Coaxial ejecting apparatus and multilayer microcapsule preparing method utilizing same

An injection device and microcapsule technology, which is applied in the field of microcapsule preparation devices, can solve problems such as uneven wall thickness and wide particle size distribution of microcapsules, and achieve the effects of raw material saving, low cost and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

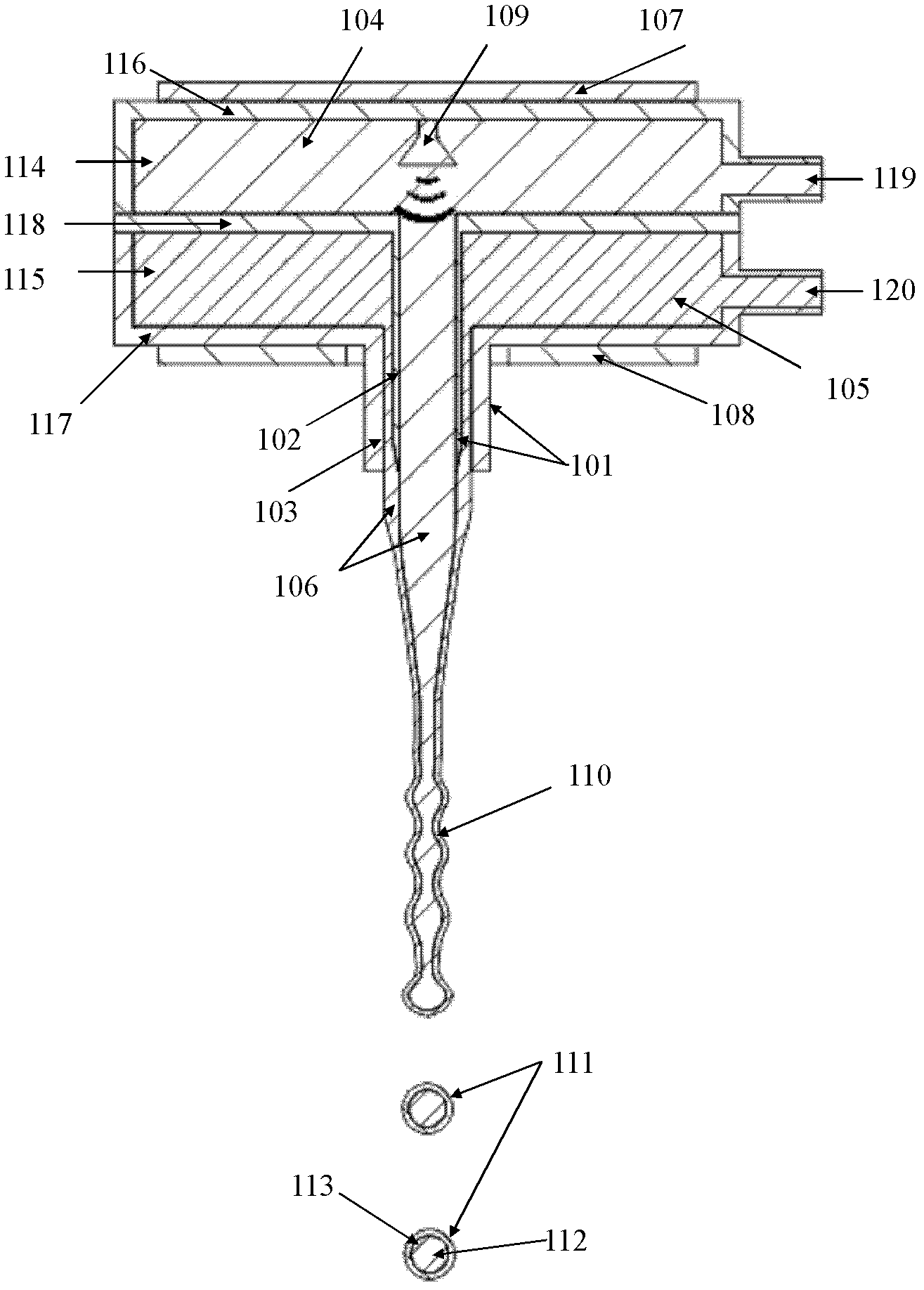

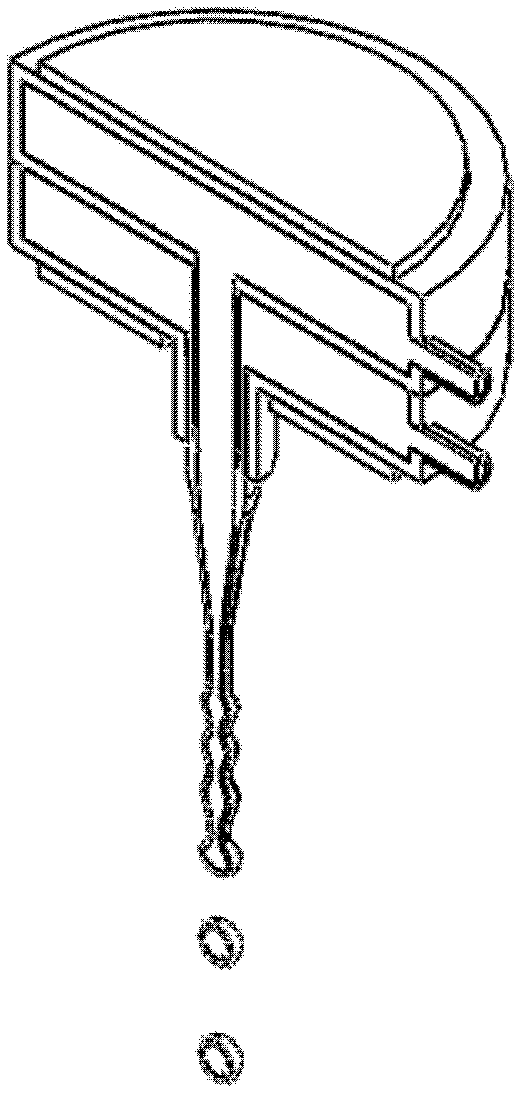

[0030] Such as Figure 1-2 Shown is a coaxial injection device for preparing double-layer microcapsules, which includes a coaxial nozzle, a liquid storage body structure, a disturbance device, and a pressure and flow control device. The structure of the liquid storage body is composed of a liquid chamber a shell 116, a liquid chamber b shell 117, and a partition 118. The liquid chamber a shell 116 and the partition 118 enclose a liquid chamber a114. The core liquid 104 is filled in the liquid chamber a114 and there is a There is a core liquid inlet 119, a shell 117 of the liquid chamber b and a partition 118 to form a liquid chamber b115, and the liquid chamber b115 is filled with a shell liquid 105 that is incompatible with the core liquid and is provided with a shell liquid inlet 120; coaxial The nozzle 101 includes an inner layer nozzle 102 and an outer layer nozzle 103 provided outside the inner layer nozzle. The inner layer nozzle 102 is a hollow tube with one end in a co...

Embodiment 2

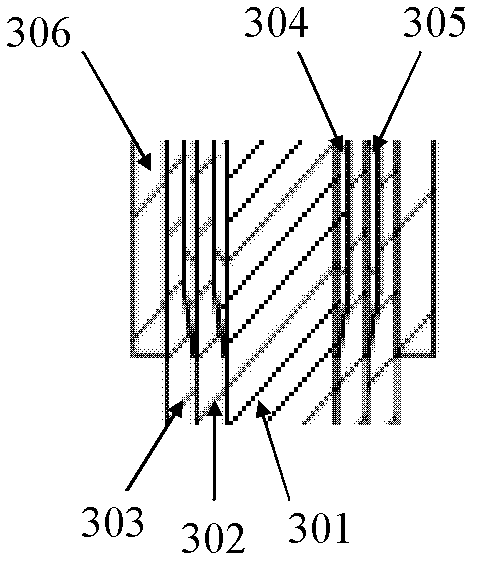

[0042] A coaxial injection device for preparing three-layer microcapsules, the device includes a coaxial nozzle, a liquid storage body structure, a disturbance device, and a pressure and flow control device. Such as image 3 As shown, the coaxial nozzles include the inner layer nozzle 304, the outer layer nozzle a305 and the outer layer nozzle b306, each layer of nozzles is nested layer by layer, there is a gap between the nozzles of the adjacent layers, and the liquid chambers connected to the nozzles of the adjacent layers are filled with Mutual immiscible liquids; the structure of the liquid storage body and the coaxial nozzle correspond to three liquid chambers and two partitions separating the liquid chambers, the inner nozzle 304 is connected to the liquid chamber filled with core liquid, and the two outer layers The nozzles are respectively connected to the liquid chambers filled with different shell liquids, and the liquid inlets of each liquid chamber are connected to...

Embodiment 3

[0044] The method for preparing a single-shell multi-core microcapsule using the same coaxial injection device as in Example 1 is as follows: first start the pressure and flow control device to inject the solution into the liquid chamber, and start the disturbance device, and the coaxial nozzle 101 will inject the solution into the liquid chamber. The core liquid 104 in a114 and the shell liquid 105 in the liquid chamber b115 are ejected simultaneously at the same speed to form a double-layer liquid column 106; the disturbance frequency of the disturbance device a117 corresponding to the core liquid is adjusted to the disturbance device corresponding to the shell liquid Integer multiples of the disturbance frequency of b118, set the vibration phase of the two disturbance devices to be the same, and control the disturbance magnitude so that the core liquid splits before the shell liquid, and the single-shell multi-core microcapsules can be obtained as Figure 7 As shown, a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com