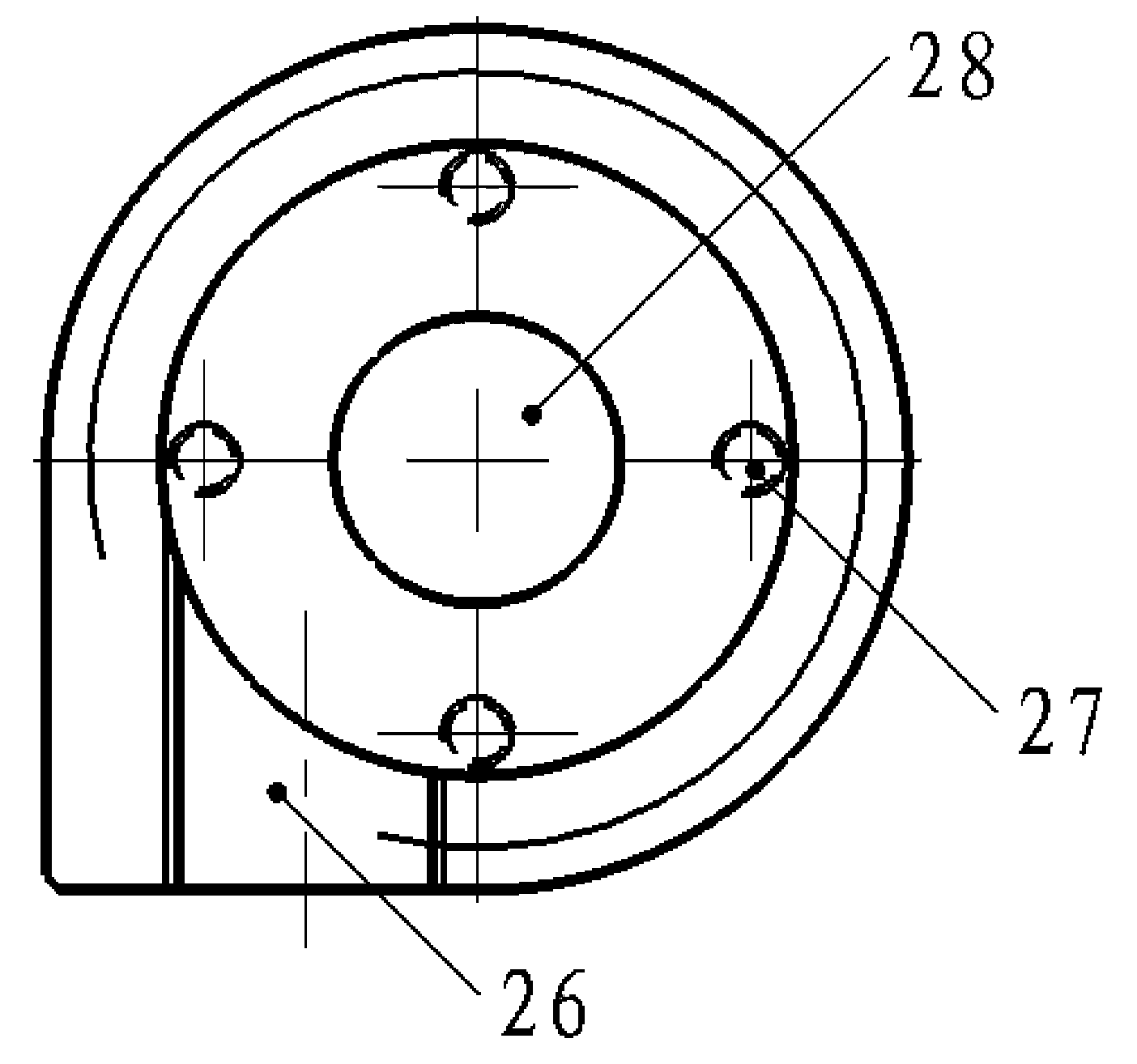

Machine tool for depositing optical fiber preform rods by outside chemical vapor deposition method

InactiveCN103964684ABest spray distanceHigh precisionGlass making apparatusGlass productionGranularityDeposition process

The invention relates to a machine tool for depositing optical fiber preform rods by an outside chemical vapor deposition method. The machine tool comprises a tool body; a reciprocating seat and blow lamps are respectively arranged on the tool body; rotary chucks are arranged on the reciprocating seat. The machine tool is characterized in that the blow lamps correspond to the rotary chucks, and are mounted below the axis of rotation; the blow lamps are connected with a feeding mechanism; the feeding direction of the feeding mechanism is perpendicular to the axis of rotation. The blow lamps can be subjected to dynamic regulation and control with the change of the deposition diameters of the optical fiber preform rods, so that the distances between the blow lamps and the deposition surfaces of the optical fiber preform rods are kept to be relatively constant, the blow lamps are always kept to be at optimal jet distance during the deposition process, so that not only can the uniformity of the jet dust granularity be maintained, but also the deposition precision and the deposition quality of the preform rods can be effectively improved, which effectively improves the deposition processing efficiency; the rotary chucks and the blow lamps are adopted, so that the processing efficiency of the optical fiber preform rods can be improved greatly.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

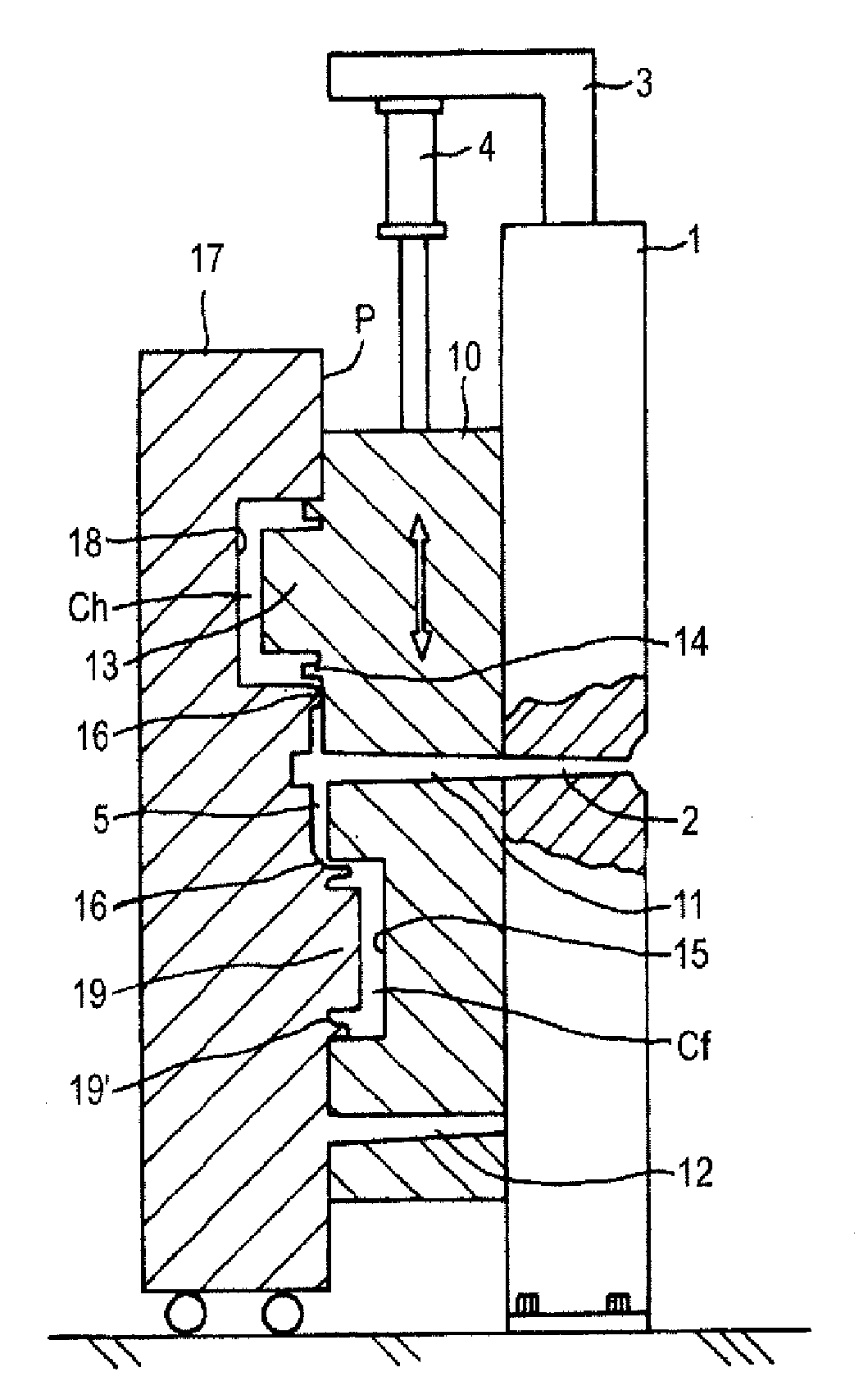

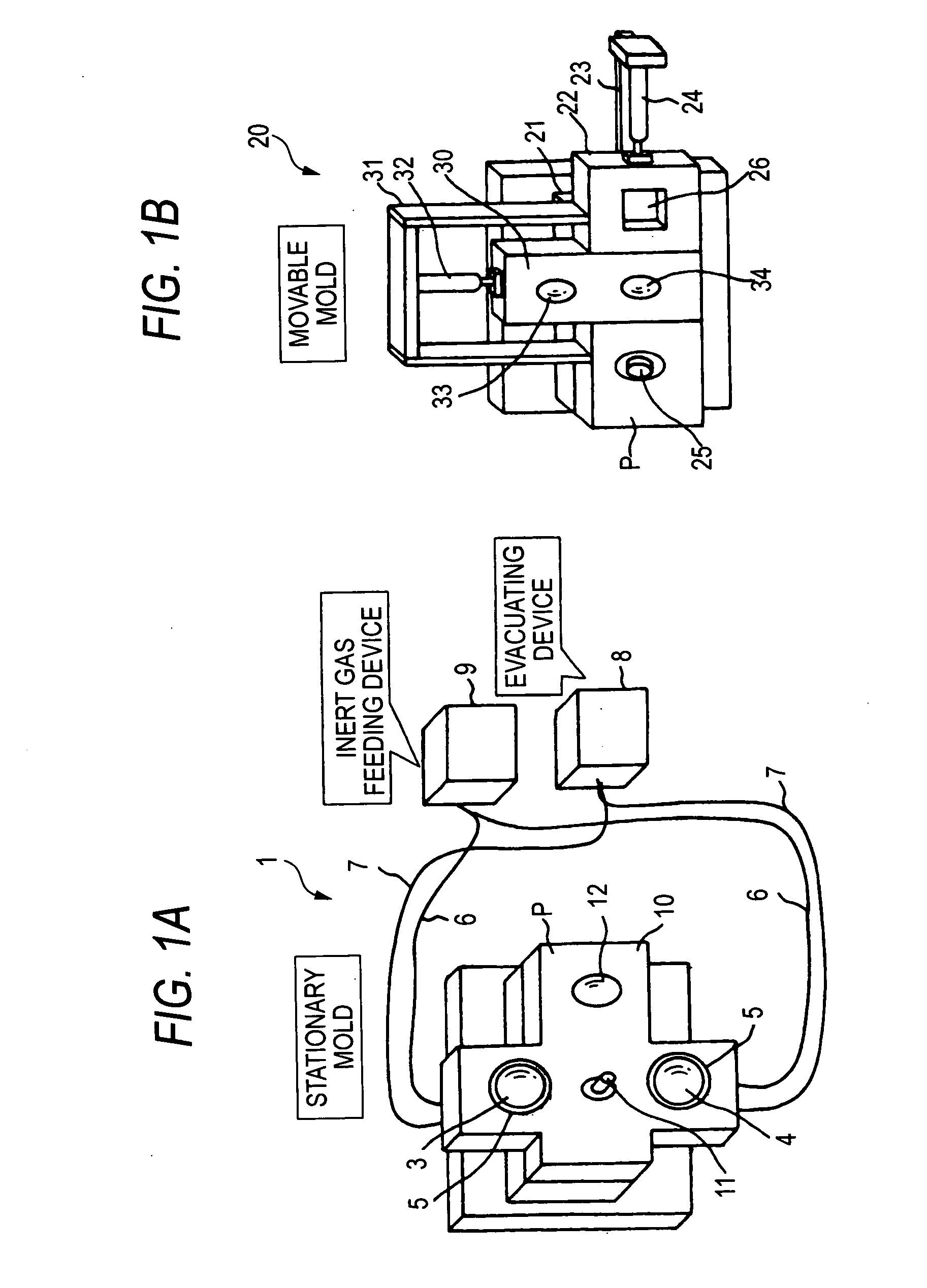

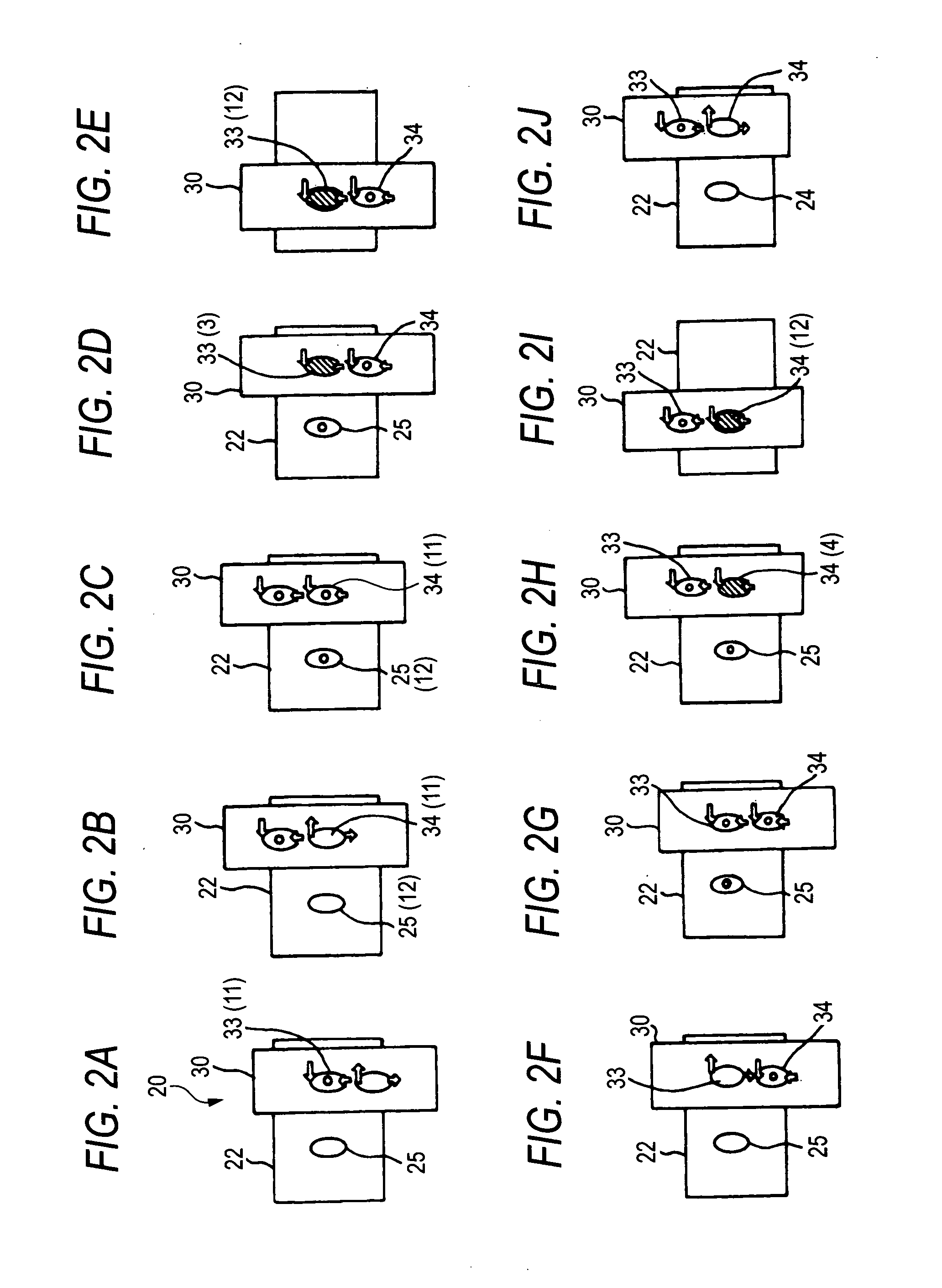

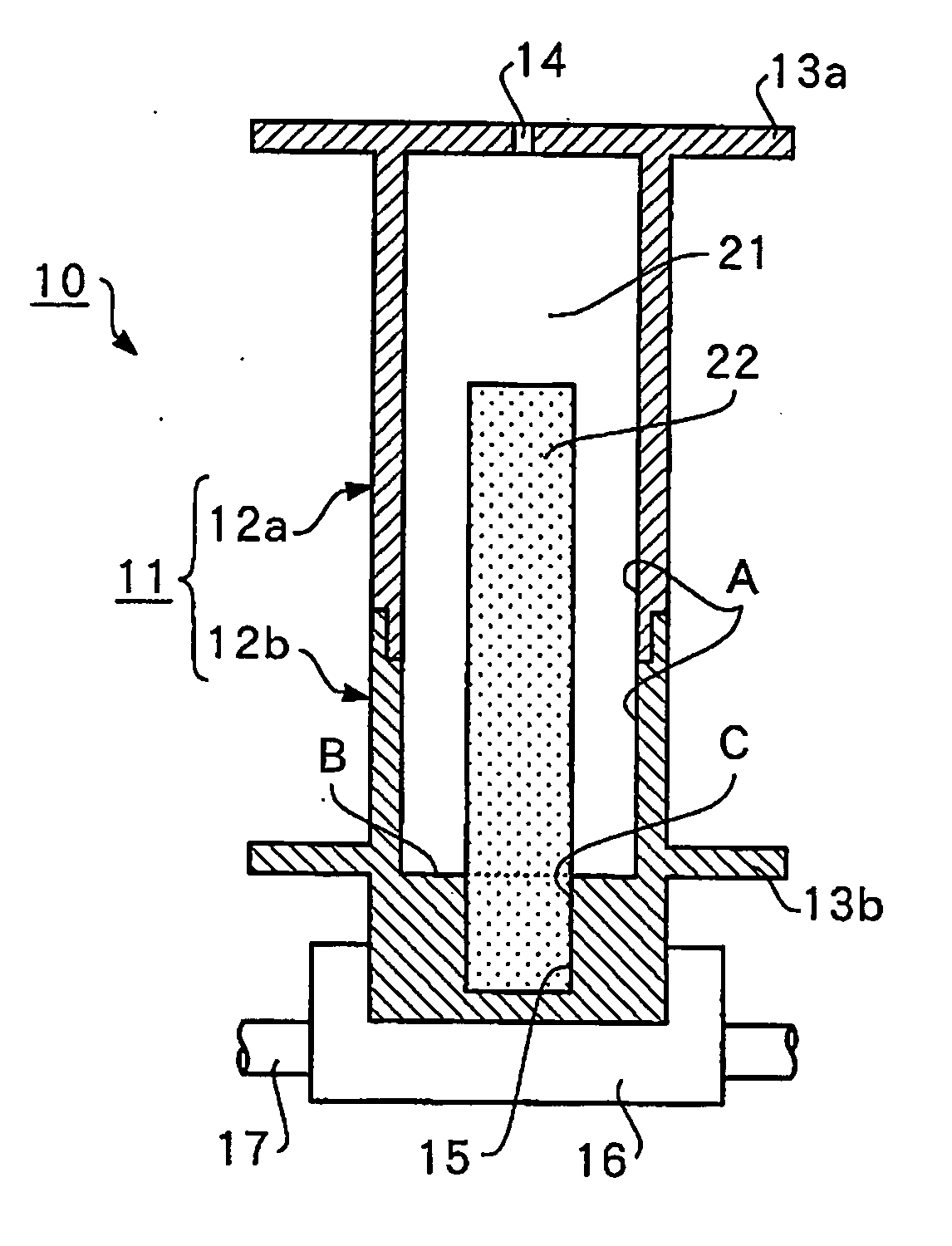

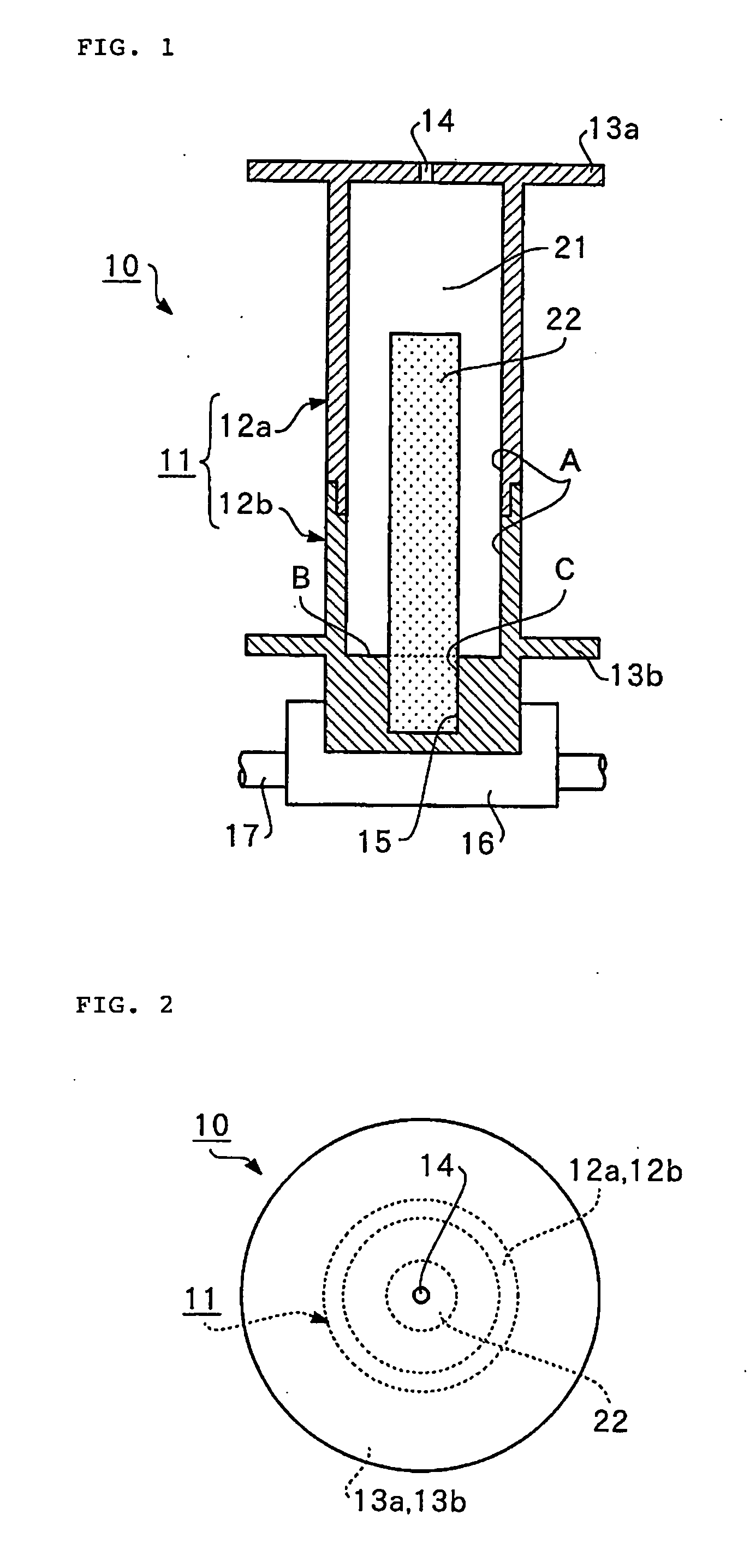

Method and apparatus for forming hollow moldings having thin film on inner surface

InactiveUS20080079191A1Improve deposition qualityInexpensively formedMouldsConfectioneryEngineeringMechanical engineering

A movable mold and a slide mold are employed. There is also employed a deposition apparatus which is equipped with a deposition element such as a target electrode in the inside of a depositing chamber. A body portion and a cover member are primarily molded by the movable mold and the slide mold. The molds are opened while the body portion being left in the movable mold and while cover member being left in slide mold. The body portion left in the movable mold is deposited in the molds with its inner surface being covered with the depositing chamber. Next, the slide mold is driven so that the cover member may be registered with the deposited body portion. Then, a secondary molding resin is injected to integrate the body portion and the cover member.

Owner:JAPAN STEEL WORKS LTD

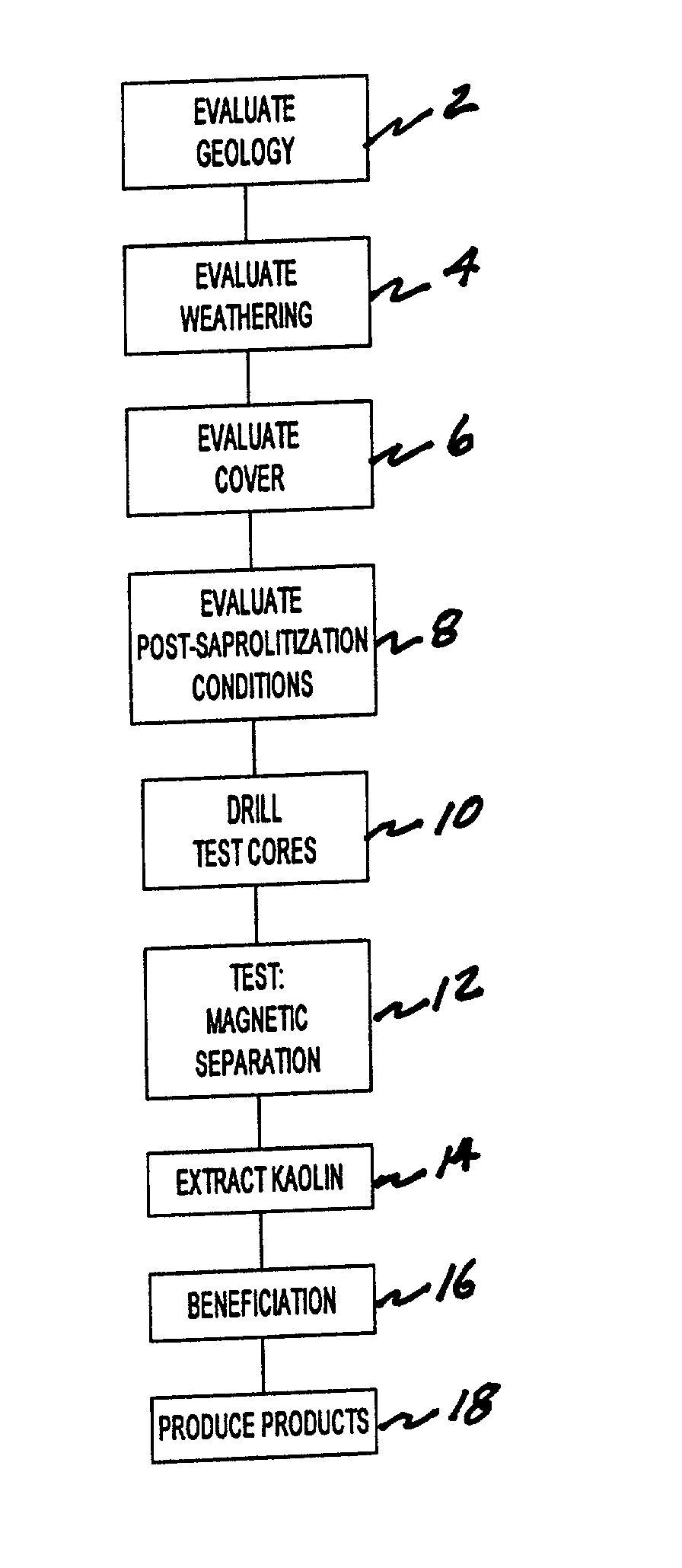

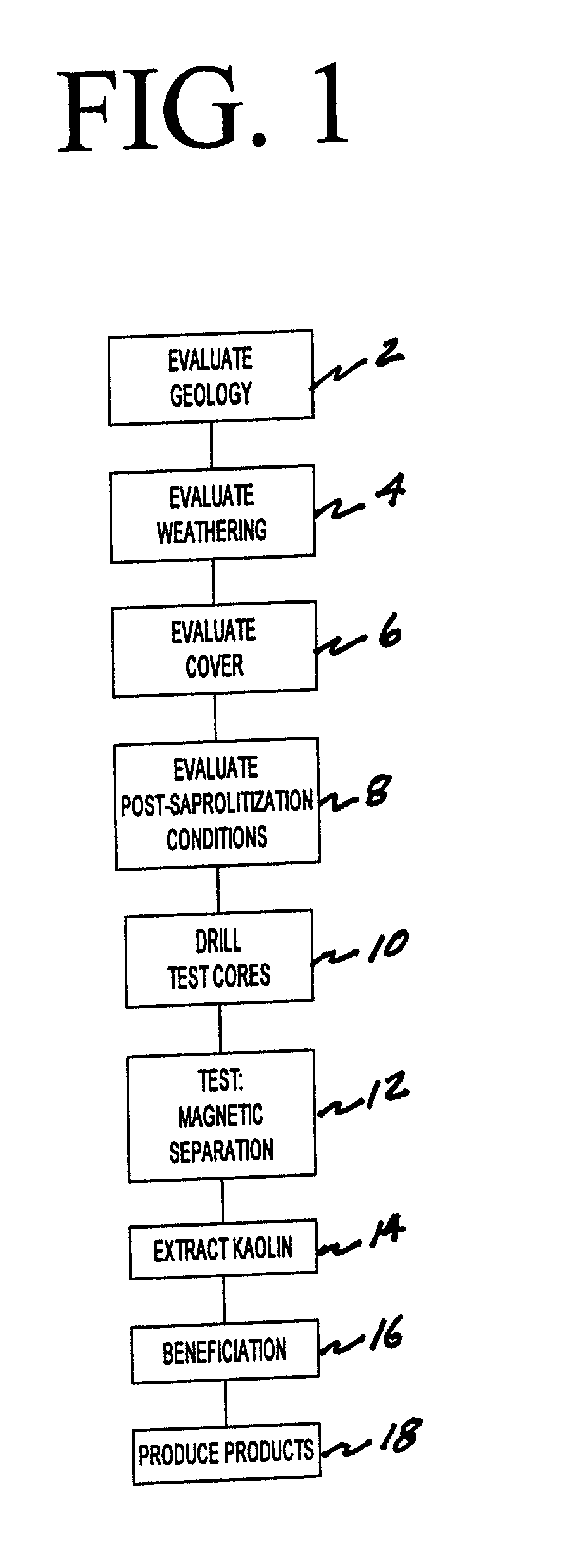

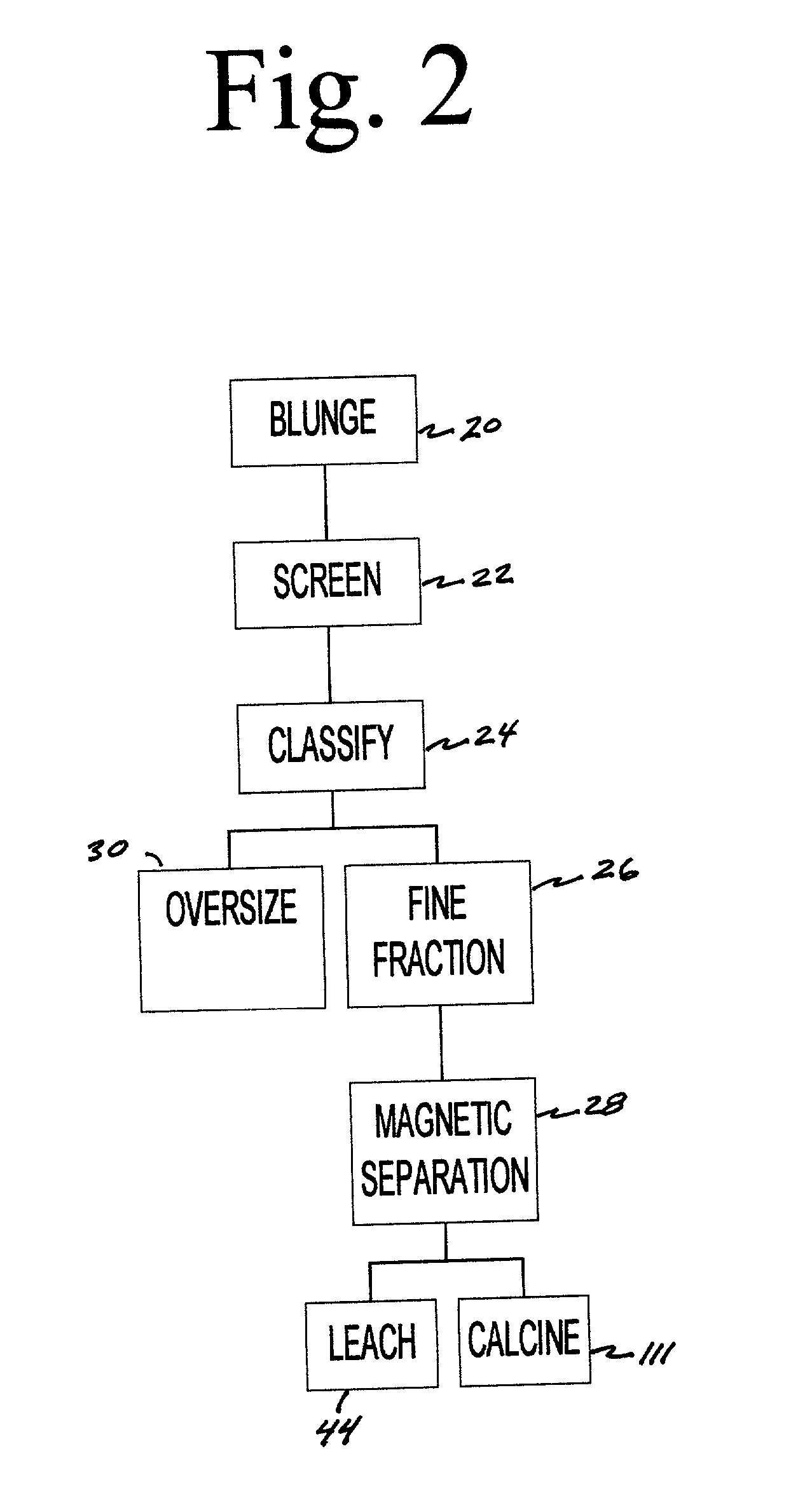

Novel clay and products

InactiveUS20030027708A1High qualitySmall loadNatural cellulose pulp/paperSpecial paperMaterials science

Owner:GINN MICHAEL +1

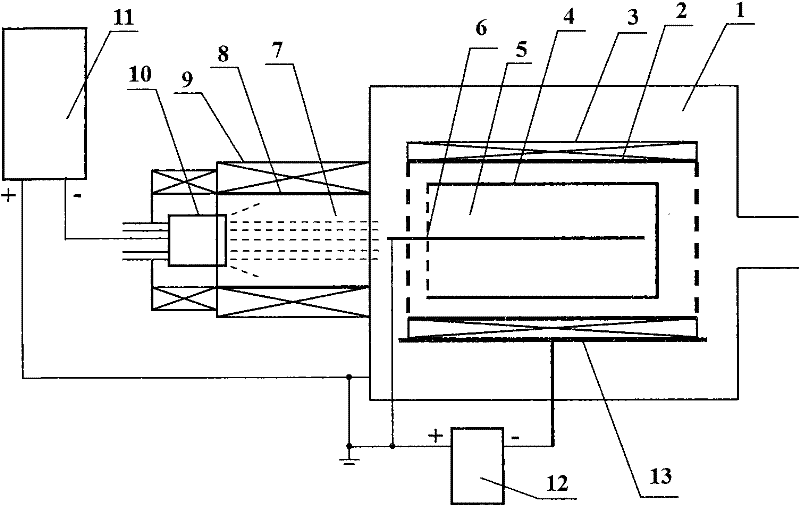

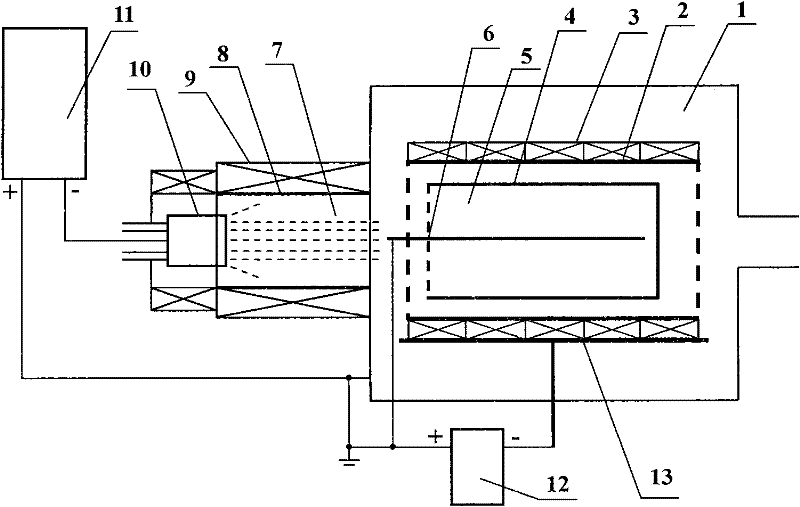

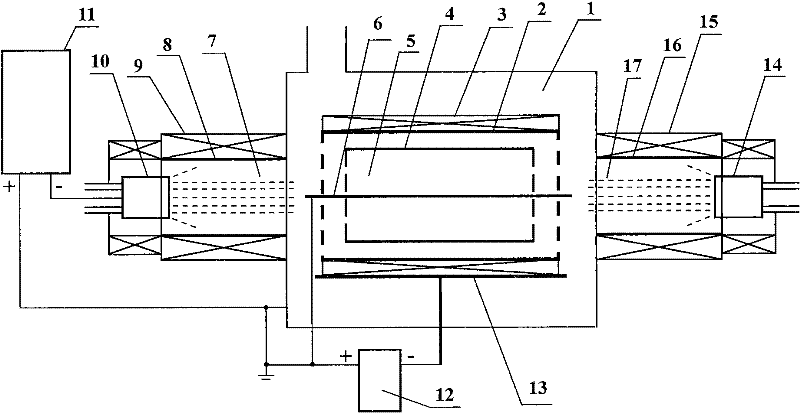

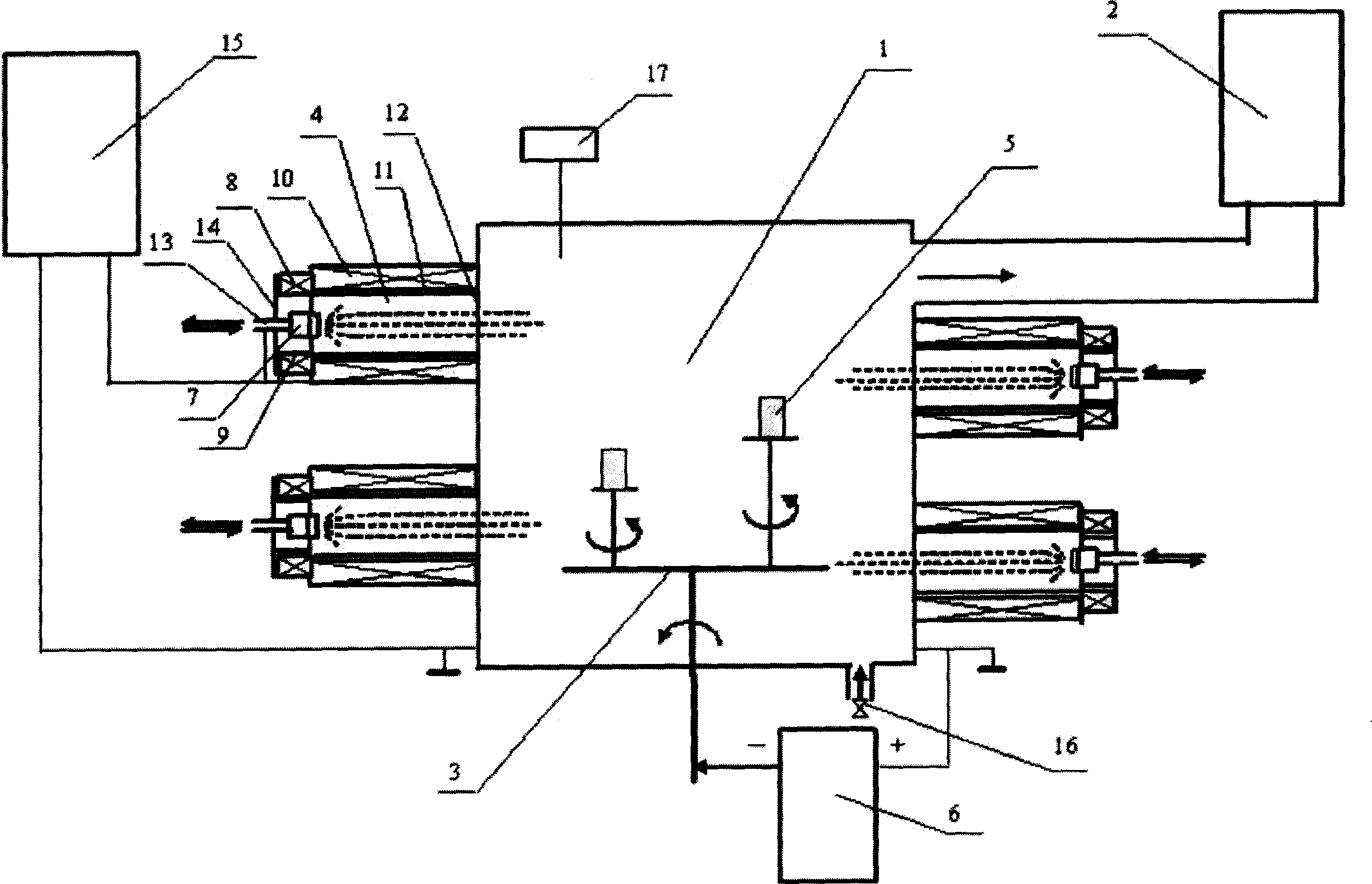

Magnetic field for plating on inner wall of long pipe and field-enhanced arc ion plating device

ActiveCN102345097AGuaranteed Utilization EfficiencyParameters are adjustable and convenientVacuum evaporation coatingSputtering coatingTransmission channelVacuum chamber

The invention, belonging to the field of surface modification on materials, relates to a magnetic field for plating on inner wall of long pipe and a field-enhanced arc ion plating device, characterized in that: the magnetic field is used to restrain and control the plasma beam motion trail in the arc ion plating process, two sets of magnetic field generators are arranged in an arc ion plating deposition device, one set is arranged on the plasma transmission channel outside a vacuum chamber for using the magnetic field to focus the plasma beam and restrain the diameter of cross section and transmission efficiency when transmitting the plasma beam, and the other set is arranged on the outside of a tubular workpiece in the vacuum chamber for guiding the plasma beam to diffuse along with the central axial direction of the tubular workpiece; field enhancement is used in arc ion plating for using the magnetic field to realize accelerated directional flow of plasma, a pulsed electric field is arranged in the workpiece; the magnetic field and electric field are used to restrain and control the plasma beam, so as to realize the coating deposition of the plasma on the inner wall of the tube. The invention is suitable for depositing coatings on the inner wall of tubular workpiece which is used as the service surface.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

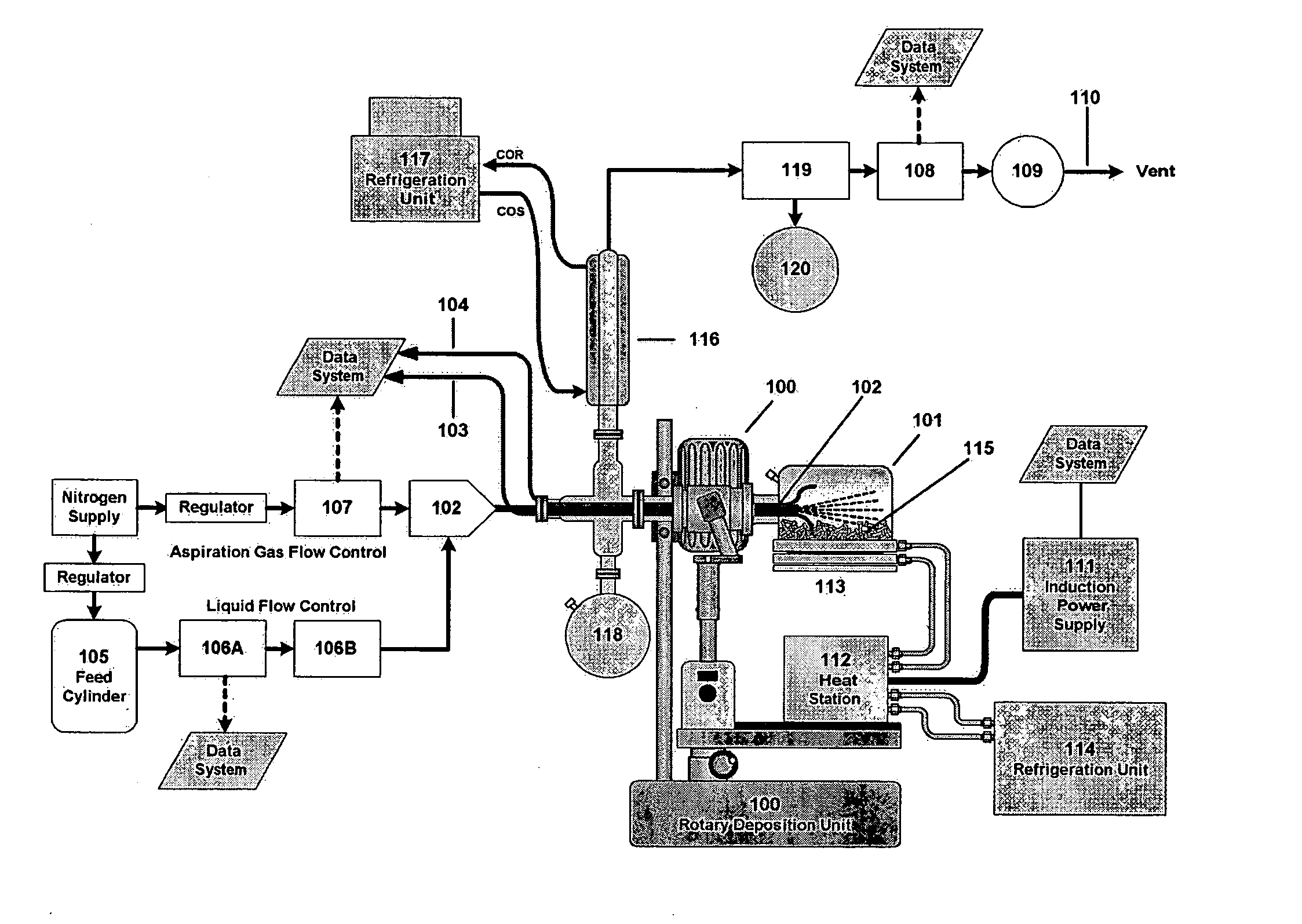

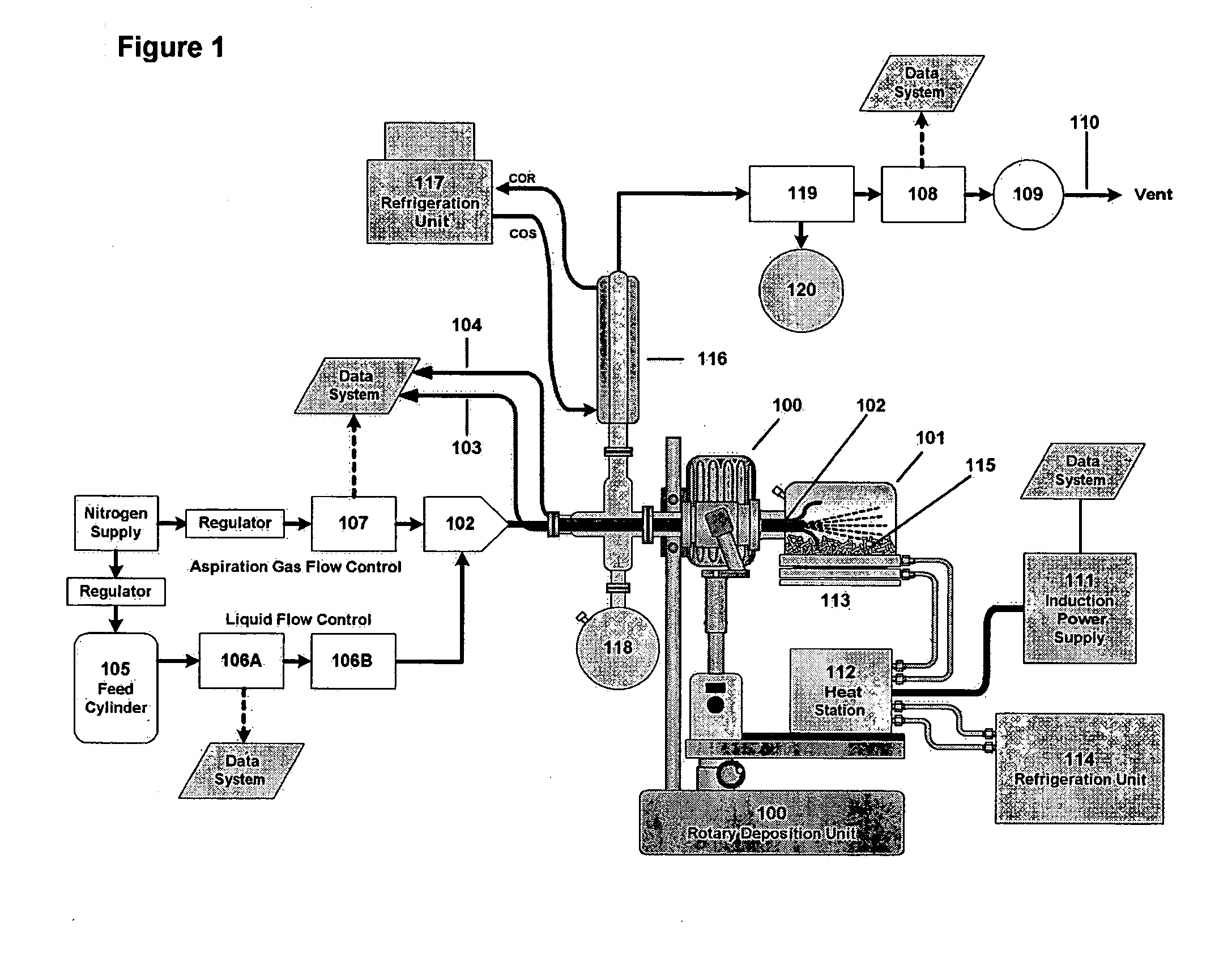

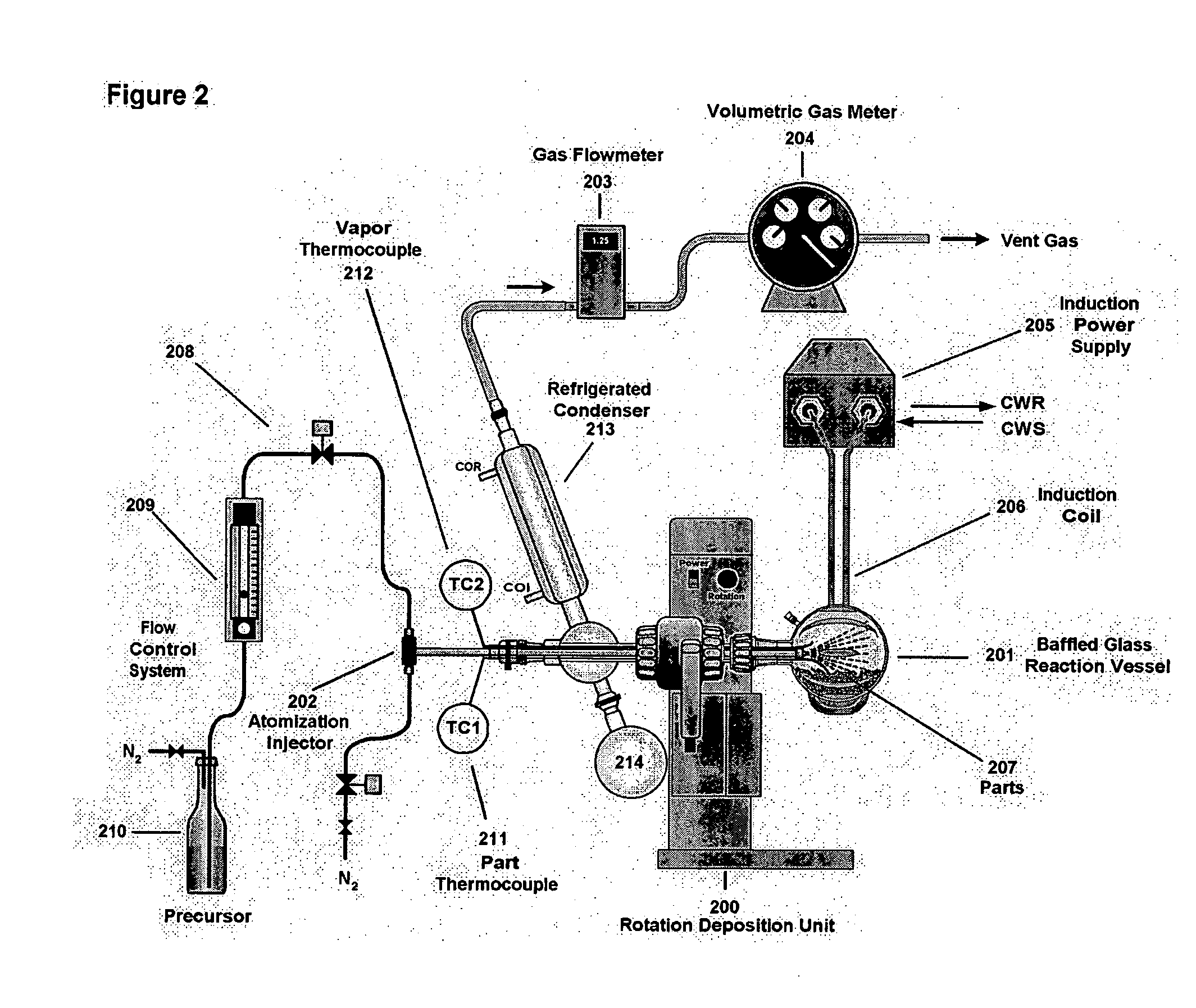

Metallization of substrate(s) by a liquid/vapor deposition process

InactiveUS20050064211A1Improve deposition qualityReduce productionDielectric heatingInduction heatingTemperature controlGas phase

A process for depositing a substantially pure, conformal metal layer on one or more substrates through the decomposition of a metal-containing precursor. During this deposition process, the substrate(s) is maintained at a temperature greater than the decomposition temperature of the precursor while the surrounding atmosphere is maintained at a temperature lower than the decomposition temperature of the precursor. The precursor is dispersed within a transport medium, e.g., a vapor phase. The concentration of the metal-containing precursor(s) in the vapor phase, which also contains liquid therein, can be at a level to provide conditions at or near saturation for the metal precursor(s). In ensuring the aforementioned temperature control between the transport media and substrate, and in maintaining saturation conditions for the transport media, the quality of the deposited metal thin film is markedly improved and the production of by-product metal dust is greatly reduced or substantially eliminated.

Owner:AKZO NOBEL NV

Equipment and method for low temperature depositing high-quality decorative film by electric arc ion plating

ActiveCN1804105AImprove deposition qualityMeet surface coating requirementsVacuum evaporation coatingSputtering coatingLow temperature depositionElectromagnetic field

The arc ion plating and depositing high-quality decorative film method comprises: using cathode arc source with double-EM field to filter large grain and impulse negative bias voltage to control deposition temperature in arc ion plating. Compared with prior art, this invention deposits high-quality Cr, Zr, Ti, Al and alloy or nitrate film or carbide film to meet decorative request and resistance to wear and corrosion, reduces little efficiency, improves quality greatly special the film surface quality, and has wide application.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

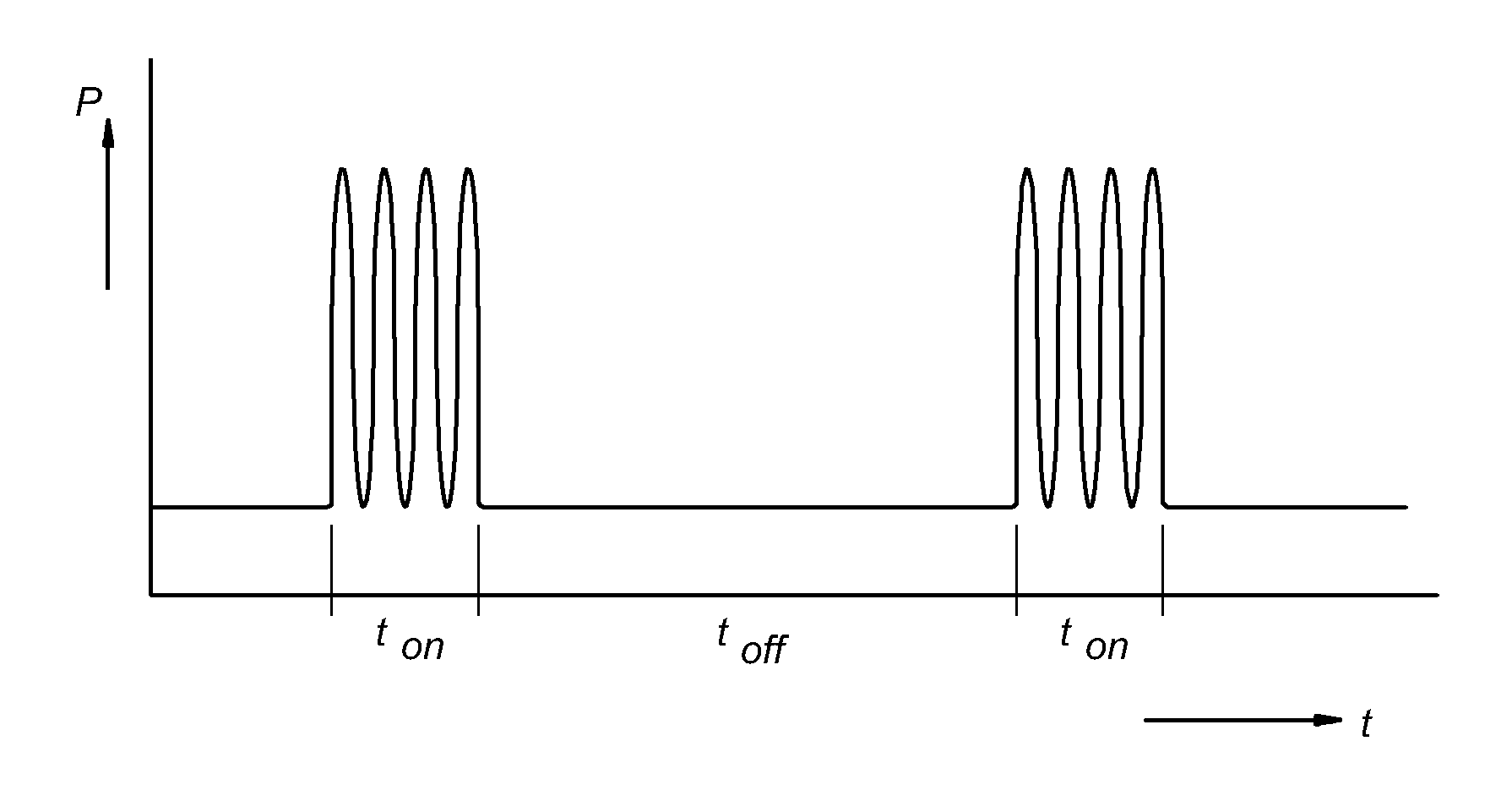

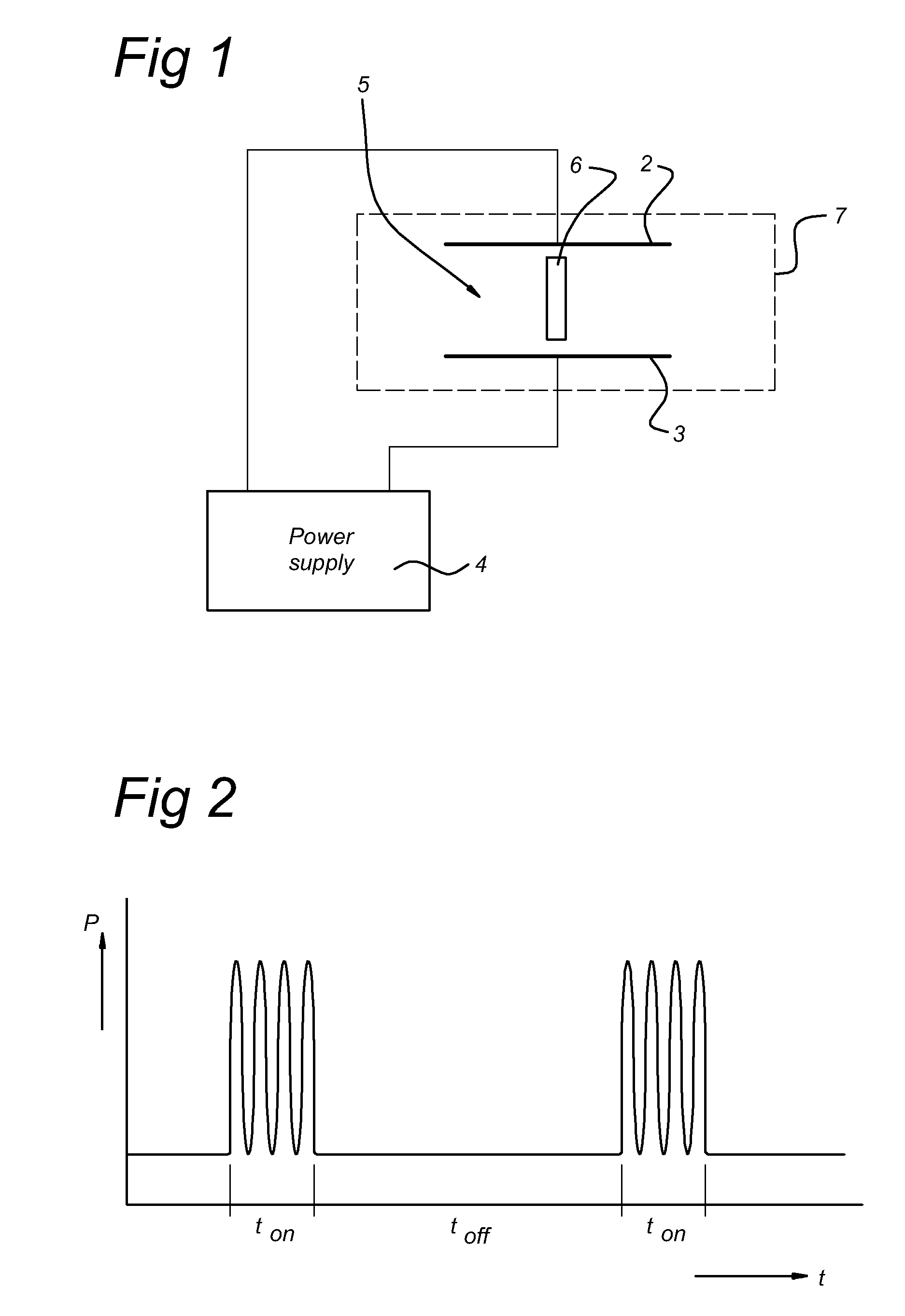

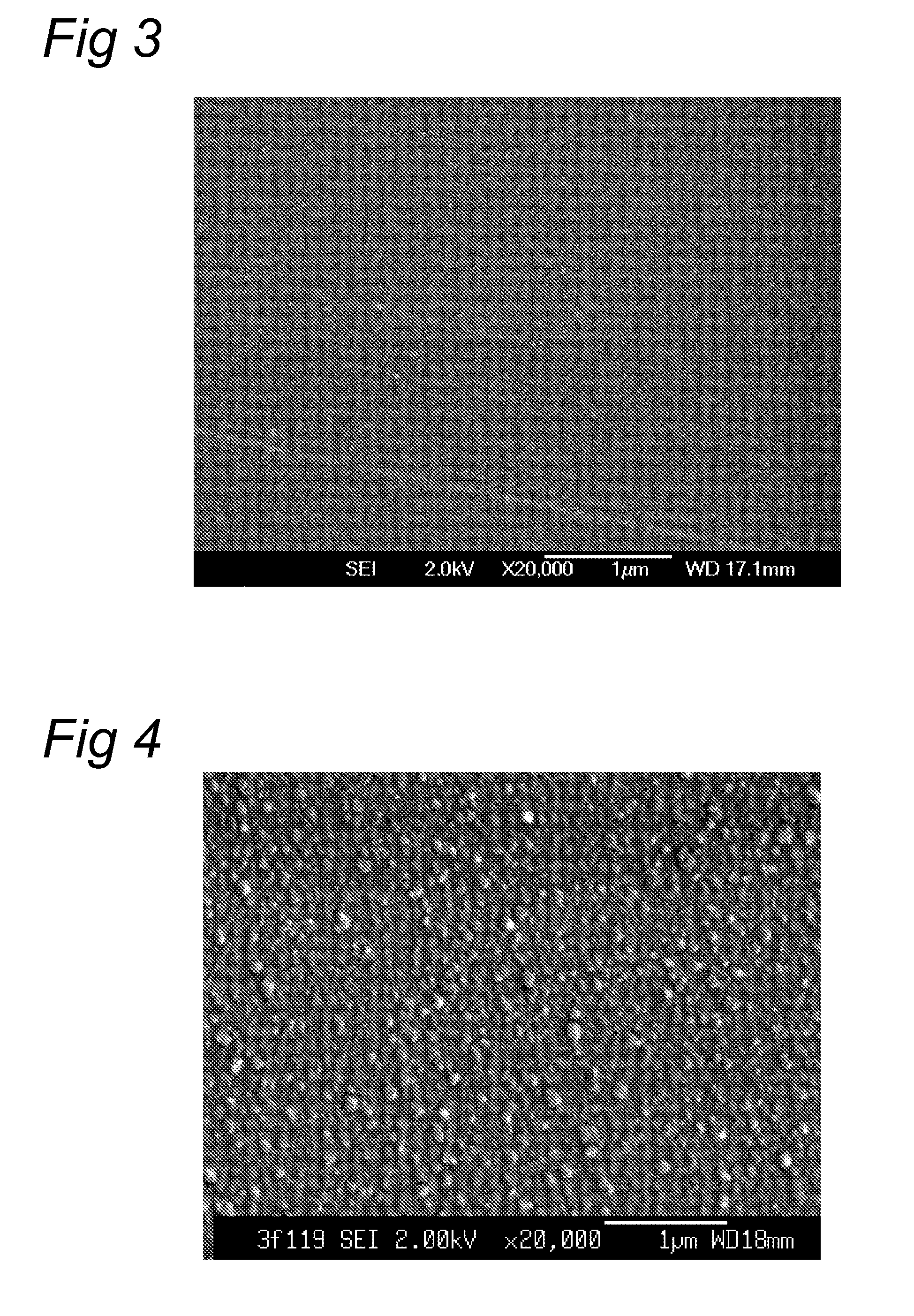

Short pulse atmospheric pressure glow discharge method and apparatus

InactiveUS20090304949A1Restrict formEnhance layeringElectric discharge tubesChemical vapor deposition coatingGas compositionProduct gas

Method and plasma generating apparatus for generating an atmospheric pressure glow discharge plasma in a treatment space (5) filled with a gas composition. Two electrodes (2, 3) are connected to a power supply (4) for providing electrical power during an on-time (ton). The power supply (4) is arranged to provide a periodic signal with an on-time (ton) which is shorter than a predetermined time period, the predetermined time period corresponding substantially to the time necessary for a dust coagulation center from the gas composition to become a cluster in the treatment space (5). This method and apparatus may be used for depositing a layer of material on a substrate (6) in the treatment space (5).

Owner:FUJIFILM MFG EURO

Cladding device for water-cooling wall of circulating fluidized bed boiler

ActiveCN103276392AGuaranteed deposition qualityHigh operating costsMetallic material coating processesCombustionFluidized bed

The invention relates to a cladding device for a water-cooling wall of a circulating fluidized bed boiler, aiming at solving the problems that the existing circulating fluidized bed boiler produces a great deal of material during combustion, and the heating surface of a hearth is scoured by the material, so that the water-cooling wall of the boiler is seriously corroded, and the safe running of the boiler is influenced; and when being used for cladding the water-cooling wall of the circulating fluidized bed boiler, the traditional cladding technology has the problem that the cladding efficiency is low, the quality of the clad surface is poor, the labor intensity of workers is high, the work environment is poor and radiation to the human body is high. A melting gun swing device is arranged at one side of the upper end of a connecting plate, and a driving motor is arranged at the other side of the connecting plate; the driving motor is connected with the melting gun swing device in a transmission way; the front end of the melting gun swing device is provided with a melting gun; and the driving motor is connected with a computer by a control circuit. The cladding device is used for cladding the water-cooling wall of the circulating fluidized bed boiler.

Owner:HARBIN KENENG CLADDING TECH

Sputtering target and process for producing the same

InactiveUS7344660B2Eliminate the problemImprove production yieldPig casting plantsConductive materialSulfurVolumetric Mass Density

A manufacturing method of a sputtering target having mainly oxychalcogenide containing La and Cu by sintering at least one or more powders selected from an elementary substance of a constituent element, oxide or chalcogenide as the raw material, characterized in including a reaction step of retaining the [material] at a temperature of 850° C. or less for 1 hour or more during the sintering step, wherein this [material], after the reaction step, is subject to pressure sintering at a temperature that is higher than the reaction step temperature. In addition to increasing the density of a P-type transparent conductive material target having mainly oxychalcogenide containing La and Cu and enabling the enlargement of the target at a low manufacturing cost, the existence of unreacted matter in the target can be eliminated, the production yield can be improved by suppressing the generation of cracks in the target, and the quality of deposition formed by sputtering this kind of target can also be improved.

Owner:JX NIPPON MINING & METALS CORP

Paraxial powder-feeding working head for laser powder processing

ActiveCN103526199AInput satisfiesPrecise control of flow rateMetallic material coating processesFixed frameMetallurgy

The invention relates to a paraxial powder-feeding working head for laser powder processing. The paraxial powder-feeding working head comprises a powder-gas separator, a powder-gas input chamber, a fast-plug connector, a powder collecting chamber, a first powder conveying tube, a processing gas input chamber, a processing gas collecting piece, a processing gas input joint, a fixed frame, a second powder conveying tube, a third powder conveying tube and a powder spray nozzle, wherein the processing gas collecting piece is a gradual-contraction funnel shaped component; a throttle valve is used for outputting a powder-carrying gas input by a powder feeder; a stainless steel wire net is arranged at the front end of the throttle valve. According to the paraxial powder-feeding working head disclosed by the invention, separation of metal powder and conveyed powder-carrying gas is realized, so that on one hand, outflow rate of the metal powder from the spray nozzle is lowered to ensure stability of powder conveying amount, and therefore, stable powder output amount requirements in laser powder processing processes of laser cladding, and the like are satisfied; on the other hand, a gas different from the powder-carrying gas is input from the processing gas input joint to achieve a purpose of protecting a processing piece; meanwhile, powder spraying speed of the powder feeding spray nozzle can be adjusted in an assisted manner, so that processing effect is controlled better.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Ruthenium-Alloy Sputtering Target

ActiveUS20090114535A1Increasing target strengthImprove sintered densityCellsVacuum evaporation coatingSputteringVolumetric Mass Density

Provided is a ruthenium alloy sputtering target as a ruthenium alloy sintered compact target obtained by sintering mixed powder of ruthenium powder and metal powder capable of creating oxides easier than ruthenium, wherein purity of the target excluding gas components is 99.95 wt % or higher, said target contains 5 at % to 60 at % of metal capable of creating oxides easier than ruthenium, relative density is 99% or higher, and oxygen content as impurities is 1000 ppm or less. This ruthenium alloy sputtering target is capable of reducing its oxygen content, reducing the generation of arcing and particles during sputtering, increasing the target strength by improving the sintered density, and improving the deposition quality by strictly restricting the amount of B and P impurities in the target in order to prevent the compositional variability of B and P added in minute amounts to the Si semiconductor.

Owner:JX NIPPON MINING& METALS CORP

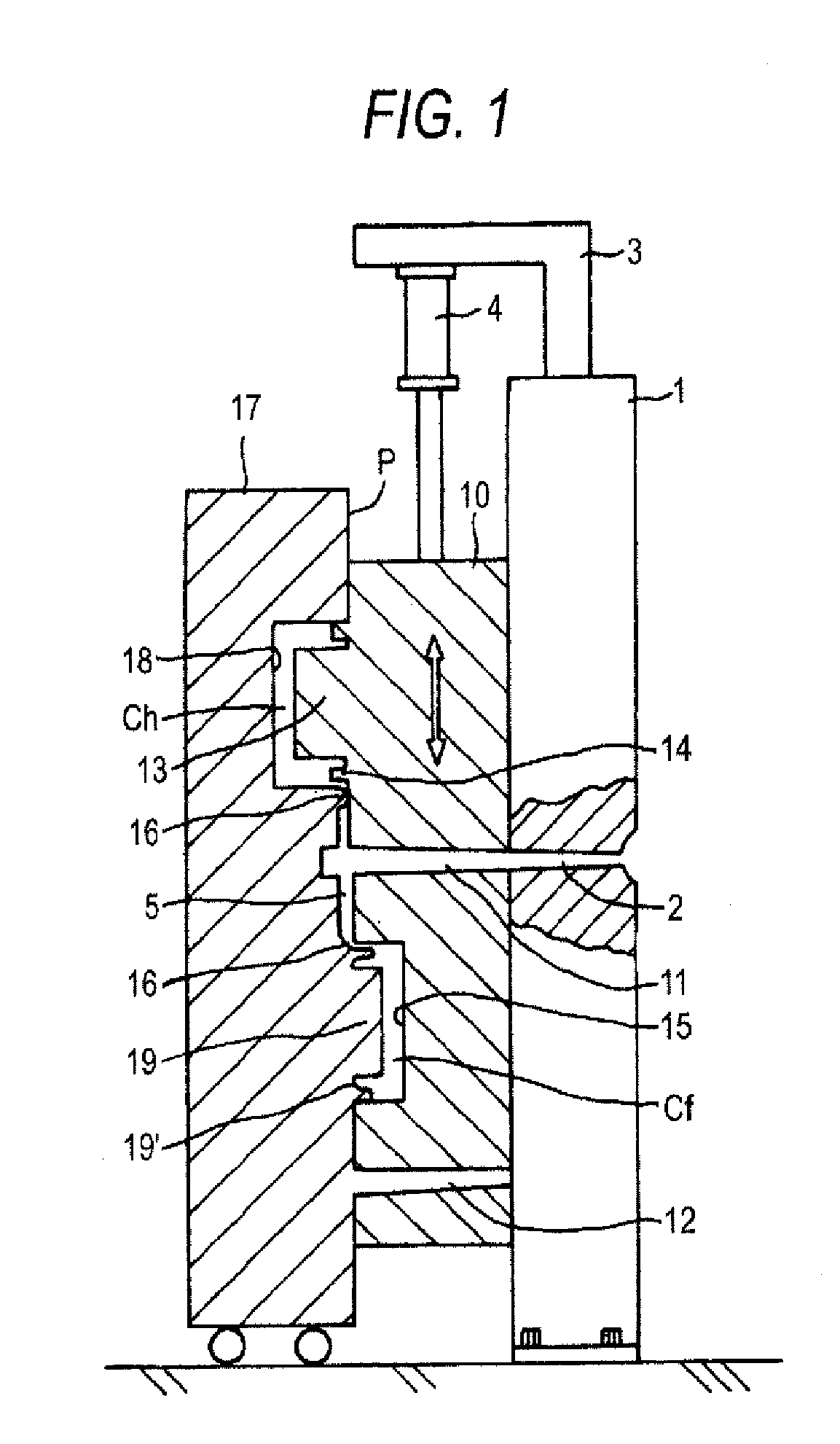

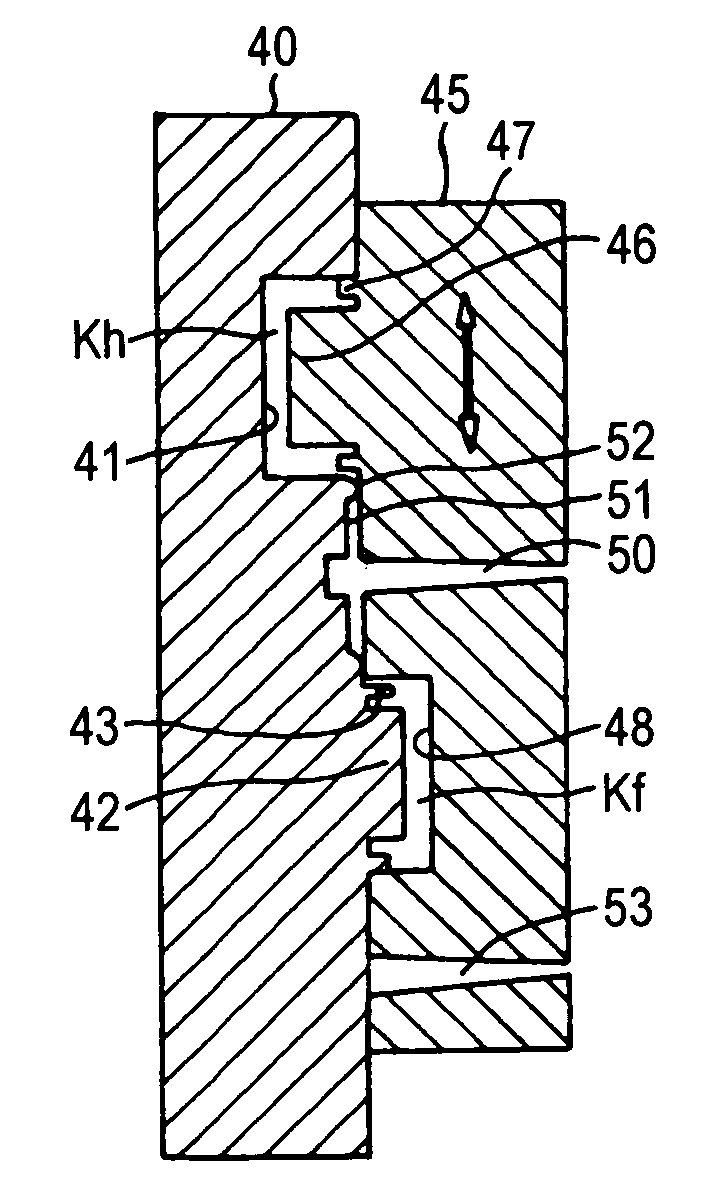

Method and apparatus for forming hollow moldings having thin film on inner surface

InactiveUS20080079192A1Improve deposition qualityAutomatically formedTailstocks/centresMouldsBiomedical engineeringMolten metal

The method employs a stationary mold having depositing recesses equipped in its inside with a deposition element such as a target electrode, and movable molds made slidable. A primary molding is performed to form a body portion and a cover member to have joint portions around their opening. The body portion left in the vertically sliding mold is deposited after it was densely covered with the depositing recesses. Next, the deposited body portion and the cover member, as left in the molds, are registered and mold clamped, and the molten metal is injected to integrated the joint portions.

Owner:JAPAN STEEL WORKS LTD

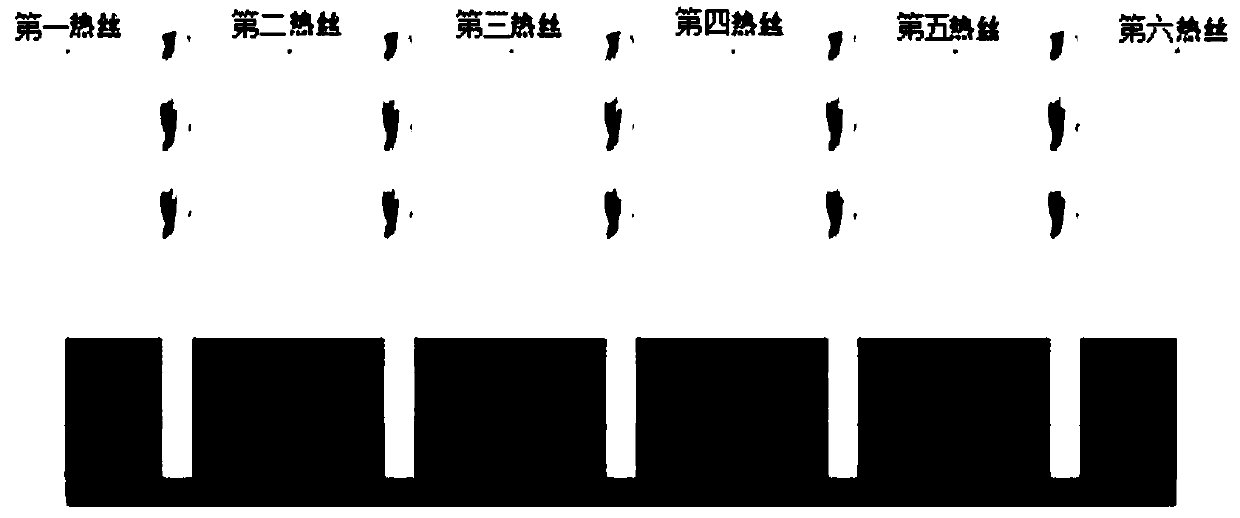

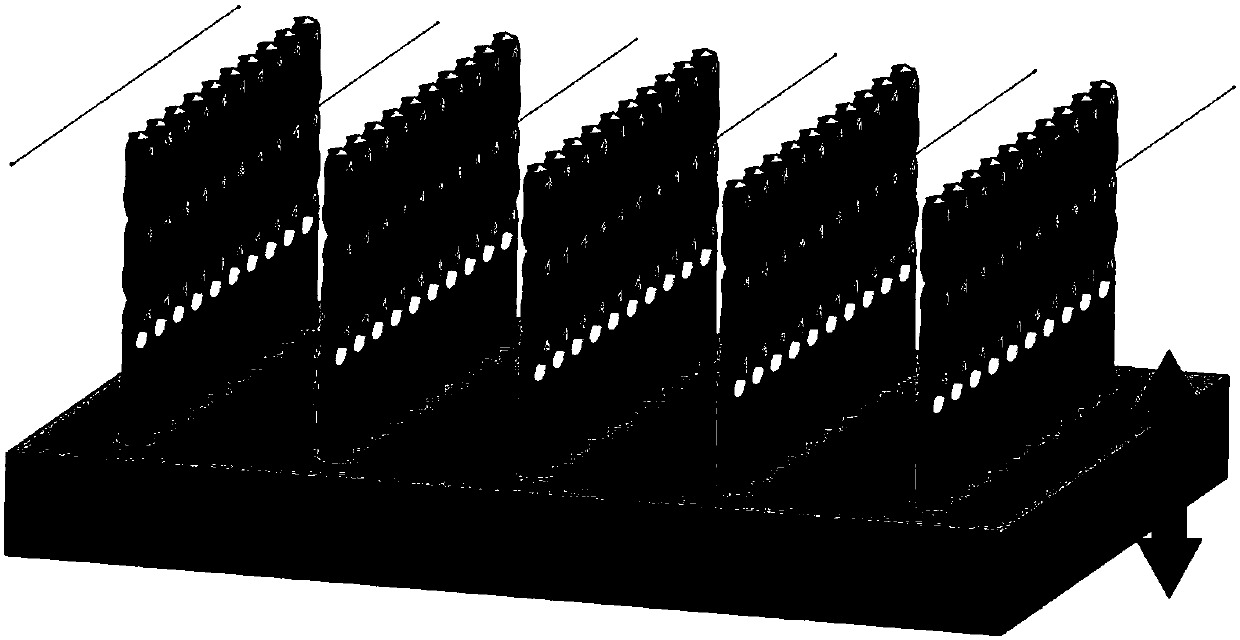

HFCVD batch preparation method of complex-shaped diamond-coated cutter

ActiveCN108559970AEvenly distributedQuality improvementChemical vapor deposition coatingHydrogenCarbon impurities

The invention discloses an HFCVD batch preparation method of a complex-shaped diamond film coated cutter. A handle of the complex-shaped cutter after being pretreated is inserted into a cutter coolingbase to be placed on the water-cooled workbench of HFCVD equipment. The cutter cooling base is formed by optimally matching a molybdenum sheet layer, a graphitic layer, a red copper layer or a stainless steel layer, and a drill hole matched with the handle in diameter and length is formed in the cutter cooling base. The HFCVD equipment adopts a single-layer hot filament. In the cutter mounting and film growing processes, the HFCVD equipment can realize free lifting of the cutter cooling base by controlling the lifting of the water-cooled workbench. Hydrogen, a carbon source and a doped sourceenter into the surface of the complex-shaped cutter to deposit a single-layer or composite diamond film. The HFCVD batch preparation method can conveniently and effectively control the temperature value of the blade area of the cutter, ensures the uniform distribution of a temperature field and a density field of a reactive group, ensures the uniform deposition of the diamond film, and avoids ofdepositing carbon impurities on the handle position to cause the phenomenon of a black bar.

Owner:SHANGHAI JIAO TONG UNIV

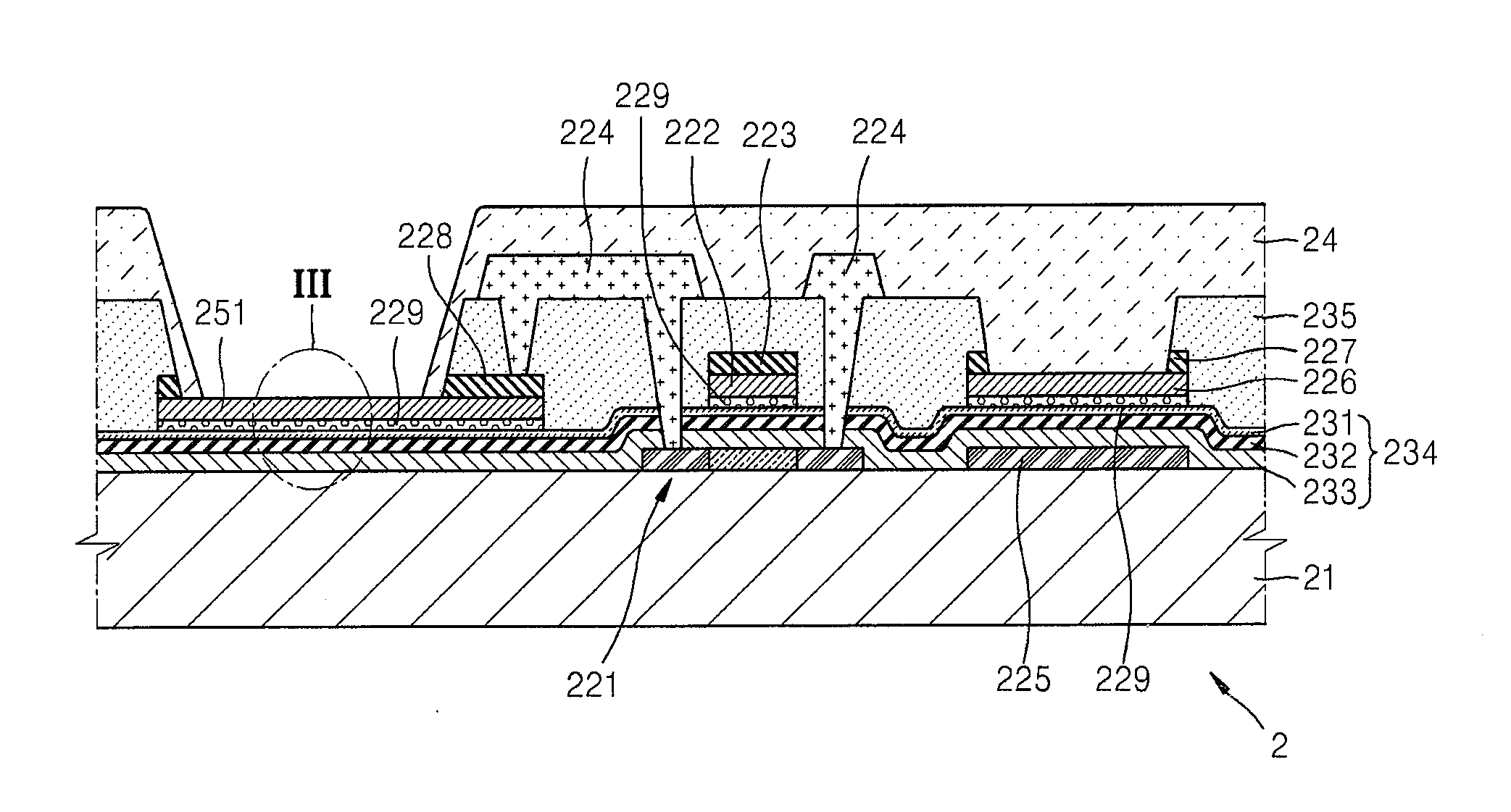

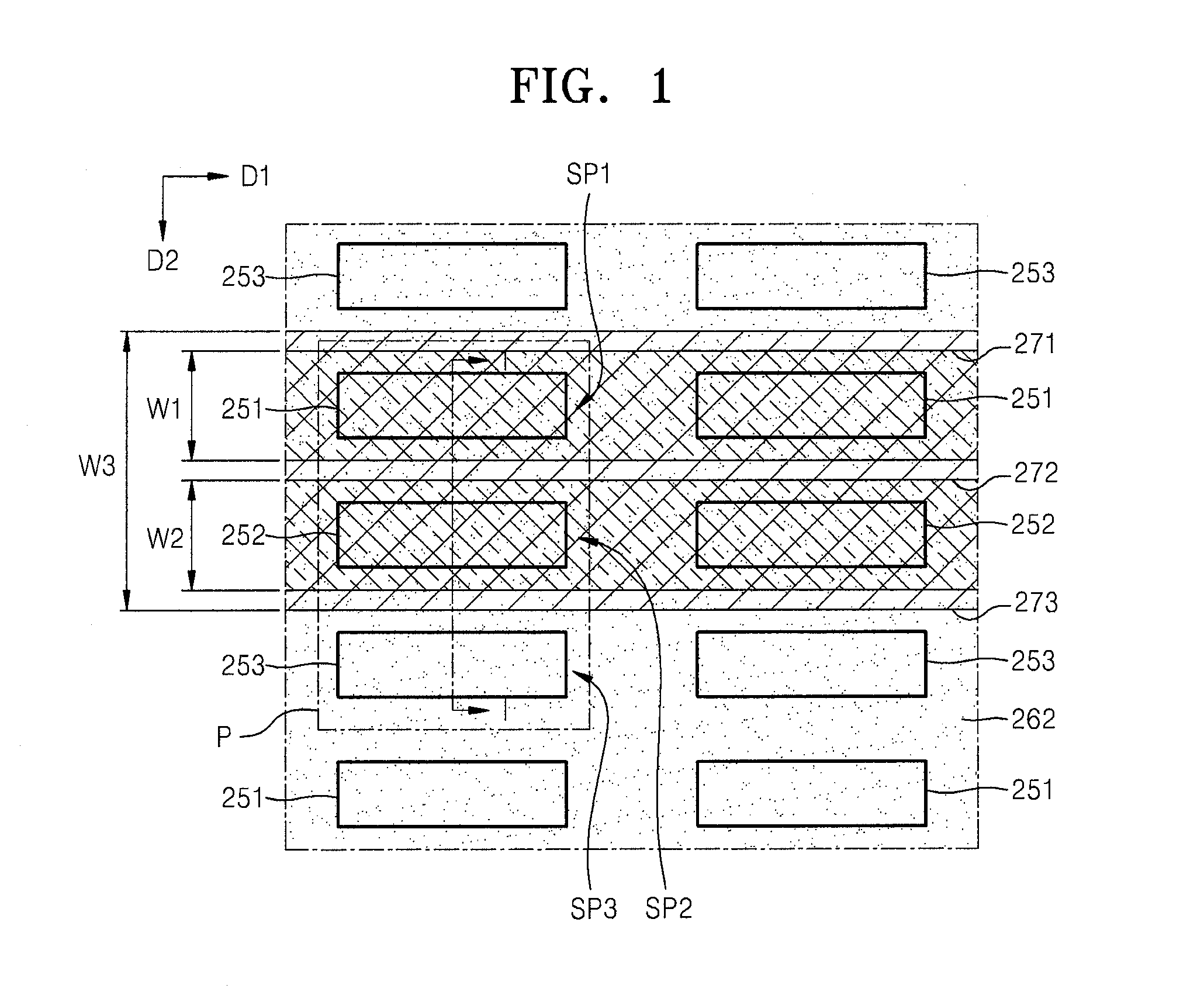

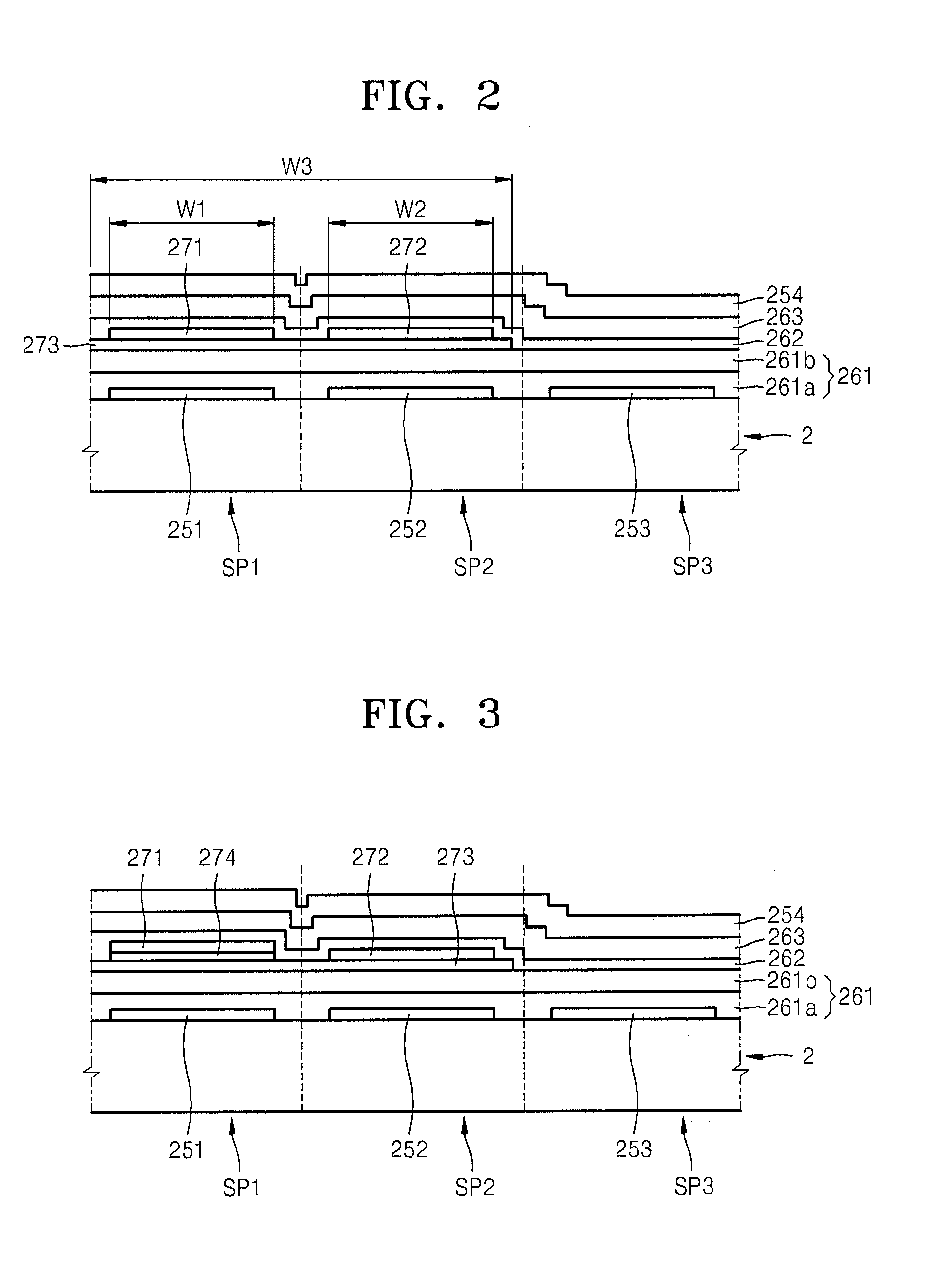

Organic light-emitting display apparatus and method of manufacturing the same

ActiveUS20140048781A1Solve low luminous efficiencyDevice property can be enhancedSolid-state devicesVacuum evaporation coatingEngineeringMaterials science

An organic light-emitting display apparatus includes a substrate comprising pixels, each of which comprises a first sub-pixel, a second sub-pixel, and a third sub-pixel, and a plurality of pixel electrodes independently formed for respective sub-pixels; a first common layer commonly formed on the pixels; first lines covering first sub-pixels arranged in a first direction, wherein the first lines comprise a first organic light-emitting layer; a plurality of second lines covering second sub-pixels arranged in the first direction, wherein the second lines comprise a second organic light-emitting layer differing from the first organic light-emitting layer; a second common layer commonly formed on the plurality of pixels, wherein the second common layer comprises a third organic light-emitting layer differing from the first organic light-emitting layer and the second organic light-emitting layer; a third common layer commonly formed on the pixels; and an opposite electrode commonly formed on the pixels.

Owner:SAMSUNG DISPLAY CO LTD

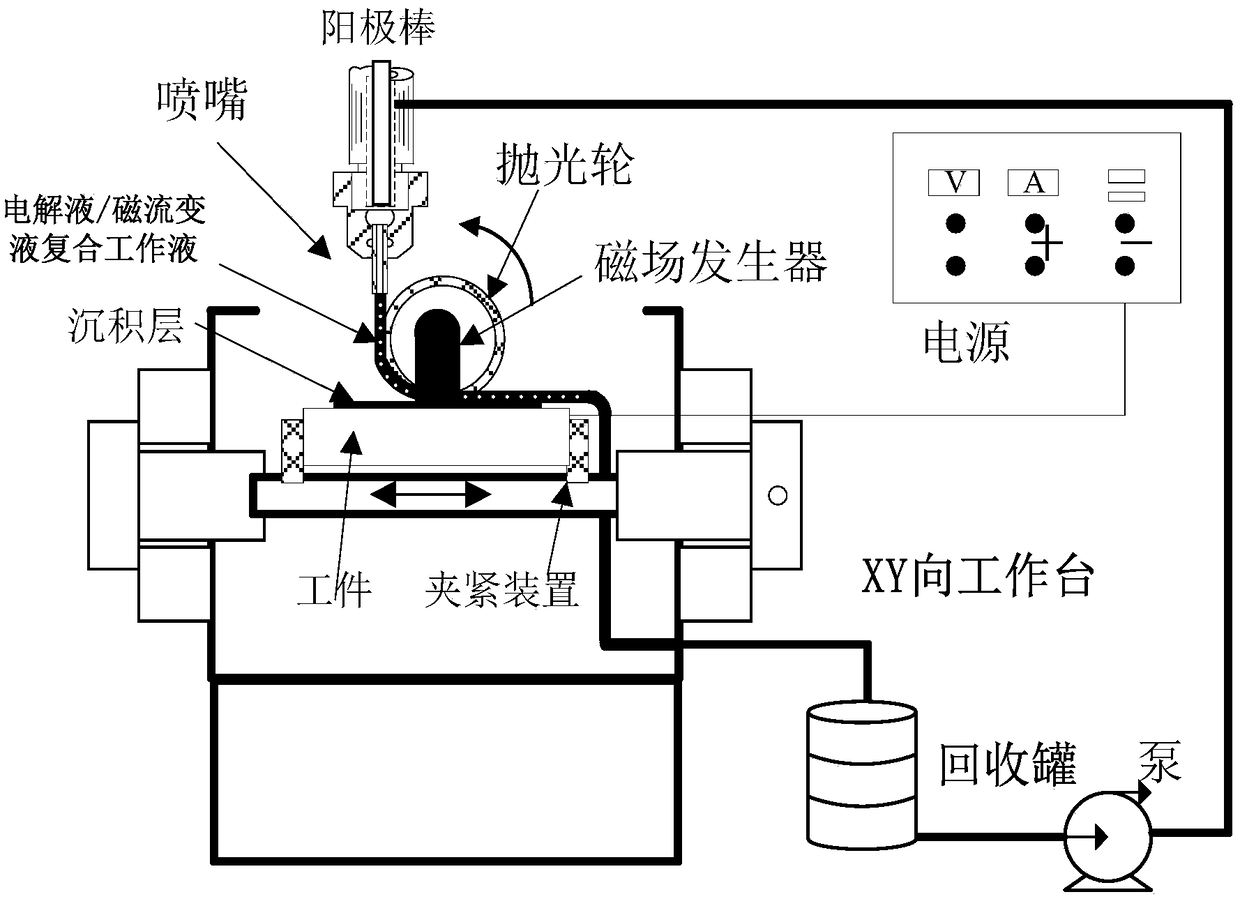

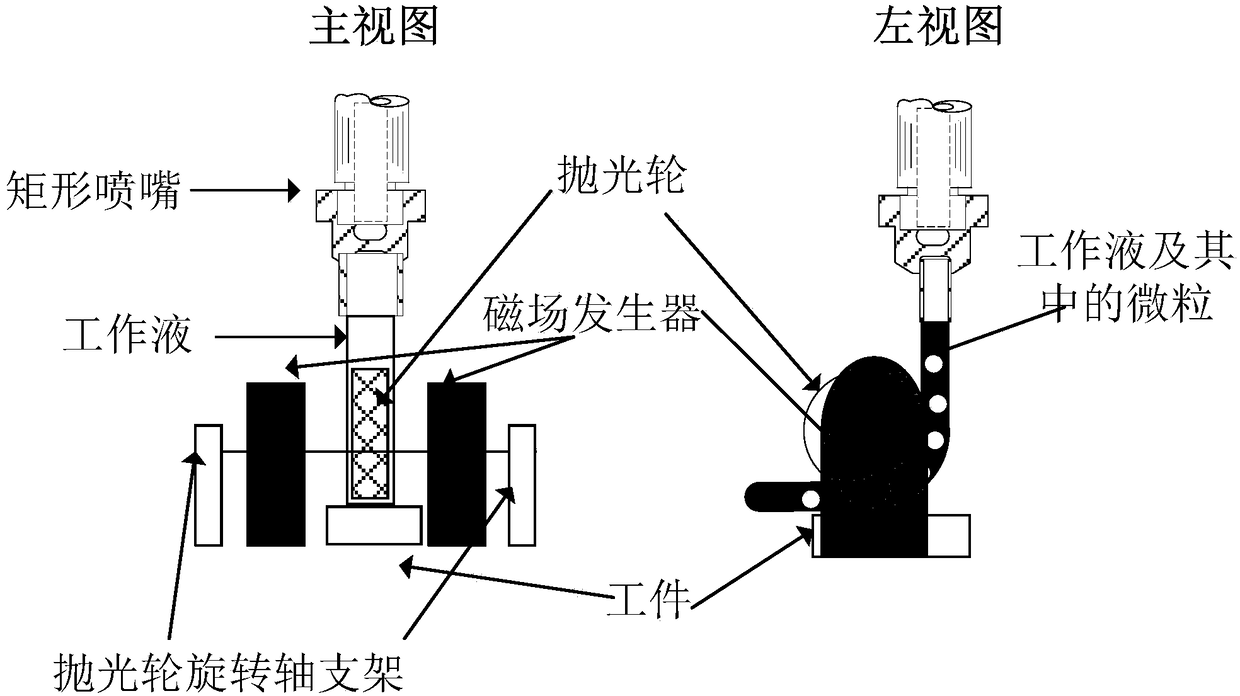

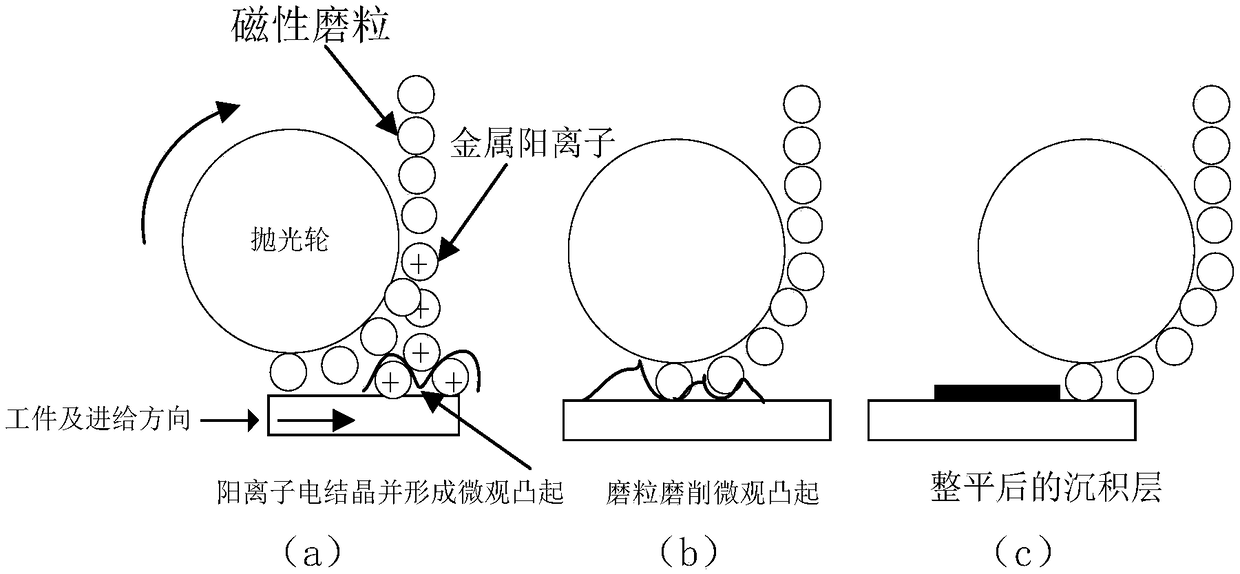

Simple and easy magnetorheological-jet electrodeposition processing method and device

InactiveCN109112593AHigh polishing precisionImprove polishing qualityEdge grinding machinesCellsNumerical controlEngineering

The invention discloses a simple and easy magnetorheological-jet electrodeposition composite processing device. The simple and easy magnetorheological-jet electrodeposition composite processing deviceis characterized in that the selection scope of a numerical control platform is provided; a simple working liquid circulating system, a combination jig, a working liquid recycling device, a magneticfield control device, a polishing wheel and a drive device fixing device are designed; a simple and easy operation principle and a method are designed.

Owner:XUZHOU NORMAL UNIVERSITY

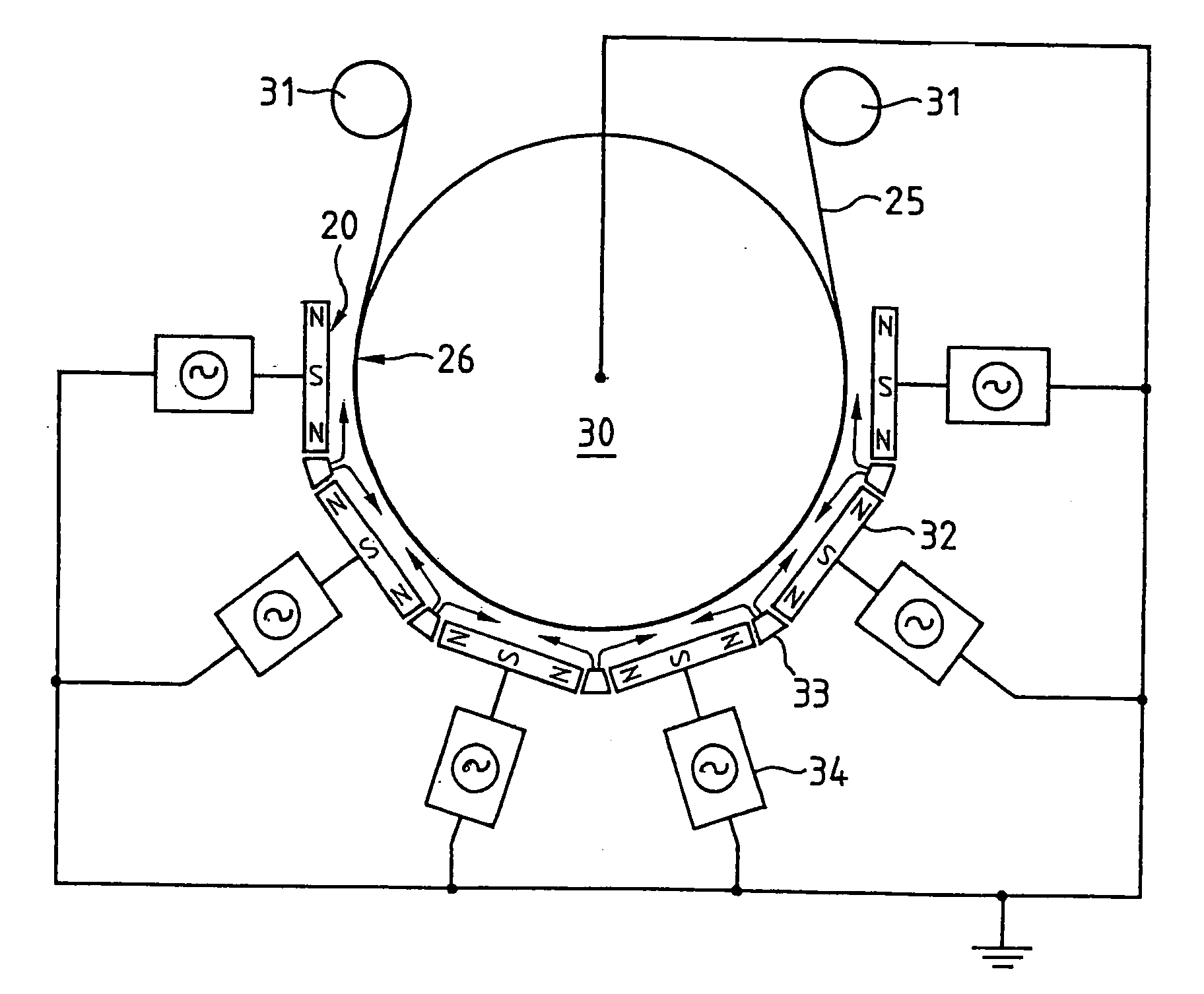

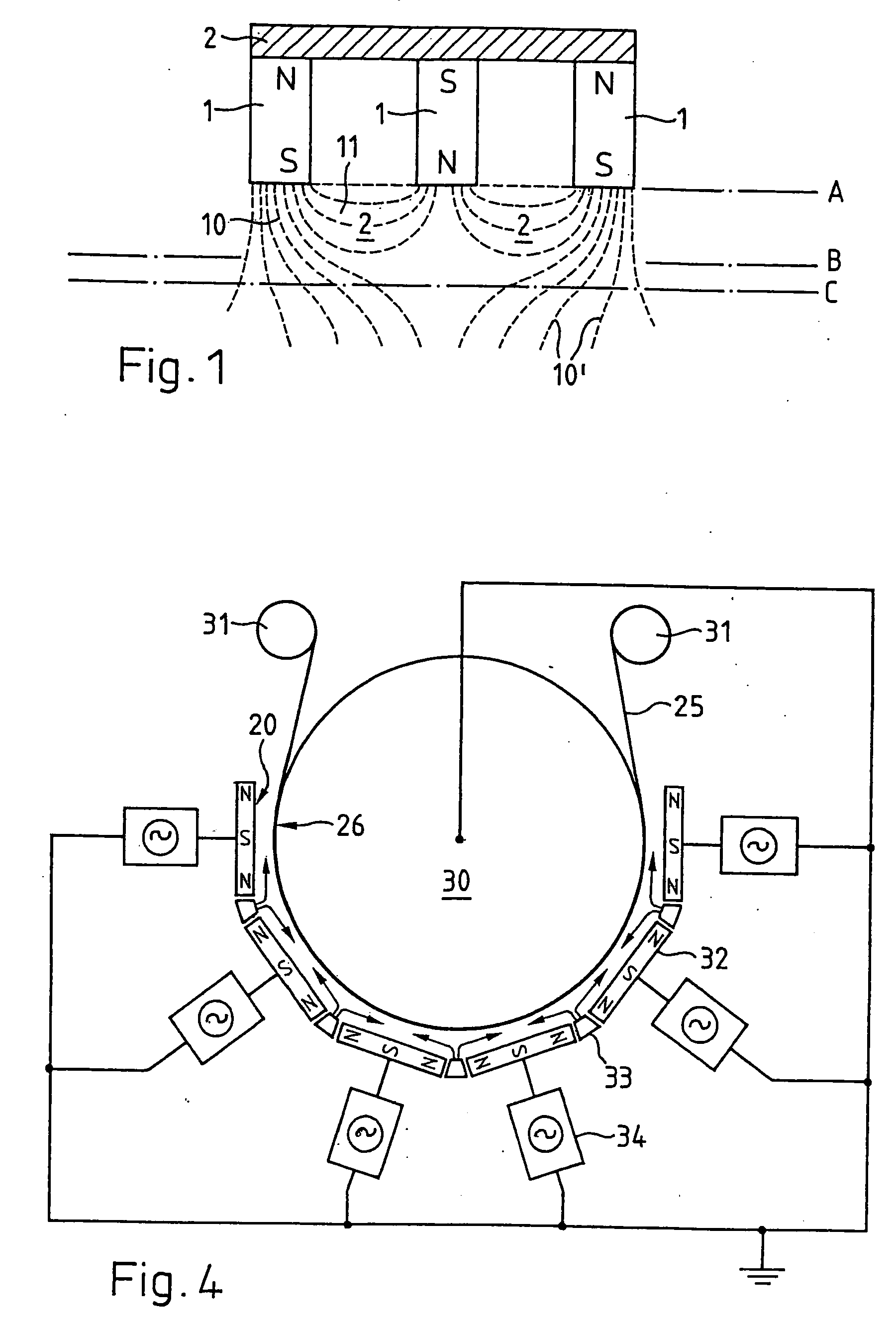

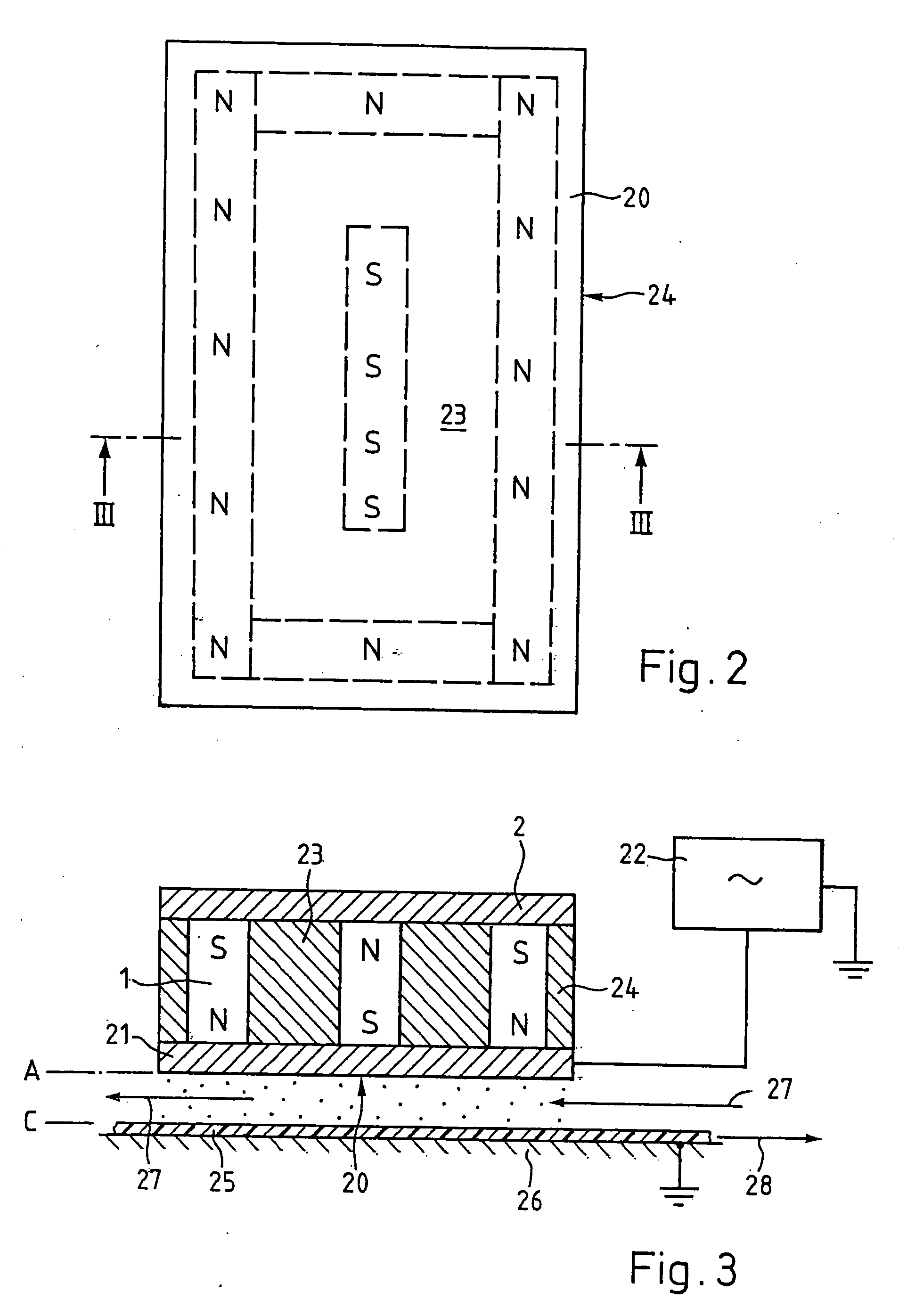

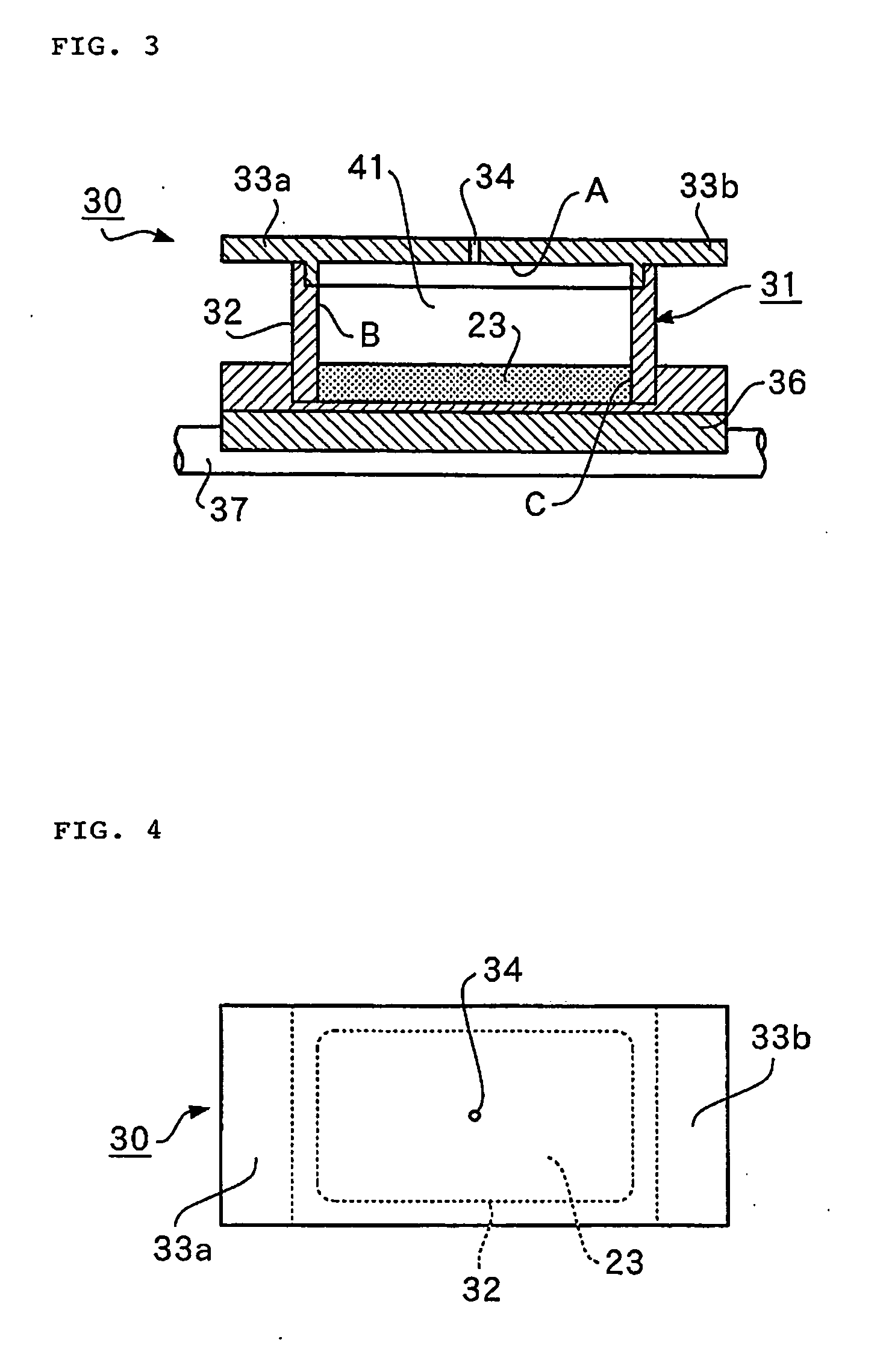

Device for carrying out a plasma-assisted process

InactiveUS20060008593A1Increase depositionImprove deposition qualityElectric discharge tubesSolid state diffusion coatingElectrical polarityMagnetic poles

A device for carrying out a plasma enhanced process includes, within a vacuum chamber, at least one magnetron electrode (32) constituting an unbalanced magnetron having a flat magnetron face (20) with peripheral and central magnetic poles of opposite polarities connected to a source (34) of alternating voltage. The device further includes a device for positioning a substrate (25), the substrate having a surface to be treated facing the magnetron face (20), and a gas supply device for supplying a process gas or process gas mixture to the space between the magnetron face (20) and the treated surface. The distance between the magnetron face (20) and the treated surface is adapted to the magnetic field created by the magnetron electrode (32) such that there is a visible plasma band running between darker tunnels formed by magnetic field lines extending between peripheral and central magnetic poles of the magnetron face (20) and the treated surface, the plasma band having a minimum width but having homogeneous brightness towards the treated surface.

Owner:TETRA LAVAL HLDG & FINANCE SA

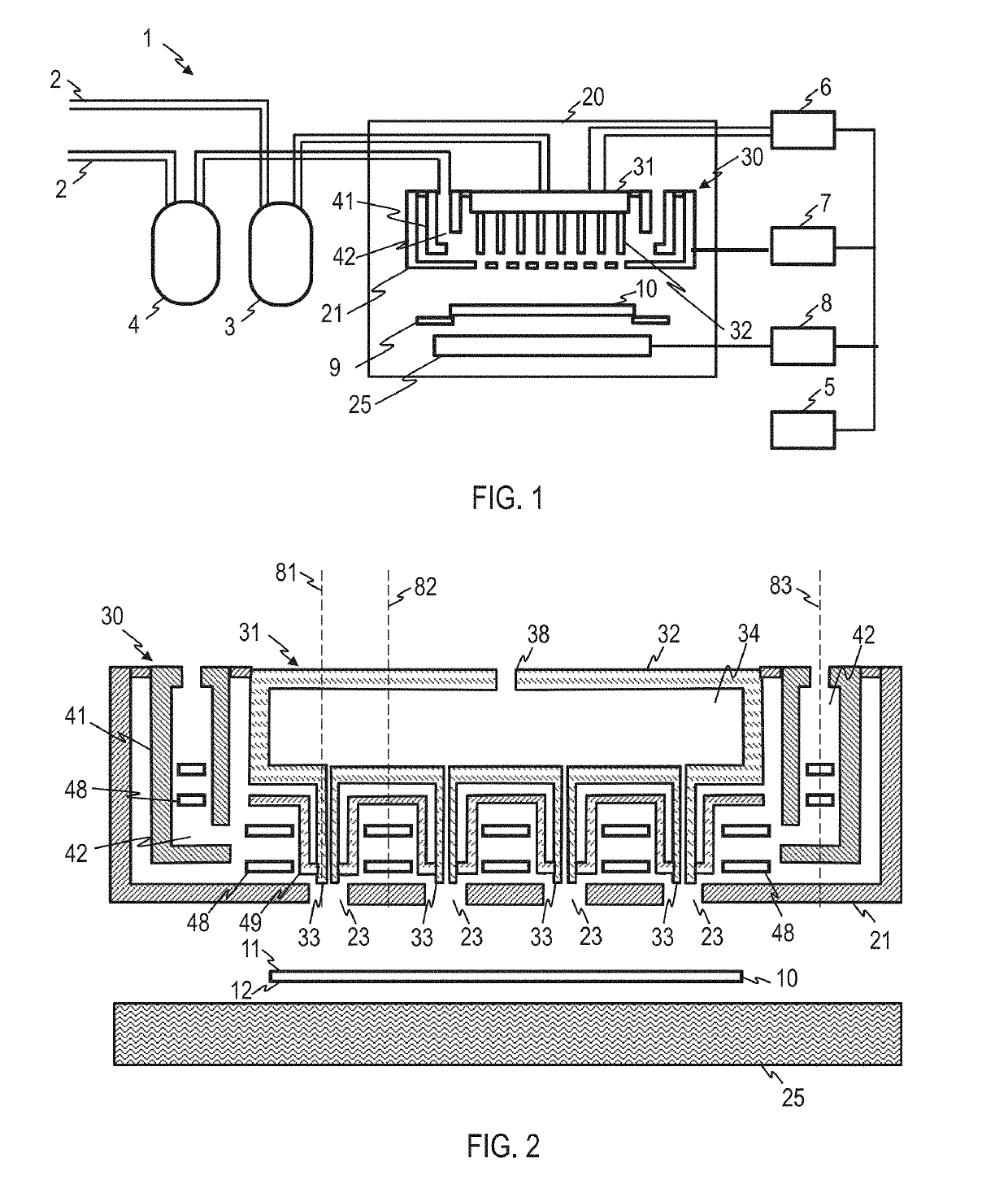

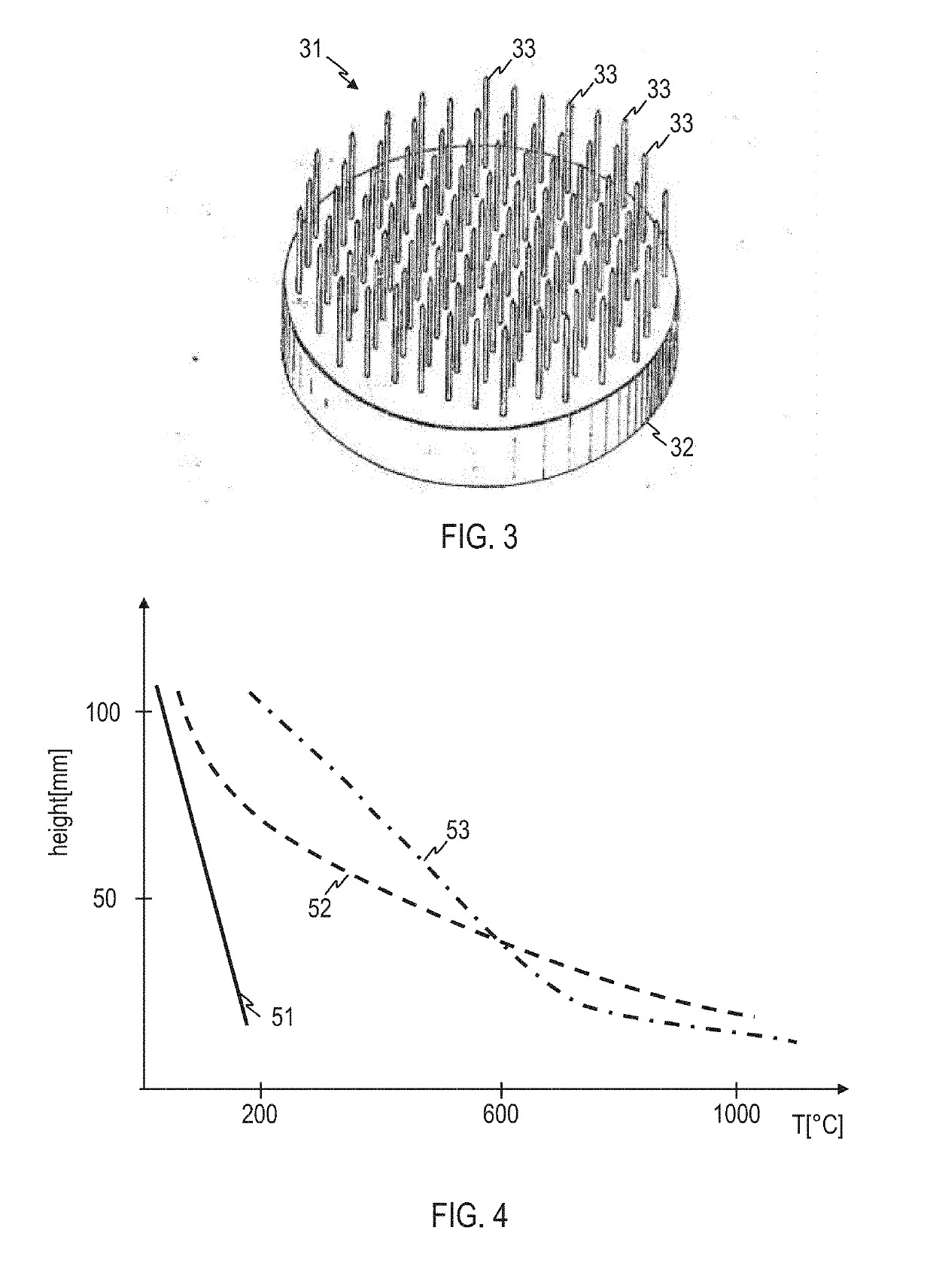

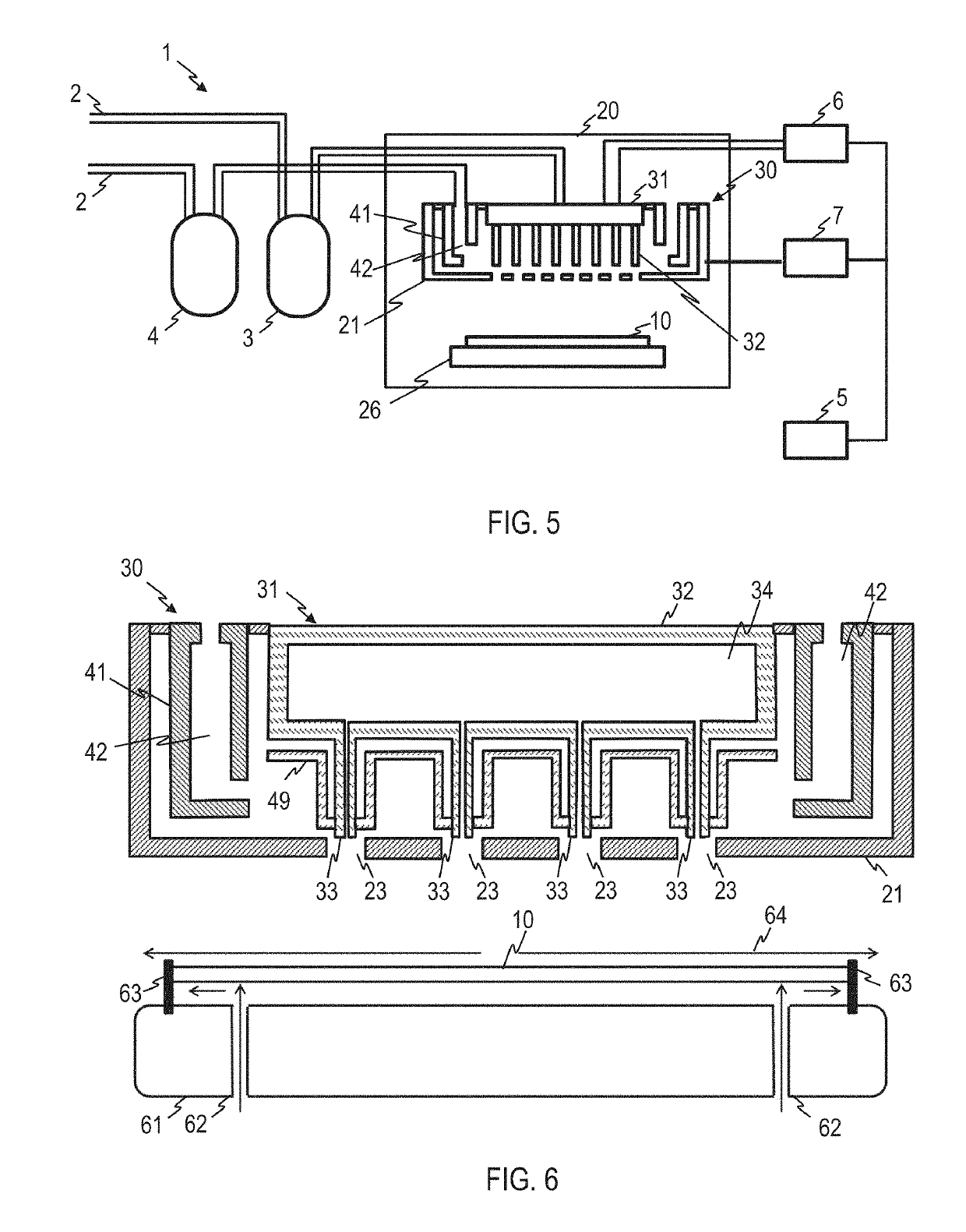

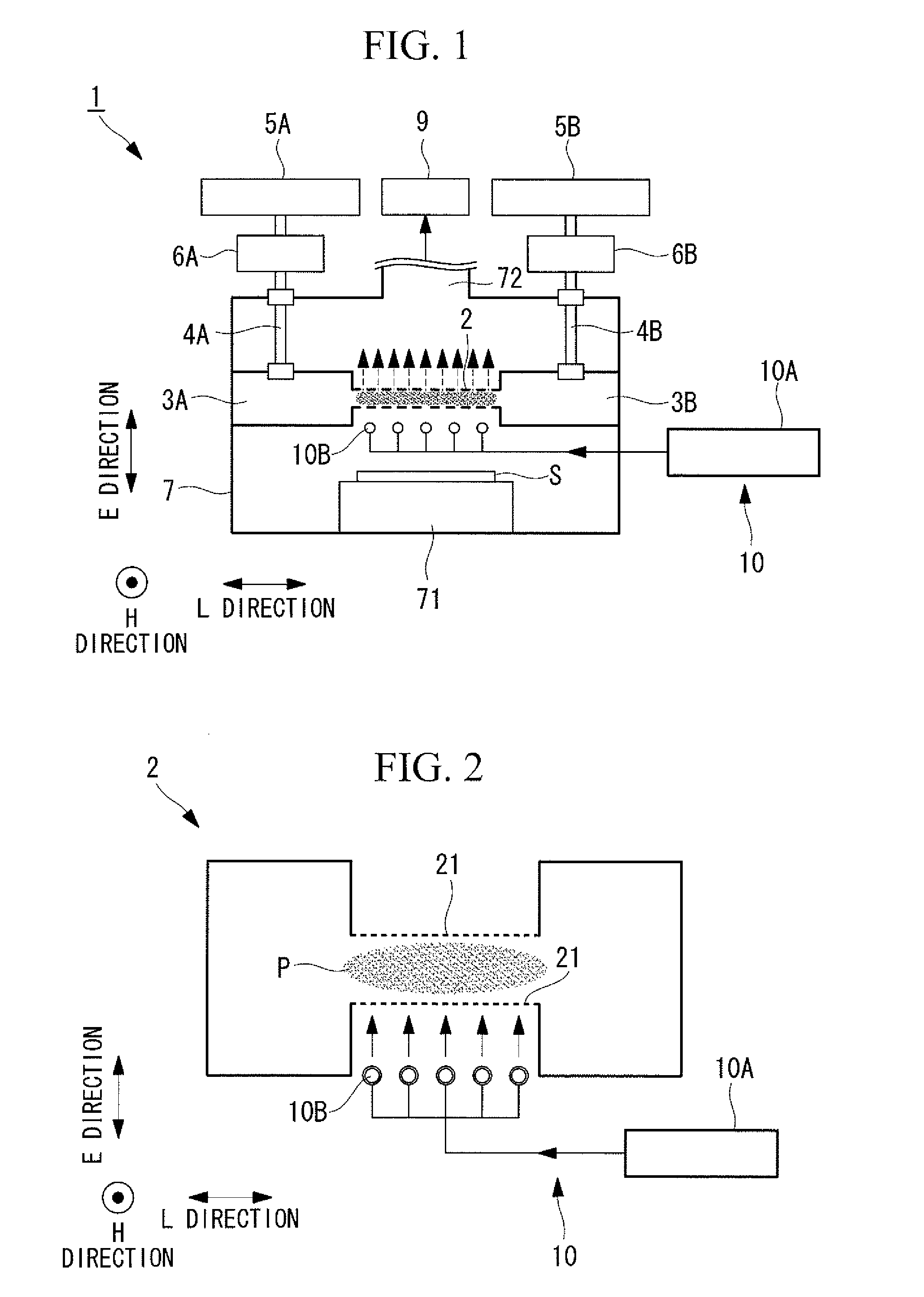

System and method for gas phase deposition

InactiveUS20190177851A1Process parameter can be rapidlyQuick changeElectric discharge tubesChemical vapor deposition coatingLevitationGas phase

A system for gas phase deposition comprises a gas injector configured to process gases to a substrate for gas phase deposition onto the substrate. The gas injector comprises a first flow path and a second flow path different from the first flow path. The system comprises a first temperature adjustment mechanism associated with the first flow path to control a temperature of a process gas passing through the first flow path. The system comprises a second temperature adjustment mechanism associated with at least the second flow path to control a temperature of a process gas passing through the second flow path. The first temperature adjustment mechanism and the second temperature adjustment mechanism are operable independently of each other. The system is configured to cause rotation and levitation of the substrate during etching of the substrate and / or deposition.

Owner:SINGULUS TECHNOLGIES AG

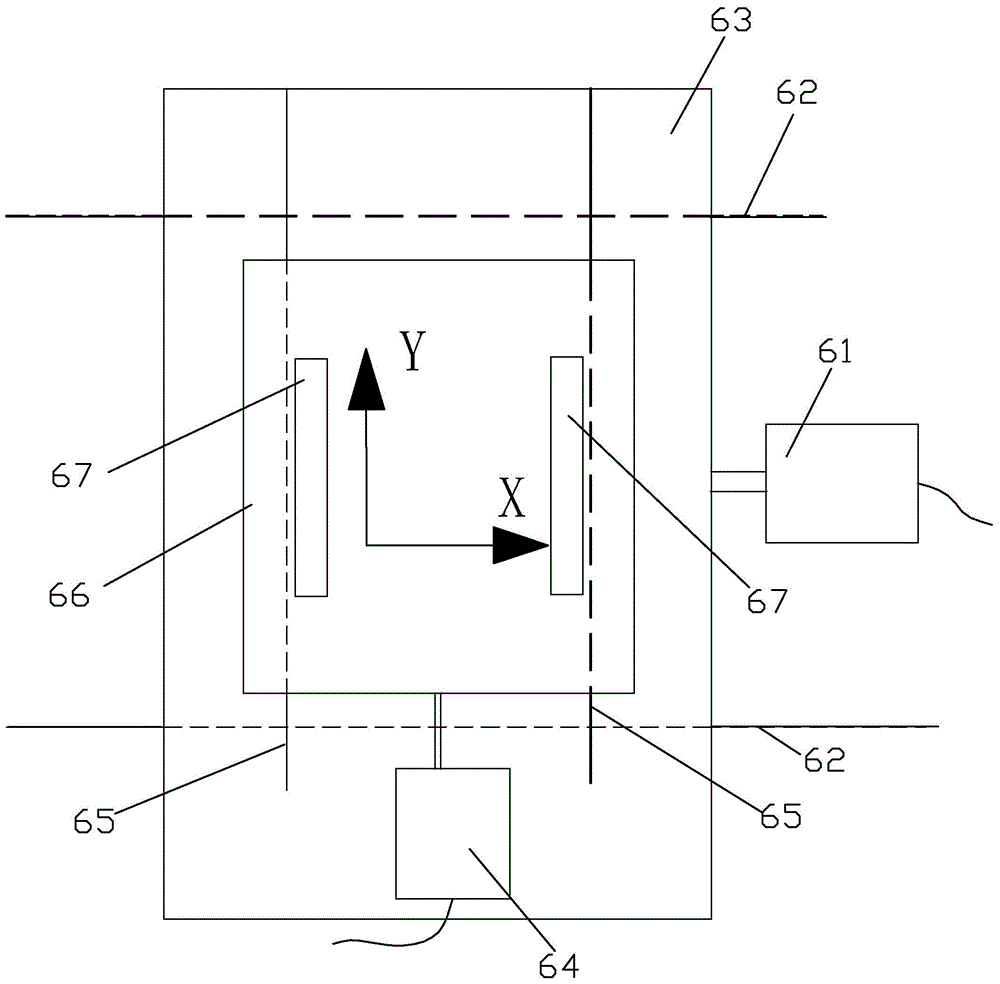

Supercritical-fluid-based 3D electrodeposition machining device and method

ActiveCN104480505AGood miscibilityImprove electric field distributionCellsAdditive manufacturing apparatusMachine partsChemical plating

The invention provides a supercritical-fluid-based 3D electrodeposition machining device and method. The device comprises a carbon dioxide gas bottle, a high-pressure pump, a digital controller, a reactor, a moving anode assembly, a moving cathode assembly, a direct-current power supply and a cathode matrix serving as a machined part, wherein the reactor is internally provided with a mechanical stirrer; the moving anode assembly comprises a Z-directional linear motor, a driving lead screw, an anode connecting rod and a moving anode; the moving cathode assembly comprises an X-directional linear motor, a Y-directional linear motor, a guide rail, a moving block and a fixture; and when the supercritical-fluid-based 3D electrodeposition machining device is used, the moving anode and the cathode matrix are respectively and electrically connected with the anode and cathode of the direct-current power supply. The machining method mainly comprises the steps of carrying out chemical plating treatment on the cathode matrix in advance; mounting the cathode matrix; preparing a supercritical fluid; carrying out electrodeposition machining and after-treatment and the like. By using the supercritical-fluid-based 3D electrodeposition machining device and method, the electrodeposition speed can be effectively increased, the deposition quality can be improved, a complex and precise metal part can be prepared through electrodeposition in a three-dimensional space, and the application field of an electrodeposition technology is widened.

Owner:JIANGSU UNIV OF TECH

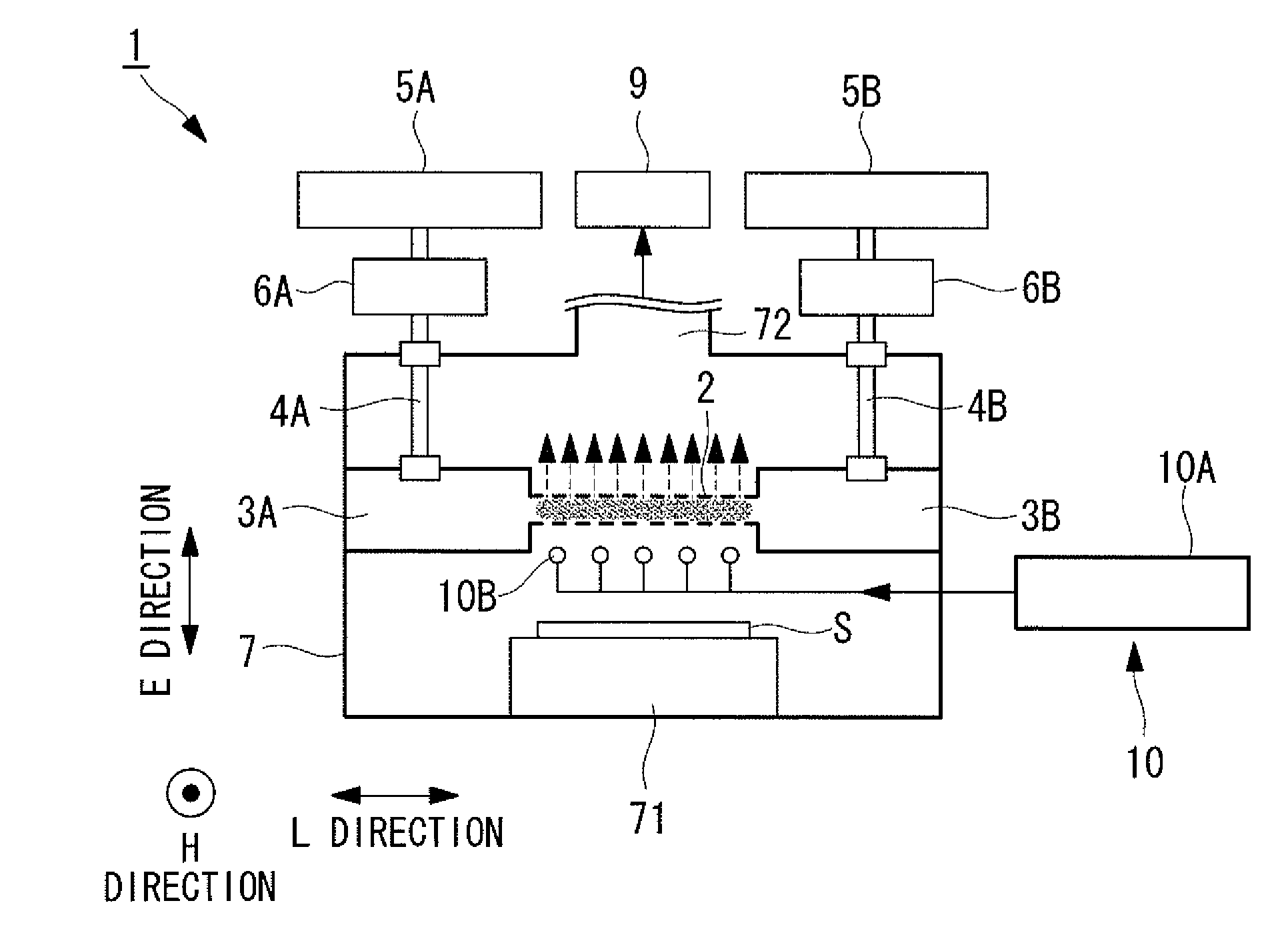

Vacuum Deposition Method and Sealed-Type Evaporation Source Apparatus for Vacuum Deposition

InactiveUS20070281081A1Increase productivityImprove deposition qualityVacuum evaporation coatingSputtering coatingRadiationVacuum deposition

A vacuum deposition method is provided. In the vacuum deposition for evaporating a sublimation evaporation material, the gas sealed-type heating container 11 has the blast aperture 14 and an area for evaporating the evaporation material by the radiation heat from the inner surface thereof. The holder 15 holds an evaporation material in a region in which the evaporation material does not evaluate due to the heat transferred from the heating container 11. Thus, the generated vapor is emitted from the blast aperture 14 into the deposition subject surface outside the container.

Owner:FUTABA CORPORATION

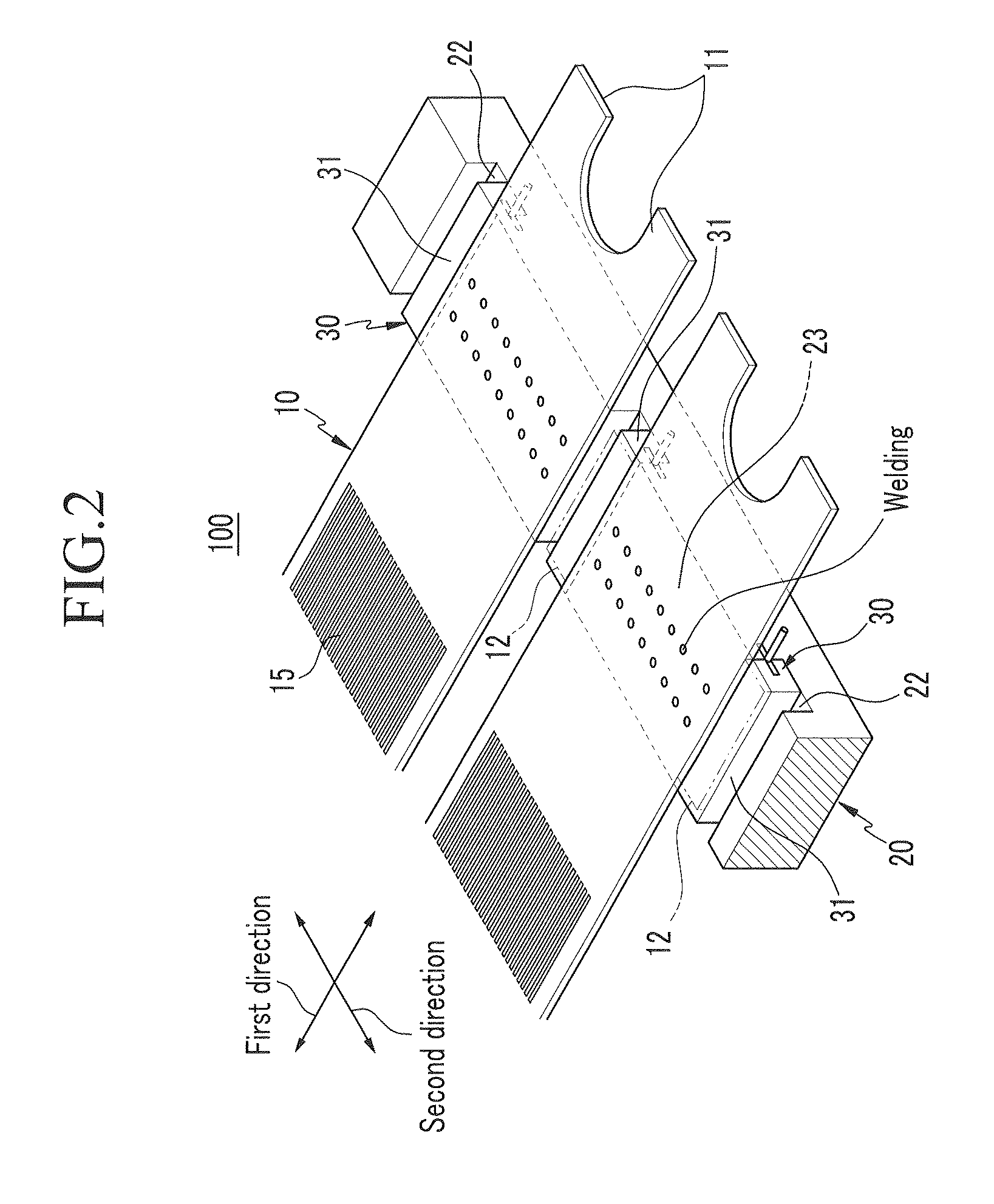

Vacuum processing apparatus

InactiveUS20110308735A1Improve deposition qualityIncrease the areaElectric discharge tubesFinal product manufactureProduct gasEngineering

A discharge chamber formed of a ridge waveguide having ridge electrodes that are disposed facing each other and that generate plasma therebetween; a gas supplying portion that is disposed adjacent to the discharge chamber and that supplies source gas, which is used to form the plasma, toward the ridge electrodes; a substrate that is disposed at a position such that the gas supplying portion is flanked by the substrate and the discharge chamber and that is subjected to the processing by the plasma; a low-pressure vessel that accommodates thereinside at least the discharge chamber, the gas supplying portion, and the substrate; and an exhaust portion that is communicated at a position in the low-pressure vessel such that this position and the gas supplying portion are disposed on either side of the discharge chamber, and that reduces the pressure inside the low-pressure vessel are provided.

Owner:MITSUBISHI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com