Cladding device for water-cooling wall of circulating fluidized bed boiler

A technology of circulating fluidized bed and cladding device, applied in the direction of metal material coating process, coating, etc., can solve problems such as affecting the safe operation of boilers, high labor intensity of workers, corrosion of boiler water walls, etc., and achieve economical operation and maintenance. cost, ensure the quality of cladding, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

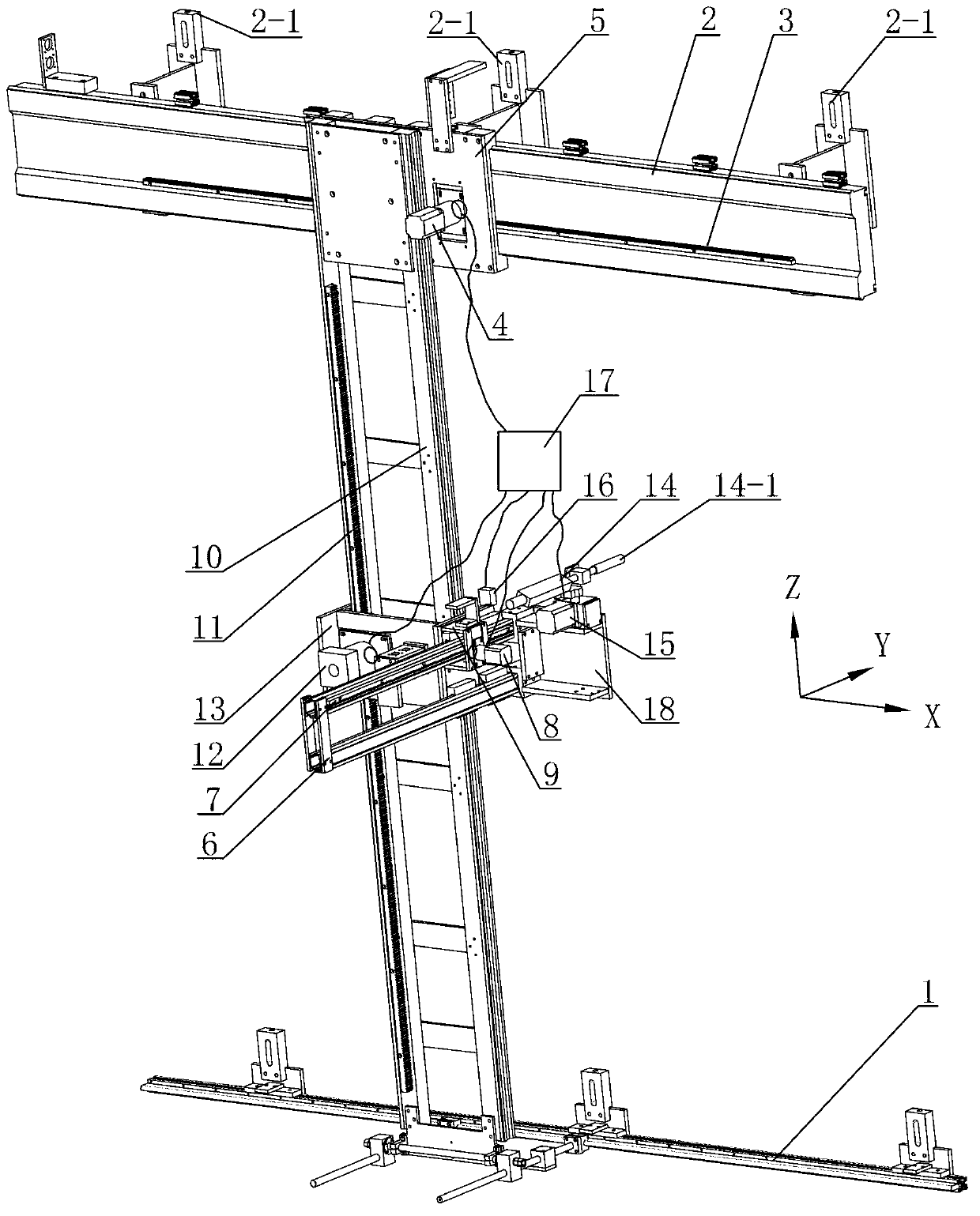

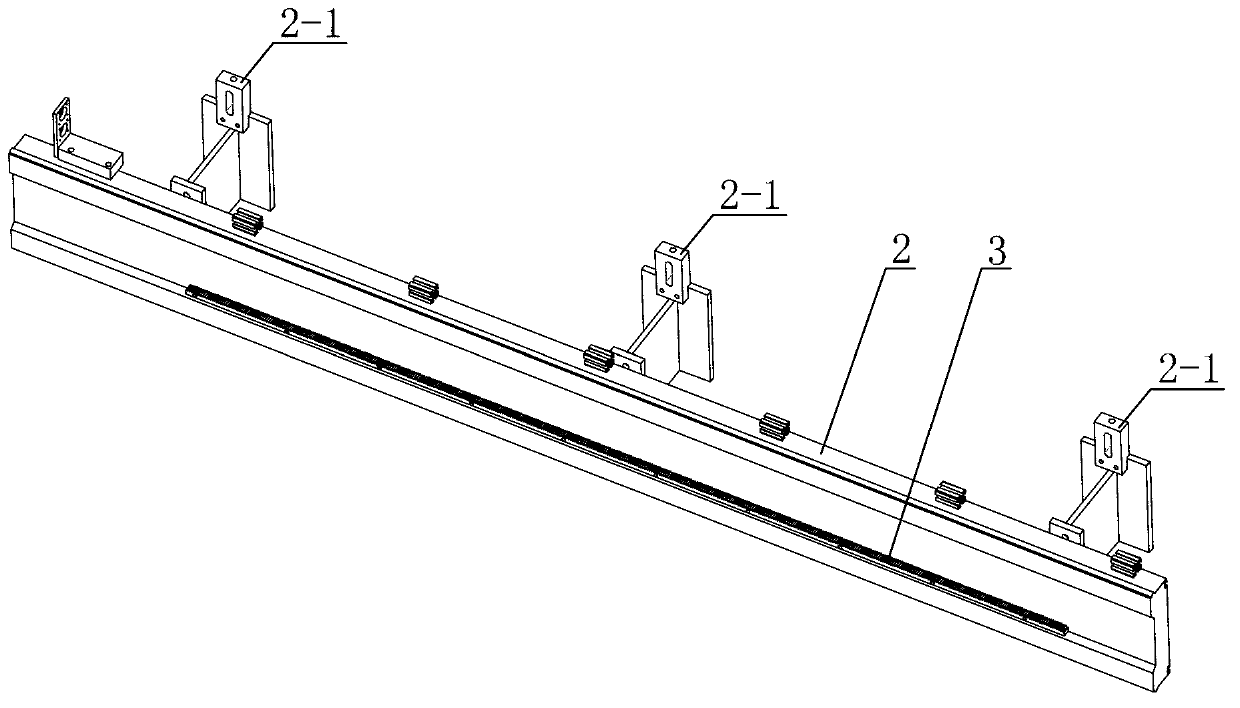

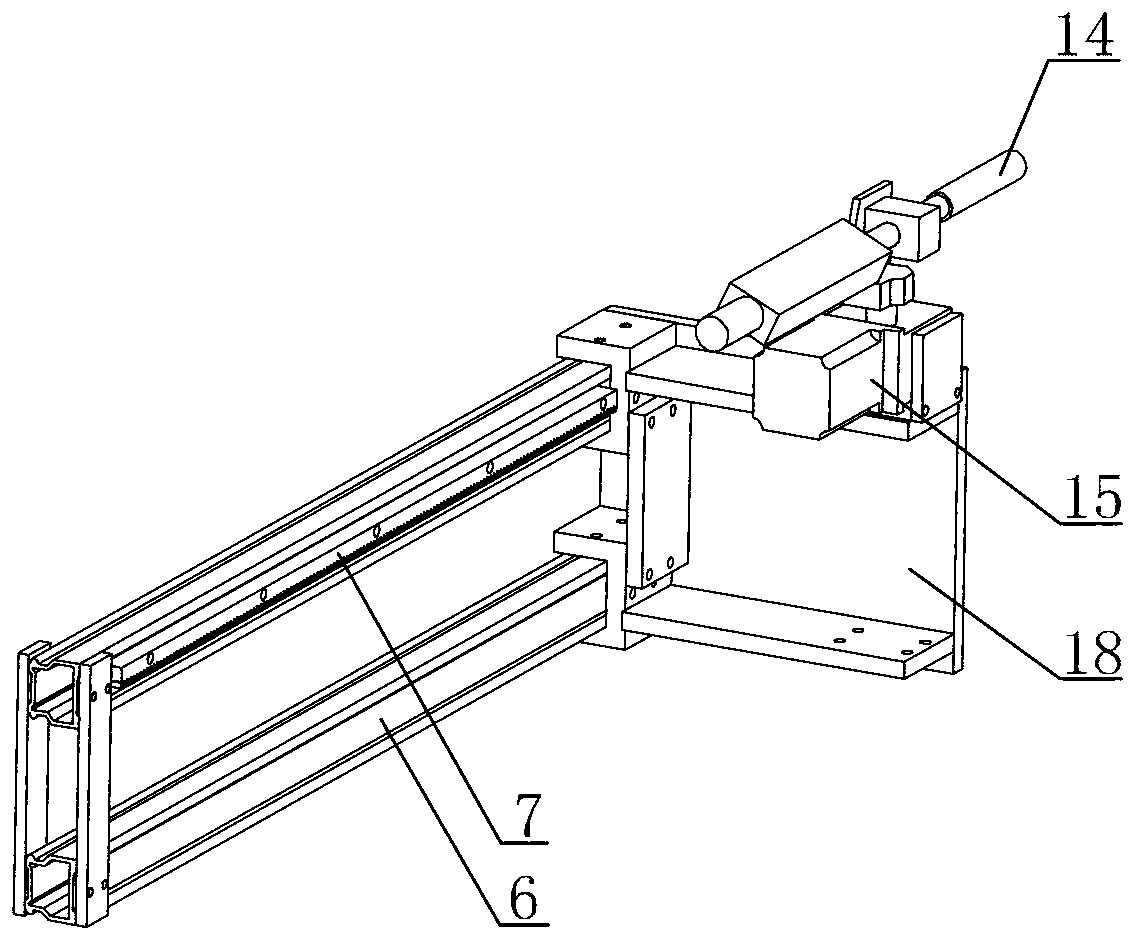

[0009] Specific implementation mode one: combine Figure 1 to Figure 5 Explain that a welding device for circulating fluidized bed boiler water wall in this embodiment includes a support guide rail base 1, an X-axis guide rail base 2, an X-axis guide rail rack 3, an X-axis guide rail motor transmission device 4, an X-axis Guide rail chute 5, Y-axis guide rail base 6, Y-axis guide rail rack 7, Y-axis guide rail motor transmission device 8, Y-axis guide rail chute 9, Z-axis guide rail base 10, Z-axis guide rail rack 11, Z-axis guide rail motor Transmission device 12, Z-axis guide rail chute 13, melting gun oscillator 14, drive motor 15, laser tracking device 16, computer 17 and connecting plate 18, support guide rail base 1 is set horizontally, Z-axis guide rail base 10 is vertically installed on the support guide rail On the base 1, the Z-axis guide rail base 10 is fixedly connected with the Z-axis guide rail rack 11, and the Z-axis guide rail rack 11 is arranged vertically, an...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 and figure 2 Note that the number of the adjustment hooks 2-1 in this embodiment is three. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 and Figure 4 To illustrate, the motor in the X-axis guide rail motor transmission device 4 of this embodiment is a servo motor. Such a design improves the transmission accuracy of the X-axis guide rail motor transmission device 4 . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0012] Specific implementation mode four: combination figure 1 and Figure 4 To illustrate, the motor in the Y-axis guide rail motor transmission device 8 of this embodiment is a servo motor. Such a design improves the transmission accuracy of the Y-axis guide rail motor transmission device 8 . Other compositions and connections are the same as those in the third embodiment.

[0013] Specific implementation mode five: combination figure 1 and 4 To illustrate, the motor in the Z-axis guide rail motor transmission device 12 of this embodiment is a servo motor. Such a design improves the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com