Supercritical heat waves heat-transfer element and its working medium loading sealing method

A technology of heat transfer element and working medium, which is used in indirect heat exchangers, lighting and heating equipment, etc. It can solve the problems of inaccurate working medium volume, inability to produce small pipe fittings, and inability to work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

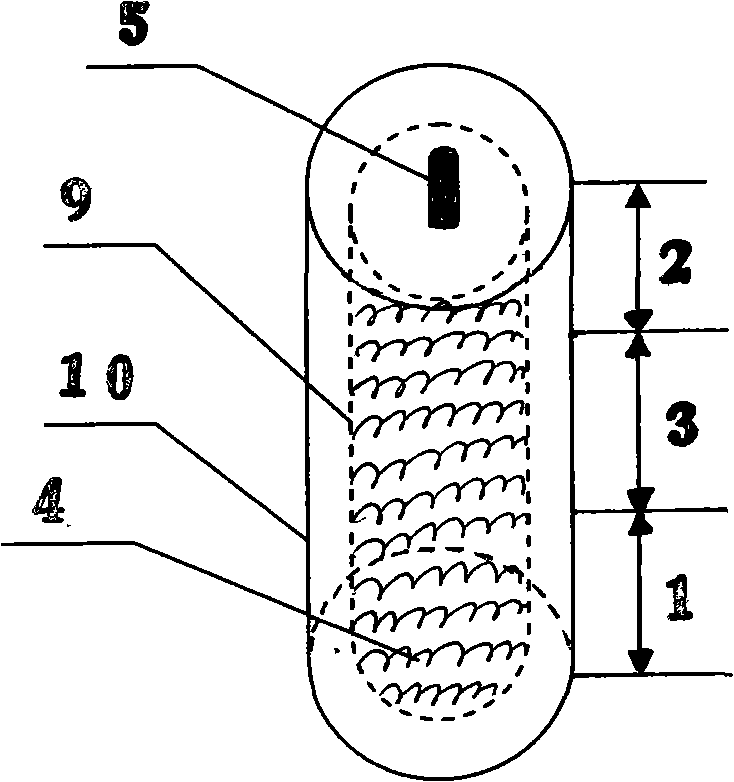

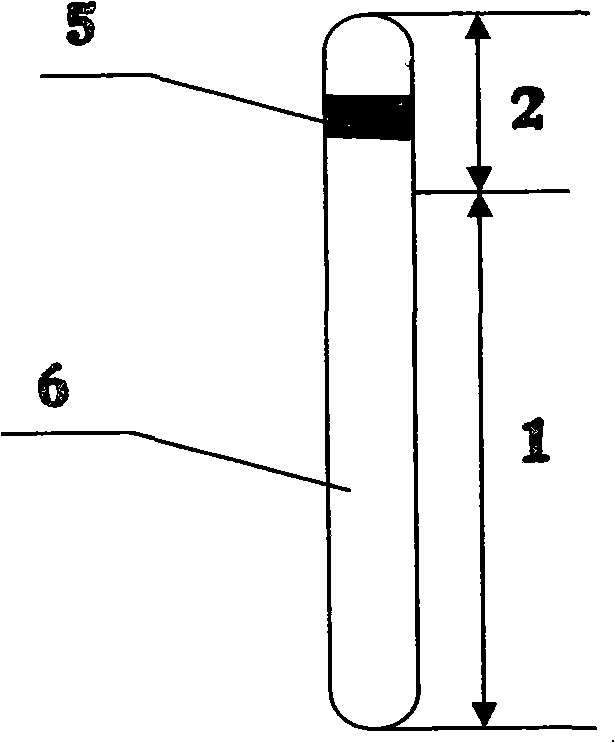

[0080] Basic supercritical heat wave heat transfer element

[0081] Please refer to figure 1 , a carbon steel pipe with a diameter of 38MM and a length of 1M. The upper and lower ends of the pipe are sealed to form a cavity. Aluminum, whose thickness is thicker than the rare earth aluminum inside, is mainly used for anti-corrosion and heat conduction, and aluminum has higher heat conduction performance than carbon steel; inside the cavity, on a sealing surface of the tube, a one-way valve is processed, A one-way valve is used to fill the carbon dioxide gas into the cavity, and the weight of the filling is 300 grams, which constitutes a basic supercritical heat-conducting element.

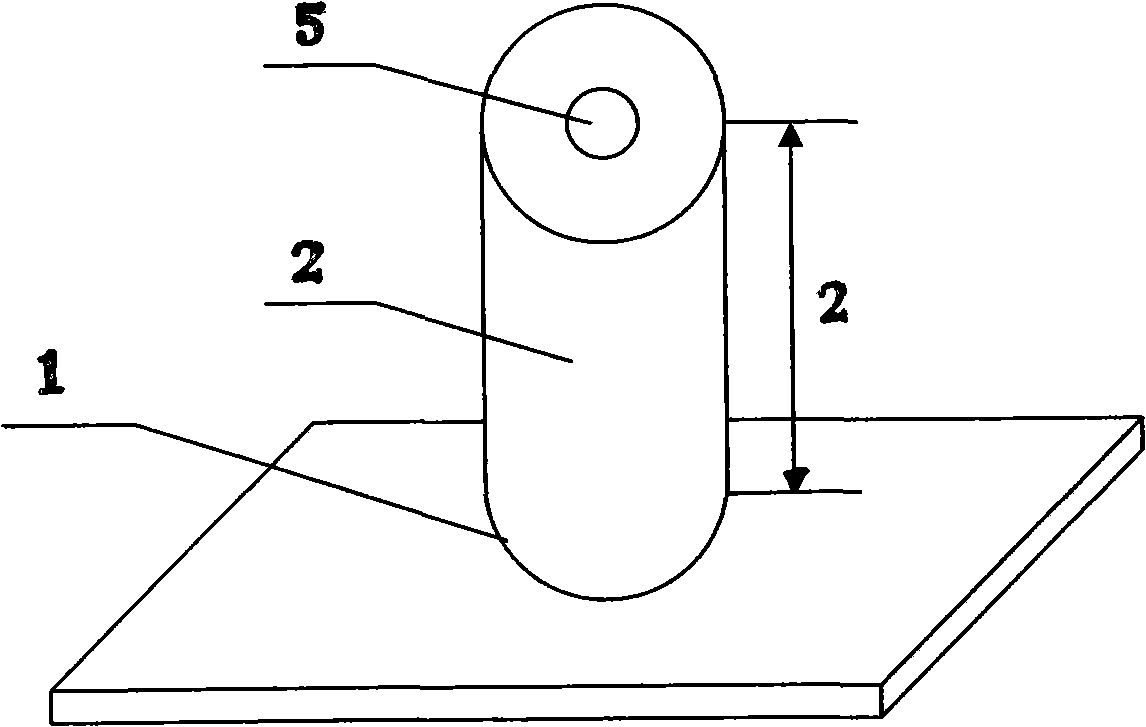

[0082] Supercritical heat wave heat transfer element for computer radiator

[0083] Please refer to figure 2 , using a copper metal tube with a diameter of 32MM and a height of 58MM, first fill its cavity with 10 grams of water, and then fill it with 30 grams of R134a supercritical working mediu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com