Magnetron sputtering device and magnetron sputtering method

A magnetron sputtering device and magnetron sputtering technology, applied in the direction of sputtering coating, ion implantation plating, metal material coating process, etc., can solve the problem of high environmental cost of thin film preparation, difficult control of thin film uniformity, thin film The repeatability of the production process is difficult to control, etc., to achieve the effect of shortening the preparation cycle, complete functions, and good automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

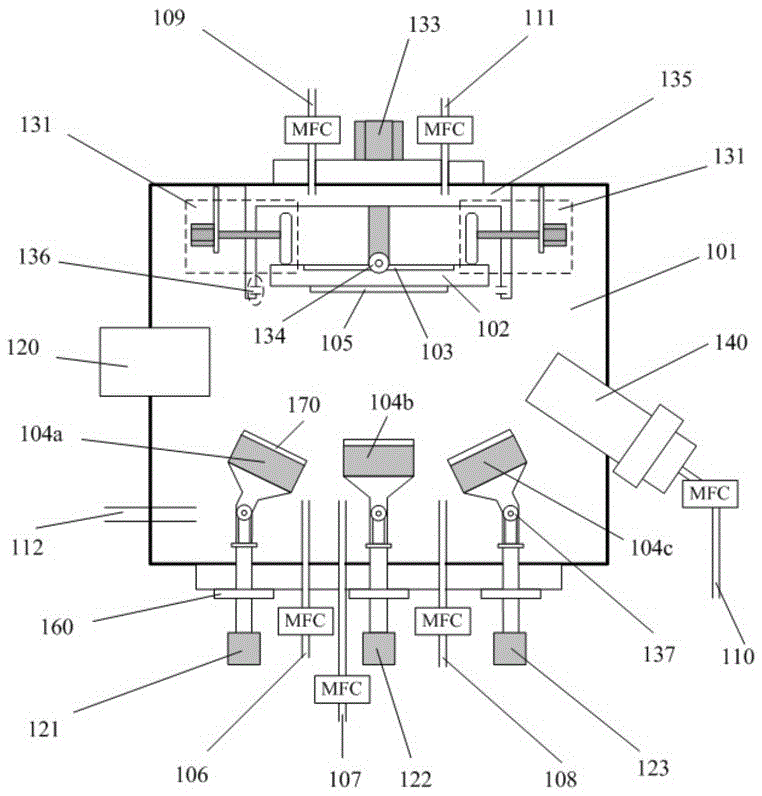

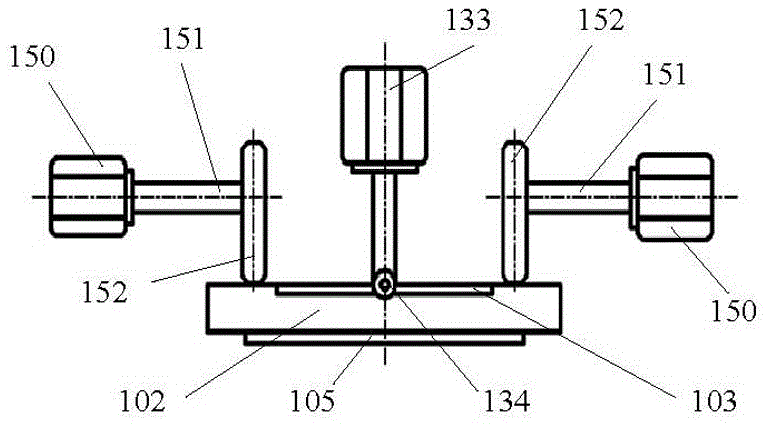

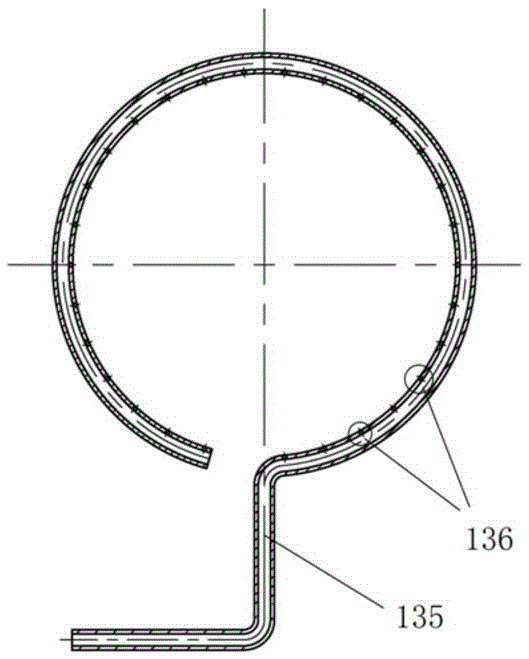

[0050] refer to Figure 1 to Figure 4 , the magnetron sputtering device of the present invention comprises:

[0051] A substrate stage 102 for placing a substrate 105;

[0052] The target 104 arranged opposite to the substrate table 102 is used to place the target material for sputtering to the substrate 105;

[0053] The reaction chamber 101, the substrate stage 102 and the target 104 are all arranged in the reaction chamber 101;

[0054] Also includes:

[0055] The angle adjusting device connected with the target 104 is used for adjusting the angle of the target 104 relative to the substrate stage 102 .

[0056] In the prior art, it is often designed that the target and the substrate table are set up facing each other, and the sputtering particles fly vertically to the substrate. When forming a film on a large-scale substrate, the film formed in the middle area of the substrate is thicker, and the film formed in the edge area is thinner. In the present invention, an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com