Device for carrying out a plasma-assisted process

a technology of plasma-assisted process and device, which is applied in the direction of chemical vapor deposition coating, electrical equipment, coating, etc., can solve the problems of high unbalanced magnetron and inability to fully confine electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

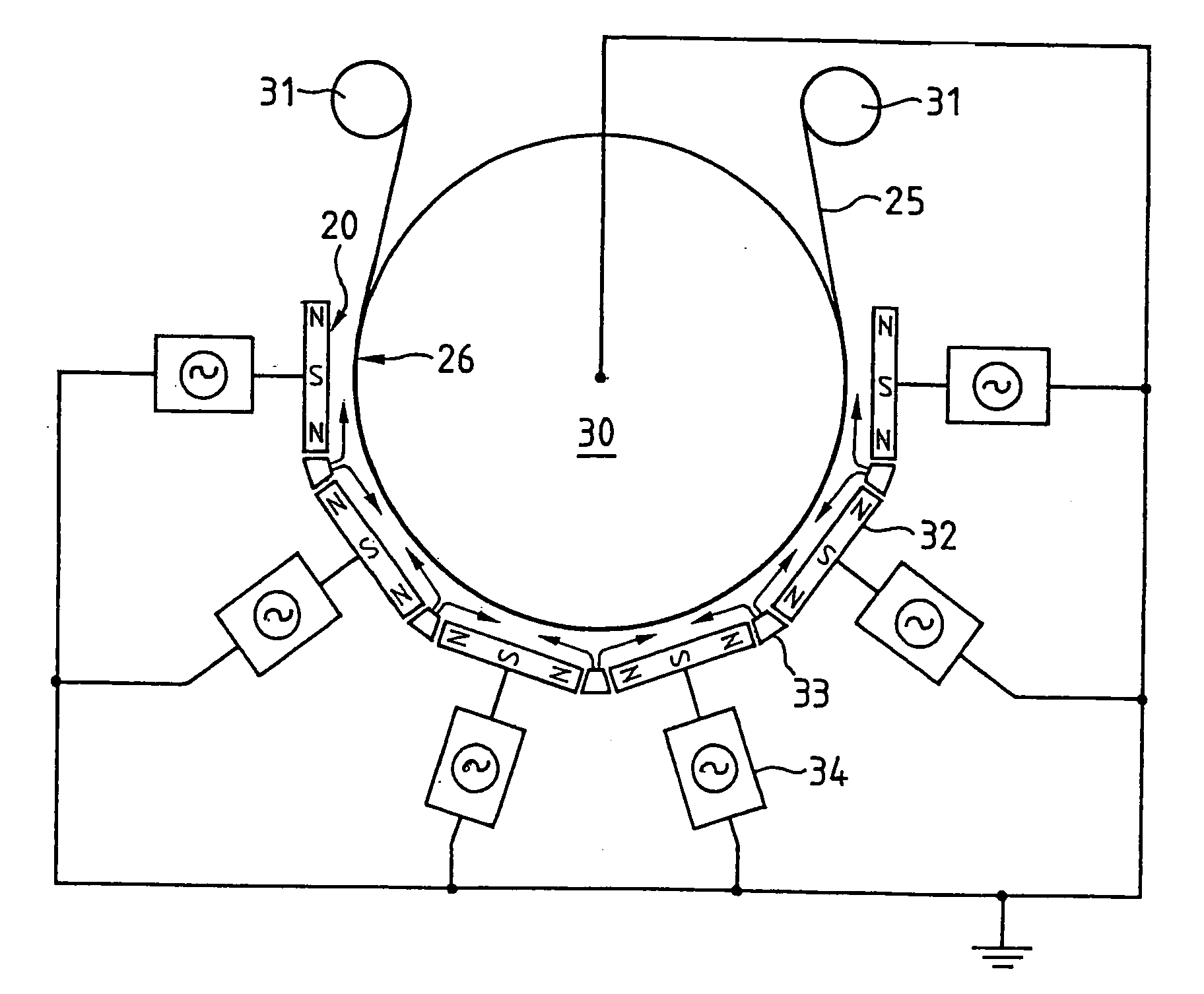

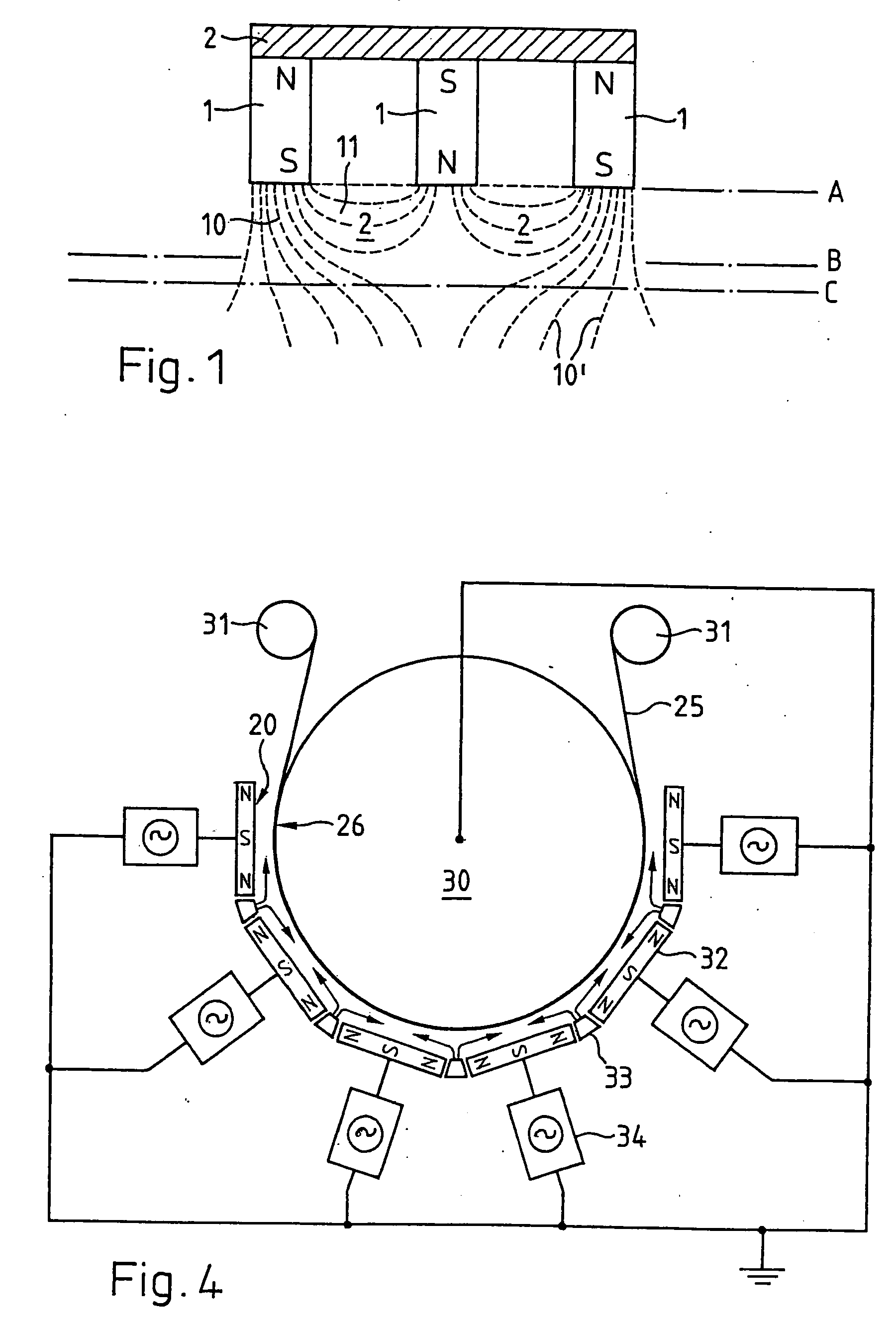

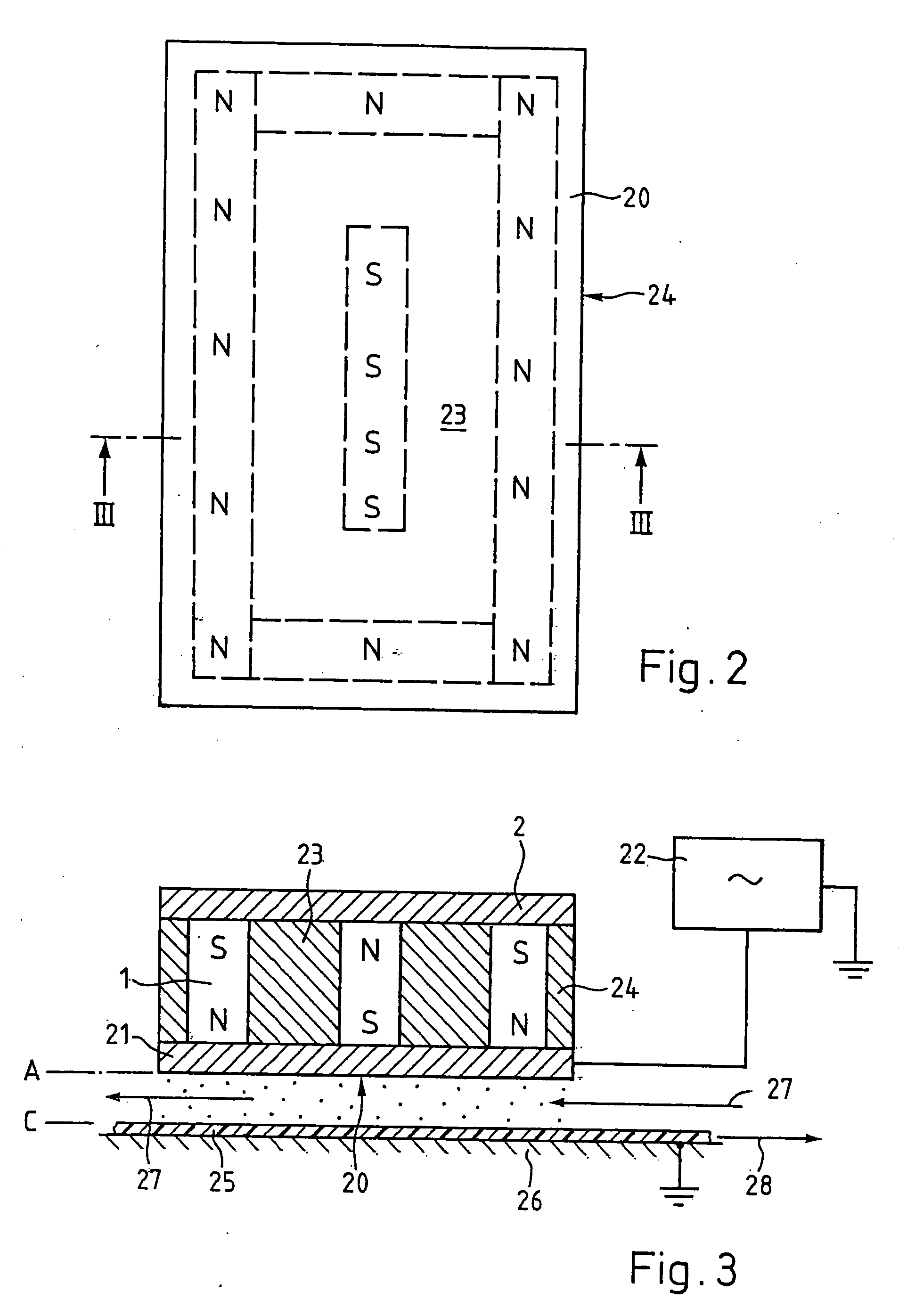

[0023] A device according to FIG. 4 with four magnetron electrodes according to FIGS. 2 and 3, each magnetron face being 600 mm long and 150 mm wide and each magnetron face comprising a central permanent magnet of a magnetic induction of ca. 100 Gauss (10−2 Tesla) and peripheral permanent magnets of ca. 200 Gauss being arranged around the central magnet with a distance between the poles of ca. 50 mm is used for coating a polymer film with silicon oxide using a plasma derived from a process gas mixture comprising an organosilicon compound and oxygen. The magnetron faces are positioned at a distance from the drum circumferential surface of ca. 60 mm (visibly such that there is a narrow bright band of plasma running beyond the tunnels along the substrate showing towards the substrate a regular intensity not being dependent on the tunnel positions). The magnetrons are powered with a total of 14 kW per m2 of magnetron face at a frequency of 40 kHz. The deposition rate such achieved is ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com