Machine tool for depositing optical fiber preform rods by outside chemical vapor deposition method

A technology of external vapor deposition and optical fiber preform, which is applied in manufacturing tools, glass manufacturing equipment, glass production, etc. It can solve the problems affecting the dust particle size and deposition effect, and affect the deposition processing efficiency, so as to maintain uniformity and improve processing Efficiency, the effect of improving efficiency

Inactive Publication Date: 2014-08-06

YANGTZE OPTICAL FIBRE & CABLE CO LTD

View PDF9 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the centerline distance between the torch and the target rod in the existing external vapor deposition equipment is fixed, and as the diameter of the deposition preform changes, the distance between the torch and the deposition surface of the preform will become smaller and smaller, which will not only Affects dust particle size and deposition effect, and also affects the efficiency of deposition processing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0019] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

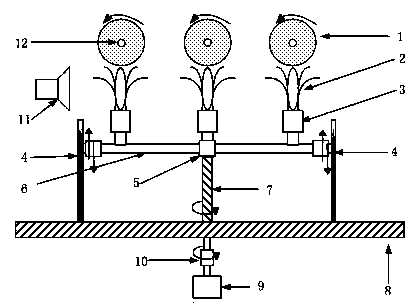

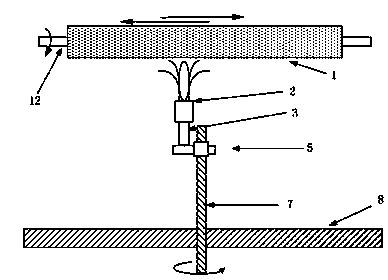

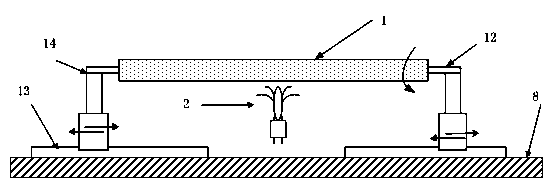

The invention relates to a machine tool for depositing optical fiber preform rods by an outside chemical vapor deposition method. The machine tool comprises a tool body; a reciprocating seat and blow lamps are respectively arranged on the tool body; rotary chucks are arranged on the reciprocating seat. The machine tool is characterized in that the blow lamps correspond to the rotary chucks, and are mounted below the axis of rotation; the blow lamps are connected with a feeding mechanism; the feeding direction of the feeding mechanism is perpendicular to the axis of rotation. The blow lamps can be subjected to dynamic regulation and control with the change of the deposition diameters of the optical fiber preform rods, so that the distances between the blow lamps and the deposition surfaces of the optical fiber preform rods are kept to be relatively constant, the blow lamps are always kept to be at optimal jet distance during the deposition process, so that not only can the uniformity of the jet dust granularity be maintained, but also the deposition precision and the deposition quality of the preform rods can be effectively improved, which effectively improves the deposition processing efficiency; the rotary chucks and the blow lamps are adopted, so that the processing efficiency of the optical fiber preform rods can be improved greatly.

Description

technical field [0001] The invention relates to an optical fiber preform external vapor deposition method deposition machine tool, which belongs to the technical field of optical fiber preform manufacturing equipment. Background technique [0002] There are many methods for manufacturing optical fiber preforms, which are currently mainly divided into in-tube deposition method and out-of-tube deposition method. The in-pipe method mainly includes the improved chemical vapor deposition method MCVD and the microwave plasma chemical vapor deposition method PCVD. The in-pipe deposition method is limited by the diameter of the deposition pipe, and the diameter is not easy to increase. It is suitable for manufacturing preformed core rods and small-diameter special For the optical fiber preform, after the core rod is made, the casing or plasma spraying is performed to manufacture the outer cladding part of the preform, and finally a large-diameter preform is manufactured. The manufac...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03B37/018

CPCY02P40/57

Inventor 张宏胜顾立新孙建华王瑞春渠驰高则尚

Owner YANGTZE OPTICAL FIBRE & CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com